Professional Documents

Culture Documents

PM 9G TRONIC en

Uploaded by

Stefan IlicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PM 9G TRONIC en

Uploaded by

Stefan IlicCopyright:

Available Formats

Added comfort and driving pleasure,

reduced consumption: the new 9GTRONIC

March 2014

Contents

Page

Short version

New nine-speed automatic transmission debuts in the

Press Information

Mercedes-Benz E 350 BlueTEC

Premiere of the new 9G-TRONIC

Long version

Discovering the inside of the 9G-TRONIC

Innovative solutions for maximum comfort and

outstanding energy efficiency

A transmission under electronic control

Artificial intelligence for a natural driving

14

experience

Developed for in-house drive systems

18

The best out of 85 billion possibilities

Review of automatic transmission development

22

22 million automatic transmissions from MercedesBenz

Technical data for the 9G-TRONIC / E 350 BlueTEC

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

27

Page 2

New nine-speed automatic transmission in the Mercedes-Benz E

350 BlueTEC

Premiere of the new 9G-TRONIC

Stuttgart. The first nine-speed automatic transmission with

torque converter, the 9G-TRONIC for premium vehicles, is

now celebrating its debut: equipped with the innovative

power transmission, the E 350 BlueTEC is set to become

one of the most fuel-efficient six-cylinder diesel models in

its class. Thanks to the high efficiency level of the patented

transmission design, NEDC fuel consumption in the E-Class

is reduced to 5.3 litres of diesel per 100 km. As is typical of

the brand, the transmission offers outstanding comfort and

barely perceptible gear changes.

In the E 350 BlueTEC, which is available in Saloon and Estate

models and comes equipped with the new 9G-TRONIC as

standard, the 185 kW (252 hp) V6 diesel engine has an average

NEDC fuel consumption of 5.3 litres of diesel per 100 kilometres

(Estate: 5.5 l/100 km), corresponding to CO 2 emissions of 138

g/km (Estate: 144 g/km). As a result, the new models with 9GTRONIC undercut their predecessors in terms of both

consumption and CO2 emissions. The higher number of gears

and the broader gear ratio spread help to increase drive comfort

and allow a significant enhancement to be achieved in terms of

converting engine power into traction.

Perfect interaction: E 350 BlueTEC with V6 diesel engine

and 9G-TRONIC

On the one hand, the overall reduction in engine speed improves

NVH comfort and therefore the pleasant sense of well-being on

board the E-Class, and on the other also cuts down external

noise by up to 4 dB(A), thus reducing the strain on the

environment. The reduced fuel consumption of the E 350

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 3

BlueTEC with

9G-TRONIC has primarily been achieved as a result of the high

efficiency level of the transmission. As part of this, the broad

ratio spread of 9.15 for gears one to nine allows a clearly

perceptible reduction in engine speed and is a decisive factor

behind the high level of energy efficiency and ride comfort.

Shortened shift and reaction times ensure optimum spontaneity

combined with outstanding ease of shifting. In manual mode and

S mode in particular, the

9G-TRONIC responds significantly more spontaneously and

enhances driving pleasure.

The particular ease of shifting of the new 9G-TRONIC - a focal

point during development and a hallmark feature of a MercedesBenz automatic transmission - comes courtesy of a

comprehensive package of measures. These include the novel

direct control system which enables short, barely perceptible

gear changes. The combination of twin-turbine torsional damper

and centrifugal pendulum technology in the torque converter

ensures outstanding drive comfort. Together with the extended

gear ratio spread, higher speeds can now be driven at lower

engine speeds for even greater comfort. In reality this translates

into being able to drive at 120 km/h in 9th gear with an engine

speed of around only 1350 rpm, for example.

Advanced technology for superior power transmission

In the case of the 9-speed automatic transmission, the

development engineers also focussed on the area of "compact

lightweight construction". Despite two additional gears and a

maximum transferable torque of up to 1000 newton metres, the

new automatic transmission requires as little installation space

as its predecessor and is also lighter in weight. The two-piece

housing design has been retained: the torque converter housing

is made of lightweight aluminium, while the transmission

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 4

housing with weight-optimised plastic oil pan is made of an even

lighter magnesium alloy.

Another goal was to implement the nine gears with a minimal

number of planetary gear sets and shift elements. Intensive,

computer-based system analysis and mock-up made it possible

to realise this goal with just four simple planetary gear sets and

six shift elements. Three speed sensors monitor operation and

provide the transmission control system with corresponding data

for effective shifting. Here it is possible for several gears to be

jumped when accelerating or decelerating, should the driving

conditions call for it.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 5

To ensure the reliable and at the same time energy efficient

supply of the

durable and shear-resistant second-generation synthetic fuel

economy engine oil, the new automatic transmission is equipped

with two pumps. The considerably smaller mechanical main

pump, featuring an off-axis design, is located next to the main

shaft and is chain-driven and fed by a separate electric auxiliary

pump. This design allows the flow of lubricating and cooling oil

to be controlled actively on demand, and also means that 9GTRONIC can benefit from a start/stop system. Thanks to the

world's first direct control system in a planetary automatic

transmission with nine gears, it has also been possible to

significantly increase hydraulic efficiency within the

transmission.

Around 22 million automatic transmissions from MercedesBenz since 1961

Mercedes-Benz has been developing and producing high-quality

automatic transmissions featuring outstanding ease of shifting,

optimum energy efficiency and dependable durability for more

than 50 years. To date, a total of around 22 million automatic

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 6

passenger car transmissions have left the manufacturing plant

in Stuttgart-Hedelfingen, close to the corporate headquarters in

Stuttgart-Untertrkheim.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 7

The 9G-TRONIC is suitable for rear-wheel and all-wheel drives as

well as hybrid and plug-in hybrid drive systems, and will be used

in almost all model series and engines in the coming years.

Contacts:

Christian Anosowitsch, tel. no.: +49 (0)711 17-75849,

christian.anosowitsch@daimler.com

Wolfgang Zanker, tel. no.: +49 (0)711 17-75847,

wolfgang.zanker@daimler.com

Further information about Mercedes-Benz is available online:

www.media.daimler.com and www.mercedes-benz.com

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 8

Discovering the inside of the 9G-TRONIC

Innovative solutions for maximum

comfort and outstanding energy

efficiency

Patented gearing concept with four planetary gear

sets and six shift elements

Nine gears with a wide ratio spread of 9.15

New torque converter: high efficiency level of 92

percent

More comfort: twin-turbine torsion damper with

centrifugal pendulum and torque converter lockup

clutch with return spring

Demand controlled oil supply: highly efficient vane cell

pump and electric auxiliary pump

Innovation: main transmission shaft with three deepdrilled holes

Compact lightweight construction: less installation

space and reduced weight

The drive element of a classic automatic transmission is the

hydrodynamic torque converter. In the new 9G-TRONIC, the

engineers have improved the hydraulic circuit in the torque

converter and increased its efficiency to up to

92 percent. This extraordinarily good figure is important for fuel

economy, as the losses imposed by physics when transferring

the engine torque to the transmission's input shaft are kept to a

minimum. In short: the 9G-TRONIC converts a very high

proportion of the engine power into tractive power. In the firstgeneration 7G-TRONIC dating from 2003, the efficiency of this

component was only 85 percent.

