Professional Documents

Culture Documents

Cast in Place Concrete TCS Q 113.03 R0

Uploaded by

Pageduesca RouelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cast in Place Concrete TCS Q 113.03 R0

Uploaded by

Pageduesca RouelCopyright:

Available Formats

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

TABLE OF CONTENTS

1.0

SCOPE

2.0

GENERAL REQUIREMENTS

3.0

CONFLICTS AND DEVIATIONS

4.0

CODES AND STANDARDS

4.1

4.2

4.3

4.4

4.5

4.6

4.7

5.0

MATERIALS

5.1

5.2

5.3

5.4

5.5

5.6

6.0

Concrete

Steel Reinforcement And Positioning Devices

Form Materials

Joint Materials

Curing Materials

Miscellaneous Materials

DESIGN AND FUNCTIONAL REQUIREMENTS

6.1

6.2

7.0

COMPANY Standards

SASO Standards

AASHTO Standards

ACI Standards

ASTM Standards

U.S. Corps Of Engineers Standards

CRSI Standards

Reinforcement

Formworks

CONCRETE WORKS

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

Preparation

Acceptance Of Concrete on Arrival

Concrete Placement

Concreting Under Water

Concreting In Hot Weather

Concreting For Slab-On-Grade

Construction Joints

Concrete Placement Acceptance

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 2 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.0

POST CONCRETE WORKS

8.1

8.2

8.3

8.4

9.0

Finishing

Removal Of Forms And Shoring

Curing

Corrosion Protection and Durability

REPAIR OF DEFECTIVE CONCRETE

9.1

9.2

9.3

9.4

9.5

9.6

9.7

10.0

TCS-Q-113.03, Rev. 0

Surface Air Voids/Sand Streaking/ Peeling /Blistering

Honeycombs

Tie Holes

Pop-Outs/ Scaling

Discoloration and Stains

Cracks

Defect With Exposed Reinforcing Steel

QUALITY CONTROL

10.1

10.2

10.3

Pre-Concreting Quality Control

Post-Concreting Quality Control

Non-Compliance of Quality Control

11.0

SUBMITTALS

12.0

APPENDICES

Appendix I

Appendix II

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 3 of 44

TRANSMISSION CONSTRUCTION STANDARD

1.0

TCS-Q-113.03, Rev. 0

SCOPE

This Transmission Construction Standard (TCS) intended to be used in the system of the

Saudi Electricity COMPANY (SEC), Saudi Arabia, covers the minimum mandatory

requirements for receiving, forming, placing, consolidating, finishing, jointing, curing and

all other related WORKS as required for Cast-In-Place Concrete.

2.0

3.0

GENERAL REQUIREMENTS

2.1

Concrete shall be constructed true to lines, dimensions and details shown on the

drawings.

2.2

The mix design, mixing, delivery and testing of normal weight, ready-mixed

concrete shall be governed by the requirements of COMPANY Material Standard

70-TMSS-03.

2.3

No material, regardless of its source, shall be incorporated in the WORK until

representative samples are taken and tested by a COMPANY approved independent

laboratory and found acceptable.

CONFLICTS AND DEVIATIONS

3.1

Any conflicts between this standard and other applicable Saudi Electricity Company

(SEC) Standards, industry standards, codes, and forms shall be resolved in writing

by the COMPANY Representative.

3.2

Any request to deviate from this standard shall be directed to the Manager of

Transmission Standards and Specifications.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 4 of 44

TRANSMISSION CONSTRUCTION STANDARD

4.0

TCS-Q-113.03, Rev. 0

CODES AND STANDARDS

The latest revisions/amendments of the following Codes, Standards and Specifications are

intended as guidance in providing an acceptable level of quality of materials and practice. In

case of conflict between these Standards and the text of this Standard, the latter shall govern.

4.1

4.2

COMPANY Transmission Standards

4.1.1 TCS-Q-113.02

Earthworks

4.1.2

Normal Weight

Concrete

4.4

Ready-Mixed

Portland

Cement

SASO Standards - Saudi Arabian Standards Organization Standards

4.2.1

4.3

70-TMSS-03

SASO/SSA 2

Steel Bars for the Reinforcement of Concrete

4.2.2 SASO/SSA 143

Portland Cement, Ordinary and Rapid Hardening

4.2.3

SASO/SSA 224

Steel Fabric for Reinforcement of Concrete

4.2.4

General Specifications for Building Construction in Kingdom of Saudi

Arabia-Latest Edition

AASHTO Standards -

American Association

Transportation Officials

of

State

4.3.1 AASHTO M182

Burlap Cloth made from Jute or Kenaf

Highway

And

ACI Standards - American Concrete Institute

4.4.1

ACI 117

Specifications

for

Tolerances

Construction and Materials

4.4.2

ACI 201.2R

Guide to Durable Concrete

4.4.3

ACI 212.3R

Chemical Admixtures for Concrete

4.4.4

ACI 214.3R

Simplified Version of the Recommended Practice for

Evaluation of Strength Test Results

4.4.5

ACI 224R

Control of Cracking in Concrete Structures

4.4.6

ACI 301M

Specifications for Structural Concrete for Buildings

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

for

Concrete

PAGE NO. 5 of 44

TRANSMISSION CONSTRUCTION STANDARD

4.4.7

4.5

ACI 302.1R

TCS-Q-113.03, Rev. 0

Guide for Concrete Floor and Slab Construction

4.4.8 ACI 304R

Guide for Measuring, Mixing, Transporting and

Placing Concrete

4.4.9

Placing Concrete by Pumping Methods

ACI 304.2R

4.4.10 ACI 305R

Hot Weather Concreting

4.4.11 ACI 308R

Standard Practice for Curing Concrete

4.4.11 ACI 309R

Guide for Consolidation of concrete

4.4.12 ACI 318RM

Building Code Requirements for Structural Concrete

and Commentary

4.4.13 ACI 347R

Guide to Formwork for Concrete

4.4.14 ACI 350R

Code Requirements for Environmental Engineering

Concrete Structures

4.4.15 ACI 503R

Use of Epoxy Compounds with Concrete

4.4.16 ACI 504R

Guide to Joint Sealant for Concrete Structures

4.4.17 ACI SP-2

Manual of Concrete Inspection

ASTM Standards - American Society For Testing And Materials

4.5.1

ASTM A 82

Standard Specification for Steel Wire, Plain, for

Concrete Reinforcement

4.5.2

ASTM A 184

Standard Specification for Welded Deformed Steel Bar

Mats for Concrete Reinforcement

4.5.3 ASTM A 185

Specification for Steel Welded Wire Reinforcement,

Plain, for Concrete

4.5.4 ASTM A 496

Standard Specification for Steel wire, Deformed, for

Concrete Reinforcement

4.5.5 ASTM A 497

Specification for Steel Welded Wire Reinforcement,

Deformed, for Concrete

4.5.6 ASTM A 615

Standard Specification for Deformed and Plain Carbon

-Steel Bars for Concrete Reinforcement

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 6 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

4.5.7 ASTM A 767

Standard Specification for Zinc-Coated (Galvanized)

Steel Bars for Concrete Reinforcement

4.5.8

ASTM A 775M

Specification for Epoxy-Coated Reinforcing Steel Bars

4.5.9

ASTM A 884

Standard Specification for Epoxy-Coated Wire and

Welded Wire Reinforcement

4.5.10 ASTM C 31M

Standard Practice for Making and Curing Concrete

Test Specimens in the Field

4.5.11 ASTM C 39

Test Method for Compressive Strength of Cylindrical

Concrete Specimens

4.5.12 ASTM C 42M

Test Method for Obtaining and Testing Drilled Cores

and Sawed Beams of Concrete

4.5.13 ASTM C 94

Specification for Ready-Mixed Concrete

4.5.14 ASTM C 125

Standard Terminology Relating to Concrete And

Concrete Aggregates

4.5.15 ASTM C 143

Standard Method of Test for Slump of Hydraulic

Cement Concrete

4.5.16 ASTM C 171

Specification for Sheet Materials for Curing Concrete

4.5.17 ASTM C 309

Specification

for

Liquid

Membrane-Forming

Compounds for Curing Concrete

4.5.18 ASTM C 494

Specification for Chemical Admixtures for Concrete

4.5.19 ASTM C 803M

Test Method for Penetration Resistance of Hardened

Concrete

4.5.20 ASTM C 805

Test Method for Rebound Number of Hardened

Concrete

4.5.21 ASTM C 1077

Standard Practice for Laboratories Testing Concrete

and Concrete Aggregates for Use in Construction and

Criteria for Laboratory Evaluation

4.5.22 ASTM C 1107

Specification for Packaged Dry, Hydraulic-Cement

Grout (Non-Shrink)

