Professional Documents

Culture Documents

Dievar D20140715

Uploaded by

Keattikhun ChaichanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dievar D20140715

Uploaded by

Keattikhun ChaichanaCopyright:

Available Formats

DIEVAR

UDDEHOLM

DIEVAR

DIEVAR

REFERENCE STANDARD

ASSAB DF-2

ARNE

ASSAB DF-3

AISI

WNr.

JIS

O1

(1.2510)

(SKS 3)

O1

(1.2510)

(SKS 3)

ASSAB XW-5

SVERKER 3

D6 (D3)

(1.2436)

(SKD 2)

ASSAB XW-10

RIGOR

A2

1.2363

SKD 12

ASSAB XW-41

SVERKER 21

D2

1.2379

SKD 11

D2

1.2379

SKD 11

ASSAB XW-42

CARMO

CARMO

1.2358

CALMAX

CALMAX

1.2358

CALDIE

CALDIE

ASSAB 88

SLEIPNER

ASSAB PM 23 SUPERCLEAN

VANADIS 23 SUPERCLEAN

(M3:2)

1.3395

SKH 53

ASSAB PM 30 SUPERCLEAN

VANADIS 30 SUPERCLEAN

(M3:2 + Co)

1.3294

SKH 40

ASSAB PM 60 SUPERCLEAN

VANADIS 60 SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANCRON 40 SUPERCLEAN

VANCRON 40 SUPERCLEAN

ELMAX SUPERCLEAN

ELMAX SUPERCLEAN

(1.3292)

ASSAB 518

P20

1.2311

ASSAB 618

P20 Mod.

1.2738

ASSAB 618 HH

P20 Mod.

1.2738

ASSAB 618 T

P20 Mod.

1.2738 Mod.

ASSAB 718 SUPREME

IMPAX SUPREME

P20 Mod.

1.2738

ASSAB 718 HH

IMPAX HH

P20 Mod.

1.2738

NIMAX

NIMAX

MIRRAX 40

MIRRAX 40

VIDAR 1 ESR

VIDAR 1 ESR

UNIMAX

UNIMAX

CORRAX

CORRAX

ASSAB 2083

420 Mod.

H11

1.2343

SKD 6

420

1.2083

SUS 420J2

STAVAX ESR

STAVAX ESR

420 Mod.

1.2083 ESR

SUS 420J2

MIRRAX ESR

MIRRAX ESR

420 Mod.

POLMAX

POLMAX

RAMAX HH

RAMAX HH

ROYALLOY

ROYALLOY

420 F Mod.

PRODAX

ASSAB MM40

ALVAR 14

ALVAR 14

ASSAB 2714

ASSAB 8407 2M

ORVAR 2M

ASSAB 8407 SUPREME

ORVAR SUPREME

DIEVAR

DIEVAR

HOTVAR

HOTVAR

QRO 90 SUPREME

QRO 90 SUPREME

1.2714

SKT 4

1.2714

SKT 4

H13

1.2344

SKD 61

H13 Premium

1.2344 ESR

SKD 61

4340

1.6582

SNCM8

ASSAB 709

4140

1.7225

SCM4

ASSAB 760

1050

1.1730

S50C

ASSAB 705

ASSAB is a trademark of ASSAB Pacific Pte Ltd.

The information contained herein is based on our present state of knowledge and is intended to provide general notes on our products and their uses.

It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose.

Each user of ASSAB products is responsible for making its own determination as to the suitability of ASSAB products and services.

Edition D140715

DIEVAR

DIEVAR

Dievar is a hot work die steel specially developed by Uddeholm Tooling,

our steel mill in Sweden, to provide the best possible performance.

The chemical composition and the very latest in production technique

make the property profile outstanding. Dievar possesses a combination of

excellent toughness and very good hot strength, resulting in a superior hot

work die steel that have excellent resistance to heat checking and gross

cracking.

Dievar is suitable for high demand hot work applications like die casting,

extrusion and forging. The property profile also makes it a suitable choice

in other applications such as plastic moulding (e.g., to solve chipping/

cracking) and High Performance Steel.

Dievar offers the potential for significant improvements in die life, thereby

improving the tooling economy.

