Professional Documents

Culture Documents

Physicochemical Properties of Palm Oil and Palm Kernel Oil Blend Fractions

Uploaded by

Evan KeeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Physicochemical Properties of Palm Oil and Palm Kernel Oil Blend Fractions

Uploaded by

Evan KeeCopyright:

Available Formats

International Food Research Journal 22(4): 1390-1395

Journal homepage: http://www.ifrj.upm.edu.my

Physicochemical properties of palm oil and palm kernel oil blend fractions

after interesterification

Norizzah, A. R., 1Norsyamimi, M., 2Zaliha, O., 1Nur Azimah, K. and

2

Siti Hazirah, M. F.

Faculty of Applied Sciences, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, Malaysia

2

Malaysian Palm Oil Board, Persiaran Institusi, Bandar Baru Bangi, 43000 Kajang, Selangor,

Malaysia

Article history

Abstract

The objective of this study was to determine the physicochemical properties of olein and

stearin fractions obtained from non-interesterified (NIE), chemically interesterified (CIE) and

enzymatically interesterified (EIE) 50:50 palm oil and palm kernel oil blend. The potential

applications of both olein and stearin fractions were also identified. Stearin and olein fractions

were obtained through a single stage dry fractionation at 25C. The physicochemical properties

analysed include percent yield, fatty acid composition (FAC), iodine value (IV), smoke point,

Keywords

cloud point, slip meting point (SMP) and solid fat content. Results indicated that the percent

olein yield was higher from the EIE (85%) and NIE blends (82.2%) than in CIE blend (41.8%).

Fractionation

The EIE blend produce liquid fraction with the highest amount of unsaturated fatty acid (~50%).

Chemical interesterification

Enzymatic interesterification Hence, the olein fraction of EIE blend best met the requirement to be used as frying oil based

on the highest smoke point (265.1C) and lowest cloud point (6.2C). On the other hand, the

Palm oil

stearin fraction of CIE blend might be suitable to be used in margarine formulation as it has

Palm kernel oil

SMP close to body temperature.

Received: 24 July 2014

Received in revised form:

17 December 2014

Accepted: 22 December 2014

All Rights Reserved

Introduction

Oil palm (Elaeis guineensis) produces two

different types of oil which are palm oil and palm

kernel oil. The fruit of oil palm yields about 20-22%

of its oil from the fibrous mesocarp and 10% of the

total yield is from the white kernel flesh (Berger &

Noraini, 2005). The application of palm oil and palm

kernel oil are very limited in their original form due

to their specific chemical composition. To diversify

the functions and usage of fats and oils, modification

is done especially to improvise the physicochemical

characteristics and stability. The frequently

used modification methods are fractionation,

hydrogenation, blending and interesterification

(Khalid et al., 2011). Blending technique is the

simplest and cheapest way to modify oils. However,

blending does not result in chemical modification of

the triacylglycerols composition (Chen et al., 2007).

Interesterification (IE) is a process of rearranging

fatty acids within and between triacylglycerols,

resulting changes in physicochemical properties of

the oils and fats. It has long been used for modification

of fat and oil mixtures in industries. The process

produces randomly distributed fatty acid residues

among the triacylglycerols and usually carried

*Corresponding author.

Email: norizzah850@salam.uitm.edu.my

Tel: 603-55444476; Fax: 603-55435559

out at high temperature (Zaida and Yusof, 1999;

Fauzi et al., 2013). On the other hand, enzymatic

interesterification can be regiospecific, react at low

temperatures and easy to handle (Ajithkumar, 2011).

Palm oil is semisolid at room temperature, while

palm kernel oil contains triacylglycerols that melted

sharply at about body temperature.

By applying the modification techniques, new

product such as oil suitable for edible purposes can

be obtained. Hence, the objectives of this study

was to determine the physicochemical properties of

olein and stearin fractions obtained from the 50:50

non-interesterified, chemically interesterified and

enzymatically interesterified palm oil and palm

kernel oil blends. The most suitable stearin and olein

fractions obtained from this study will be identified

for certain food applications.

Materials and Methods

Materials

Refined, bleached and deodourised (RBD) palm

oil (PO) and palm kernel oil (PKO) were obtained

from Golden Jomalina Sdn. Bhd., Klang, Malaysia.

The chemicals used were either analytical or HPLC

grade. Commercial immobilised Themomyces

1391

Norizzah et al./IFRJ 22(4): 1390-1395

lanuginosus lipase, Lipozyme TL IM was obtained

from Novozyme (Denmark). Palm oil and PKO were

melted at 60C before blending at 50:50 (w/w) ratio.