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 7 of 44

TRANSMISSION CONSTRUCTION STANDARD

4.6

4.7

TCS-Q-113.03, Rev. 0

4.5.23 ASTM D 1751

Preformed Expansion Joint Filler for Concrete Paving

and Structural Construction

4.5.24 ASTM C 1602

Standard Test Method for Mixing Water used in the

Production of Hydraulic Cement Concrete

4.5.25 ASTM C 1603

Standard Test Method for Measurement of Solids in

Water

4.5.26 ASTM D 1752

Preformed Sponge Rubber and Cork Expansion Joint

Filler for Concrete Paving and Structural Construction

4.5.27 ASTM D 3963

Standard Specification for Fabrication and jobsite

Handling of Epoxy-Coated Steel Reinforcing Bars

4.5.28 ASTM E 96M

Test Methods for Water Vapor Transmission of

Materials

U.S. Corps Of Engineers Standards

4.6.1

CRD C513

Rubber Waterstops

4.6.2

CRD C572

Polyvinyl Chloride (PVC) Waterstops

4.6.3

CRD C583

Expansive Grout

4.6.4

CRD C621

Non-Shrink Grout

CRSI Standards - Concrete Reinforcing Steel Institute

4.7.1

Manual of Standard Practice for Reinforced Concrete Construction

4.7.2

Manual of Concrete Reinforcing Steel Institute

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 8 of 44

TRANSMISSION CONSTRUCTION STANDARD

5.0

TCS-Q-113.03, Rev. 0

MATERIALS

5.1

Concrete

5.1.1

Concrete shall be ready-mixed, truck delivered, supplied from a batching

plant by a supplier acceptable to The COMPANY. Concrete shall fully

comply with all the requirements of COMPANY Standard 70-TMSS-03.

5.1.2

Field-mixed concrete may be used where it is impractical to procure readymixed concrete due to remoteness of the concrete pour location, or, for any

other reason, making it difficult to sustain the pre-pour concrete temperature

and plasticity within the required limits. Approval of a trial mix design is

required from the COMPANY for this purpose, if mix design differs from the

one originally approved.

After all materials are charged in the drum, the batch mixer shall be rotated at

the manufacturer's recommended speed, for at least 1-1/2 minutes for

quantities less than or equal to 1 cubic meter and increased by 20 seconds for

every additional cubic meter or fraction thereof. Batching and mixing shall

be done as per Section 7.2 of ACI 301M.

5.1.3

5.2

Grouts mentioned below shall be chloride free, high performance, free

flowing, non-catalyzed, shrinkage compensated and hydrogen free in

addition to the following requirements:

a.

Pre-Mixed, Non-Shrink, Non-Metallic Cementitious

conforming to CRD C621 or ASTM C 1107

b.

Expansive Grouts, conforming to CRD C583

Grouts,

Steel Reinforcement and Positioning Devices

5.2.1

Reinforcing bars shall be deformed or plain billet steel bars in conformance

with SASO/SSA 2 and ASTM 615.

5.2.2 Welded wire fabrics shall be electrically welded cold-drawn wire with

minimum yield strength of 240 MPa in conformance with the following:

SASO/SSA 224

ASTM A 185 Plain Wire

ASTM A 497 Deformed wire

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 9 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

5.2.3 Devices such as spacers, chairs, bolsters, ties, etc., used for spacing,

supporting and fastening the steel reinforcement shall conform to the

requirements of Concrete Reinforcing Steel Institute (CRSI) Manual.

5.2.4 Epoxy-Coated reinforcing steel bars shall satisfy the requirements of ASTM

A 775M.

5.3

Form Materials

5.3.1

Form materials shall conform to ACI 347R and shall be of wood, steel,

driven steel sheet piling or other approved material. The type, size, shape,

quality and strength of all materials of which the forms are to be made shall

be consistent with the specified finishes and safety. Plywood for formwork

material shall meet the requirements of APA grade-trademarked, USPS PS 1,

B-B plywood, exterior type, Class 1, sealed edges, mill oiled and not less

than 20 mm thick.

5.3.2

Embedded form ties shall be of a non-metallic material or galvanized steel.

5.3.3

Form Release Agent

Form Release Agent shall be non-staining, non-reactive, rust preventive,

guaranteed to be compatible with subsequent surface applications to

concrete.

5.4

For Wood Forms:

Straight, refined, pale, paraffin mineral oil, or

approved equivalent

For Steel Forms:

Refined mineral oil suitably compounded, or approved

equivalent

Joint Materials

5.4.1

Joint Fillers and Joint Sealant

Joint filler material shall be extruded closed cell polyethylene foam rod or

polyurethane foam rod conforming to the requirements of ASTM D 1751 or

ASTM D 1752.

Joint sealant shall conform to the requirements of ASTM D 2628.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 10 of 44

TRANSMISSION CONSTRUCTION STANDARD

5.4.2

TCS-Q-113.03, Rev. 0

Waterstops

Size and type shall be as shown on the design drawings and shall satisfy the

following material requirements:

Rubber made, Conforming to CRD C513

PVC made, Conforming to CRD C572

5.5

Curing Materials

5.5.1

Different curing materials and their requirements are as given in the Tables I

and II below:

Table I

Item

Standard

Impervious Sheeting

ASTM C 171

Burlap

AASHTO M 182

Liquid MembraneForming Compound

ASTM C 309,

Type 2

5.5.2

TCSQ11303R0/SZA

Requirements

Remarks

Minimum weight

0.29 kg/m2.

Fabric woven of

jute or kenaf

Potable water for curing shall be clean and free from injurious amounts of

oil, acids, alkalies, salts, organic materials or other substances that may be

deleterious to concrete or steel reinforcement and shall meet the requirements

listed in the Table below:

Date of Approval: April 10, 2006

PAGE NO. 11 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

Table II

Form of Contamination

Maximum

Concentration

(ppm)

(%)

Total Dissolved Solids

2000

0.2

Sulfates (SO4)

500

0.05

Alkali carbonates and Bicarbonates

500

0.05

Chlorides

300

0.03

Suspended Solids

500

0.05

pH Value

6.5 - 8.5

Note: Submit analysis results if approved source is changed.

5.6

Miscellaneous Materials

5.6.1

Vapor Barriers

Polyethylene sheeting shall conform with ASTM E 154 and shall be a

minimum of two (2) layers of 150 microns thick each.

5.6.2

Chamfer Strips

Chamfer Strips shall be of Wood, PVC or neoprene and shall be approved by

the COMPANY Representative.

5.6.3

Dovetail Anchor Slots, Anchoring Inserts, Fabricated Embedments

These items to be used at site subject to approval by the COMPANY

Representative.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 12 of 44

TRANSMISSION CONSTRUCTION STANDARD

6.0

TCS-Q-113.03, Rev. 0

DESIGN AND FUNCTIONAL REQUIREMENTS

6.1

Reinforcement

6.1.1

All reinforcement at the time of placing shall be free of loose mill scale or

rust, dirt, mud, oil or any coating that would adversely affect bonding of the

reinforcement to concrete.

6.1.2

All reinforcing bars shall be cut and fabricated in accordance with the

dimensions shown on the approved construction drawings. Hooks and bends

shall be in accordance with ACI 318RM.

6.1.3 All reinforcing bars shall be bent cold. Tolerance for longitudinal location of

bends and ends of reinforcement shall be 50 mm, except at discontinuous

ends of members where tolerance shall be l2 mm. Fabrication tolerances

shall conform to ACI 117. Once steel has been bent, it shall not be re-bent.