DIEVAR

General

Dievar is a high performance chromium-molybdenumvanadium alloyed hot work tool steel which offers a very

good resistance to heat checking, gross cracking, hot

wear and plastic deformation. Dievar is characterised by:

DIE CASTING

Excellent toughness and ductility in all directions

Good temper resistance

Good high-temperature strength

Excellent hardenability

Good dimensional stability throughout heat

treatment and coating operations

Type

Cr-Mo-V alloyed hot work tool steel

Standard

specification

None

Delivery

condition

Soft annealed to approx. 160 HB

Colour code

Yellow / Grey

Part

Aluminium / Magnesium alloys

Dies

44-50 HRC

EXTRUSION

Dievar is a premium hot work tool steel developed by

Uddeholm. It is manufactured utilising the very latest in

production and refining techniques. The Dievar

development has yielded a die steel with the ultimate

resistance to heat checking, gross cracking, hot wear

and plastic deformation. The unique properties profile

of Dievar makes it the best choice for die casting, forging

and extrusion.

Applications

Heat checking is one of the most common failure

mechanisms, e.g., in die casting and nowadays also in

forging applications. Dievars superior ductility yields the

highest possible level of heat checking resistance. With

Dievars outstanding toughness and hardenability, its

resistance to heat checking will be further improved.

If gross cracking is not a factor, then a higher working

hardness can be utilised (+2 HRC).

Part

Copper

alloys

Aluminium /

Magnesium alloys

Dies

46-52 HRC

46-52 HRC

44-52 HRC

Liners, dummy

blocks, stems

HOT FORGING

Regardless of the dominant failure mechanism (e.g.,

heat checking, gross cracking, hot wear or plastic

deformation), Dievar offers the potential for significant

improvements in die life as well as tooling economy.

Part

Dievar is the material of choice for the high demand die

casting, forging and extrusion industries.

Inserts

Steel / Aluminium

44-52 HRC

DIEVAR

Properties

The reported properties are representative of samples

which have been taken from the centre of a 610 x 203

mm bar. Unless otherwise indicated, all specimens were

hardened at 1025C, quenched in oil and tempered

2 + 2 hours at 615C to 451 HRC.

PHYSICAL PROPERTIES

Charpy V-notch impact toughness at elevated

temperatures

Short transverse direction.

Hardened and tempered to 44 - 46 HRC.

Temperature

At a hardness of approximately 45 HRC, the minimum

average unnotched impact ductility is 300 J in the short

transverse direction.

20C

Impact energy, J

400C

140

600C

120

Density

kg/m3

Modulus of elasticity

MPa

7800

7700

7600

210 000

180 000

145 000

45 HRC

100

80

47 HRC

60

Coefficient of

thermal expansion

per C from 20C

13.3 x 10 -6

12.7 x 10 -6

40

20

Thermal

conductivity

W/m C

31

50 HRC

32

50

100 150

200 250 300 350 400 450C

Testing temperature

MECHANICAL PROPERTIES

Temper resistance

Approximate tensile properties at room temperature,

tested in the short transverse direction.

Hardness

The specimens have been hardened and tempered to

45 HRC, and then held at different temperatures from

1 to 100 hours.

44 HRC

48 HRC

52 HRC

Tensile

strength, Rm

1480 MPa

1640 MPa

1900 MPa

Yield

strength, RP0.2

1210 MPa

1380 MPa

1560 MPa

Elongation, A 5

13 %

13 %

12.5 %

Reduction of

area, Z

55 %

55 %

52 %

Hardness, HRC

50

500C

45

550C

40

35

Approximate tensile properties at elevated

temperatures

600C

30

Short transverse direction, 451 HRC.

A5, Z

%

100

Rm, Rp0.2

MPa

2000

Z

1800

90

25

0.1

650C

10

100

Time, h

80

1600

70

1400

Rm

1200

60

50

1000

800

40

Rp0.2

30

600

20

400

200

10

A5

100

200

300

400

500

Testing temperature

600

700C

DIEVAR

Heat treatment

SOFT ANNEALING

QUENCHING

Protect the steel and heat through to 850C. Then cool

in the furnace at 10C per hour to 650C, then freely in air.

As a general rule, quench rates should be as rapid as

possible. Accelerated quench rates are required to

optimise tool properties specifically with regards to

toughness and resistance to gross cracking. However,

risk of excessive distortion and cracking must be

considered.

STRESS RELIEVING

The quenching media should be capable of creating a

fully hardened microstructure. Different quench rates

for Dievar are defined by the CCT graph as shown in

page 7.