Chemical and enzymatic interesterification

Chemical and enzymatic interesterification of

the oil blends were conducted according to MPOB

Test Method (2004) using sodium methoxide and

Lipozyme TL IM as catalysts, respectively.

Dry fractionation

Dry fractionation was carried out using a

circulatory refrigerated bath (ThermoHaake C25P,

Karlrushe, Germany). About 100 g sample was

placed in 200 ml borosilicate glass bottle. Sample

was heated in the bath at 70C for 30 min to destroy

the crystal nuclei. The sample was then cooled (using

ramping mode) in the same bath to 25C in 1 h.

While holding at 25C for 90 min, the sample was

continuously stirred with a helix stirrer (Ika RW11

Labortechnik, Staufen, Germany) at a constant speed

of 100 rpm. After 3 h of total heating, cooling and

holding time, the sample was immediately subjected

to vacuum filtration with Whatman No. 4 filter paper.

While filtering, temperature was maintained at 25C

until filtration process completed.

Percent yield

After dry fractionation process, liquid fraction

collected from the conical flask was weighed and

reported as olein yield (g) while solid fraction on the

filter paper was weighed and reported as stearin yield

(g). The percentage of yield was calculated as follow:

% Olein = Olein yield (g)/Olein + Stearin (g) x 100%

% Stearin = Stearin yield (g)/ Olein + Stearin yield

(g) x 100%

where,

Olein + Stearin yield (g) = 100 g (as the total sample

used in this study)

Fatty acid composition

A gas chromatograph (Agilent 6890N) with

flame ionisation detector (GC-FID) was used for

determination of fatty acid composition. Fatty acid

methyl esters (FAME) were prepared by acidic

catalysed esterification. Fifty mg of sample was

saponified for 30 min using 10 ml of KOH (0.5

mol/l). One ml of concentrated H2SO4 then was

added. After 30 min, the FAME was extracted with

25 ml of hexane. One l of the solution was used for

injection. The capillary column (EC-WAX, Alltech)

30 m 0.25 mm ID was used for FAME analyses

with temperature of detector at 300C. Helium with

flow rate of 1.5 ml/min was used as carrier gas and

oven temperature was set at 220C. Identification of

fatty acid composition was determined by comparing

peak retention times with commercial standards.

Iodine value

Iodine value (IV) was determined according to

MPOB Test Method (2004). Blank and triplicate

determinations were carried out under same

conditions. Iodine value was calculated using the

following equation:

IV = 12.69 M (Vb Vs)

W

M = Molarity of sodium thiosulphate solution

used

Vb = Volume in mL of sodium thiosulphate

solution used for blank test

Vs = Volume in mL of sodium thiosulphate used

for sample test

W = Weight in gram of sample

Cloud point

Determination of cloud point was conducted

according to MPOB Test Method (2004). The oil

sample (60-75 g) was filtered through a Whatman No.

1 filter paper. The filtered oils were heated to 130C

for 5 min and about 45 ml of the heated oil was poured

into a Beatson sample bottle. The bottle and content

were cooled in a water-bath that was thermostatically

controlled at 5C below the expected cloud point. The

oils were kept stirred while cooling to prevent supercooling and solidification of fat crystals on the side

or bottom of the bottle. The bottle was removed from

the bath and inspected regularly. The cloud point was

taken as the temperature at which that portion of the

thermometer immersed in the oil is no longer visible

when viewed horizontally through the bottle and

sample. Samples were run in triplicate and average

values were taken.

Slip melting point

Slip melting point (SMP) was determined

according to AOCS Method Cc.3.25 (AOCS, 1990).

In this method, capillary tubes were filled with fat

until 1 cm high column. The temperature at which the

fat column rises was reported as SMP. Samples were

run in triplicate and mean values were calculated.

Solid fat content

Solid fat content (SFC) was measured using

a minispec pulsed Nuclear Magnetic Resonance

Norizzah et al./IFRJ 22(4): 1390-1395

1392

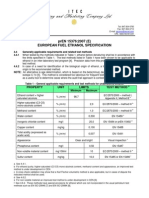

Table 1. Percent yield, iodine value, slip melting point, smoke point and cloud point of

NIE, CIE and EIE of 50:50 PO:PKO (w/w) blend fractions

Notes: a,b,c Means in the same column within the group with different letters are significantly

different (p<0.05). NIE, Non-interesterified; CIE, Chemically interesterified; EIE, Enzymatically

interesterified; SMP, Slip melting point

(pNMR) spectrometer (Bruker, Karlrushe, Germany).