6.1.4

Reinforcing bars shall be placed to the following tolerances:

Clear Distance to Formed Surfaces: 6 mm

Minimum Spacing Between Bars: -6 mm

Top Bars in Slab and Beams:

Members 200 mm deep or Less 6 mm

Members more than 200 mm, but not over 600 mm deep: l2 mm

Members more than 600 mm deep : 25 mm

Bars may be moved as necessary to avoid interference with adjoining bars,

conduits or embedded items. The COMPANY Representative's approval is

required for movements by more than 1 bar diameter or which exceed the

tolerance.

6.1.5

Steel reinforcement shall be checked against drawings for bending details. It

shall be ensured that all steel reinforcement are accurately in place and firmly

secured against possible displacements.

6.1.6

Reinforcing steel splices shall be made only as required and permitted on

locations shown on the approved construction drawings.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 13 of 44

TRANSMISSION CONSTRUCTION STANDARD

6.1.7

TCS-Q-113.03, Rev. 0

Where steel reinforcement is supported by means of concrete bricks or

blocks, these shall be made of the same grade of concrete to be used for the

structure. PVC or HDPE spacers and chairs can be used after approval by the

COMPANY Representative.

6.1.8 Unless otherwise specified, reinforcement shall be held in position by means

of approved spacers so that a minimum clear covers of concrete, as given

below in Table III are maintained:

Table III

Concrete members in

contact with soil and

water incl. slabs-ongrade

Columns and walls

exposed to atmosphere

up to 3 m height from

grade level

Columns and walls

above 3 m height from

grade level and beams

Slabs and joists exposed

to atmosphere

Minimum Cover in mm

Exposure Condition

Very

Severe and

Severe

Moderate

Mild

75

75

75

75

50

50

50

50

40

40

40 for >35 mm bars 40 for >35 mm bars

30 for <35 mm bars 20 for <35 mm bars

Ensurance of the required minimum clear cover shall not result in the

reduction at site, of the design effective depth of the member.

6.1.9

TCSQ11303R0/SZA

All bolts, sleeves, anchors, dowels, fastenings or other items to be embedded

in the concrete shall be accurately positioned and firmly secured against

possible displacement. When concrete is placed at locations where anchor

bolts, stub angles or other items requiring high accuracy are present, wooden

or steel templates shall be carefully and accurately fabricated and set. Anchor

bolts shall be plumb and within 2 mm of the position shown on the approved

construction drawings.

Date of Approval: April 10, 2006

PAGE NO. 14 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

6.1.10 Metallic sleeves shall not be allowed and anchor bolts shall not be in contact

with reinforcing steel.

6.1.11 Welding for reinforcing bars shall not be permitted unless the mill test

reports were furnished indicating that the steel has been modified for

weldability. Welding shall be done as per requirements of AWS D1.4 (TESW-1).

6.2

Formworks

Forms shall be used, wherever necessary, to confine concrete and shape it to the

dimensions required in the design drawings. The forms shall be sufficiently tight to

prevent leakage of cement paste/mortar from the concrete. Formwork shall be

constructed so that the concrete surfaces conform to the tolerance limit listed in ACI

117.

6.2.1

Formwork shall be designed, erected, supported, braced and maintained so

that it will safely support all anticipated loads (vertical & lateral) that might

be applied to the formwork until such loads can be supported by the concrete

structure.

6.2.2

Forms shall be properly braced or tied together with standard accessories to

maintain the position and shape during placing and curing of concrete.

6.2.3

Maximum deflection of facing form materials, which reflect in concrete

surfaces exposed to view shall not exceed 1/240 of the span between

structural supports.

6.2.4

Eccentric loads on any part of the formwork shall be avoided unless these

members have been designed for such loadings.

6.2.5

Where necessary, to maintain the tolerances indicated, the formwork shall be

cambered to compensate for anticipated deflections due to the weight and

pressure of the fresh concrete, and also due to any construction loads which

may exceed the design live load.

6.2.6

The surface of the forms shall provide the correct finish, as specified in

Section 8.1, Finishing.

6.2.7

Forms for wall openings shall be constructed so as to facilitate loosening and

removal. Form material shall be good so as not to be disfigured by moisture

or heat.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 15 of 44

TRANSMISSION CONSTRUCTION STANDARD

6.2.8

TCS-Q-113.03, Rev. 0

Form Ties

Embedded ties for holding forms shall remain and shall be terminated within

the concrete at a distance of not less than the specified concrete cover. Snap

ties or through-bolts shall not be used. COMPANY approval is required for

form ties of other types.

6.2.9

Forms for Sloped Surfaces

Forms for sloped surfaces shall be built so that the sheathing can be placed

board-by-board immediately ahead of concrete placement, so as to enable

ready access for placement, vibration, inspection and repair of the concrete.

The sheathing shall also be built so that the boards can be removed one by

one from the bottom up, as soon as the concrete has attained sufficient

stiffness to prevent sagging. Surfaces of construction joints and finished

surfaces with slopes steeper than 4 (horizontal) to 1 (vertical) shall be formed

as required herein.

6.2.10 Forms For Curved Surfaces

The forms shall be constructed so that the curvature is continuous between

sections. Where necessary to meet requirements for curvature, the form

lumber shall be built up of laminated splines cut to make tight, smooth form

surfaces.

After the forms have been constructed, all surface imperfections shall be

corrected, and all surface irregularities at matching faces of form material

shall be dressed to the specified curvature.

6.2.11 In areas where removal of the formworks is not possible, or the working

space is very small, permanent formworks of concrete blocks filled with

grout/mortar mix with strength not less than that of the concrete blocks can

be used.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 16 of 44

TRANSMISSION CONSTRUCTION STANDARD

7.0

TCS-Q-113.03, Rev. 0

CONCRETE WORKS

7.1

Preparation

Following are the preparatory works to be done prior to Concrete placement:

7.1.1

Concrete shall not be placed until all formwork, embedded parts, steel

reinforcement, foundation surfaces and joints involved in the placing have

been inspected and approved by the COMPANY Representative.

7.1.2

Surfaces of forms and embedded items shall be cleaned of all encrustations

of mortar, grout or other foreign materials. Forms shall be coated with an

approved form release agent, which is compatible with a subsequent coating

system (if any) on the concrete surface. Lubricating (machine) oil shall not be

used.

7.1.3

All necessary checks, as required in the concrete pour and placement card,

(Appendix I), shall be made and approved by the COMPANY Representative

before concrete placement commences.

7.1.4 Provision at site of the required number and rating of vibrators needed for a

specific concrete pour including a standby power source shall be ensured.

7.2

7.1.5

All precautions related to concrete placement in hot weather (refer to Section

7.5) shall also be ensured.

7.1.6

All concrete laitance (on reinforcing bars) and other unsound material shall

be removed before placing of new concrete against hardened concrete.

Acceptance of Concrete on Arrival

7.2.1

Upon arrival of concrete at the place of deposition, the delivery ticket shall

be checked to ensure that all information required as per 70-TMSS-03 is

available and duly complied with.

7.2.2

The concrete shall reach the jobsite such that it can be compacted in its final

position within the time duration mentioned in 70-TMSS-03 from the time of

introduction of cement into the aggregates. In case of dry mix, the time is

considered from the instant of adding the water from the approved source.

7.2.3

Re-tempering or addition of water in excess of the design water/cementitious

material ratio, to compensate for slump loss resulting from delays in delivery

or placement, is strictly prohibited.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 17 of 44

TRANSMISSION CONSTRUCTION STANDARD

7.3

TCS-Q-113.03, Rev. 0

7.2.4

Addition of super plasticizers is permitted only at site. Where the slump is

deemed inappropriate for acceptable workability, a high range water reducing

admixture (super plasticizer), conforming to ASTM C494, may be added

immediately prior to the placement of concrete and in accordance with the

manufacturer's recommendations (especially with respect to dosage and

mixing time). This addition shall be recorded in the concrete placement card

(Appendix I).

7.2.5

The temperature of concrete while leaving the mixing plant should be such

that at the time of final placement, the maximum temperature of concrete

does not exceed the limits mentioned in 70-TMSS-03.