The heat generated during operation is reliably dissipated via

the transmission oil cooler. Conversely, the 9G-TRONIC requires

no additional radiator to warm the cold transmission oil when

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 9

cold-starting under Arctic conditions. The second-generation,

synthetic Fuel Economy low-friction oil also performs reliably at

extremely low temperatures.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 10

More comfort: twin turbine torsion damper and

centrifugal pendulum

One of the most comfort-enhancing and at the same time fuelsaving features is the torsion damper, which compensates even

more effectively for eccentricities and vibrations within the

transmission. A basic physical law operates in this case: the

lower the rpm and road speed, and the lower the number of

cylinders, the more pronounced these can be. This results in a

conflict of aims between comfort and fuel-efficient operation. It

is resolved by the use of a twin turbine torsion damper

additionally fitted with a centrifugal pendulum. Depending on

the rpm, this shifts the centre of gravity and also allows

comfortable vehicle operation in the most fuel-efficient

operating range.

Moreover, the optimised damping enables slip in the torque

converter lockup clutch to be reduced considerably, which

likewise contributes to fuel economy.

For the first time, a return spring has been integrated into the

torque converter lockup clutch of the 9G-TRONIC. The multi-disc

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 11

lockup clutch was previously only hydraulically controlled. Use of

the return pressure spring allows reliable and comfortable

activation even at very low rpm.

New gearing concept with nine speeds patented

worldwide

An intensive, computer-based system analysis and mock-up

made it possible to realise a nine-speed transmission with just

four simple planetary gear sets and six shift elements.

Mercedes-Benz has secured a worldwide patent for this specific

configuration, which the engineers consider to be the best

possible.

A planetary gear set consists of the outer ring gear, the inner

centre gear and between them the planetary carrier with the

four planetary gears and their bearings. Four planetary gears are

required in the 9G-TRONIC so that the expected torque of up to

1000 newton metres can be reliably transferred in future

engine/transmission combinations.

The ring gear, planetary carrier and centre gear in a planetary

gear set are connected by carriers and multi-disc clutches, or

braked by the multi-disc brakes which are supported by the

transmission housing. This enables the planetary gears to

transfer drive torque to the inner teeth of the outer ring gear or

to the outer teeth of the inner centre gear. The result is several

gear ratios, and at the same time it is possible to reverse the

direction of rotation for e.g. reverse gear.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 12

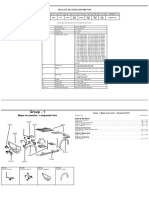

Structure of the planetary gear set

The gear ratio is the ratio between the number of gear teeth on

the driving and transferring gears. Depending which planetary

gear sets are connected in series, blocked or separated,

multiplying the part ratios produces the overall ratio for the

relevant transmission gear.

In the 9G-TRONIC, the individual gears are engaged by three

multi-disc clutches and three multi-disc brakes. The purpose of

the multi-disc clutches is to transfer the drive torque between

two components as a friction connection.

The ratio configuration of gears one to nine allows a wide ratio

spread of 9.15. For the same performance compared to

preceding transmissions, the rpm level is considerably lowered as a decisive factor for the high energy efficiency and NVH

comfort of models equipped with the 9G-TRONIC.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 13

Reliable oil supply using the power of two pumps

To ensure the reliable and at the same time highly efficient

supply of the durable and shear-resistant 2nd-generation

synthetic fuel economy engine oil, the 9G-TRONIC is fitted with

two pumps. The considerably size-reduced, mechanical main

pump installed "off-axis" lies next to the main shaft and is driven

via a chain. In an automatic transmission such as 7G-TRONIC,

the main oil pump previously ringed the transmission shaft and

was directly driven. This meant that the diameter of the

transmission shaft prevented the pump from being reduced in

size as desired. For this reason the highly efficient vane cell

pump is now placed alongside the main shaft ("off-axis"), and is

reduced in size to suit requirements.

The mechanical main pump, which ensures the oil supply to the

electrohydraulically controlled automatic transmission when the

internal combustion engine is running, is backed up by a

separate electric auxiliary pump. On the one hand this design

enables the flow of lubrication and coolant to be controlled

actively on demand, and at the same time also means that the

9G-TRONIC can benefit from a start/stop system. In subsequent

hybrid applications, this additional oil delivery also allows socalled "sailing", i.e. maintaining a constant speed without using

the internal combustion engine.

When the engine is off - for example at a red traffic light in

start/stop mode - the electric auxiliary pump is actuated,

ensuring a defined basic pressure and guaranteeing that all

necessary functions are maintained. When the driver wishes to

move off on a green light, oil delivery by the electric pump after

engine-starting guarantees immediate and agile acceleration. In

certain operating states with the engine running, the auxiliary

pump also assists the main pump, for example at very low

engine speeds or in very high temperatures. In this case the flow

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 14

of oil is added as needed to ensure smooth gear shifts or when

there is a higher cooling requirement.

This innovative oil supply concept using a mechanical main

pump and

electric auxiliary pump, as well as demand-related control,

accounts for around 54 percent of the total fuel-saving potential

of the 9G-TRONIC. The relationship is clear: the less oil that has

to be moved within the transmission by more efficient pumps,

the higher the overall efficiency. The fully synthetic Fuel

Economy low-friction oil also contributes to this.

Maximum precision: main transmission shaft with three

deep-drilled holes

The main transmission shaft is another technical highlight of the

9G-TRONIC. Firstly, it is one of the longest shafts in the entire

automotive industry at

550.9 millimetres. Secondly, it performs other functions in

addition to its main purpose of power transmission: using a

sophisticated internal ducting system, the shaft also performs

various lubricating, cooling and control functions.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 15

On the engine side, a large axial hollow-drilled hole measuring a

few centimetres supplies the front planetary gear set with oil,

which reaches the right places via smaller transverse holes. The

drilled holes on the output side of the main shaft are far more

interesting, however. Three parallel holes each measuring 6.1

millimetres are deep-drilled into the transmission shaft with a

core diameter of 16 millimetres to a depth of up to 361.5

millimetres. These three deep-drilled holes have various

functions in the 9G-TRONIC: via transverse holes, they ensure a

defined oil flow rate to lubricate and cool the planetary gear sets

and shift elements. They also perform an important control

function, and transfer the set gearshift pressure to the muiltidisc clutches and brakes.

World premiere of a new drilling process

The machining of such a shaft is a production engineering

masterpiece. The requirements are particularly exacting when

drilling the three deep holes. To date no other automotive

manufacturer or machine tool producer has dared to undertake

such a task, with such a ratio between shaft diameter and hole

depth.

To illustrate the requirements: Over their entire length of up to

361.5 millimetres, the deep-drilled holes must precisely meet

the requirements to just a few thousandths of a millimetre.