The MPOB parallel method was used, in which

sample in NMR tube was first melted at 70C for 30

min, followed by chilling at 0C for 90 min, and then

held at each measuring temperature for 30 min prior

to measurement (MPOB Test Method, 2004). The

process of melting, chilling and holding of samples

were carried out in a pre-equilibrated thermostatted

water baths. Samples were run in triplicate and the

values were averaged.

Smoke point

The temperature at which samples give off a thin,

continuous stream of bluish smoke was measured

according to AOAC Method (1999).

Statistical analysis

Selected data obtained were subjected to oneway ANOVA to determine significant differences

among the samples defined at p<0.05. Data analysis

was performed using SPSS program version 17.

Results and Discussion

Percent yield

The percent olein and stearin yields are given

in Table 1. The enzymatic interesterified (EIE) and

non-interesterified (NIE) 50:50 PO:PKO blend

significantly (p<0.05) produced higher olein fraction

(85.0% and 82.8%, respectively) than chemically

interesterified blend (41.8%). While for stearin

fraction, CIE 50:50 PO:PKO blend produced

significantly higher (p<0.05) yield (58.2%) than NIE

and EIE (17.2% and 14.9%, respectively). In dry

fractionation, high and low melting triacylglycerols

are separated by partial crystallisation based on

differences in melting points of triacylglycerols

and followed by filtration (Sellami et al., 2012).

Triacylglycerols are redistributed into two phases

during dry fractionation process. The more saturated

triacylglycerols are gradually concentrated into solid

phase (stearin) as the fractionation process proceeds

while the more unsaturated one is left in the liquid

phase (olein).

Iodine value

Iodine value (IV) is a measure of degree of

unsaturation and is used to characterise fats and oils.

The iodine values for both fractions of NIE, CIE

and EIE 50:50 PO: PKO are shown in Table 1. The

EIE olein fraction had significantly (p<0.05) higher

IV than CIE and NIE olein fractions. For stearin

fraction, the CIE had significantly higher (p<0.05)

iodine value than NIE but was not significantly

different (p>0.05) from the EIE. The olein fractions

had high IV than their respective stearin fractions

indicating olein fractions were more unsaturated than

their stearin fractions. Iodine value of olein is related

to smoke point and cloud point of the blend fractions.

The higher the iodine value, the higher the smoke

point and the lower the cloud point.

Most of the low melting triacylglycerols (TAG)

had been separated during the single dry fractionation

process. Result shows that EIE olein has the best

properties as frying oil as it has significantly the

highest (p<0.05) smoke point and the lowest cloud

point. The iodine value of stearin fractions are related

to slip melting point of fats. The higher the degree of

unsaturation, the lower the slip melting point will be.

In this study, the CIE stearin fraction has the highest

IV and the lowest slip melting point as shown in

Table 1.

Slip melting point

The slip melting points of NIE, EIE and CIE

stearin fraction is given in Table 1. The slip melting

point of NIE stearin (48.3C) was significantly highest

(p<0.05) among the EIE (44.3C) and CIE (36.7C).

The stearin fraction of NIE blend melted at highest

temperature indicating it is more saturated than CIE

and EIE stearins. The slip melting point of the NIE,

EIE and CIE oil blends before dry fractionation were

27.7C, 27C and 29.5C, respectively. Changes

in melting characteristics of stearin are generally

due to redistribution of the fatty acid chains within

the triacylglycerol molecules (Sellami et al. 2012).

1393

Norizzah et al./IFRJ 22(4): 1390-1395

Table 2. Fatty acid composition (%) of NIE, EIE and CIE 50:50 PO:PKO blend fractions

Notes: C12:0, Lauric; C14:0, Myristic; C16:0, Palmitic; C18:0, Stearic; C18:1, Oleic; C18:2,

Linoleic; EIE, Enzymatically interesterified; CIE, Chemically interesterified; NIE, Non-interesterified,

PO, Palm oil; PKO, Palm kernel oil

The low and high melting triacylglycerols has been

separated by partial crystallisation and fitration in dry

fractionation process.

Sakina (2000) revealed that interesterified fat

made with blends of palm oil had the slip melting

point decreased as quantity of palm kernel oil in the

mixture increased due to presence of short or medium

chain fatty acids in palm kernel oil. Melting properties

of stearin become very important characteristic

in making food products especially margarine.