7.2.6

The testing requirements of 70-TMSS-03 shall be fully met for the evaluation

and acceptance of concrete.

Concrete Placement

7.3.1

Concrete shall be placed in accordance with ACI 301M and ACI 304, unless

otherwise stated.

7.3.2

Placing equipment shall be capable of providing a continuous supply of

concrete at site of final deposit without separation of ingredients and without

interruptions, sufficient to permit loss of plasticity between successive

increments.

7.3.3

Concrete shall not be dropped through congested reinforcing steel which may

cause segregation of the coarse aggregates. Restrict the free fall of fresh

concrete within 1.0 meters. Employ spouts or flexible drop chutes to avoid

nesting of coarse aggregates.

7.3.4

Concrete shall be placed and consolidated in continuous layers of uniform

depth not exceeding 450 mm in thickness, except in large mass pours where

it may be necessary to increase the layer thickness to 600 mm. Concrete shall

not be allowed to flow laterally a distance greater than 1.0 m from the point

of deposit.

7.3.5

Following details shall also be observed at the time of placing concrete:

TCSQ11303R0/SZA

a.

Concrete shall not be placed where standing water is present. The

water shall be removed by pressurised air or sponging.

b.

Movement of concrete shall only be by shovel and not by raking.

c.

Re-tempering of concrete shall not be done after placement.

Date of Approval: April 10, 2006

PAGE NO. 18 of 44

TRANSMISSION CONSTRUCTION STANDARD

7.3.6

TCS-Q-113.03, Rev. 0

Where concrete is placed by pumping, the following requirements shall

apply:

a.

Pumping equipment shall be with adequate pumping capacity and

boom-length.

b.

The placement shall be controlled to avoid segregation of the

discharged concrete.

c.

Slump obtained at the point of final placement shall be as specified in

70-TMSS-03.

d.

Concrete shall not be conveyed through pipe made of aluminum or

aluminum alloy.

e.

Minimum Inside Diameter (I.D.) of hose shall be:

Table IV

Maximum Size of Aggregate

Minimum ID of Hose

40 mm

150 mm

20 mm

100 mm

7.3.7

Lean concrete mat 75 mm thick with minimum fc 17 MPa shall be laid under

structural foundations, unless stated otherwise in design drawings. A vapor

barrier, two (2) layers of polyethylene sheet with 150 microns thick each,

shall be laid on top of the lean concrete mat.

7.3.8

After concreting is started, it shall be carried on as a continuous operation

until the placing of a panel or section, as defined by its boundaries or a

predetermined joint is completed. Construction joints shall be placed

horizontally or vertically with keys and dowels. For construction joints, refer

Section 7.7.2.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 19 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

7.3.9 Consolidation

a.

Concrete shall be thoroughly consolidated (compacted) and worked

around the reinforcement steel, around embedded items and into

corners of forms, eliminating all air or stone pockets which may cause

honeycombs, pitting or planes of weakness.

b.

Vibrators in adequate number and rating shall be employed as to

properly consolidate and ease the placement of concrete. Equipment

for consolidation shall be as per ACI 309R.

In normal circumstances, refer to Table V below for guidance.

Table V

TCSQ11303R0/SZA

Maximum Size of

Aggregate

Minimum Outer Diameter of

Vibrator Head

40 mm

75 mm

20 mm

50 mm

c.

Vibrators shall be employed with care so that the designed positions

of the reinforcing bars will not be altered.

d.

Internal vibrators shall have a minimum frequency of 8,000 vibrations

per minute and sufficient amplitude to consolidate the concrete

effectively.

e.

Vibrators shall not be used to move or spread concrete horizontally.

f.

Vibrators shall be inserted and withdrawn at points approximately

450 mm apart. At each insertion (minimum 100 mm deep), the

duration shall be sufficient to consolidate the concrete without

segregation, generally from 5 to 15 seconds.

g.

Vibrators shall be operated in a near vertical position, allowing the

vibrating head to penetrate the upper layer under its own weight, and

to enter and vibrate the concrete in the upper portion of the

underlying layer.

Date of Approval: April 10, 2006

PAGE NO. 20 of 44

TRANSMISSION CONSTRUCTION STANDARD

7.4

7.5

TCS-Q-113.03, Rev. 0

h.

Concrete shall be vibrated in two stages as per ACI 309. Care shall be

taken to avoid loss of bonding between steel and concrete during revibration. The initial stage of vibration shall be at the time of concrete

placement. The second stage of vibration shall be as late as the

formed concrete will respond to the vibrator, where the running

internal vibrator will sink due to its own weight into the concrete.

Timing of re-vibration is of particular importance in hot weather

concreting and especially in application on thin slabs.

i.

Standby vibrators shall be available during concrete placement.

Concreting Under Water

7.4.1

Concreting under water shall be done by the "Tremie" method. This method

consists of placing concrete through a vertical pipe, allowing the concrete to

flow from the bottom. This method shall be applicable for deeper work and

confined areas.

7.4.2

The dry pipe method requires a Tremie pipe that is watertight, including

gasketed and bolted flanges at the couplings. The pressure seal plate, which

is at the bottom of the Tremie pipe keeps the Tremie pipe watertight, while

concrete is extruded from it under pressure and such that the discharge end of

the Tremie bottom moves gradually (upwards or away) and is always under

900 mm (approximately) head of fresh concrete. The equipment and

placement procedure shall conform to ACI 304R.

Concreting in Hot Weather

Hot weather concrete practice shall be adopted when the ambient temperature

(maximum air temperature during daytime) is 32C or above with low relative

humidity and wind velocity that will seriously impair the quality and strength of

concrete. For hot weather definition see ACI 305.

7.5.1 In dry areas, concreting may be done, if permitted by COMPANY

Representative when temperature and humidity are confirmed to be

comfortable for work.

7.5.2

Placement of concrete in hot weather shall be in accordance with

recommended practice of ACI 305R, unless otherwise specified.

7.5.3 Concrete shall be scheduled for placement during the early (cooler) morning

hours or at night in hot weather and high relative humid conditions.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 21 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

7.5.4

The temperature of concrete at the point of final placement shall at all times

be less than the limits specified in 70-TMSS-03.

7.5.5

A water-reducing and set-retarding admixture conforming to ASTM C494,

Type D, and possessing a reliable performance history shall be used.

7.5.6

Part of the mixing water shall be substituted by an equivalent amount of ice,

when necessary, to obtain the allowable placement temperature. The ice shall

be finely crushed to avoid slump loss and cold joints.

7.5.7

Temperature of concrete shall be measured 50 mm below the surface

immediately prior to placement in the forms.

7.5.8 Reinforcing steel and forms shall be protected from direct sun rays.

Whenever ice is used in concrete, reinforcing steel and forms shall be cooled

off with potable water, immediately before concrete placement, unless

arrangements are made for night time concreting.

7.5.9

Concrete shall not be placed under wind blown sand conditions. Concrete

placement shall be planned taking into consideration the humid conditions

and requirement mentioned in Section 7.5.8.

7.5.10 Provisions shall be made for erecting windbreaks and sunshades, fog

spraying of reinforcement, dampening subrgrade and forms, placing concrete

at the lowest practicable temperature, reducing time between placement of

concrete and start of curing, and minimizing evaporation particularly during

the first few hours subsequent to placing concrete shall be made in advance

of placement.

7.6

Concreting for Slabs-on-Grade

7.6.1

Slabs-on-grade shall be placed upon two (2) layers of 150 microns thick

each, polyethylene sheets as vapor barrier over a lean concrete mat of

thickness as specified in the approved construction drawings.

7.6.2

Placing shall follow the guidelines in ACI 302.1R and shall be in compliance

with the following requirements:

TCSQ11303R0/SZA

a.

Concrete shall be placed continuously so that each unit of operation

will be monolithic in construction.

b.

Concrete shall be placed in alternate checker board pattern,

terminating at contraction or expansion joints.

Date of Approval: April 10, 2006

PAGE NO. 22 of 44

TRANSMISSION CONSTRUCTION STANDARD

7.7

TCS-Q-113.03, Rev. 0

c.

Construction joints shall be located and as shown in the approved

construction drawings.

d.