Machining must follow precisely defined geometrical

specifications:

distance and parallelity of the holes versus each other

distance and parallelity of the holes versus the outer

surface of the shaft

avoidance of twisting during the drilling process

radial positioning of the three drilled holes to ensure a

free flow to the transverse holes

correct depth of the individual holes

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 16

residue-free drilling with no microfine swarf remaining in

the holes

Reduction in cooling lubricants by 99.9 percent

As if the requirements were not already stringent enough, the

developers set themselves other challenges. The operation was

to be carried out with the minimum quantity of cooling

lubricants. In addition, complex guidance of the 370-millimetre

long drill bits was to be avoided and the processing time was to

be considerably reduced.

Implementing these requirements produced impressive results.

Conventional cooling lubricants are completely dispensed with

when producing the

9G-TRONIC drive shaft. During the drilling process, a fine oil/air

mist is sufficient for lubrication; this reaches the drilling face

through a duct in the single-fluted drills. The generated heat and

swarf are conducted away with no residue via a bead in the side

of these single-fluted drills. The savings made possible by this

so-called mist cooling technology are enormous. The

requirement is reduced by 99.9 percent compared with

conventional production processes. Specifically: whereas around

18,000 litres of cooling lubricant per hour were previously

needed, the mist cooling technology requires only 0.3 litres.

Even more specifically: rather than the capacity of an entire road

tanker, the content of a household drinking glass is sufficient to

ensure the high quality of the machining process.

Shorter processing times with improved quality

The processing time per shaft has been shortened just as

dramatically, while improving production quality. To minimise

cycle times in the production process, the production engineers

eliminated the usual guide sleeves when spot-drilling. The

machines drill the deep holes "free-hand", so to speak, while

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 17

maintaining absolute dimensional accuracy. In addition, the

single-fluted drills of cemented carbide allow high working

speeds. Whereas the figure was around 125 millimetres per

minute in the case of 7G-TRONIC PLUS, the new drills allow a

speed of over 250 millimetres per minute. The net result is that

it takes just under three minutes to process the main

transmission shaft - around 63 percent less than the cycle time

during the production of the 7G-TRONIC PLUS.

With the above improvements, Mercedes-Benz is further

implementing the "Green Production" project in its production

locations. This is because taken together, these improvements

not only increase productivity and process quality, but of course

also reduce the environmental burden by enabling savings in

terms of cooling lubricants and a reduction in energy

requirements thanks to shorter processing times.

Compact lightweight construction: reduced weight with

the same installation space

With the change in generation from the 7G-TRONIC to the 9GTRONIC, the development engineers placed further emphasis on

the area of "compact lightweight design". Despite two additional

gears and a maximum transferable torque of up to 1000 newton

metres, the new automatic transmission requires just as little

installation space as its predecessor, the 7G-TRONIC PLUS, and is

also one kilogram lighter.

The two-piece housing design has been retained: the torque

converter housing is made of lightweight aluminium alloy. The

transmission housing with a weight-optimised plastic oil pan is

made of an even lighter magnesium alloy.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 18

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 19

Transmission controlled by electronics

Artificial intelligence for a natural

driving experience

Supreme mechatronics: fully integrated transmission

control

All gearshifting, lubricating and control components

completely integrated into the housing

Extensive sensor system for outstanding gearshift

quality

Optimised electromagnetic compatibility ensures

disturbance-free operation

Three transmissions modes: Economy, Sport and

Manual

A special feature of the 9G-TRONIC is the "fully integrated

transmission control". This design is based on the following

principle: all the components for gearshifting, lubricating and

control processes are fully integrated into the transmission

housing, improving the control quality and reliability of the

9G-TRONIC. The advantage of this new direct control is more

efficient use of the hydraulic power. In this direct control system,

the hydraulic gearshifting element is directly linked to the

electromagnetic valve. The hydraulic control slides now only

have one third of their original diameter. This means that control

of the six shift elements (three multi-disc clutches and three

multi-disc brakes) can be much faster and more efficient.

9G-TRONIC command centre integrated into the onboard

electronics architecture

In the case of "fully integrated transmission control", the

actuating unit for the electric transmission oil pump, the control

unit, all the electro-magnets, as well as the complete sensor

system comprising rpm, temperature, pressure and position

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 20

sensors, are combined together on a single mounting bracket.

The control unit becomes the command centre for the 9GTRONIC, and is incorporated into the electronics architecture of

the vehicle. Apart from data obtained from the transmission

itself, the integrated 9G-TRONIC control system uses information

from the drive control (e.g. engine speed, accelerator position),

the dynamic control systems (steering angle, linear and lateral

dynamics) and the safety systems (interventions by ABS, BAS

Plus, Collision Prevention Assist, DISTRONIC), and is able to

control all shift processes optimally using these data. There are

also advantages in terms of electromagnetic compatibility

(EMC), as mutual influencing by various electronic components

is avoided. Extensive tests in the EMC laboratory showed this to

be the case. The software necessary for all control processes

was developed in-house, at the Mercedes-Benz Technology

Center (MTC). Only the control units, i.e. the hardware, come

from a supplier.

In addition to the temperature, pressure and position sensors,

three rpm sensors continuously monitor the operating state of

the 9G-TRONIC and provide the transmission control system with

the following data for effective gear shifts:

internal transmission rpm (rpm of the main transmission

shaft).

rpm of the turbine (output rpm of the torque converter).

output speed.

The extensive, networked sensor system with its continuous

comparison of all rpm values makes it possible for several gears

to be skipped when accelerating or decelerating, should the

driving situation call for it.

Who does what with whom: the power flow in 1st gear as

an example

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 21

The following is an example using the power flow in 1st gear.

Planetary gear sets 1 / 2 / 3, the multi-disc brake A / B and the

multi-disc clutch E are involved here:

The inner centre gear of the 1st gear set is part of the

drive shaft, and therefore permanently connected to it.

The planetary carrier of the 1st gear set is connected to

the outer ring gear of the 2nd gear set via the 2nd multidisc clutch.

The multi-disc brake A brakes the inner centre gear of the

2nd gear set. This increases the torque while reducing the

rpm.

The outer ring gear of the 2nd gear set has a mechanical

connection to the inner centre gear of the 3rd gear set.

The planetary gears of the 3rd gear set rotate in the outer

ring gear braked by multi-disc brake B, and transfer the

increased torque at reduced rpm to the drive shaft.

The output shaft rotates with reduced input rpm and a

significant torque increase in the engine's direction of

rotation.

As shown in the diagram:

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 22

Power transfer follows the following principle:

The output rpm is reduced in the lower gears. This leads

to lower speeds at the drive wheels while increasing

tractive power and drive torque.

Conversely, the output rpm is much higher in the higher

gears. This leads to higher speeds at the drive wheels,

accompanied by lower drive torque.

Variety of modes: Economy, Sport, Manual and "Shortterm M"

The three transmission modes of the 9G-TRONIC allow an

individual control strategy depending on the traffic situation or

the driver's personal preferences. In ECO mode the control is

equivalent to a very economical driving style: upshifts are

performed sooner, and the handling is gentler overall to support

an economical driving style at lower engine speeds. In SPORT or

MANUAL modes the response and shift times are shortened, and

there is higher revving in the gears to support a dynamic and

sporty driving style.