According to deMan et al. (1989), margarine that has

fairly low solids at low temperatures allow it to be

spreadable directly from refrigerator. In addition, fat

blends should be completely melted below 37C for

good oral melt down. Hence this study shows that

CIE stearin is suitable to be used as table margarine

as it has melting point close to 37C.

Smoke point

The smoke point of NIE, EIE and CIE 50:50 PO:

PKO olein fraction is as indicated in Table 1. The

EIE olein fraction had significantly higher (p<0.05)

smoke point (265.1C) than olein obtained from NIE

(231.7C) and CIE (243.3C) blends. According to

Berger (2005), the recommended smoke point for

palm oil must be above 215C (preferably above

220C) and smoke point of oil is dependent on the

content of some minor component especially the

free fatty acids. Based on the result, the olein blend

fractions analysed were suitable to be used as frying

oil. The higher the smoke point, the better the frying

oil will be. The EIE blend fraction has the best quality

as frying oil as it has the highest smoke point.

Cloud point

Cloud point is an important analysis to determine

the temperature at which oil turned to be cloudy due

to the first stage of crystallisation. The cloud points

of olein obtained from all blends ranged between

6.3 to 11C as shown in Table 1. The NIE olein

had significantly (p<0.05) the highest cloud point

(10.9C) followed by CIE (7.9C) and EIE (6.3C).

The olein of NIE blend appeared to be cloudy at

high temperature compared to CIE and EIE olein.

The lowest cloud point of olein from EIE blend was

due to higher unsaturated fatty acids (as indicated in

Table 2) compared to olein from the NIE and CIE

blends. The cloud point is closely related to degree of

unsaturation where the more unsaturated a sample is,

the lower the cloud point will be (Khalid et al., 2011).

Lai et al. (2005) reported that cloud point value for

palm oil is +11.5C. This shows that chemical and

enzymatic modification of palm oil and palm kernel

oil blend render the cloud points of olein to be lower

than normal palm oil.

Solid fat content

The suitability of oils and fats for a particular

application is greatly influenced by their solid fat

content (SFC). This characteristic is important to

determine the spreadability, general appearance

and organoleptic properties of fat and oil especially

margarine (Jirasubkunakorn et al., 2007). The solid

fat content of stearin fraction is related to fatty

acid content and triacylglycerol in that particular

component. The SFC of stearin is given in Figure 1.

The SFC proles of all the stearin fractions were

similar. Generally, the NIE stearin had high SFC

value compared to EIE and CIE stearin. The NIE

stearin totally melted at 50C, while EIE stearin and

CIE stearin melted at 45C and 40C, respectively.

There were no significant difference (p>0.05) in

SFC between the EIE and CIE stearin fractions at all

measured temperatures. High amount of saturated

fatty acids contributed to high SFC.

Fatty acid composition

The fatty acid composition of olein and stearin

fractions are shown in Table 2. The major fatty acid

Norizzah et al./IFRJ 22(4): 1390-1395

1394

References

Figure 1. Percent of solid fat content of NIE, CIE and

EIE of 50:50 PO:PKO stearin fractions as a function of

temperature

in olein fraction was oleic acid with 40.58% in EIE,

followed by 32.37% in CIE and 31.45% in NIE. For

stearin fraction, palmitic acid present in large amount

with 34.51%, 32.70% and 29.52% in NIE, EIE and

CIE blends, respectively. The different amounts of

fatty acids presence in the fractions even though from

the same blend ratio was due to the rearrangement

of fatty acids the glycerol backbone during

interesterification. Other fatty acids that present in

appreciable amounts in both the olein and stearin

fractions were lauric and myristic acids. The fatty

acid composition influenced the physical properties

of the fractions.

Conclusion

Single fractionation of the NIE, CIE, and EIE

50:50 PO:PKO blends at 25C produced stearin

and olein with different physicochemical properties.

The olein fraction from EIE PO:PKO blend has the

highest IV (49.2) and smoke point (265.1C) with the

lowest cloud point (6.3C) due to presence of high

amount of unsatutared fatty acids (~50%) compared

to NIE and CIE olein fractions. Hence, EIE olein

fraction has the most suitable properties for frying

purpose. On the other hand, CIE PO:PKO blend

produced the highest amount stearin fraction with

the highest IV (33.08) and had SMP close to body

temperature (36.7C). Thus, this stearin fraction

has the most suitable properties to be used for table

margarine formulation.

Acknowledgements

The financial support for this project was provided

by Fundamental Research Grants Scheme (FRGS),

Ministry of Higher Education, Malaysia, while the

equipment and facilities was supported by Universiti

Teknologi MARA and Malaysian Palm Oil Board.