Expansion and Contraction Joints shall be provided as shown on the

approved construction drawings.

e.

Concrete joints shall be filled with a joint sealant and filler as detailed

in the approved construction drawings.

Construction Joints

Construction joints are hardened concrete surfaces to which fresh concrete is poured

so as to make it monolithic, with the existing concrete being so rigid that the fresh

concrete cannot be made monolithic by vibration.

7.7.1

Cleaning at Joints

Construction joints shall be clean with exposed sound aggregates, rough in

profile and damp, before pouring adjoining fresh concrete. Cleaning shall

consist of removal of all laitance, loose or defective concrete, coatings, sand,

sealing compound and/or other foreign materials. If required by the

COMPANY Representative, the concrete surface at all the construction joints

shall be uniformly chipped approximately 6.0 mm in a manner that will

remove laitance, loosened aggregates or damaged concrete at the surface.

Joints shall be cleaned/washed thoroughly with air-water jets and the

hardened concrete surface shall be pre-soaked for the last eight (8) hours

immediately before fresh concrete is placed.

Surfaces of contraction joints and control joints shall be coated with an

approved bond breaker prior to the placement of adjoining fresh concrete.

7.7.2

Location of Joints

Construction joints, expansion joints and control joints shall be provided at

the locations and in accordance with details shown on approved construction

drawings. In absence of such details, the practices of ACI 224.3 shall be

adopted.

Where construction joints have to be provided for any unanticipated reason,

and hence have not been indicated on the design drawings, the joints shall be

in accordance with ACI 301M.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 23 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

Beams, girders, haunches, drop panels and capitals shall be placed

monolithically as part of a slab system, unless otherwise shown in the design

drawings or specifications.

Construction Joints shall be so made and located as not to impair the strength

of the structure. Suitable provision shall be made for transfer of shear and

other forces through construction joints.

7.7.3

Providing Watertight joints

Watertight joints shall be provided at locations shown on the approved

construction drawings. Unless indicated otherwise, PVC type waterstop of a

practical width for the intended application shall be used. Installation shall be

as per manufacturer's recommendations.

7.8

Concrete Placement Acceptance

Concrete shall be protected from damage due to impact, overloading, marring and

cracking of surfaces due to rapid drying.

Inspection of post concrete-placement activities, listed below (but not limited to)

shall be part of the acceptance process, taking special precautions demanded by hot

weather conditions (Section 7.5).

-Finishing and Jointing

-Curing

-Formwork and Shore Removal

-Re-shoring and Re-shore Removal

-Concrete Testing, Evaluation and Acceptance, as outlined in 70-TMSS-03

All necessary checks and monitoring, as required in the "Post Concrete Placement

Acceptance Card," Appendix II, shall be made and then approved by the

COMPANY Representative before final acceptance.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 24 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.0

TCS-Q-113.03, Rev. 0

POST CONCRETE WORKS

8.1

Finishing

8.1.1

All concrete floors and slabs shall be classified by their intended use, as per

ACI 302.1R. Tools and finishing procedures for each class shall also be in

accordance with ACI 302.1R.

8.1.2 Sidewalks and other outdoor areas subject to foot traffic shall receive a nonskid finish by drawing a fine, soft bristled broom over the trowelled surface.

Edges and joints shall be tooled.

8.1.3

Concrete surfaces shall be screeded and finished to the required tolerance

class as specified in ACI 117.

Surface with irregularities shall be tested by the use of a template consisting

of a straightedge or equivalent thereof for curved surfaces. The length of the

template shall be 1.5 meters for testing of formed surfaces and 3 meters for

testing of unformed surfaces.

8.1.4

Finishes to Unformed Concrete Surfaces

a.

TYPE U I:

This is a screeded finish for surfaces of roads, foundations, beds,

slabs and structural members to be covered by backfill, subsequent

stages of construction, bonded concrete, topping or cement mortar

beds to receive pavings and exposed surfaces or paving where

superior finish is not required. It is also the first stage of Type U2 and

U3 finishes. The finishing operation consists of levelling and

screeding the concrete to produce a unifom plane or ridged surface,

with the surplus concrete being struck off by a straight edge

immediately after compaction.

b.

TYPE U2:

This finish is a wood floated finish for surfaces of beds and slabs to

receive mastic pavings or block or tile pavings where a hard, smooth,

steel-trowelled surface is not required. Floating shall be done only

after the concrete has hardened sufficiently and may be done by hand

or machine. Care shall be taken to ensure that the concrete is worked

no more than is necessary to produce a uniform surface free of screed

marks.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 25 of 44

TRANSMISSION CONSTRUCTION STANDARD

c.

TCS-Q-113.03, Rev. 0

TYPE U3:

This finish is a hard, dense, smooth steel-trowelled finish for surfaces

of concrete pavings, tops of walls, copings or other members exposed

to weathering, surface beds and slabs to receive thin flexible sheet

and/or tile.

d.

TYPE U4:

This finish is a broom finish for surfaces, which are for foot traffic,

e.g., walks and steps where a special finish is not designated. A

broom finish is obtained by motion of a broom in a pattern acceptable

to the COMPANY. Workmanship is to be similar to that of adjacent

areas.

e.

TYPE U5:

This finish is a non-slip (dry shake) finish for surfaces where slipping

could be hazardous. Application shall be as per manufacturer's

recommendations.

f.

Type U6:

This is a hard, dense, smooth power floated finish for surfaces of

exposed rafts in basements and reinforced concrete floor slabs both

exposed and to receive epoxy or ordinary paints.

g.

Type U7

This is a hard, dense, smooth surfaces to receive epoxy screed floor

toppings like switchgear rooms.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 26 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.1.5

TCS-Q-113.03, Rev. 0

Formed Finishes for Concrete

a.

TYPE FI:

This finish is for surfaces against which backfill or further concrete

will be placed. Formwork shall consist of sawn boards, sheet metal,

plywood or any other suitable material, which will prevent the loss of

cement paste/mortar when concrete is vibrated.

b.

TYPE F2:

This finish is for surfaces, which are permanently exposed to view,

but where the highest standard of finish is not required. Forms for

providing a Type F2 finish shall be faced with wrought or finished

boards with square edges arranged in a uniform pattern. Alternatively,

plywood or metal panels may be used if they are free from defects

likely to detract from the general appearance of the finished surface.

Joints between the boards and panels shall be horizontal or vertical

unless otherwise directed. This finish shall be such as to require no

general filling of surface pitting; however, fins, surface discolorations

or other minor defects shall be repaired by approved methods.

c.

TYPE F3:

This is for surfaces prominently exposed to view where good

appearance and alignment are of special architectural importance. To

achieve this finish, which shall be free of board marks, the formwork

shall be faced with plywood or an equivalent material in large sheets.

The sheets shall be arranged in an approved uniform pattern.

Wherever possible, joints between sheets shall be arranged to

coincide with architectural features, sills, window heads or changes in

direction of the surface. All joints between panels shall be vertical or

horizontal, unless otherwise directed. Suitable joints shall be provided

between sheets. The joints shall be arranged and fitted so that no

blemish or mark is imparted to the finished surfaces. Unfaced

wrought boarding or standard steel panels will not be permitted for

Type F3 finish. The use of internal metal ties shall not be allowed.

8.1.6

Quality of Finish

The quality of finish shall not be inferior to that specified in the drawings.

Plastering of defective concrete as a means of achieving the required finish

shall not be permitted.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 27 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.1.7

8.2

TCS-Q-113.03, Rev. 0

Miscellaneous Requirements

a.

Surfaces on which mortar/grout is to be placed shall be chipped a

minimum of 3 mm deep and thoroughly cleaned.

b.

Spreading dry cement on a wet surface to absorb excess water shall

not be permitted.

c.

Slabs which will be covered with tiles shall be screeded.

Removal of Forms and Shoring

8.2.1

Precautions

The removal of formwork shall be in accordance to a planned procedure,

considering the temporary support of the whole structure, as well as that of

each individual member. This shall be worked out prior to construction and

shall be based on a structural analysis. Forms (except those used for slabs on

grade) shall be removed upon COMPANY Representative's approval after

the concrete has gained sufficient strength to support its weight and

superimposed loads. In addition, following items shall be taken into account

as a minimum;

8.2.2

a.