After rough machining, the tool should be heated

through to 650C, holding time 2 hours. Cool slowly

to 500C, then freely in air.

High speed gas/circulating atmosphere

Vacuum (high speed gas with sufficient positive

pressure). An interrupted quench at 320450C is

recommended for distortion control, or when quench

cracking is a concern.

Martempering bath, salt bath or fluidised bed at

450550C

Martempering bath, salt bath or fluidised bed at

approx. 180200C

Warm oil, approx. 80C

HARDENING

Preheating temperature: 600900C. Normally a

minimum of two preheats, the first in the 600650C

range, and the second in the 820850C range. When

three preheats are used, the second is carried out

at 820C, and the third at 900C.

Austenitising temperature: 10001030C

Temperature

C

Soaking time

minutes

Hardness before

tempering

1000

30

522 HRC

1025

30

552 HRC

Note: Temper the tool as soon as its temperature

reaches 5070C.

TEMPERING

Choose the tempering temperature according to the

hardness required by reference to the tempering graph

below. Temper at least three times for die casting dies,

and two times for forging and extrusion tools. The tool

should be cooled to room temperature between the

tempers. The minimum holding time at tempering

temperature is 2 hours.

Soaking time = time at hardening temperature after the

tool is fully heated through.

Tempering in the range of 500550C is normally not

recommended, and it will result in a lower toughness.

Protect the tool against decarburisation and oxidation during

austenitising.

Tempering graph

Hardness, HRC

60

Hardness, grain size and retained austenite as

functions of austenitising temperature

Grain

size

ASTM Hardness, HRC

10 60

8

58

56

1000C

Retained austenite

1010

1020

1030

1040 1050C

Austenitising temperture

Temper

45

54

50

990 1000

50

Grain size

Hardness

52

Austenitising temperature

1025C

55

Retained austenite %

Retained austenite, %

40

35

30

25

Retained austenite

100

200

300

400

500

Tempering temperature (2 + 2h)

600

700C

DIEVAR

Effect of tempering temperature on room

temperature Charpy V-notch impact energy

DIMENSIONAL CHANGES DURING HARDENING

AND TEMPERING

Short transverse direction.

During hardening and tempering, the tool is exposed

to both thermal and transformation stresses. These

stresses will result in distortion. Insufficient levels of

machine stock may result in slower than recommended

quench rates during heat treatment. To reduce the

level of distortion, a stress relief is always recommended

bewteen rough and semi-finish machining, prior to

hardening.

Impact strength

60

Hardness HRC

60

50

50

40

40

Temper brittleness zone

30

30

20

20

10

10

200

300

400

500

600

For a stress relieved Dievar tool, a minimum machining

allowance of 0.3% is recommended to correct for

distortion during heat treatment with a rapid quench.

700C

Tempering temperature (2h + 2h)

CCT graph

Austenitising temperature 1025C. Holding time 30 minutes.

C

1100

Austenitising temperature 1025C

Holding time 30 minutes

1000

AC1 = 890C

900

AC1 = 820C

Carbides

800

Pearlite

700

600

500

Cooling Hardness

Curve No. HV 10

400

300

1

2

3

4

5

6

7

8

9

Bainite

MS

200

Mf

Martensite

100

1

10

100

1

1000

10

1.5

10 000

10

100 000

100

1000

1

0.2

1.5

15

280

1248

3205

5200

10400

20800

41600

Seconds

Minutes

10

90

681

627

620

592

566

488

468

464

405

T800-500

(sec)

600

100 Hours

Air cooling of

bars, mm

DIEVAR

Machining recommendations

The cutting data below are to be considered as guiding

values and as starting points for developing your own

best practice.

MILLING

Face and square shoulder milling

Condition: Soft annealed condition ~160 HB

TURNING

Cutting data

parameters

Rough

turning

Fine

turning

Fine

turning

150 - 200

Feed (f)

mm/r

0.2 - 0.4

0.05 - 0.2

0.05 - 0.3

2-4

0.5 - 2

0.5 - 2

P20 - P30

Coated

carbide

P10

Coated

carbide or

cermet

Carbide

designation

ISO

Turning

with HSS

Turning with cabide

Cutting speed

(vc)

m/min

Depth of cut (ap)

mm

Milling with carbide

Cutting data

parameters

200 - 250

Rough milling

Fine milling

Cutting speed

(vc)