Association of Official Analytical Chemists (AOAC).

1999. Official Methods of Analysis. 16th Edition.

Washington: Association of Analytical Chemists Inc.

American Oil Chemists Society (AOCS). 1990. Official

and Tentative Methods of the American Oil Chemists

Society, 15th Edition. Champaign: American Oil

Chemists Society Press.

Ajithkumar, G. 2011. Analysis, modification and

evaluation of the cold flow properties of vegetable oils

as base oils for industrial lubricants. India: Cochin

University of Science and Technology, Ph. D. Thesis.

Berger, K.G. and Noraini, I. 2005. Formulation of zerotrans fatty acid shortening and margarines and

other food fats with products of palm oil. Journal of

American Oil Chemists Society 86: 775-782.

Berger, K.G. 2005. Characteristics of palm oil products

used in frying. The Use of palm Oil In Frying.

Malaysian Palm Oil Promotion Council, Malaysia

AOCS, (1997). Official Methods and Recommended

Practices of the American Oil Chemists Society.

Champaign, v.1-2.

Chen, C.W., Chong, C.L., Ghazali, H.M., and Lai, O.M.

2007. Interpretation of triacylglycerol profiles of palm

oil, palm kernel oil and their binary blends. Food

Chemistry 100: 178-191.

deMan, L., deMan, J.M. and Blackman, B. 1989.

Physical and textural evaluation of some shortening

and margarines. Journal of American Oil Chemists

Society 66: 128-131.

Fauzi, S.H.M., Rashid, N.A. and Zaliha, O. 2013. Effects

of chemical interesterification on the physicochemical,

microstructural and thermal properties of palm

stearin, palm kernel oil and soybean oil blends. Food

Chemistry 137: 8-17.

Jirasubkunakorn, W., Bell, A.E., Gordon, M.H. and Smith,

K.W. 2007. Effects of variation in the palm stearin:

Palm olein ratio on the crystallisation of a low-trans

shortening. Food Chemistry 103: 477-485.

Khalid, K., Mushaireen, M., Kamaruzaman, J. and

Rahman, A. 2011. Lowering of palm oil cloud point

by enzymatic acidolysis. World Applied Science

Journal 12: 28-31.

Lai, T.C., Nazaruddin, R., Ooi, T.L., Mamot, S. and

Zalifah, K. 2005. Strategies for decreasing the pour

point and cloud point of palm oil products. European

Journal of Lipid Science Technology 107: 505-512.

MPOB Test Method. 2004. Methods of Test for Palm Oil

and Palm Oil Products, Malaysia: Malaysian Palm Oil

Board.

Sellami, M., Ghamgui, H., Frikha, F., Gargouri, Y. and

Miled, N. 2012. Enzymatic transesterification of

palm stearin and olein blends to produce zero-trans

margarine fat. BMC Biotechnology 12: 48.

Sakina, K. 2000. Semi-solid fat by interesterification of

red palm oil with other vegetable oils. Department

of Lipid Science and Traditional Foods Central Food

Technological Research Institute, Mysore.

Zaida, Z. and Yusof, M.S.A. 1999. Enzymatic

1395

Norizzah et al./IFRJ 22(4): 1390-1395

interesterication of palm stearin and palm kernel

olein. Journal of American Oil Chemists Society 76:

1003-1008.

You might also like

- Improvements Biodiesel en 14214Document171 pagesImprovements Biodiesel en 14214Ramadhan Dipta MaulaNo ratings yet

- Aocs Color MethodDocument4 pagesAocs Color MethodAngga YesNo ratings yet

- Hydroxyl Value of Fatty Oils and Acids: Standard Test Method ForDocument3 pagesHydroxyl Value of Fatty Oils and Acids: Standard Test Method ForAl7amdlellah100% (1)

- Fatty Acid EthanolamideDocument9 pagesFatty Acid Ethanolamidegaurav chauhanNo ratings yet

- Agilent - Determination of Methanol Content in Biodiesel According To En-14110Document2 pagesAgilent - Determination of Methanol Content in Biodiesel According To En-14110anuradha.d.bhat9860No ratings yet

- Is Iso 1066 1975Document9 pagesIs Iso 1066 1975Clausius ClapeyronNo ratings yet

- SS en 14105 2020 en PDFDocument11 pagesSS en 14105 2020 en PDFAhmed NoreldinNo ratings yet

- General Catalogue Tintometer Lovibond Oils-FatsDocument12 pagesGeneral Catalogue Tintometer Lovibond Oils-FatsAlex CárdenasNo ratings yet