Like the 7G-TRONIC PLUS before it, the 9G-TRONIC also has the

automatic mode "short-term M", which makes operation even

easier and more comfortable. The driver can now also engage

the required gear using the shift paddles in ECO and SPORT

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 23

mode, without first activating MANUAL mode. "Short-term M"

remains active if there are repeated manual gear shifts or a

sporty driving style is maintained with higher linear and lateral

acceleration levels. In contrast to permanently activated

MANUAL mode, however, "Short-term M" is deactivated after a

certain period without higher power requirements, and the

transmission reverts to the original mode.

Operation of the 9G-TRONIC is unchanged compared with the

preceding

7G-TRONIC: R, N and D are selected using the DIRECT SELECT

lever on the right of the steering column, while the three

transmission modes ECO, SPORT and MANUAL are activated with

a switch on the centre console. The well-proven positioning and

operation of the steering wheel shift paddles are also

unchanged. The central display in the centre dial instrument

reliably informs the driver which gear is engaged, and which

transmission mode is active

(e.g. "D9 E" = ninth gear, ECO mode).

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 24

Developed for in-house drive systems

The best out of 85 billion possibilities

Innovative, computer-based systems analysis and

synthesis to define the 9G-TRONIC gear set concept

85 billion transmission structures examined

Improved configuration thanks to a new powertrain

test bench

Prototype testing over 5 million kilometres

The 9G-TRONIC was designed and implemented using a

completely new development process. For the first time an

intensive, computer-based systems analysis and synthesis was

used to define the gear set concept. Here the developers were

able to define and implement a single optimum solution from

among the total of more than 85 billion possible structures

which would theoretically be feasible from the combination of

planetary gear sets and shift elements for a nine-speed

automatic transmission. Mercedes-Benz has secured this

configuration for its own use and patented it worldwide. Another

goal was to implement the nine gears with a minimal number of

planetary gear sets and shift elements. The digital transmission

synthesis described enabled this requirement to be met using

only four simple planetary gear sets and six shift elements.

However, this new development approach in the conceptual

phase is not an automatic transmission programme culminating

in a fully-fledged automatic transmission that only needs to be

realised. Instead, after an initial phase in which the transmission

structures are first presorted with precise parameters, the

search begins for the best solution for a complete transmission.

This must meet all the functional requirements while fitting into

the available installation space.

Virtual testing to verify the hardware and software

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 25

The developers already carried out extensive virtual test series

before practical trials of the new 9G-TRONIC on test benches and

in prototypes began. Using Software in the Loop (SiL) or

Hardware in the loop (HiL) processes, each new software

function in the entire transmission control system was

thoroughly verified. For this purpose the entire electronics

architecture of the 9G-TRONIC with all its control units, sensors,

lines, actuators and the complete control software was put

together and connected to a digital simulator that represented

real operating conditions with a wide range of parameters. Using

the results of these tests, the transmission control was then

refined to perfection.

This was followed by extensive and detailed practical trials,

which were very demanding in view of the planned applications

for the 9G-TRONIC ranging from saloon and sports cars through

to off-roaders. In the process the prototypes were spared no

torture: as when testing a new vehicle generation, the 9GTRONIC had to prove its worth in all manner of operating

conditions in real vehicles. This included test series such as on

and off-road, in trailer operations, long journeys under full load,

on mountain passes or in inner-city stop-and-go traffic.

To ensure that the 9G-TRONIC also performed reliably under the

toughest climatic conditions ranging from freezing Arctic

temperatures to burning tropical heat, a worldwide programme

of trials was initiated that reflected the special demands on an

automatic transmission and covered all climatic zones. These

driving tests were supplemented with tests in the state-of-theart climate tunnels in Sindelfingen. Here the encapsulated

dynamometers are able to set and maintain temperatures

ranging from -40 to +60 degrees Celsius, and speeds of up to

200 km/h. These standardised conditions enable much more

rapid and precise adjustments to be made.

Premiere of the new vehicle powertrain test bench (FATS)

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 26

The new vehicle powertrain test bench (German abbreviation

"FATS") is one of the most modern test benches of its kind in the

automotive industry, and was first used during the development

phase for the 9G-TRONIC. In contrast to conventional

dynamometers, the test vehicles in FATS are on wheels but

these do not spin during testing. Instead special test wheels are

used - these have a freewheeling through-drive, and allow the

front and rear wheel hubs to be directly coupled to the test unit

via shafts. Each of these four shafts in turn transfers the torque

generated by the electric motors to the wheel hubs, based on

the relevant test programme. The advantages of this setup: the

entire powertrain and all dynamic control systems respond as

they would under real conditions on the road.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 27

Moreover, FATS allows the simulation of all road surface and

operating conditions, which is why this test unit is also known as

a "road to rig" test bench. From configurations such as different

levels of grip on the left/right sides of the road and different

levels of grip between the front and rear axles to the so-called

"chess board" (different levels of diagonal grip between the

axles), and right up to uphill and downhill gradients or a wide

variety of driving manoeuvres - the new test rig is able to

examine the powertrain dynamics of a vehicle in many different

ways. This was previously not possible, as conventional

dynamometers are unable to simulate these test parameters.

In addition to an automatic programme in which the relevant

control elements of the 9G-TRONIC are actuated by robots and

defined test routines are carried out, FATS also allows a manual

mode. In this case the test engineers sit inside the vehicle

during the test cycle, and operate the controls as they would in

normal road traffic. This enables problems that only occur

irregularly or haphazardly in normal test operations to be

precisely localised, so that suitable counter-measures can be

taken.

Blocked or pivoted: test benches for endurance runs and

to verify the oil supply

In addition to FATS, other test units were used during the

development phase for the 9G-TRONIC which tested the longterm durability and oil circuit of the transmission under all

conceivable conditions. In the so-called block test rig, the

powertrain with its engine, 9G-TRONIC and propshaft is

assembled and tortured on previously recorded, digitised test

routes for example with high-speed endurance runs on an oval

circuit, or on steep mountain gradients with or without a trailer.

Air drag and rolling resistance are simulated by an electric motor

connected to the propshaft.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 28

As a reliable oil supply and the necessary oil levels within the

transmission under all operating conditions can only be partly

simulated in a computer model, the engineers came up with a

test rig with "X-ray eyes". They produced a transparent

transmission housing for the 9G-TRONIC from a high-strength

plastic, installed the complete automatic transmission assembly

inside it and mounted this "glass 9G-TRONIC" on a special

pivoting test rig. During the subsequent test runs the glass

transmission was subjected to different engine speeds, oil

temperatures from -20 to +120 degrees C and various tilting

angles along the longitudinal and transverse axis to simulate

linear and lateral acceleration. In the process the oil circuit was

monitored with the help of HD cameras and optimised where

necessary.

Thanks to this intensive preparation with virtual tests and

extensive test rig operation, the practical trials with prototypes

were able to commence at a very high level of maturity, making

the entire test procedure much more effective. More than 5

million kilometres were covered during these practical trials in a

wide range of prototypes.