The structural system that exists at the various stages of construction

and the construction loadings corresponding to these stages

b.

The strength of the concrete at the various ages during construction

c.

The influence of deformations of the structure and shoring system on

the distribution of dead loads and construction loadings during the

various stages of construction

d.

The strength and spacing of shores used, as well as the method of

shoring, bracing, shore removal and re-shoring, including the

minimum time intervals between the various operations

De-Shuttering Period

Where the structure is adequately supported on shores, the side forms of

beams, girders, columns, walls and similar vertical forms may generally be

removed after the stated durations (refer Tables VI & VII) of "cumulative

curing time," provided the side forms support no loads other than the lateral

pressure of the plastic concrete. "Cumulative Curing Time" represents the

sum of time intervals, not necessarily consecutive, during which the

temperature of the air surrounding the concrete is above 10C.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 28 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

Table VI

Period (Days)

Location / Item

Walls (Note a)

Columns (Note a)

Sides of Beams and Girders (Note a)

Pan Joist Forms: (Note b)

0.75 meter wide or less

Over 0.75 meter wide

1

3

4

Table VII

Period (Days)

Structural live load is

Less Than Structural

More Than Structural

Dead Load

Dead Load

14

7

Location / Item

Arch Centers

Joist, Beam or Girder Soffits (Note c)

Under 3 m clear span between supports

3 m to 6 m clear span between supports

Over 6 m clear span between supports

7 (Note d)

14 (Note d)

21 (Note d)

4

7

14

One-Way Floor Slabs (Note c)

Under 3 m clear span between supports

3 m to 6 m clear span between supports

Over 6 m clear span between supports

4 (Note d)

7 (Note d)

10 (Note d)

3

4

7

Two-Way Slab Systems

TCSQ11303R0/SZA

The removal shall be per ACI 347-14. Removal

times are contingent on reshores where required,

being placed as soon as practicable after

stripping operations are complete, but not later

than the end of the working day in which

stripping occurs.

Date of Approval: April 10, 2006

PAGE NO. 29 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

Notes Related to Tables VI and VII:

a)

If the forms also support formwork for slab or beam soffits, the

removal times of the latter shall govern.

b)

Shall be of those which can be removed without disturbing forming

or shoring

c)

Distances between supports refer to structural supports and not to

temporary formwork or shores.

d)

Where forms may be removed without disturbing shores, use half of

the values shown, but not less than 3 days.

e)

The durations mentioned in Tables VI and VII do not apply to

concrete utilizing set retarding admixtures and blended cements. In

such cases, these durations shall be extended, and approved by the

COMPANY.

8.2.3

Forms shall be removed in such a manner so as not to impair safety and/or

serviceability of the structure and prevent damage to the concrete thereby.

Wooden wedges only shall be used between the concrete surface and the

form where force is necessary to separate the form from the concrete. Metal

wedges, bars or tools shall not be used for this purpose.

8.2.4

Forms not supporting dead mass may be loosened and removed as soon as

the concrete has hardened sufficiently to prevent damage from form removal.

All forms and falsework supporting concrete beams and slabs, or other

members subject to bending stress, shall not be removed or released until

job-cured test cylinders are tested to show a strength of not less than 80% of

the current mean 28-day strength. Methods of removal tending to induce

shocks, jolts or fractures in concrete will not be permitted.

8.2.5 Construction loads exceeding the combination of superimposed dead load

plus specific live load shall not be supported on any unshored portion of the

structure under construction, unless analysis indicates adequate strength to

support such additional loads.

8.2.6

TCSQ11303R0/SZA

Any required repairs or damaged finish treatment shall be performed as soon

as the forms have been removed, and shall then be followed immediately by

the specified curing.

Date of Approval: April 10, 2006

PAGE NO. 30 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.3

TCS-Q-113.03, Rev. 0

Curing

All concrete shall be cured with specified potable water, Section 5.5.2, and in

accordance with recommendations of ACI 308 and ACI 305R, and as specified

herein, immediately after finishing flatwork or removal of forms. Concrete shall be

protected from premature drying, temperature extremes and mechanical injury for

the entire specified curing period. Moisture loss from surfaces placed against

wooden forms shall be minimized by keeping the forms continuously wet until they

can be safely removed. After removal of forms curing shall continue.

Note: No concrete shall be allowed for casting, unless the curing proposal is

approved.

8.3.1

Methods of curing:

One of the following methods shall be used to cure concrete:

a.

Pond Curing:

Pond curing shall comprise of at least 40 mm deep potable water

covering the entire surface of the concrete. The water shall be

replenished when less than 50 mm deep to assure that a 40 mm

minimum depth is maintained.

Additional protection/precautions (from direct sun rays) for the

ponded water shall be done to avoid temperature rise during hot

summer conditions.

b.

Wet Burlap Curing:

Wet burlap curing shall comprise of at least two (2) layers of

constantly damped burlap laid tight against the pre-soaked concrete

surface. The burlap shall be kept uniformly damp, so that lighter

patches or drier burlap are not evident, by a clock valve regulated soil

soaker hose supplied with water at adequate pressure.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 31 of 44

TRANSMISSION CONSTRUCTION STANDARD

c.

TCS-Q-113.03, Rev. 0

Membrane Curing:

Application of this type of curing shall be restricted to non-critical

situation/structures and in keeping with compatibility of the

membrane forming compound with a subsequent protective coating

on the cured concrete. Whenever used, membrane curing shall be

preceded by saturation of concrete with sprayed water. This water

shall be sealed against evaporation from the concrete surface, by

application of a white (reflective) curing membrane in strict

accordance with the manufacturer's recommendations.

8.3.3

Only water curing shall be used in the following cases:

a.

Silica fume/fly ash modified concrete

b.

Mass concrete

c.

Critical situations/structures

d.

Hot weather conditions, as defined in Section 7.5.

8.3.4

Any alternative methods of curing requires approval of the COMPANY

before use. The choice of methods employed shall be combined as required

to provide adequate thermal protection. The curing methods for hot weather

shall be part of the hot weather concreting submittal, where due emphasis

shall be laid upon an extended curing period and an increase of thermal

protection. Protection shall be provided to concrete from heavy rains, flowing

water and mechanical injury.

8.3.5

All concrete shall be continuously cured for at least seven (7) days, except as

specified below:

Un-reinforced Mass Concrete

14 days

Concrete Blended with Pozzolanic material:

TCSQ11303R0/SZA

November to April (Cold weather condition)

14 days

Remaining period (Hot weather condition)

21 days

Date of Approval: April 10, 2006

PAGE NO. 32 of 44

TRANSMISSION CONSTRUCTION STANDARD

8.3.6

TCS-Q-113.03, Rev. 0

A formalized curing record shall be maintained at the Site for inspection and

verification by the COMPANY Representative.

Minimum mandatory information to be provided in the curing record:

8.4

a.

Time duration between concrete placement and actual start of curing

process

b.

Type of curing

c.

Conformance of curing materials to specification

d.

Physical arrangements including frequency of replenishment, etc.

e.

Duration of curing process

f.

Satisfactory compliance statement

Corrosion Protection and Durability

To produce durable concrete of high quality in resisting corrosion and adverse

environmental conditions, the guidelines presented in ACI 201.2R shall be followed

in construction practices. Some of the practices are, but not limited to, the following:

8.4.1

All concrete foundations and slabs-on-grade shall be laid on two (2) layers of

150 microns thick each, polyethylene sheeting as vapor barrier over 75 mm

thick lean concrete as mentioned in Section 7.3.6.

8.4.2 All concrete surfaces below grade and in contact with soil shall be protected

by waterproofing coating/membrane material, unless specified otherwise in

the approved design drawings. The coating membrane shall extend 150 mm

above ground level, unless aesthetically unacceptable. COMPANY approval

is required for the waterproofing material.