- Evaluation of Analytical Methods For Determination of Moisture Crude Protein Crude Fat & Crude Fiber in Distillers Dried Grains With SolublesDocument13 pagesEvaluation of Analytical Methods For Determination of Moisture Crude Protein Crude Fat & Crude Fiber in Distillers Dried Grains With SolublesSV_TokanNo ratings yet

- EN 14103 - ThermoDocument4 pagesEN 14103 - ThermoLuciana TrisnaNo ratings yet

- A Review of Chromatographic Characterization Techniques For BioDocument13 pagesA Review of Chromatographic Characterization Techniques For BioTravis KirinNo ratings yet

- Astm d5768 PDFDocument3 pagesAstm d5768 PDFAmir HamzahNo ratings yet

- Sist en 14110 2019Document9 pagesSist en 14110 2019Ahmed NoreldinNo ratings yet

- Analytical-Methods-1998 - FAT & OIL HANDBOOKDocument6 pagesAnalytical-Methods-1998 - FAT & OIL HANDBOOKLuki Wahyuning TiyasNo ratings yet

- As 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andDocument8 pagesAs 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andSAI Global - APACNo ratings yet

- 991.20 Nitrogeno Total en Leche - KjeldahlDocument2 pages991.20 Nitrogeno Total en Leche - KjeldahlBleidy NieblesNo ratings yet

- AOCS Ce6 - 86 (HPLC-Antioksidan Level) - 1Document6 pagesAOCS Ce6 - 86 (HPLC-Antioksidan Level) - 1Muhammad Nurul Masyhudi100% (1)

- ISO 10539 - 2012 Fats and Oils - AlkalinityDocument11 pagesISO 10539 - 2012 Fats and Oils - AlkalinityJocilene DantasNo ratings yet

- Bailey's Industrial Oil and Fat Products Volume 1Document673 pagesBailey's Industrial Oil and Fat Products Volume 1FGHNo ratings yet

- 2.4.18 Free FormaldehydeDocument2 pages2.4.18 Free FormaldehydeMulayam Singh YadavNo ratings yet

- Standard Methods For The Analysis of Oils, Fats and DerivativeDocument151 pagesStandard Methods For The Analysis of Oils, Fats and Derivativepatchris36No ratings yet

- C1111-10 (Reapproved 2015)Document6 pagesC1111-10 (Reapproved 2015)Mohamad ZandiNo ratings yet

- E 1405 - 98 R99 - Rte0mdutotDocument3 pagesE 1405 - 98 R99 - Rte0mdutotdelta lab sangliNo ratings yet

- Bulk Sampling, Handling, and Preparing Edible Vegetable Oils For Sensory EvaluationDocument4 pagesBulk Sampling, Handling, and Preparing Edible Vegetable Oils For Sensory EvaluationAlevj DbNo ratings yet

- Astm-D664-2018 TanDocument11 pagesAstm-D664-2018 Tanleonardo ariefNo ratings yet

- As 2300.1.2.1-1991 Methods of Chemical and Physical Testing For The Dairying Industry General Methods and PriDocument2 pagesAs 2300.1.2.1-1991 Methods of Chemical and Physical Testing For The Dairying Industry General Methods and PriSAI Global - APACNo ratings yet

- Astm e 301-88 Standard Test Method For Total Acidity of Organic AcidsDocument3 pagesAstm e 301-88 Standard Test Method For Total Acidity of Organic AcidsGianinaRoncalChávezNo ratings yet

- Descriptive Sensory Evaluation of Virgin Coconut Oil and RefinedDocument7 pagesDescriptive Sensory Evaluation of Virgin Coconut Oil and Refineddiwata444No ratings yet

- Oils and FatDocument12 pagesOils and FatAgeng Wahyu PatrianitaNo ratings yet

- Determination of Benzene and Toluene in Finished Motor and Aviation Gasoline by Gas ChromatographyDocument7 pagesDetermination of Benzene and Toluene in Finished Motor and Aviation Gasoline by Gas ChromatographyJako MishyNo ratings yet

- AOCS Method Ce 1c-89Document4 pagesAOCS Method Ce 1c-89Lam Lai YanNo ratings yet

- AOCS Ce 1d91Document3 pagesAOCS Ce 1d91Lucas de Melo100% (1)

- En 14331 PDFDocument5 pagesEn 14331 PDFWynona BasilioNo ratings yet

- Iso TS 27265-2009Document16 pagesIso TS 27265-2009Farhad British WingsNo ratings yet