The extensive test programme ensures the reliability and longterm durability of the 9G-TRONIC as a hallmark of the brand.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 29

Review of automatic transmission development

22 million automatic transmissions

from

Mercedes-Benz

1961: first automatic transmission from MercedesBenz

The first electronically controlled 7-speed automatic

transmission

with torque converter, the 7G-TRONIC, came from

Mercedes-Benz

The 9G-TRONIC is already the seventh automatic

transmission generation from Mercedes-Benz

In the interests of improving driving comfort, Mercedes-Benz

began the development of transmissions to reduce the driver's

workload as an early stage. As early as 1930, the Model 770

"Grand Mercedes" was equipped with a semi-automatic, suctionoperated linkage for the overdrive. This milestone was a first

step by Mercedes-Benz on the way to an automatic

transmission. However, the first really automatic transmission, a

three-speed torque converter transmission, offered by MercedesBenz for the Model 300 "Adenauer" from autumn 1955 was an

American design by Borg-Warner.

In 1957 the "Hydrak" hydraulic automatic clutch developed inhouse appeared as an optional extra for the 190, 219 and 220 S

models. This system combined a hydraulic start-off clutch and a

conventional single-disc dry clutch for clutch

engagement/disengagement during gear changes with an

overrunning clutch bypassing the hydraulic clutch. With

"Hydrak" the Mercedes-Benz driver no longer needed to operate

a clutch, though gear changes continued to be manual.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 30

The first automatic transmission from Mercedes-Benz

appeared in 1961

As a completely new development produced in-house, the fullyfledged four-speed automatic transmission available from 1961

for the luxury class saloons, coups and convertibles proved a

trailblazer for the entire industry. In contrast to Borg-Warner's

automatic transmission, this in-house design had no torque

converter but rather a hydraulic clutch, with the advantage of

lower power losses. The downstream four-speed planetary

gearbox consisted of two planetary gear sets, three multi-disc

clutches and three band brakes. From 1963 every MercedesBenz car model and even the 230 SL sports car - was

optionally available with an automatic transmission.

In 1972 Mercedes-Benz changed over to a newly developed

generation of automatic torque converter transmissions, which

established themselves as three or four-speed transmissions in

all model series by 1973. From 1979 Mercedes-Benz introduced

a newly developed generation of automatic torque converter

transmissions which excelled with high efficiency, a wider torque

conversion range and reduced fuel consumption. The version for

the most powerful engines was now also equipped with four

rather than three gears. In 1989 a variant with five speeds was

added for the six-cylinder models.

In 1995 the new five-speed automatic introduced by MercedesBenz for the V12 and V8 models was a major milestone in

automatic transmission development. For the first time it

combines an electronic control system and a torque converter

lock-up clutch. The result was significantly improved ride

comfort and reduced fuel consumption. The transmissions

computer automatically adapted its gearshifting characteristics

to the current driving situation and the individual wishes of the

driver. In addition the electronics adjusted the shift points on

uphill or downhill gradients, preventing sudden gear changes

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 31

that could unfavourably affect vehicle handling. It also excelled

by having two transmission modes and being of modern

lightweight construction. In 1998 an improved variant of the

five-speed automatic transmissions entered series production for

the new S-Class (220 series), featuring a further development in

the form of Touchshift.

7G-TRONIC: the first electronically controlled sevenspeed automatic torque converter transmission

In 2003 Mercedes-Benz reached new heights with the 7GTRONIC, the world's first electronically controlled seven-speed

automatic torque converter transmission for passenger cars.

This made Mercedes-Benz models more economical and faster in

acceleration. In addition this transmission significantly improved

gearshift comfort. Having seven ratios allowed small increases in

engine speed making it easier to ensure the right ratio for the

current driving situation. At the same time the ratio spread

between the lowest and highest gear became larger. This

reduced the average engine speed a plus point in terms of

both fuel consumption and noise comfort. During rapid

downshifts (kick-down) the individual gears were no longer

necessarily shifted in sequence. Instead the control system of

the new 7G-TRONIC transmission skipped individual gears if

necessary, e.g. shifting from seventh directly to fifth gear and

then to third gear. Depending on the driving situation, this

meant that the previous four gearshift operations required to

accelerate the car rapidly during kick-down were reduced to two.

At the same time the quality of gear shifts was greatly improved.

They became much smoother and hardly perceptible,

particularly in the upper gears.

In 2005 Mercedes-Benz dispensed with the usual automatic

selector lever in the centre console of the new M-Class, the RClass and the S-Class, and instead used a stalk on the steering

column with which the driver operated the transmission the

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 32

DIRECT SELECT gearshift. Additional steering wheel shift buttons

allowed manual preselection of the seven gears. This enabled

the driver to make optimal use of the power from six or eight

cylinders in any driving situation.

From 2008 the Mercedes-Benz SL became available with 7GTRONIC Sport and steering wheel shift paddles. This featured a

double-declutch function activated during manual downshifts.

This not only produced a very sporty sound, but was also in the

interests of safety and comfort, as the double-declutching

synchronised the crankshaft and transmission speeds. The

advantage: gear shifts became even smoother, and typical load

cycle reactions were noticeably reduced. In 2009 the AMG

SPEEDSHIFT DCT 7-speed sports transmission appeared for the

SLS AMG. This excelled with fast gear changes and practically no

interruptions in tractive power. Four different transmission

modes were available to the driver: the fuel-efficient "C"

(Controlled Efficiency), "S" (Sport), "S+" (Sport plus) and "M"

(Manual). An automatic double-declutching function was active

in Sport, Sport plus and Manual mode, and all modes could be

conveniently operated via a rotary control in the AMG DRIVE

UNIT. The RACE START function allowed optimal traction as did

the mechanical differential lock integrated into the compact

transmission housing.

2010: the sixth generation of automatic transmissions

7G-TRONIC PLUS

In 2010 Mercedes-Benz presented a further development of its

seven-speed automatic transmission with the new-generation

CL-Class (216 series):

7G-TRONIC PLUS. This was even more comfortable, faster and

more economical than the first-generation 7G-TRONIC. An

engine connection with further reduced torque converter slip

and significantly lower internal power losses optimised the

efficiency. The various innovations ensured that in ECO mode,

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 33

there was a reduction in engine speeds that greatly contributed

to fuel savings. In 2012 the new SL was likewise launched with

the 7G-TRONIC PLUS. New feature: the Roadster was the first

Mercedes-Benz to be equipped with the newly developed DIRECT

SELECT gearshift in the centre console, a feature reminiscent of

a high-quality joystick. In this way the premium brand

established a completely new generation of centre gear shifts

for vehicles with shift-by-wire transmission technology.

The latest development stage of the 7G-TRONIC PLUS entered

use in 2013, in the E 300 BlueTEC HYBRID. Here Mercedes-Benz

combines the 2.2-litre four-cylinder diesel engine developing 150

kW (204 hp) with a powerful hybrid module. The 20 kW electric

motor is integrated into the transmission's torque converter

housing. The electric motor assists the diesel engine when

accelerating (boosting), and is used to recuperate braking

energy in generator operation. At the same time it is suitable for

purely electric driving.

First AUTOTRONIC CVT transmission in the A-Class

In 2004 Mercedes-Benz introduced the AUTOTRONIC system

developed in-house as an optional extra for the A-Class (169

series). AUTOTRONIC operates on the principle of a

"continuously variable transmission" (CVT), in which the ratios

are varied continuously using a pulley wheel variator.