m/min

130 - 180

180 - 220

Feed (f z)

mm/tooth

0.2 - 0.4

0.1 - 0.2

2-4

P20 - P40

Coated carbide

P10

Coated carbide

or cermet

15 - 20

Depth of cut (ap)

mm

Carbide

designation

ISO

End milling

High speed steel

Type of milling

Cutting data

parameters

Solid

carbide

Carbide

indexable

insert

High speed

steel

130 - 170

120 - 160

25 - 301

Feed (f)

mm/tooth

0.03 - 0.202

0.08 - 0.202

0.05 - 0.352

Carbide

designation

ISO

P20 - P30

DRILLING

High speed steel twist drill

Drill diameter

mm

Cutting speed (vc)

m/min

Feed (f)

mm/r

15 - 20 *

0.05 - 0.15

5 - 10

15 - 20 *

0.15 - 0.20

10 - 15

15 - 20 *

0.20 - 0.25

15 - 20

15 - 20 *

0.25 - 0.35

Cutting speed

(vc)

m/min

For coated HSS end mill, vc~ 4550 m/min

* For coated HSS drill, vc~ 3540 m/min

GRINDING

Wheel recommendation

Carbide drill

Type of grinding

Type of drill

Cutting data

parameters

Cutting speed

(vc)

m/min

Feed (f)

mm/r

1

2

Indexable

insert

Solid

carbide

180 - 220

120 - 150

60 - 90

0.05 - 0.252

0.10 - 0.252

0.15 - 0.252

Drill with replaceable or brazed carbide tip

Depending on drill diameter

Brazed

carbide1

Grinding wheel designation

Face grinding straight wheel

A 46 HV

Face grinding segments

A 24 GV

Cylindrical grinding

A 46 LV

Internal grinding

A 46 JV

Profile grinding

A 100 LV

DIEVAR

Machining recommendations

The cutting data below are to be considered as guiding

values and as starting points for developing your own

best practice.

MILLING

Face and square shoulder milling

Condition: Hardened and tempered to 451 HRC

TURNING

Cutting data

parameters

Turning with carbide

Rough turning

Fine turning

Cutting speed

(vc)

m/min

40 - 60

70 - 90

Feed (f)

mm/r

0.2 - 0.4

0.05 - 0.2

1-2

0.5 - 1

Depth of cut (ap)

mm

Carbide

designation

ISO

Milling with carbide

Cutting data

parameters

P20 - P30

Coated carbide

Rough milling

Fine milling

Cutting speed

(vc)

m/min

50 - 90

90 - 130

Feed (f z)

mm/tooth

0.2 - 0.4

0.1 - 0.2

2-4

P20 - P40

Coated carbide

P10

Coated carbide

or cermet

Depth of cut (ap)

mm

Carbide

designation

ISO

P10

Coated carbide or

cermet

End milling

Type of milling

Cutting data

parameters

DRILLING

Solid

carbide

Carbide

indexable

insert

High speed

steel

TiCN coated

60 - 80

70 - 90

5 - 10

Feed (f)

mm/tooth

0.03 - 0.201

0.08 - 0.201

0.05 - 0.351

Carbide

designation

ISO

P10 - P20

High speed steel twist drill (TiCN coated)

Drill diameter

mm

Cutting speed (vc)

m/min

Feed (f)

mm/r

4-6

0.05 - 0.10

5 - 10

4-6

0.10 - 0.15

10 - 15

4-6

0.15 - 0.20

15 - 20

4-6

0.20 - 0.30

Cutting speed

(vc)

m/min

Depending on radial depth of cut and cutter diameter

GRINDING

Wheel recommendation

Carbide drill

Type of grinding

Type of drill

Cutting data

parameters

Cutting speed

(vc)

m/min

Feed (f)

mm/r

1

2

Indexable

insert

Solid

carbide

Brazed

carbide1

60 - 80

60 - 80

40 - 50

0.05 - 0.252

0.10 - 0.252

0.15 - 0.252

Grinding wheel designation

Face grinding straight wheel

A 46 HV

Face grinding segments

A 36 GV

Cylindrical grinding

A 60 KV

Internal grinding

A 60 IV

Profile grinding

A 120 JV

Drill with replaceable or brazed carbide tip

Depending on drill diameter

DIEVAR

Surface treatment

NITRIDING AND NITROCARBURISING

Depth of nitriding

Nitriding and nitrocarburising result in a hard surface

layer which has the potential to improve resistance to

wear and soldering, as well as resistance to premature

heat checking. Dievar can be nitrided using gas or

plasma. It can also be nitrocarburised via gas or salt

bath process. The nitriding and nitrocarburising

temperature should be at least 2550C below the

highest previous tempering temperature, depending

upon the process time and temperature. Otherwise,

a permanent loss of core hardness, strength, and/or

dimensional tolerances may be experienced.