Tanking system, with approved water proofing materials, shall be done for

shallow concrete foundations in Sabkhah soils. For deep foundations in

Sabkhah soils, steel casing should be used as an extra protection or any other

approved protection methods.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 33 of 44

TRANSMISSION CONSTRUCTION STANDARD

9.0

TCS-Q-113.03, Rev. 0

REPAIR OF DEFECTIVE CONCRETE

Special care shall be taken by adopting new/latest methods during the construction in order

to minimize future concrete repairs.

Concrete shall be repaired if defective or if in the opinion of the COMPANY Representative

does not meet the specified requirements. Repair of defects and imperfections, described

below, shall be started within 24 hours of form removal and shall be completed without

delay. For color matching, the use of a mixture of white and gray cements is permitted.

Listed below are various types of defects, mostly encountered in newly-constructed

concrete, and methods for their repair. All repair procedures shall be submitted to the

COMPANY for approval. All repaired areas shall be properly moist cured for a minimum of

seven (7) days and as recommended by the repair materials' manufacturer.

9.1

Surface Air Voids/Sand Streaking/Peeling/Blistering

Pre-packaged cementitious repair products shall be mixed and used as per

manufacturer's recommendations. Fins shall be neatly removed from exposed

surfaces.

9.2

Honeycombs

Concrete in honeycomb areas shall be chipped to a depth of 25 mm or more, as

needed to reach sound concrete, with edges perpendicular to the surface. Any loose

concrete shall be removed and the surface kept clean and free from contaminants. An

area, determined from a perimeter extending at least 150 mm beyond the chipped

region shall be pre-soaked for at least the last 8 hours immediately prior to repair.

A mortar mix with strength not less than that of the original concrete at 28 days age

shall be brushed into the cavity. Immediately after, a dry pack patching mortar shall

be applied, the mix composition being similar to that of the parent concrete. The

water content shall be the minimum amount required for handling and placing. The

mortar shall be compacted in layers into the cavity and screeded off to protrude

slightly from the surrounding surface and then left undisturbed for one or two hours

before finishing. During application, each layer shall be solidly compacted over its

entire surface by the use of a hard wood board and a hammer.

Alternatively, a pre-packaged, non-shrink grout with strength equal to or exceeding

the parent concrete strength shall be used.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 34 of 44

TRANSMISSION CONSTRUCTION STANDARD

9.3

TCS-Q-113.03, Rev. 0

Tie Holes

Holes from removed ties shall be repaired using the same grout/mortar mix as for

honeycombs. If the holes are limited in depth, then a dry pack consistency grout

shall be used. Concrete surfaces shall be pre-soaked for at least the last 8 hours, prior

to repair.

9.4

Pop-outs /Scaling

All the affected materials, which may have an area larger than that from first visual

appearance, shall be removed. The same repair procedure as for the honeycombs,

shall be used.

9.5

Discoloration and Stains

Concrete surfaces shall be clean of all dirt and stains caused during construction. The

discoloration and Stains shall be minimized by utilizing proper construction

practices. If discoloration or stains do occur, procedures and materials for repair and

modification shall be submitted to The COMPANY for approval.

The discoloration may be caused by the following conditions:

a.

Change in Mix

b.

Aggregate Transparency

c.

Hydration Discoloration

d.

Segregation Discoloration

e.

Drying Discoloration

f.

Cold Joints Discoloration

g.

Improper Concreting and Finishing Practices

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 35 of 44

TRANSMISSION CONSTRUCTION STANDARD

9.6

TCS-Q-113.03, Rev. 0

Cracks

Any cracks detected shall be reported to the COMPANY Representative

immediately. Depending on the cause and type of cracking and the need for repairs,

the cracks shall be repaired using either rigid patching or elastomeric caulking based

upon approval by the COMPANY.

The method of repairs are any one of the following or a suitable combination of

more than one of:

9.7

a.

Sealing

b.

VGrooving

c.

Resin injection

Defects with Exposed Reinforcing Steel

Concrete replacement shall be used for large defects and when reinforcing steel bars

are exposed. Other materials may be proposed for approval by the COMPANY.

Surface preparation for the repair is as given below:

Concrete shall be removed to a depth of 25 mm to 50 mm (depending upon the

member thickness and maximum aggregate size) behind the exposed reinforcing bar.

Area to be repaired shall be cleaned, pre-soaked for the last eight (8) hours before

placement of concrete or repair mortar, and repair as for honeycombs shall be made.

When the repaired region is thicker than 75 mm, 10 mm maximum aggregate size

shall be mixed with the repair mortar. Strength of the repair material shall not be less

than the original concrete strength at 28 days.

Immediately before placement, the concrete repair mix shall be re-mixed if desired,

to reduce the subsequent shrinkage.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 36 of 44

TRANSMISSION CONSTRUCTION STANDARD

10.0

TCS-Q-113.03, Rev. 0

QUALITY CONTROL

Quality Control Program shall be implemented in all respects after approval by the

COMPANY in practice at every stage of work. Quality Control and Quality Assurance shall

be done, as required in 70-TMSS-03, including the following functions:

10.1

Pre-Concreting Quality Control

10.1.1 Inspection and approval of the batching and mixing, facilities, and metering

(dispensing) calibration records

10.1.2 Inspection, testing and approval of concrete materials

10.1.3 Inspection and approval of excavation, formwork, reinforcing steel, shoring,

falsework, bracing, supports, embedded items, joints, waterstops, etc.

10.1.4 Inspection and approval of placement, consolidation and finishing operations

10.1.5 Checking the items listed in the concrete placement card (Appendix I)

10.2

Post-Concreting Quality Control

10.2.1 Inspection and approval of form removal, including reshoring operations

10.2.2 Inspection and approval of curing facilities

10.2.3. Inspection and approval of testing facilities

10.3

Non-Compliance of Quality Control

Following actions shall be taken in case of work not being conducted per the

requirements of COMPANY Standards:

10.3.1 Postponing concreting operations until outstanding requirements are fulfilled

10.3.2 Rejection of materials or workmanship, which do not conform to the

specifications

10.3.3 Stop any WORK, which is not being done in accordance with this Standard

and report immediately to the COMPANY, providing records, upon

discovery of any non-compliance

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 37 of 44

TRANSMISSION CONSTRUCTION STANDARD

11.0

SUBMITTALS

11.1

12.0

TCS-Q-113.03, Rev. 0

Working drawings for the following shall be prepared:

a.

Details of Formwork System

b.

Methods of Form Construction and Erection

c.

Falsework and Computations

d.

Location of Form Joints, Form Ties and Construction Joints

e.

Sequence of Form Removal and Computations

11.2

A working schedule for the dates and rate of concrete placement for each item of

WORK shall be prepared. This shall be done periodically, as acceptable to The

COMPANY.

11.3

Document describing quality control and Quality program shall be submited to The

COMPANY for approval prior to start of any work at site.

11.4

Special methods for compliance with hot weather concreting, including delivery,

placement, curing and protection requirements shall be included in quality control

and Quality program. This shall be in addition to a curing proposal to be submitted

for approval.

APPENDICES

APPENDIX I: Please see next page.

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 38 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

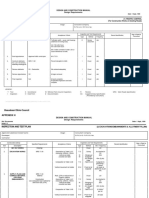

CONCRETE POUR CARD AND PLACEMENT RECORD

SAUDI ELECTRICITY COMPANY (SEC)

CONTRACTOR:

CONTRACT

J.O. NO.

POUR CARD NO.

NO.

LOCATION OF POUR:

DESCRIPTION OF POUR:

TYPE AND SOURCE OF CONCRETE

QUANTITY/ VOLUME OF CONCRETE

CHECK LIST

INSPECTED & APPROVED

DATE

BY

Line and Grade

Formwork and Waterstop

Reinforcement

Embedded Metals

Embedded Pipes

Embedded Conduits & Ground Wires

Preparation of Embedded Joints

Waterproofing

Cleanliness and Access

Verification of Rate of Placement Cu. m/ hr.