Accordingly, it does not employ the paired gear wheels normally

used in automatic transmissions. The main advantages of

AUTOTRONIC compared with a conventional manual

transmission are improved ride comfort, extra flexibility and

quicker acceleration.

The 7G-DCT dual clutch transmission: comfortable and

efficient

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 34

In 2011 a further Mercedes-Benz automatic transmission

celebrated its debut in the B-Class: the 7G-DCT dual clutch

transmission. Extremely compact, highly adaptable to engine

speeds thanks to seven gears and start/stop capable by virtue of

an electric oil pump, this transmission performs gear shifts with

no interruption in tractive power and combines the comfort of an

automatic with the efficiency of a manual transmission. 7G-DCT

is an automated three-shaft manual transmission consisting of

two partial transmissions, each with its own clutch. Both clutch

actuation and gear changing are fully automatic without any

interruption in tractive power, It allows both exceptionally

comfortable and dynamic driving.

Thanks to its seven gears, it offers an exceptionally large spread

of up to 7.99. This means that a very short transmission ratio is

available when moving off on an uphill slope with a high

payload, for example, while during cruising the engine speed

can be lowered considerably. For the first time the efficiency of

this transmission matches that of a manual transmission.

The new 4MATIC for the compact models also combined with 7GDCT. The special feature of this technology is that the power flow

to the rear drive train is provided by a compact power take-off

unit (PTU) which is fully integrated into the main transmission

and supplied with lubricant from the latter's oil circuit. This

configuration gives rise to substantial weight advantages over

competitor systems that branch off power by means of an addon component with its own oil circuit. The models A 45 AMG, CLA

45 AMG and GLA 45 AMG feature a particularly sporty variant of

this drive technology. The AMG SPEEDSHIFT DCT 7-speed sports

transmission is specifically configured for the world's most

powerful four-cylinder engine, and thrills with its additional

functions of double-declutching and RACE START.

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 35

Technical data for the 9G-TRONIC

_________________________________________________________________________________

Transmission

Electronically controlled automatic

transmission

9G-TRONIC

9+R

Aluminium/magnesium

Number of gears

Torque

converter/transmission

housing

Cooling/lubrication

on-demand active control of the lubricating

and

cooling oil flow; mechanical main pump,

electric auxiliary oil pump

Gear sets

4 planetary gear sets

Control

Hydraulic direct control

Shift elements

3 multi-disc brakes, 3 multi-disc clutches

Starting device

Hydraulic torque converter

Efficiency of starting device %

92

Lockup clutch

Multi-disc clutch with return spring

Comfort elements

Twin-turbine torsion damper with

centrifugal pendulum

Sensors

Three for rpm, temperature, pressure and

position

Control unit

Fully integrated transmission control unit

Gear change/transmission

DIRECT SELECT gearshift / E,S, M, Shortmode

term M

Possible drive configurations

Rear-wheel drive

4MATIC all-wheel drive

Hybrid drive

Plug-in hybrid drive

ECO start/stop as standard

Gear ratios, i=

1st gear

5.50

2nd gear

3.33

3rd gear

2.32

4th gear

1.66

5th gear

1.21

6th gear

1.00

7th gear

0.87

8th gear

0.72

9th gear

0.60

Reverse

R -4.93

Ratio spread

9.15

_________________________________________________________________________

Suitable engines

Number of

cylinders/arrangement

Max. output

Max. input torque

4, 6, 8, 12/in-line and V engines

kW/hp

Nm

open

1000

_________________________________________________________________________

Dimensions and weights

Overall length

mm

Overall width

mm

Overall height

mm

approx. 639- 649

384

391

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 36

Length of main transmission mm

shaft

Weight (including torque

kg

converter and transmission

oil)

550

95

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 37

Mercedes-Benz E 350 BlueTEC Saloon (9GTRONIC)

Engine

Number of

cylinders/arrangement

Displacement

Bore x stroke

Rated output

Rated torque

Compression ratio

Mixture formation

V6, 4 valves per cylinder

cc

mm

kW/hp

Nm

2987

83.0 x 92.0

185/252 at 3600 rpm

620 at 1600-2400 rpm

15.5: 1

High-pressure fuel injection with commonrail technology, VNT turbocharger, EDC

Power transmission

Transmission

Gear ratios

Final-drive ratio

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

7th gear

8th gear

9th gear

Reverse

Chassis and suspension

Front axle

Independent multi-link front suspension, coil

springs, twin-tube gas-filled shock absorbers,

anti-roll bar

Independent multi-link rear suspension, coil

springs, single-tube shock absorbers, anti-roll

bar

Internally ventilated and perforated disc

brakes at front, internally ventilated disc

brakes at rear, electric parking brake, ABS,

Brake Assist, ESP

Electromechanical rack-and-pinion power

steering

7.5 J x 16

225/55 R 16 W

Rear axle

Braking system

Steering

Wheels

Tyres

Dimensions and weights

Wheelbase

Track, front/rear

Length (overall)

Width (overall)

Height (overall)

Turning circle

Boot capacity max.*

Kerb weight acc. to EC

Payload

Perm. gross vehicle weight

Tank capacity/incl. reserve of

9G-TRONIC automatic transmission

2.24

5.50

3.33

2.32

1.66

1.21

1.00

0.87

0.72

0.60

-4.93

mm

mm

mm

mm

mm

m

l

kg

kg

kg

l

2874

1583/1599

4879

1854

1475

11.28

490

1885

555

2440

59.0/8.0

Performance and fuel consumption

Acceleration 0-100 km/h

sec.

6.6

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 38

Top speed

Combined fuel consumption

CO2 emissions

km/h

250

l/100 km 5.3 - 5.6

g/km

138 - 148

*acc. to VDA measuring method

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 39

Mercedes-Benz E 350 BlueTEC Estate (9GTRONIC)

Engine

Number of

cylinders/arrangement

Displacement

Bore x stroke

Rated output

Rated torque

Compression ratio

Mixture formation

V6, 4 valves per cylinder

cc

mm

kW/hp

Nm

2987

83.0 x 92.0

185/252 at 3600 rpm

620 at 1600-2400 rpm

15.5: 1

High-pressure fuel injection with commonrail technology, VNT turbocharger, EDC

Power transmission

Transmission

Gear ratios

Final-drive ratio

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

7th gear

8th gear

9th gear

Reverse

Chassis and suspension

Front axle

Independent multi-link front suspension, coil

springs, twin-tube gas-filled shock absorbers,

anti-roll bar

Independent multi-link rear suspension, air

springs, twin-tube gas-filled shock absorbers,

anti-roll bar

Internally ventilated and perforated disc

brakes at front, internally ventilated disc

brakes at rear, electric parking brake, ABS,

Brake Assist, ESP

Electromechanical rack-and-pinion power

steering

7.5 J x 16

225/55 R 16 W

Rear axle

Braking system

Steering

Wheels

Tyres

Dimensions and weights

Wheelbase

Track, front/rear

Length (overall)

Width (overall)

Height (overall)

Turning circle

Boot capacity max.*

Kerb weight acc. to EC

Payload

Perm. gross vehicle weight

Tank capacity/incl. reserve of

9G-TRONIC automatic transmission

2.24

5.50

3.33

2.31

1.66

1.21

1.00

0.87

0.72

0.60

-4.93

mm

mm

mm

mm

mm

m

l

kg

kg

kg

l

2874

1583/1604

4905

1854

1507

11.28

1855

1955

595

2550

59.0/8.0

Performance and fuel consumption

Acceleration 0-100 km/h

sec.