- D 1957 Hydroxyl ValueDocument3 pagesD 1957 Hydroxyl ValueJean Carlos NoriegaNo ratings yet

- 5989 7259enDocument82 pages5989 7259enKung KleeNo ratings yet

- Iso 3675 en PDFDocument6 pagesIso 3675 en PDFGery Arturo Perez AltamarNo ratings yet

- En 15376 European Fuel Alcohol Specifications (Itec)Document1 pageEn 15376 European Fuel Alcohol Specifications (Itec)Dimas Eko Prasetyo100% (1)

- Contractual Methods of Analysis 2017Document11 pagesContractual Methods of Analysis 2017jaimeNo ratings yet

- Iso 3104 2020 enDocument11 pagesIso 3104 2020 enJacek BursztynowiczNo ratings yet

- MSA and MAA by AutotitratorDocument4 pagesMSA and MAA by AutotitratorJeevan PradhanNo ratings yet

- GcmsDocument5 pagesGcmsMuhammad FahmiNo ratings yet

- ASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesDocument5 pagesASTM D874 - 2000 - Sulfated Ash From Lubricating Oils and AdditivesConstantinos ChristodoulouNo ratings yet

- Gc-Fid Method Development and Method Validation of Eugenol in Clove Oil Extracted by HydrodistillationDocument11 pagesGc-Fid Method Development and Method Validation of Eugenol in Clove Oil Extracted by HydrodistillationIJAR JOURNALNo ratings yet

- 2022 - 04 - 20 - VIVA-B-FIX Line TRG-PolymersDocument15 pages2022 - 04 - 20 - VIVA-B-FIX Line TRG-PolymersJagdish PatelNo ratings yet

- Analytical Procedures For The Determintion of Vitamins B1 and B2 in Foods, Feeds and Supplements - 3ML9qDocument28 pagesAnalytical Procedures For The Determintion of Vitamins B1 and B2 in Foods, Feeds and Supplements - 3ML9qCristina AlexandraNo ratings yet

- TVB-N in Fish and ShrimpsDocument8 pagesTVB-N in Fish and ShrimpsRizal Eka NugrahaNo ratings yet

- 2015 16 Cataloge AocsDocument36 pages2015 16 Cataloge AocsHarun DoğarNo ratings yet

- Metler Toledo TtitratorDocument138 pagesMetler Toledo TtitratorteddydeNo ratings yet

- D664 Potentimetry Titrator SopDocument8 pagesD664 Potentimetry Titrator SopRachmat AriandaNo ratings yet

- Method 1 Crude Fiber A2000Document3 pagesMethod 1 Crude Fiber A2000LUSIANANo ratings yet

- PNS en 14103 - Fame PDFDocument13 pagesPNS en 14103 - Fame PDFWynona BasilioNo ratings yet

- EN 14105 - ThermoDocument8 pagesEN 14105 - ThermoLuciana TrisnaNo ratings yet

- Determination of Acid Values in Organic Solvents, Oils, Fats, PolymersDocument3 pagesDetermination of Acid Values in Organic Solvents, Oils, Fats, PolymersJotyajirao SuryawanshiNo ratings yet

- D 1946 - 90 R00 - Rde5ndyDocument5 pagesD 1946 - 90 R00 - Rde5ndyCalvinNo ratings yet

- Manual of Methods OF Analysis of Foods: Oils and FatsDocument109 pagesManual of Methods OF Analysis of Foods: Oils and FatsKateryna BondarenkoNo ratings yet

- Codex Soybean ProductsDocument163 pagesCodex Soybean ProductskfujiwarNo ratings yet

- 1 4931281 PDFDocument7 pages1 4931281 PDFFina Mustika SimanjuntakNo ratings yet

- 42 IFRJ 21 (01) 2014 Zarinah 169Document5 pages42 IFRJ 21 (01) 2014 Zarinah 169putriNo ratings yet

- Determinarea Proteinelor La UleiuriDocument8 pagesDeterminarea Proteinelor La UleiuriVoicu ValeriuNo ratings yet

- Dairy Permeate Standard: Product DefinitionDocument2 pagesDairy Permeate Standard: Product DefinitionEvan KeeNo ratings yet

- CIE MechanismDocument6 pagesCIE MechanismEvan KeeNo ratings yet

- Specific Gravity and Aeration in BatterDocument2 pagesSpecific Gravity and Aeration in BatterEvan KeeNo ratings yet