During nitriding and nitrocarburising, a brittle compound

layer, known as the white layer, may be generated. The

white layer is very brittle and may result in cracking or

spalling when exposed to heavy mechanical or thermal

loads. As a general rule, the white layer formation

must be avoided.

Process

Surface

hardness

HV0.2

Depth*

mm

Gas nitriding at

510C

10

30

1100

1100

0.16

0.22

Plasma nitriding

at 480C

10

1100

0.15

1100

0.13

1100

0.08

Nitrocarburising

in gas at

580C

in salt bath at

580C

*

Time

h

Depth of case = distance from surface where hardness is 50 HV0.2 over base

hardness

Electrical discharge machining

Following the EDM process, the applicable die surfaces

are covered with a resolidified layer (white layer) and a

rehardened and untempered layer, both of which are very

brittle and hence detrimental to die performance.

If EDM is used, the white layer must be completely

removed by grinding or stoning. After finish machining,

the tool should be given an additional temper at approx.

25C below the highest previous tempering temperature.

Nitriding in ammonia gas at 510C, or plasma nitriding at

480C, both result in a surface hardness of approx.

1100 HV0.2 . In general, plasma nitriding is the preferred

method because of better control over nitrogen

potential. However, careful gas nitriding can give

perfectly acceptable results.

The surface hardness after nitrocarburising in either gas

or salt bath at 580C is approx. 1100 HV0.2 .

10

DIEVAR

Welding

Further information

Welding of die components can be performed, with

acceptable results, as long as proper precautions are

taken during the preparation of the joint, the filler

material selection, the preheating of the die, the controlled

cooling of the die and the post weld heat treatment

processes. The following guidelines summarise the most

important welding process parameters.

Welding

method

TIG

MMA

Working

temp.1

325 - 375C

325 - 375C

Filler

material

QRO 90 TIG-WELD

DIEVAR TIG-WELD

QRO 90 WELD

475C

475C

Maximum

interpass

temp.2

Cooling

rate

Hardness

after

welding

For further information, i.e., steel selection, heat

treatment, application and availability, please contact our

ASSAB office nearest to you.

20 - 40C/h for the first 2 to 3 hours and

then freely in air

50 - 55 HRC

50 - 55 HRC

Heat treatment after welding

1

2

Hardened

condition

Temper at 25C below the original tempering temperature.

Soft

annealed

condition

Soft anneal the material at 850C

in protected atmosphere.

Then cool in the furnace at 10C per hour

to 600C, then freely in air.

Preheating temperature must be established throughout the die and must be

maintained for the entire welding process, to prevent weld cracking

The temperature of the tool in the weld area immediately before the second

and subsequent pass of a multiple pass weld. When exceeded, there is a

risk of distortion of the tool or soft zones around the weld.

11

DIEVAR

Relative comparison of ASSAB hot work die steels

QUALITATIVE COMPARISON OF CRITICAL DIE STEEL PROPERTIES

ASSAB grade

Temper

resistance

Hot yield

strength

Creep

strength

Coefficient

of thermal

expansion

Heat

conductivity

Ductility

ALVAR 14

ASSAB 8407 2M

ASSAB 8407 SUPREME

DIEVAR

HOTVAR

QRO 90 SUPREME

QUALITATIVE COMPARISON OF RESISTANCE TO DIFFERENT DIE FAILURES

ASSAB grade

ALVAR 14

ASSAB 8407 2M

ASSAB 8407 SUPREME

DIEVAR

HOTVAR

QRO 90 SUPREME

12

Heat

checking

Gross

cracking

Hot wear /

Erosion

Plastic

deformation

Corrosion (Al)

DIEVAR

13

DIEVAR

Case study

RESISTANCE TO HEAT CHECKING

Product

: Automotive housing

Work material : A380 Aluminium alloy

Work temp. : 690C

Tooling size : 406 x 508 x 508 mm

Die material : Premium H13 at 44-46 HRC vs DIEVAR 46-48 HRC

Background : Severe heat checking begins on Premium H13 at approximately 20,000 shots.