6.9

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

Page 40

Top speed

Combined fuel consumption

CO2 emissions

km/h

250

l/100 km 5.5 - 5.7

g/km

144 - 150

*acc. to VDA measuring method

Daimler Communications, 70546 Stuttgart/Germany

Mercedes-Benz - A Daimler Brand

You might also like

- AisinDocument147 pagesAisinRicardo Javier89% (35)

- Pressing Force Calculator UpdatedDocument25 pagesPressing Force Calculator Updatedanush_swaminathanNo ratings yet

- Formula Sheet Applied Mechanics Design PDFDocument11 pagesFormula Sheet Applied Mechanics Design PDFdsn_sarmaNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- 286 Ho 722.9 062504Document79 pages286 Ho 722.9 062504arkhom196% (28)

- 2011 08 001 002 enDocument49 pages2011 08 001 002 enAlex Maceira Graterol100% (3)

- BMW 3-Series (E30) Performance Guide: 1982-1994From EverandBMW 3-Series (E30) Performance Guide: 1982-1994Rating: 4.5 out of 5 stars4.5/5 (18)

- 2013 09 002 002 enDocument58 pages2013 09 002 002 enStefan Ilic80% (5)

- 722.9 Introduction To MercedesDocument46 pages722.9 Introduction To MercedesThePokeOne89% (9)

- BMW 3-Series (E36) 1992-1999: How to Build and ModifyFrom EverandBMW 3-Series (E36) 1992-1999: How to Build and ModifyRating: 5 out of 5 stars5/5 (5)

- ZF 9HPDocument4 pagesZF 9HPAndrei Todea100% (2)

- Vol. IVDocument501 pagesVol. IVsvenkzNo ratings yet

- Audi 01J Multitronic CVTDocument99 pagesAudi 01J Multitronic CVTenes_br95% (20)

- Manual 0am PDFDocument72 pagesManual 0am PDFCarlos Garcia Godoy100% (7)

- 722.9 TransDocument16 pages722.9 TransDavid Rosado100% (5)

- Tte 0913Document76 pagesTte 0913Deepak Chachra75% (4)

- DSGDocument66 pagesDSGTM12550% (2)

- UwfsDocument60 pagesUwfsbyungchul kim50% (2)

- 5hp19e 130209063629 Phpapp02Document54 pages5hp19e 130209063629 Phpapp02Luis Miguelo80% (10)

- BMW 3 Series - E36 Restoration Tips & TechniquesFrom EverandBMW 3 Series - E36 Restoration Tips & TechniquesRating: 5 out of 5 stars5/5 (4)

- Audi SSPDocument26 pagesAudi SSPAndrei Brka100% (1)

- 6hp19 26 PDFDocument92 pages6hp19 26 PDFВиталий Черненко100% (7)

- N47tu Top enDocument60 pagesN47tu Top enAdrian NegoiNo ratings yet

- ST813 - M DCT DrivelogicDocument58 pagesST813 - M DCT DrivelogicBogathroz100% (2)

- 7g-Tronic 722.9Document74 pages7g-Tronic 722.9Maxim Maklakov87% (15)

- DSG DQ200 Gearbox Rattle Noise Causes and SolutionsDocument7 pagesDSG DQ200 Gearbox Rattle Noise Causes and SolutionsGeorges Ali50% (2)

- TranmisiiDocument15 pagesTranmisiiCătălin-Ionuţ Cioabă100% (2)

- 03 - F48 PowertrainDocument38 pages03 - F48 Powertrainainginer100% (1)

- Audi A4Document5 pagesAudi A4Mohammed MochrifNo ratings yet

- DSG Clutch Removal Tool Set Eng Printer PDFDocument16 pagesDSG Clutch Removal Tool Set Eng Printer PDFMohammed MochrifNo ratings yet

- Weistec 722.9 Valve Body Removal and Installation GuideDocument7 pagesWeistec 722.9 Valve Body Removal and Installation Guideossoski0% (1)

- D4B8048F894-6-Speed Dual Clutch Gearbox 0DD Hybrid VehiclesDocument106 pagesD4B8048F894-6-Speed Dual Clutch Gearbox 0DD Hybrid VehiclesCarlos Garcia Godoy100% (1)

- DIY: DSG (02E) Transmission - 40,000 Miles Maintenance ServiceDocument11 pagesDIY: DSG (02E) Transmission - 40,000 Miles Maintenance ServiceJ.K.jr.bad.100% (4)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

- The 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103Document48 pagesThe 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103jorge Angel Lope50% (2)

- PI RR4 0300 Engine N74 enDocument66 pagesPI RR4 0300 Engine N74 enIván Blanco Fernández100% (1)

- F11 DriveDocument44 pagesF11 DriveLucian GrigorieNo ratings yet

- 722.6 90's Shifter ServiceDocument4 pages722.6 90's Shifter ServiceJack Carl100% (2)

- 420 SEL 560 SEL 560 SEC: Owner's ManualDocument121 pages420 SEL 560 SEL 560 SEC: Owner's ManualCons100% (1)

- SSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWDocument32 pagesSSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWFarid Mch100% (3)

- Pages 2Document88 pagesPages 2Miguel Gutierrez100% (1)

- Hybrid SystemDocument16 pagesHybrid SystemAhmed EldeebNo ratings yet

- 287 Ho 03 M272 (Fah) 08-05-04Document76 pages287 Ho 03 M272 (Fah) 08-05-04arkhom1100% (3)

- VW 4MOTION With Four-Wheel Drive Coupling Gen IVDocument28 pagesVW 4MOTION With Four-Wheel Drive Coupling Gen IVbenjaminhuku100% (1)

- Article 0001 Ravigneaux Planetary TransmissionDocument9 pagesArticle 0001 Ravigneaux Planetary Transmissionthisisjinesh100% (1)

- Cat 950F Transmission PDFDocument13 pagesCat 950F Transmission PDFMehdi Chakroune100% (2)

- 722.9 TipsDocument41 pages722.9 TipsStefan Ilic100% (3)

- 722.9 TipsDocument41 pages722.9 TipsStefan Ilic100% (3)

- 722.9 TipsDocument41 pages722.9 TipsStefan Ilic100% (3)

- 8HP45Document8 pages8HP45Adrian Biasussi Biasuzzi100% (7)

- D 9 NDocument6 pagesD 9 NAldo Cesar Mina SosaNo ratings yet

- Tcu Dsg7 Dq200: Complaints and Error CodesDocument5 pagesTcu Dsg7 Dq200: Complaints and Error CodesEmre YAPICI0% (1)