- GS Resting TubeDocument2 pagesGS Resting TubeEvan KeeNo ratings yet

- Food Engineering Aspects of Baking Sweet GoodsDocument30 pagesFood Engineering Aspects of Baking Sweet GoodsEvan KeeNo ratings yet

- CHT - Hfa - Girls - Z - 2 - 5 WHO Growth ChartDocument1 pageCHT - Hfa - Girls - Z - 2 - 5 WHO Growth ChartEvan KeeNo ratings yet

- Creativity & Innovation Brainstorming TechniquesDocument50 pagesCreativity & Innovation Brainstorming TechniquesFirdhaus SakaffNo ratings yet

- MK Slide PDFDocument26 pagesMK Slide PDFPrabakaran NrdNo ratings yet

- Michael Parenti - The Demonization of Slobodan MilosevicDocument9 pagesMichael Parenti - The Demonization of Slobodan MilosevicRicardo Castro Camba100% (1)

- Dubai TalesDocument16 pagesDubai Talesbooksarabia100% (2)

- Eapp Module 1Document6 pagesEapp Module 1Benson CornejaNo ratings yet

- Exposicion Verbos y AdverbiosDocument37 pagesExposicion Verbos y AdverbiosmonicaNo ratings yet

- The Peppers, Cracklings, and Knots of Wool Cookbook The Global Migration of African CuisineDocument486 pagesThe Peppers, Cracklings, and Knots of Wool Cookbook The Global Migration of African Cuisinemikefcebu100% (1)

- Why-Most Investors Are Mostly Wrong Most of The TimeDocument3 pagesWhy-Most Investors Are Mostly Wrong Most of The TimeBharat SahniNo ratings yet

- SKI Report2008 - 50 2Document46 pagesSKI Report2008 - 50 2nada safitriNo ratings yet

- UntitledDocument8 pagesUntitledMara GanalNo ratings yet

- The Impact of Video Gaming To The Academic Performance of The Psychology Students in San Beda UniversityDocument5 pagesThe Impact of Video Gaming To The Academic Performance of The Psychology Students in San Beda UniversityMarky Laury GameplaysNo ratings yet

- Mod B - HSC EssayDocument11 pagesMod B - HSC EssayAryan GuptaNo ratings yet

- A Management and Leadership TheoriesDocument43 pagesA Management and Leadership TheoriesKrezielDulosEscobarNo ratings yet

- Hanssen, Eirik.Document17 pagesHanssen, Eirik.crazijoeNo ratings yet

- Fundamentals of Marketing Management: by Prabhat Ranjan Choudhury, Sr. Lecturer, B.J.B (A) College, BhubaneswarDocument53 pagesFundamentals of Marketing Management: by Prabhat Ranjan Choudhury, Sr. Lecturer, B.J.B (A) College, Bhubaneswarprabhatrc4235No ratings yet

- God As CreatorDocument2 pagesGod As CreatorNeil MayorNo ratings yet

- Being Mortal: Medicine and What Matters in The EndDocument15 pagesBeing Mortal: Medicine and What Matters in The EndEsteban0% (19)

- Presente Progresive TenseDocument21 pagesPresente Progresive TenseAriana ChanganaquiNo ratings yet

- ESC Cardiomyopathy ClassificationDocument7 pagesESC Cardiomyopathy Classificationvalerius83No ratings yet

- Sample File: A of TheDocument6 pagesSample File: A of TheMegan KennedyNo ratings yet

- Item Bank - Science 5 - 2ND QuarterDocument11 pagesItem Bank - Science 5 - 2ND QuarterJasmine AguilaNo ratings yet

- Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsDocument2 pagesCriteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsReyno D. Paca-anasNo ratings yet

- Geographical Milieu of Ancient KashiDocument14 pagesGeographical Milieu of Ancient Kashismk11No ratings yet

- Norman 2017Document7 pagesNorman 2017Lee HaeunNo ratings yet

- Tfa Essay RubricDocument1 pageTfa Essay Rubricapi-448269753No ratings yet

- ENG101 Final Term NOTES by VU LearningDocument15 pagesENG101 Final Term NOTES by VU LearningAbdul WahabNo ratings yet

- Project Dayan PrathaDocument29 pagesProject Dayan PrathaSHREYA KUMARINo ratings yet

- Project Report On Amazon vs. FlipkartDocument86 pagesProject Report On Amazon vs. FlipkartDimple100% (3)

- NAT FOR GRADE 12 (MOCK TEST) Language and CommunicationDocument6 pagesNAT FOR GRADE 12 (MOCK TEST) Language and CommunicationMonica CastroNo ratings yet