The customer wanted better die life.

Premium H13

DIEVAR

Comparison of Premium H13 and DIEVAR after 42,000 shots.

Premium H13

14

DIEVAR

DIEVAR

Ningbo

ASSAB Tooling Technology

(Ningbo) Co., Ltd.

Tel : +86 574 8680 7188

Fax: +86 574 8680 7166

info.ningbo@assab.com

Cikarang*

PT. ASSAB Steels Indonesia

Tel : +62 21 461 1314

Fax: +62 21 461 1306/

+62 21 461 1309

info.cikarang@assab.com

MALAYSIA

Kuala Lumpur - Head Office

ASSAB Steels (Malaysia) Sdn. Bhd.

Tel : +60 3 6189 0022

Fax: +60 3 6189 0044/55

info.kualalumpur@assab.com

Tel : +62 21 5316 0720-1

Jiangxi*

ASSAB Tooling (Dong Guan)

Co, Ltd., Jiangxi Branch

Tel : +86 769 2289 7888

Fax : +86 769 2289 9312

info.jiangxi@assab.com

15

Choosing the right steel is of vital importance. ASSAB engineers

and metallurgists are always ready to assist you in your choice of

the optimum steel grade and the best treatment for each application.

ASSAB not only supplies steel products with superior quality, we offer

state-of-the-art machining, heat treatment and surface treatment

services to enhance steel properties to meet your requirement in

the shortest lead time. Using holistic approach as a one-stop solution

provider, we are more than just another tool steel supplier.

ASSAB and Uddeholm are present on every continent. This ensures

you that high-quality tool steels and local support are available

wherever you are. Together we secure our position as the world's

leading supplier of tooling materials.

For more information, please visit www.assab.com

You might also like

- Linea L186SS Oven ManualDocument19 pagesLinea L186SS Oven Manualdmwx50% (2)

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- EFI BasicsDocument168 pagesEFI BasicsBryanMaes100% (1)

- Buna EP LanxessDocument51 pagesBuna EP LanxessANHVUDRCNo ratings yet

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDocument4 pagesDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNo ratings yet

- DPWH - Guard HouseDocument180 pagesDPWH - Guard HouseErnest BelmesNo ratings yet

- Absolute LYFT Pulsed Eddy CurrentDocument2 pagesAbsolute LYFT Pulsed Eddy CurrentgulmuhrNo ratings yet

- Service Manual: Tigercat T250B Track LoaderDocument176 pagesService Manual: Tigercat T250B Track LoaderGabriely MuriloNo ratings yet

- Daikin VRV II R-22Document346 pagesDaikin VRV II R-22Danilo FIloteo73% (11)

- Maintenance & RepairDocument26 pagesMaintenance & RepairGrid Lock100% (1)

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- YSS Die Casting Die MaterialDocument14 pagesYSS Die Casting Die MaterialVishal BalkwadeNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- Rolling Technology Training Programme - AnnealingDocument52 pagesRolling Technology Training Programme - Annealingrabikm100% (1)

- Post WeldDocument4 pagesPost WelddanemsalNo ratings yet

- Unit 10 Thermogravimetric AnalysisDocument24 pagesUnit 10 Thermogravimetric Analysismaidhily83% (6)

- Calmax D20140711 PDFDocument12 pagesCalmax D20140711 PDFSinan YıldızNo ratings yet

- ASSAB PM 23 SuperClean Brochure English PDFDocument12 pagesASSAB PM 23 SuperClean Brochure English PDFnithiNo ratings yet

- PB Uddeholm Sleipner EnglishDocument12 pagesPB Uddeholm Sleipner EnglishAlfya ChinikamwalaNo ratings yet

- Assab - XW 10 D20140711Document8 pagesAssab - XW 10 D20140711Orlando CellanNo ratings yet

- ASSAB PM 30 SuperClean Brochure EnglishDocument12 pagesASSAB PM 30 SuperClean Brochure EnglishnithiNo ratings yet