- Dual-Clutch Transmission (DCT) or Direct-Shift Gearbox (DSG)Document13 pagesDual-Clutch Transmission (DCT) or Direct-Shift Gearbox (DSG)Har NeetNo ratings yet

- Of Gear Aps: Mercedes Model 722.6 5 Speed + Lockup Gearbox ControllerDocument61 pagesOf Gear Aps: Mercedes Model 722.6 5 Speed + Lockup Gearbox ControllerSvetoslav Arnaudov100% (2)

- 05 - SMG IiiDocument25 pages05 - SMG IiiRobert MoreauNo ratings yet

- B 82WagoneerJeepTSMPart2 ChassisDocument457 pagesB 82WagoneerJeepTSMPart2 ChassisingemexNo ratings yet

- Maintenance and Service Manual: Powershift TransmissionDocument243 pagesMaintenance and Service Manual: Powershift TransmissionMichael Maluenda Castillo100% (3)

- SSP 457 Audi A8 2010 Power TransmissionDocument68 pagesSSP 457 Audi A8 2010 Power TransmissionEderson BjjNo ratings yet

- Tiguan OverviewDocument44 pagesTiguan OverviewBadoiu LiviuNo ratings yet

- Bosch Lean Manufacturing Guidebook-1Document16 pagesBosch Lean Manufacturing Guidebook-1minal potavatreNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- Gypsum Solutions 2014Document9 pagesGypsum Solutions 2014Stefan IlicNo ratings yet

- Gypsum Solutions 2014Document9 pagesGypsum Solutions 2014Stefan IlicNo ratings yet

- 2008 A5 BrochureDocument52 pages2008 A5 BrochurePeter BondarNo ratings yet

- Mercedes 7-Speed Automatic TransmissionDocument2 pagesMercedes 7-Speed Automatic TransmissionanachingpainNo ratings yet

- 7G PlusDocument6 pages7G PlusBogathrozNo ratings yet

- Joining two I profilesDocument1 pageJoining two I profilesStefan IlicNo ratings yet

- EBSCO Training Kragujevac 11-12-2015Document1 pageEBSCO Training Kragujevac 11-12-2015Stefan IlicNo ratings yet

- Trakka Pty. Limited: Revving Up Motorhome/Special-Purpose Vehicle Development With Solidworks ProfessionalDocument3 pagesTrakka Pty. Limited: Revving Up Motorhome/Special-Purpose Vehicle Development With Solidworks ProfessionalStefan IlicNo ratings yet

- Transkript 2018Document1 pageTranskript 2018Stefan IlicNo ratings yet

- World Class ManufacturingDocument6 pagesWorld Class ManufacturingStefan Ilic100% (1)

- FirestoneDocument108 pagesFirestoneEduardoNo ratings yet

- Efficient planetary gear train analysis techniquesDocument5 pagesEfficient planetary gear train analysis techniquesStefan IlicNo ratings yet

- Pert Method 850 KiikbrDocument1 pagePert Method 850 KiikbrStefan IlicNo ratings yet

- Mechanism and Machine Theory: Wen-Hsiang HsiehDocument23 pagesMechanism and Machine Theory: Wen-Hsiang HsiehStefan IlicNo ratings yet

- Us 2761333Document6 pagesUs 2761333Stefan IlicNo ratings yet

- Mechanism and Machine Theory: Roland Mathis, Yves RemondDocument13 pagesMechanism and Machine Theory: Roland Mathis, Yves RemondStefan IlicNo ratings yet

- Konstr - Alata I Pribora IDocument133 pagesKonstr - Alata I Pribora IStefan IlicNo ratings yet

- Children of The VoidDocument43 pagesChildren of The Voidpetermcleod117No ratings yet

- Podesavanje VCmasterDocument1 pagePodesavanje VCmasterStefan IlicNo ratings yet

- April 2, 1940.: P. Ravigneaux - 2,195,783Document9 pagesApril 2, 1940.: P. Ravigneaux - 2,195,783Stefan IlicNo ratings yet

- US2631476Document17 pagesUS2631476Stefan IlicNo ratings yet

- SaeDocument184 pagesSaehariprasanNo ratings yet

- SLK-Class Specifications 03.2014 2Document11 pagesSLK-Class Specifications 03.2014 2Stefan IlicNo ratings yet

- IgoM14 Brochure Metric enDocument4 pagesIgoM14 Brochure Metric enStefan IlicNo ratings yet

- US2631476Document17 pagesUS2631476Stefan IlicNo ratings yet

- Alpha Stern Drive: Installation and AdjustmentsDocument14 pagesAlpha Stern Drive: Installation and AdjustmentsiwessberNo ratings yet

- Sumitomo HSM PDFDocument36 pagesSumitomo HSM PDFArnaldo Nunes FazanNo ratings yet

- Vin Plate Decoding InformationDocument642 pagesVin Plate Decoding InformationTatiana BernalNo ratings yet

- How Hovercrafts WorkDocument10 pagesHow Hovercrafts WorkHarish VermaNo ratings yet

- Installation, Operation and Maintenance Manual for AS-series GearboxesDocument35 pagesInstallation, Operation and Maintenance Manual for AS-series GearboxesRamesh BhosleNo ratings yet

- Setting the standard for electromagnetic clutch-brake combinationsDocument36 pagesSetting the standard for electromagnetic clutch-brake combinationsfrankNo ratings yet

- d4 FlyweelDocument2 pagesd4 FlyweelCarlos AlvarezNo ratings yet

- Auto Manual Two WheelersDocument40 pagesAuto Manual Two WheelersChandra Adi PradanaNo ratings yet

- Smartflex General CatalogueDocument8 pagesSmartflex General CatalogueBang OchimNo ratings yet

- 06 GA6HP26Z Auto Trans ColorDocument48 pages06 GA6HP26Z Auto Trans ColorGeorge HristovNo ratings yet

- TM 5-3895-369-24PDocument512 pagesTM 5-3895-369-24PAdvocateNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,051,824 B1Document23 pagesUnited States Patent: (12) (10) Patent No.: US 7,051,824 B1Agnivesh PandeyNo ratings yet

- Unit IV-evhv Drive TrainDocument33 pagesUnit IV-evhv Drive TrainRajesh BhaskarlaNo ratings yet

- Design Project 11Document38 pagesDesign Project 11Hemanth VeeraNo ratings yet

- Fersa Solutions - USA Application PDFDocument149 pagesFersa Solutions - USA Application PDFnetemma97No ratings yet

- SM Pw170es-6k-962Document625 pagesSM Pw170es-6k-962Эрнест Бекиров100% (1)

- Keeping Your Business On The Move: Demag DrivesDocument24 pagesKeeping Your Business On The Move: Demag DrivesAndrés RamírezNo ratings yet

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocument14 pagesBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNo ratings yet

- DMTP 5100Document41 pagesDMTP 5100Henry GelvisNo ratings yet

- Manual Z562Document49 pagesManual Z562Tomas AurilaNo ratings yet

- Ax90022 I001 Scx10 Honcho RTRDocument52 pagesAx90022 I001 Scx10 Honcho RTRAitorMentaNo ratings yet