Professional Documents

Culture Documents

S09 Air Circuit General

Uploaded by

Anonymous iu95trpxNCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S09 Air Circuit General

Uploaded by

Anonymous iu95trpxNCopyright:

Available Formats

Page 1

AIR FLUSHING CIRCUIT

MAINTENANCE MANUAL

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

Page 2

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

PRELIMINARY REMARKS

1/1

SAFETY

1/2

ABOUT THIS BOOKLET

EXPLANATION PLAN

AIR SUPPLY

3/1

MACHINE AIR COMPRESSOR

3/2

AIR CLEANER

AIR FLUSHING CIRCUIT

AIR RECEIVER

LUBRICATED AIR CIRCUIT

5/1

WATER SEPARATOR

5/2

PRESSURE SWITCH

5/3

PRESSURE REDUCER

5/4

AIR OILER

5/5

OIL INDICATOR

4

4/1

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

10

A 23-06-2004 AR-RL-FL

AIR FLUSHING CIRCUIT

Page 3

1 PRELIMINARY REMARKS

1/1 SAFETY

The informations contained in this manual must be studied and thoroughly assimilated before

undertaking any maintenance work on the equipment

Remember: SAFETY FIRST!

Always observe the warnings accompanied by the following symbols.

WARNING Operation, maintenance and adjustments are only allowed to persons with

specific training in operation and maintenance of the equipment. Read the operating

and maintenance instructions before using or servicing the equipment.

WARNING: Before starting any maintenance operation ensure that the machine is in a

safe location with good safety, ventilation and lighting conditions. Ensure that lifting

equipments and pedestals are compatible with elements weight. Follow all the safety

instructions and ware safety protections as gloves, goggle, helmet, safety boots, ear

protectors.

WARNING: Before any operation stabilize and fix steadily all the elements on suitable

pedestals. Stop the power packs, switch the general power breaker. Place a tag or a

board to warn other members of the personnel that maintenance work on the machine

WARNING is in progress.

WARNING: Pressurized oil jets could cause severe injuries. Before any operation on

hydraulic circuit, STOP the power packs and release remaining pressure in

components by operating hydraulic control levers several times. Always release the

static

pressure in cylinders before disassemble them.

WARNING

NEVER WORK ON AN OPERATING CIRCUIT.

WARNING: While tests are in progress, do not allow any other member of the

personnel to stand in the area surrounding the machine. Stay at the control station to

be able to stop the movement and switch off the power pack.

WARNING

WARNING: Maintenance, adjustment and repairs are restricted to qualified personnel

with special training for the particular equipment. Always read the instructions carefully

before starting any maintenance work.

WARNING

CAUTION: Always use suitable tools and work in a clean place when dismantling and

assembling hydraulic components. After removing cylinders the hydraulic inlet/outlet

ports must be plugged to prevent dirt and air intrusion during operation.

WARNING: The operator must always wear required personal protection, such as safety

helmet, protective overall, safety boots, hearing protectors, safety goggles etc.

WARNING

WARNING: Danger of high pressure oil jets.

High pressure oil jets can cause serious personal injuries.

Release the pressure in the hydraulic circuits before opening caps or connections.

(Accumulator, Cylinder and Hydraulic circuit)

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

Page 4

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

WARNING: Danger of hot surface.

Hot surface can cause serious injuries.

Components rod, shank or hydraulic component can be hot and before

starting a maintenance work, please let them cool off.

The operator must have adequate wears as gloves.

WARNING: Crushing hazard : do not stay in dangerous area, for instance: central

articulation, front chassis and rear chassis.

WARNING

SAFETY

Always follow the

marked safety instructions, and

observe caution while working.

The following safety instructions are general rules.

Keep tools and drilling

equipment clean.

Do not attempt any such repairs or adjustments that you do not fully

understand.

ABOUT THE SAFETY OF REPAIRS

Certain workstages require the use of the feed mechanism during the repair.

Make sure then that:

- no danger is caused to anybody.

- the machine can be immediately stopped when necessary.

- the powerpack is stopped again before the repair-work is continued.

Before starting any repair-work move away from the area where you have just

drilled.

Use proper tools.

Always wear protective clothing, eye protection, earmuffs, safety footwear, and

other safety equipment required by the work.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

Page 5

1/2 ABOUT THIS BOOKLET

The present manual is destined for the use of personnel in charge of carrying out, servicing and

maintenance operations on Jumbos.

It contains maintenance operations schedule and operating methods concerning the main elements of

the AIR FLUSHING CIRCUIT.

Note that servicing and maintenance operations must be carried out by personnel with the required

qualifications, technical knowledge, and proper training on the machine.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

Page 6

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

2 EXPLANATION PLAN

TO BOOM 2 (*2)

AIR OILER

LUBRICATED AIR

TO ROCK DRILL

OIL INDICATOR

TO BOOM 1

WATER / AIR

WATER

TO FLUSHING HEAD

T - FITTING

PRESSURE

REDUCER

(*3)

PRESSURE

SWITCH

AIR RECEIVER

(*2)

WATER

SEPARATOR

MACHINE AIR

COMPRESSOR

AIR FLUSHING

VALVE

CONTROL PANEL

A

ir

ci flu

rc sh

u i in

t g

Lu

ai br

r c ic

irc a t e

ui d

t

(*1)

AIR CLEANER

ir

s

up

pl

y

(*3)

MINES AIR

(*1) Depends on rock drill

The elements localisation depends on machine range.

See the operator manual to know their localisation.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

(*2) Depends on application

(*3) Optional equipment

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

Page 7

3 AIR SUPPLY

3/1 MACHINE AIR COMPRESSOR

Different types of compressor can be mounted on the drilling machines.

FOR ALL COMPRESSOR MAINTENANCE OPERATIONS, SEE

COMPRESSOR MAINTENANCE MANUAL ENCLOSED IN THIS SECTION.

1 : Clogging indicator

2 : Air filter

3 : Air circuit pressure gauge

4 : Compressor oil temperature

(Compressor type CT10 shown)

Maintenance operations at each shift :

- Check that there is no pressure left in the circuit when motors are stopped.

- Verify that the clogging indicator is located in the green zone, if it is in red zone, all compressor

filter elements must be replace. After filters replacement, reset the clogging indicator.

- Check compressor oil level, add oil if needed. (Prior to add oil, make sure that there is no

pressure remainning in the circuit).

Maintenance operations every weeks :

- Start the compressor, check the pressure. The pressure should not exceed 2 or 2.5 bar when

installing a gauge at the inlet port of the rock drill. According to the length of the air line the

pressure at the compressor or at the oiler may be higher. Adjust the compressor pressure to get

2 bar at the rock drill inlet port.

If a pressure reducer is installed on the machine, it is then possible to adjust the compressor

pressure to 7 bar.

Maintenance operations every months :

- Replace filters elements.

- Replace cartridge element of oil separator.

Replace Compressor oil after 500 drilling hours.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

Page 8

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

3/2 AIR CLEANER

If the machine is equiped with mines air connection (optional equipment), the air flushing can be

assured wether by machine compressor or by mines air.

The mines air contains too much dust to supply the flushing circuit, a filter device like the IP5 air

cleaner is so needed.

1

1 - Water separator

2 - Tank

3 - Drain valve

Maintenance operations at each shift :

Bleed the air cleaner, full by condensed water.

4 AIR FLUSHING CIRCUIT

4/1 AIR RECEIVER

One, two or three air receivers can be

mounted, depending on machine

applications.

These air receivers are used to stock

suficiently air to assure the flushing with

wether compressor or mines air.

The air receivers are each equiped by one

safety valve (which keep the circuit in a

safety pressure under 8 bar), and a drain

valve.

Maintenance operations at each shift :

- Stop the compressor and bleed the air receiver(s), full by condensed water.

- Check that safety valves are not damaged.

Replace air receivers after 10 years of use.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

A 23-06-2004 AR-RL-FL

AIR FLUSHING CIRCUIT

Page 9

5 LUBRICATED AIR CIRCUIT

In standard drilling operation, it is necessary to provide a flow mixed air and oil at 2.5 bar to

lubricate the rock drill shank and the bronze driver to protect them from water and dust intrusion.

If the mixt pressure is to low, the pressure switch stops the drilling feed forward movement.

A lack in this lubrication will result in rapid damage or destruction of the rock drill.

It is so of prime importance to permanently assure a correct functioning of the pressurized

lubricated air circuit and its main components.

5/1 WATER SEPARATOR

The water separator (reclaimer) is necessary to prevent water presence in the rock drill and avoid

its destruction.

Maintenance operations at each shift :

Bleed the water separator, full by water contained in oil.

5/2 PRESSURE SWITCH

This component is an informer, when the circuit pressure is less than 1 bar a warning light is

switched on and the drilling feed forward movement stop. It is exacly the same when the pressure

is higher than 2.5 bar.

5/3 PRESSURE REDUCER

The reducer is installed to protect the rock drill against over-pressure that could cause failures.

The air pressure to the rock drill must be adjusted and reduced to 2/2.5 bar.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

Page 10

AIR FLUSHING CIRCUIT

A 23-06-2004 AR-RL-FL

5/4 AIR OILER

FOR ALL AIR OILER MAINTENANCE OPERATIONS, SEE AIR OILER

MAINTENANCE MANUAL ENCLOSED IN THIS SECTION.

6

5

1 : Lubrication pump

2 : Oil flow adjustement screw

3

3 : Sight glass

4 : Drain valve

5 : Oil flow adjusting device connection.

6 : Manifold

(Air oiler type KVL shown)

Maintenance operations at each shift :

- Bleed the water separator : Slightly open the drain valve, let the condensed water get out the

oiler. Make sure that there is no remaining pressure in the circuit. The gauge should show 0bar.

- Check oil level : Remove the filling plug used as a dipstick. Add rock drill oil if the level is too low.

- Start the compressor, check that oil flows regularly by looking the sight glass.

Maintenance operations every weeks :

- Drain the reservoir, replace the lubrication oil.

- Check the oil flow

- Remove the oil flow adjusting device, undo the adjusting device connection.

Start the compressor. Wait a couple of minutes until the reservoir is correctly pressurized.

Adjust the oil flow to get 30 drops of oil per minute and per boom. Retighten the oil flow adjusting

device to the manifold.

5/5 OIL INDICATOR

This component allows the operator to check the flow of the mixt use to the rock drill.

Keep the glass clean.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 LYON cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

You might also like

- Practica de FiltrosDocument210 pagesPractica de FiltrosAnonymous iu95trpxNNo ratings yet

- Exersises QuantifiersDocument1 pageExersises QuantifiersAnonymous iu95trpxNNo ratings yet

- Homework Week 6 (1) ListoDocument2 pagesHomework Week 6 (1) ListoAnonymous iu95trpxNNo ratings yet

- Spssv20 Introduction 2013Document30 pagesSpssv20 Introduction 2013Anonymous iu95trpxNNo ratings yet

- BoomDocument59 pagesBoomAnonymous iu95trpxN100% (1)

- 17 - Datos Tecnicos PDFDocument4 pages17 - Datos Tecnicos PDFAnonymous iu95trpxNNo ratings yet

- S01 General Pre-Start Check ListDocument1 pageS01 General Pre-Start Check ListAnonymous iu95trpxNNo ratings yet

- Compressor LE 22-75 2930 1213 04 SparePartListDocument64 pagesCompressor LE 22-75 2930 1213 04 SparePartListllllcesarllllNo ratings yet

- S00 FrontPage Service 4092 - ENDocument2 pagesS00 FrontPage Service 4092 - ENAnonymous iu95trpxNNo ratings yet

- Martillo Perforador X2Document10 pagesMartillo Perforador X2Anonymous iu95trpxNNo ratings yet

- Quasar 1FDocument72 pagesQuasar 1FAnonymous iu95trpxNNo ratings yet

- 9853 6202 50d Spare Part Catalogue COP 1838 C-VersionDocument28 pages9853 6202 50d Spare Part Catalogue COP 1838 C-VersionAnonymous iu95trpxNNo ratings yet

- Martillo Perforador X2Document10 pagesMartillo Perforador X2Anonymous iu95trpxNNo ratings yet

- s05 Boom b14nvDocument20 pagess05 Boom b14nvAnonymous iu95trpxNNo ratings yet

- 9853 6202 50d Spare Part Catalogue COP 1838 C-VersionDocument28 pages9853 6202 50d Spare Part Catalogue COP 1838 C-VersionAnonymous iu95trpxNNo ratings yet

- S03 AccumulatorDocument12 pagesS03 AccumulatorRaphael Ruiz RamosNo ratings yet

- Quasar 1FDocument72 pagesQuasar 1FAnonymous iu95trpxNNo ratings yet

- S00 General SafetyDocument32 pagesS00 General SafetyAnonymous iu95trpxNNo ratings yet

- S01 Hydraulic Cylinders - All CylindersDocument13 pagesS01 Hydraulic Cylinders - All CylindersAnonymous iu95trpxNNo ratings yet

- s05 Boom b26f b26xlfDocument24 pagess05 Boom b26f b26xlfAnonymous iu95trpxNNo ratings yet

- S03 Rock Drill HLX5 MaintenanceDocument16 pagesS03 Rock Drill HLX5 MaintenanceAnonymous iu95trpxN100% (4)

- S10 Water Circuit GeneralDocument13 pagesS10 Water Circuit GeneralAnonymous iu95trpxNNo ratings yet

- S11 Axera 5 Electric SystemDocument22 pagesS11 Axera 5 Electric SystemAnonymous iu95trpxNNo ratings yet

- s07 Axle Ford New d45Document27 pagess07 Axle Ford New d45Anonymous iu95trpxNNo ratings yet

- s10 Water Pump Grundfos Cr1 Cr3 Cr5Document8 pagess10 Water Pump Grundfos Cr1 Cr3 Cr5Anonymous iu95trpxNNo ratings yet

- S05 Rotary Actuator 360°Document14 pagesS05 Rotary Actuator 360°Anonymous iu95trpxNNo ratings yet

- S04 Drill Feed TF & TFX 500Document31 pagesS04 Drill Feed TF & TFX 500Anonymous iu95trpxN100% (2)

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- s07 Tramming Axera Robolt Solo 5 enDocument18 pagess07 Tramming Axera Robolt Solo 5 enAnonymous iu95trpxNNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SSP+19+1 6L+1 8l+petrol+enginesDocument48 pagesSSP+19+1 6L+1 8l+petrol+enginesMurugan KNo ratings yet

- Operation & Maintenance Manual: Lift Trucks BC20S-5, BC25S-5, BC25SE-5 BC30S-5, BC32S-5 B20S-5, B25S-5, B30S-5, B32S-5Document133 pagesOperation & Maintenance Manual: Lift Trucks BC20S-5, BC25S-5, BC25SE-5 BC30S-5, BC32S-5 B20S-5, B25S-5, B30S-5, B32S-5Rat Sorina100% (5)

- Electronic Device Semiconductor-InstDocument7 pagesElectronic Device Semiconductor-InstPablo SequeraNo ratings yet

- Filtros Cat d7r Cat Grupo 2Document3 pagesFiltros Cat d7r Cat Grupo 29873987398793No ratings yet

- Toll Road Project - Specifications Section 9 - PavementsDocument32 pagesToll Road Project - Specifications Section 9 - PavementsadhystiraNo ratings yet

- IndexDocument30 pagesIndexhortalemosNo ratings yet

- Mechanics of Fluids Question Bank PDFDocument11 pagesMechanics of Fluids Question Bank PDFSuresh Raju100% (2)

- ViktorDocument140 pagesViktorDani Sherlock100% (1)

- Loads For Starting On Unit 7-FADocument2 pagesLoads For Starting On Unit 7-FAmohammadkassarNo ratings yet

- Boomer S1 L: Low Profile Face Drilling Rig For Drifts and Tunnels With Cross Sections Up To 29 MDocument8 pagesBoomer S1 L: Low Profile Face Drilling Rig For Drifts and Tunnels With Cross Sections Up To 29 MDiegoAndresJofreVillablanca100% (1)

- Hazardous Area Guide: For Atex & Iecex (Zones/Groups)Document1 pageHazardous Area Guide: For Atex & Iecex (Zones/Groups)Sandra Yadhit Higuera ArchilaNo ratings yet

- Combustion ReactionsDocument6 pagesCombustion ReactionsGess LabradorNo ratings yet

- Transport X OperationpDocument23 pagesTransport X Operationpmahm.tahaNo ratings yet

- Stirling Engine - A Beginners GuideDocument108 pagesStirling Engine - A Beginners Guideamsci99100% (4)

- Goulds 3700Document9 pagesGoulds 3700JackNo ratings yet

- Crude Distillation UnitsDocument32 pagesCrude Distillation Unitsmoujahed100% (1)

- Final Report RetrofittingDocument47 pagesFinal Report RetrofittingvalaNo ratings yet

- Uh-1 - 10 C20Document134 pagesUh-1 - 10 C20Clifford McKeithan100% (1)

- Presented By:: SHUBHAM MISHRA (1513231170) Electronics and Communication Branch 4 YearDocument19 pagesPresented By:: SHUBHAM MISHRA (1513231170) Electronics and Communication Branch 4 YearShubham MishraNo ratings yet

- Summary of Blended Coal FeedingDocument3 pagesSummary of Blended Coal FeedingS V NAGESHNo ratings yet

- Conversion Calculator SpreadsheetDocument2 pagesConversion Calculator SpreadsheetKezia Jenytha Rose NababanNo ratings yet

- Code 386 RepairDocument12 pagesCode 386 RepairCarlos A RomeroNo ratings yet

- GreaseDocument13 pagesGreaseParth Shah100% (2)

- Eum 20230918Document31 pagesEum 20230918Govend BarNo ratings yet

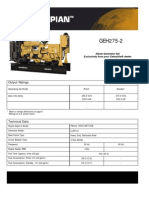

- GEH275Document4 pagesGEH275foroNo ratings yet

- YUKON-Manual EN ID DC68-03073Q-04 PDFDocument88 pagesYUKON-Manual EN ID DC68-03073Q-04 PDFSaidNo ratings yet

- IGC2 Sample AnswersDocument7 pagesIGC2 Sample Answerspapaji75% (4)

- HVPE Operation and MaintenanceDocument116 pagesHVPE Operation and MaintenanceMinerva AbantoNo ratings yet

- Non Conventional Energy SourcesDocument10 pagesNon Conventional Energy SourcesDivya Reddy SurkantiNo ratings yet

- Inspection EngineerDocument8 pagesInspection Engineervishal bailurNo ratings yet