- Corrax D20140714Document8 pagesCorrax D20140714mj_davis04No ratings yet

- Asaab 8407 - 2MDocument11 pagesAsaab 8407 - 2MPrabath MadusankaNo ratings yet

- A New Die Material For Longer Service LifeDocument12 pagesA New Die Material For Longer Service LifeLuis SantosNo ratings yet

- PB Uddeholm Calmax EnglishDocument12 pagesPB Uddeholm Calmax EnglishxulubNo ratings yet

- Dac BDocument15 pagesDac BArief BudimanNo ratings yet

- Uddeholm Qro90supremeDocument12 pagesUddeholm Qro90supremeDarwin Anderson GNo ratings yet

- Yss Tool Steels BDocument77 pagesYss Tool Steels BneramjanNo ratings yet

- GB Grade Asp 2060Document2 pagesGB Grade Asp 2060João MirandaNo ratings yet

- OCR12VMDocument4 pagesOCR12VMcvgfgNo ratings yet

- D3 Wys PDFDocument3 pagesD3 Wys PDFEdilson Sarmiento AlonsoNo ratings yet

- Damasteel Martensitic Damascus SteelDocument6 pagesDamasteel Martensitic Damascus SteelsurintanNo ratings yet

- Assab - XW 42 150216Document8 pagesAssab - XW 42 150216Rachmadi NorcahyoNo ratings yet

- Aisi A2: Cold Work Tool SteelDocument21 pagesAisi A2: Cold Work Tool SteelRahul NambiarNo ratings yet

- YSS Cold Working Die PDFDocument11 pagesYSS Cold Working Die PDFHoang Le VuNo ratings yet

- D2 Tool Steel: CompositionDocument2 pagesD2 Tool Steel: CompositionsabahatNo ratings yet

- PB Uddeholm Sverker 21 EnglishDocument12 pagesPB Uddeholm Sverker 21 EnglishKOSTASPDFNo ratings yet

- Aisi D2: Cold Work Tool SteelDocument7 pagesAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNo ratings yet

- D2 Data SheetDocument9 pagesD2 Data SheetJim ToddNo ratings yet

- D2 Tool Steel: Shipping PolicyDocument2 pagesD2 Tool Steel: Shipping Policyالسيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Assab MaterialDocument8 pagesAssab MaterialFadzlly Abd JalilNo ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- X210CR12 GradeDocument3 pagesX210CR12 GradekartsoftNo ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- CPM3V DSDocument2 pagesCPM3V DSuighuigNo ratings yet

- X5CrNiCuNb 16-41.4542Document2 pagesX5CrNiCuNb 16-41.4542nuesteNo ratings yet

- BRM2Document3 pagesBRM2王向荣No ratings yet

- PB Uddeholm Sverker 21 EnglishDocument12 pagesPB Uddeholm Sverker 21 EnglishulfwisenNo ratings yet

- Acero A11Document2 pagesAcero A11Jose LuisNo ratings yet

- Assab Stavax EsrDocument6 pagesAssab Stavax EsrAnonymous Wi2Pd2UgPINo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- Material Info - HSS M-42Document4 pagesMaterial Info - HSS M-42ਗਗਨ ਜੋਤNo ratings yet

- DataSheets2010 - Datasheet CPM 154 CMv12010Document2 pagesDataSheets2010 - Datasheet CPM 154 CMv12010jobseekeramatxNo ratings yet

- Duplex Stainless Steel 329 or 1.4460 PDFDocument2 pagesDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- D2 Tool Steel SpecificationDocument1 pageD2 Tool Steel SpecificationRamdika Nur HariantoNo ratings yet

- Specification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelDocument2 pagesSpecification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelBalaji RGNo ratings yet

- LSS A286Document2 pagesLSS A286anhntran4850No ratings yet

- EN26Document3 pagesEN26Moldoveanu TeodorNo ratings yet

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- 9ni Cryogenic Materials PDFDocument5 pages9ni Cryogenic Materials PDFyogie4061100% (1)

- High-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCDocument3 pagesHigh-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCpvdangNo ratings yet

- Datasheet Sandvik 12c27 enDocument4 pagesDatasheet Sandvik 12c27 enRizqi D. KurniantoNo ratings yet

- Hoja de Especificaciones Del Acero T-410Document2 pagesHoja de Especificaciones Del Acero T-410cristobal_tl2277No ratings yet

- 17-4 PH Bar Data SheetDocument2 pages17-4 PH Bar Data SheetBryan KellyNo ratings yet

- 2010 Datasheet DMV 825Document4 pages2010 Datasheet DMV 825Roman BorovkovNo ratings yet

- W 500Document9 pagesW 500amantessNo ratings yet

- 1.2379 X153Crmov12 Cppu: Chemical CompositionDocument2 pages1.2379 X153Crmov12 Cppu: Chemical CompositionAdrian Finichiu100% (1)

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- Tech Uddeholm-Vancron ENDocument11 pagesTech Uddeholm-Vancron ENsobheysaidNo ratings yet

- Influence of Pitting Corrosion On Fatigue and CorrDocument9 pagesInfluence of Pitting Corrosion On Fatigue and CorrKeattikhun ChaichanaNo ratings yet

- Casteps Tool122014Document12 pagesCasteps Tool122014Keattikhun ChaichanaNo ratings yet

- Germany Tourist VisaDocument1 pageGermany Tourist VisaKeattikhun ChaichanaNo ratings yet

- Screen Shot 2560-01-22 at 10.12.41 PM PDFDocument1 pageScreen Shot 2560-01-22 at 10.12.41 PM PDFKeattikhun ChaichanaNo ratings yet

- Heat TransferDocument7 pagesHeat TransferKeattikhun ChaichanaNo ratings yet

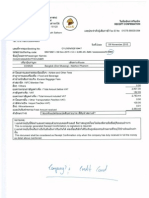

- Test Report: Company Tambon Bo-Winra. SrirachaDocument1 pageTest Report: Company Tambon Bo-Winra. SrirachaKeattikhun ChaichanaNo ratings yet

- Front Billet Loading OverviewDocument1 pageFront Billet Loading OverviewKeattikhun ChaichanaNo ratings yet

- Vacation LeaveDocument1 pageVacation LeaveKeattikhun ChaichanaNo ratings yet

- Changing FlightDocument1 pageChanging FlightKeattikhun ChaichanaNo ratings yet

- AirAsia - Web Check-InDocument3 pagesAirAsia - Web Check-InKeattikhun ChaichanaNo ratings yet

- Heat TransferDocument7 pagesHeat TransferKeattikhun ChaichanaNo ratings yet

- 080 Chlorine AlkalineDocument6 pages080 Chlorine AlkalineChristian CoboNo ratings yet

- Brosur RomoraDocument43 pagesBrosur RomoraDonie TheaNo ratings yet

- C10129004 PDFDocument20 pagesC10129004 PDFChristopherNo ratings yet

- EGS100L24R Instruction ManualDocument72 pagesEGS100L24R Instruction ManualAlexis CruzNo ratings yet

- K SpanDocument36 pagesK SpanMerve MerveNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- Seger Formula Glaze Calculator - Buscar Con GoogleDocument1 pageSeger Formula Glaze Calculator - Buscar Con Googlemartafrias7No ratings yet

- CPWD - DAR - Vol - I - 14092023-Civil 152-161Document10 pagesCPWD - DAR - Vol - I - 14092023-Civil 152-161Dipanjan MitraNo ratings yet

- Chapter 8: Failure: How Do Materials Break?Document40 pagesChapter 8: Failure: How Do Materials Break?Leann FarleyNo ratings yet

- Ssnde14 Final LDocument72 pagesSsnde14 Final LmiamarchNo ratings yet

- Polypropylene: Product Data SheetDocument2 pagesPolypropylene: Product Data Sheet李万福No ratings yet

- AVKOTE 650 Typ. Method StatementDocument4 pagesAVKOTE 650 Typ. Method StatementNizarHamrouniNo ratings yet

- Copper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114Document2 pagesCopper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114alextentwentyNo ratings yet

- W7 Smith CapacitorsDocument31 pagesW7 Smith CapacitorsyjandeNo ratings yet

- Lesson 6-GlassDocument32 pagesLesson 6-Glasslewis imaNo ratings yet

- Minerals Hub Place in India Rashtriya ChemicalsDocument3 pagesMinerals Hub Place in India Rashtriya Chemicalsvivek vaishnavNo ratings yet

- FH Double-Grip Packer Technical DatasheetDocument5 pagesFH Double-Grip Packer Technical DatasheetEvolution Oil ToolsNo ratings yet

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićNo ratings yet

- Carl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiDocument1 pageCarl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiA GHAILANE EL HASSANI RABII SOUMAYANo ratings yet