Provision of Hot Weather Concreting

PLACEMENT RECORD AND DATE:

Weather

Rate of Placement

Type of Equipment Used

Type of Finish

Slump Specified/Actual

Is Water Added at Site? Yes/No If Yes,

(Only Dry Mix)

Amount of Water Added

Temperature

Curing Method

Qty Of Concrete Placed

Start Time

Finish Time

Trip Tickets Conform To

Approved Design Mix

Yes/No

Numbers Of Trip Tickets

Attached

Amount of Super Plasticizer

Were Cylinders Taken? If yes,

28 day test results

Yes/No

Amount of Super Plasticizer (SP) Added, [If Placement breakdown & other

Applicable, Only Permitted at Site]

remarks

Slump At Addition of SP

CONTRACTORS QC ENGINEERCOMPANY REPRESENTATIVE

Sign/Date/Time

Sign/Date/Time

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

PAGE NO. 39 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

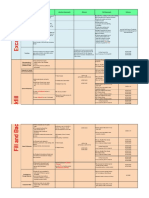

APPENDIX II

POST CONCRETE PLACEMENT ACCEPTANCE CARD (Sample Checklist)

MEMBER /ITEM

LOCATION

DATE CAST

DATE STRIPPED

DATE INSPECTED

CURING TYPE

CURING START

CURING FINISHED

NO. OF DAYS CURED

FINAL ACCEPTANCE

TCSQ11303R0/SZA

DATE:

Date of Approval: April 10, 2006

PAGE NO. 40 of 44

TCSQ11303R0/SZA

2.

1.

Sl.

No

Date of Approval: April 10, 2006

Cast in areas (Repair required)

Exposed

aggregate

uncompacted concrete

Tie holes

and

Blow holes

Uneven surfaces not meeting the

specs. requirements

Damaged surface by concrete nails,

etc

Stained & colored surfaces

Formwork Pieces Cast Into Surfaces

(Wood, Plywood, Polystyrene)

Cleaning and removal of concrete,

grout and spillage.

Honeycombing/washouts

CONCRETE FINISH

Removal time

FORM REMOVAL

DESCRIPTION

LOCATION

(Attach sketch

if required

ACTION

REQUIRED

Contractors

QA/QC Rep.

SEC

ACCEPTANCE

REMARKS

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

PAGE NO. 41 of 44

TCSQ11303R0/SZA

4.

CONCRETE FINISH (Contd)

2.

Date of Approval: April 10, 2006

Repairs required on construction

joints

Cleaning of joints and some repairs

required

Incomplete joints

JOINTS

Cleaning of door frames and some

repairs required

Cleaning and removal of formwork

and polystyrene props on blockouts

Cast-in frames & sleeves cleaning

& some repair required

Exposing & cleaning of cast-inplates & some repair required

CAST INSERTS

Finish as specified

Cleaning & removal of sprayed

curing compound

Fins & other projections

DESCRIPTION

Sl.

No

LOCATION

(Attach

sketch if

required

ACTION

REQUIRED

Contractors

QA/QC Rep.

SEC

ACCEPTANCE

REMARKS

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

PAGE NO. 42 of 44

TCSQ11303R0/SZA

Date of Approval: April 10, 2006

AS-BUILT

SURVEY

FOR

LOCATIONS AND POSITIONING

TOLERANCES PER ACI 117

8.

* Where Applicable

CONCRETE

TESTING

AND

EVALUATION (per 70-TMSS-03)

Repair required for crack width >

0.02 mm

Crack monitoring report

Visible Cracks

CRACK INVESTIGATION*

Within tolerances

7.

6.

COVER SURVEY* (If Suspected)

5.

Insufficient Reinforcement Cover

DESCRIPTION

Sl.

No

LOCATION

(Attach sketch

if required

ACTION

REQUIRED

Contractors

QA/QC Rep.

SEC

ACCEPTANCE

REMARKS

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

PAGE NO. 43 of 44

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.03, Rev. 0

ACCEPTED AS PRESENTED

REPAIRS REQUIRED AS INDICATED ABOVE

REPAIRS INSPECTED AND FOUND

SATISFACTORY, JOB ACCEPTED

RE-SCHEDULE INSPECTION

Name & Signature

Contractor's Q.C. Representative

TCSQ11303R0/SZA

COMPANY Representative

Date of Approval: April 10, 2006

PAGE NO. 44 of 44

You might also like

- Saes A 112Document27 pagesSaes A 112Julien Letombe50% (2)

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- Quality Management PlanDocument32 pagesQuality Management PlanPageduesca Rouel100% (1)

- ASTM C478-15 ManholesDocument9 pagesASTM C478-15 Manholessethhoffman85100% (1)

- Structural SpecificationsDocument102 pagesStructural SpecificationsAlden CayagaNo ratings yet

- 002-PDS-CON-011 Method Statement For TCF ConstructionDocument18 pages002-PDS-CON-011 Method Statement For TCF ConstructionMalik ZamanNo ratings yet

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Quality Plan for Steel Structure ManufacturingDocument23 pagesQuality Plan for Steel Structure ManufacturingPageduesca Rouel100% (1)

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- BS 1881-PART-111 CONCRETE Method Forn Normal Curing of TestDocument4 pagesBS 1881-PART-111 CONCRETE Method Forn Normal Curing of Testhajimak100% (1)

- Precast Pre Stressed ConcreteDocument6 pagesPrecast Pre Stressed Concretejack.simpson.changNo ratings yet

- 05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Document30 pages05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Avaan IvaanNo ratings yet

- CONCRETE CLASSES AND MIXESDocument5 pagesCONCRETE CLASSES AND MIXESAbdullah Aboodi50% (2)

- Qcs 2010 Part 8.02 EarthworksDocument20 pagesQcs 2010 Part 8.02 EarthworksRotsapNayrbNo ratings yet

- Qatif Method Statement Asphalting Works-1Document10 pagesQatif Method Statement Asphalting Works-1elbaraniNo ratings yet

- QCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFDocument16 pagesQCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFRotsapNayrbNo ratings yet

- PROJECT QUALITY PLANDocument69 pagesPROJECT QUALITY PLANnatrix029No ratings yet

- MS For Domestic Water (Hot & Cold)Document8 pagesMS For Domestic Water (Hot & Cold)Mohamed Elarabi50% (2)

- Precast Guide SpecDocument25 pagesPrecast Guide SpecpabulumzengNo ratings yet

- TCS Q 113 01 R0Document0 pagesTCS Q 113 01 R0Tori Small100% (1)

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Curing Compound ApplicationDocument3 pagesCuring Compound Applicationmoytabura96No ratings yet

- 12 Samss 008Document4 pages12 Samss 008Moustafa BayoumiNo ratings yet

- Katzung Questions PDFDocument29 pagesKatzung Questions PDFChristian Solis100% (1)

- SAILMA Steel Grades & SheetsDocument2 pagesSAILMA Steel Grades & SheetsElumalai SrinivasanNo ratings yet

- Floor Finish OptionsDocument69 pagesFloor Finish OptionsPageduesca RouelNo ratings yet

- Project Quality PlanDocument43 pagesProject Quality PlanPageduesca RouelNo ratings yet

- Transmission Construction Standard: Saudi ElectricitycompanyDocument12 pagesTransmission Construction Standard: Saudi ElectricitycompanyTori Small0% (1)

- QCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFDocument14 pagesQCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFbryanpastor106No ratings yet

- Tes H 107 01 R1 Painting PDFDocument58 pagesTes H 107 01 R1 Painting PDFUtkucan KILIÇNo ratings yet

- 3-11-8 - Pressure Vessel Cs - UopDocument31 pages3-11-8 - Pressure Vessel Cs - UopSean Davis100% (1)

- 04-1 QCS 2014Document7 pages04-1 QCS 2014Raja Ahmed Hassan100% (1)

- SEC concrete standardDocument38 pagesSEC concrete standardImran KhanNo ratings yet

- DEWA Civil Rev-15Document100 pagesDEWA Civil Rev-15Joe PsNo ratings yet

- Qatar Highway Design Manual PDFDocument254 pagesQatar Highway Design Manual PDFsudhakarmn100% (13)

- Engineering Development/Quality Inspection Test Plan (ITPDocument13 pagesEngineering Development/Quality Inspection Test Plan (ITPPageduesca RouelNo ratings yet

- Engineering Development/Quality Inspection Test Plan (ITPDocument13 pagesEngineering Development/Quality Inspection Test Plan (ITPPageduesca RouelNo ratings yet

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet