Professional Documents

Culture Documents

Senior Quality Engineer in Houston TX Resume Frank Medrano

Uploaded by

FrankMedrano0 ratings0% found this document useful (0 votes)

90 views2 pagesFrank Medrano is a highly motivated value-adding professional with precise communication skills, proven leadership abilities and extensive experience in the Quality Engineering field.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFrank Medrano is a highly motivated value-adding professional with precise communication skills, proven leadership abilities and extensive experience in the Quality Engineering field.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views2 pagesSenior Quality Engineer in Houston TX Resume Frank Medrano

Uploaded by

FrankMedranoFrank Medrano is a highly motivated value-adding professional with precise communication skills, proven leadership abilities and extensive experience in the Quality Engineering field.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

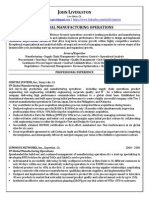

FRANK MEDRANO

Meadows Place, Texas 77477

Cell: 832-236-1161

`````

I am a highly motivated value-adding professional with precise communication skills, proven leadership abilities

and extensive experience in the Quality Engineering field. I have thirteen years of experience working all facets of

the Quality Engineering field including product line support, supplier quality issues, handling customer complaints

and new product development.

Experience:

Pentair/ Tyco Valves and Controls (Stafford, Texas): Pressure Relief Valves

Senior Quality Engineer (2007 to 2015)

- Nominated by Plant Manager to lead Facility Lean Manufacturing Root Cause Countermeasure (RCCM) effort

for multiple facilities which required introducing and motivating 130 team members and completing 23

projects from multiple departments. This was successfully completed in less than 18 months.

- RCCM Projects included: 90% Valve documentation error reduction and 65% product line defect reduction.

- Driving Lean manufacturing process documentation to identify, address and fix process &/or tact time

opportunities from zero documentation in less than 2 years.

- Introduced and Administered facility nonconformance and Supplier Quality improvement. This initiative gave

us the opportunity to identify and eliminate our two worst performing suppliers. Championed Sarbanes Oxley

initial facility compliance.

- Initiated, built and actualized certificate website for 8 facilities (670+ certificates). Continued to manage and

eliminate expired certificate. This led directly to our site being used as a worldwide model by the Sales and

Marketing group to determine capability.

- Oversaw facility third party, customer audits and customer survey information which resulted in dramatically

reducing documentation preparation by over 50% in most cases. This included ASME, ISO9000, Type Approval,

China TS certificate, Korea KGSC and Canadian Registration Numbers.

- Reversed negative customer viewpoint on Quality Assurance documentation in under 14 days which resulted

in being allowed to ship product, clear up floor space and eliminate possible safety and quality issues. This

customer had not accepted any documentation packages in the prior 6 months.

- Introduced innovative and alternative customer witness activity to reduce and eliminate on site customer

visits, multiple product testing,

o Safety and quality space issues free up test stand capacity and QA Specialist support time.

- Created and drove implementation of Indian Boiler requirements to allow for prompt shipments.

- Created documentation to address QA Document process. Maintained all facility Quality ISO9000

documentation.

Borg Warner (Sallisaw, Oklahoma): Automotive Oil Pumps

Quality Engineer: 2005 to 2006

- Responsible for APQP documentation. Integral to customer complaint interface and audit/ project

requirements.

- Completed Lean Manufacturing Certificate at University of Arkansas at Fort Smith.

- Helped prepare for TS16949. Performed internal audits, completed Measurement System Analysis projects

and developed supplier evaluation matrix.

Guide Corporation (Monroe Louisiana): Automotive Headlamps

Quality Engineer: 2002 to 2005

FRANK MEDRANO

Meadows Place, Texas 77477

Cell: 832-236-1161

Guided scrap percentage reduction from 4% to 1% in less than 30 days resulting in over a $1,000,000 savings.

Reduced first time yield defects over 50% on new product introduction line within the first five production

months.

Identified, tested, recommended and implemented vendor component design change that reduced new

product fall off by over 40%.

Conceived and verified several error-proofing ideas that eliminated process defects on new and existing

production lines.

Motorola (Fort Worth, Texas): Telecommunications

Manufacturing Engineer: 2000 to 2001

Changed stencil component design, which reduced RF component process defects from a PPM of 230 to 20

(the number one defect issue at this time).

Implemented cross training system, which was considered a benchmark practice by the TL9000 auditor.

Completed Six Sigma Black Belt training.

Pass & Seymour/ Legrand (San Antonio, Texas): Consumer Electronic Products

Manufacturing Engineering Manager: 1991 to 2000

Transferred newly purchased and other facility production lines. Modified production operations and coached

engineers in meeting customer requirements to yield 40% more products without adding overtime.

Implemented Kanban for six production lines and changed the production line layout, which reduced raw and

WIP inventory by 1,000,000 which freed up 10,000 sq. ft. and improved facility profit margin by 60% in 3

years.

Implemented operator training matrix that improved quality, completed cross training and satisfied customer

need spikes. Matrix improved operator and maintenance knowledge to achieve a win-win situation.

Established and wrote over 40 assembly procedures that were ISO9000 compliant.

Improved productivity and tact time by 20% using Theory of Constraints while adding zero capital which

accounted for 240,000 in savings. Taught and developed engineers to identifying and exploiting bottlenecks.

Sparked identification and elimination of duplicate tests that increased tester utilization by 50%.

Led FEMA completion and developed staff skills on new product that eliminated 5% of labor cost, improved

product documentation and quality mistake proofing plus identified future productivity improvements.

Specified and implemented high variety/low volume SMT production line equipment that satisfied customer

needs and was under budget.

Implemented set up reductions on maintenance and production bottleneck operations that resulted in

higher employee productivity by avoiding the need to add personnel to the payroll.

Managed preventive maintenance analysis that was compliant with ISO9000 and reduced PM hours 5% yearly

for 3 years.

Led change to add facility BOMs and labor costs from homegrown MRP system to ASI MRP that resulted in

meeting schedule of transferring over to corporate system.

Eliminated $90,000 per yr. in labor standards negotiation with subcontracting facility within a 2 day trip.

Eliminated 50-70% of touch up soldering problems on 3 lines that eliminated 1 repair operator.

Education:

Degree:

Texas A&M University

Bachelor of Science, Industrial Engineering

1987

You might also like

- Quality Manager or Quality EngineerDocument3 pagesQuality Manager or Quality Engineerapi-77217896No ratings yet

- Todd ShuderDocument3 pagesTodd ShuderToddShuderNo ratings yet

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDocument3 pagesDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2No ratings yet

- VP Director Manufacturing Operations in NYC Resume Mark IgnatowiczDocument3 pagesVP Director Manufacturing Operations in NYC Resume Mark IgnatowiczMarkIgnatowiczNo ratings yet

- Sample Resume Process Engineer Economic RecoveryDocument10 pagesSample Resume Process Engineer Economic RecoveryVijay RajaindranNo ratings yet

- Quality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanDocument4 pagesQuality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanJoannesHuseanNo ratings yet

- Experienced DGM seeks senior roleDocument5 pagesExperienced DGM seeks senior rolekavas26No ratings yet

- Quality DirectorDocument3 pagesQuality Directorapi-78871699No ratings yet

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocument2 pagesManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNo ratings yet

- Production Manager or Production SupervisorDocument3 pagesProduction Manager or Production Supervisorapi-121382640No ratings yet

- Manufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryDocument3 pagesManufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryWilliamCaryNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- Manufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseDocument3 pagesManufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseMichaelFranzeseNo ratings yet

- Juan Fadrique Molina Naranjo RESUME Rev9Document6 pagesJuan Fadrique Molina Naranjo RESUME Rev9juan molinaNo ratings yet

- Engineering Manager ResumeDocument10 pagesEngineering Manager ResumeJameel KhanNo ratings yet

- UntitledDocument2 pagesUntitledapi-77018179No ratings yet

- Quality EngineerDocument4 pagesQuality Engineerapi-78526036No ratings yet

- Plant Manager Production in Madison WI Resume Bill StechDocument2 pagesPlant Manager Production in Madison WI Resume Bill StechBillStechNo ratings yet

- Director Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerDocument5 pagesDirector Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerGarySteinerNo ratings yet

- Vice President Quality Operations in Greater Chicago IL Resume Kevin FredrichDocument2 pagesVice President Quality Operations in Greater Chicago IL Resume Kevin FredrichKevin Fredrich1No ratings yet

- Manufacturing Process Improvement EngineerDocument4 pagesManufacturing Process Improvement Engineerapi-77387206No ratings yet

- Original HM Resume5A21-1Document4 pagesOriginal HM Resume5A21-1hm4454No ratings yet

- Manager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaDocument3 pagesManager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaPhillip TapiaNo ratings yet

- Jaime M. Ramirez: Engineering / Operations / Plant ManagerDocument4 pagesJaime M. Ramirez: Engineering / Operations / Plant ManagerjaimejaimearturoNo ratings yet

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 pagesProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsNo ratings yet

- General Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyDocument2 pagesGeneral Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyKevinKelseyNo ratings yet

- Chief Operations Officer in Chicago IL Resume Pat KestnerDocument2 pagesChief Operations Officer in Chicago IL Resume Pat KestnerpatkestnerNo ratings yet

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraNo ratings yet

- Vice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDocument2 pagesVice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDennisThomasNo ratings yet

- Resume of BlouinrDocument3 pagesResume of Blouinrapi-30207141No ratings yet

- Chemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyDocument2 pagesChemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyTessaKelleyNo ratings yet

- Chad Vorse Resume AllDocument2 pagesChad Vorse Resume Allapi-253814297No ratings yet

- Quality Control & Assurance SystemsDocument42 pagesQuality Control & Assurance Systemssurender20111991No ratings yet

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFpandajayNo ratings yet

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDocument2 pagesOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2No ratings yet

- Plant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanDocument3 pagesPlant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanSamuelBeamanNo ratings yet

- Quality Technical Leader in Marietta GA Resume Wayne BoldenDocument2 pagesQuality Technical Leader in Marietta GA Resume Wayne BoldenWayneBoldenNo ratings yet

- Manufacturing Engineer Production Manager in New York City Resume Ivan DominguezDocument2 pagesManufacturing Engineer Production Manager in New York City Resume Ivan DominguezIvanDominguezNo ratings yet

- Director Manufacturing Supply Chain Quality in Roanoke VA Resume Laurence GilDocument2 pagesDirector Manufacturing Supply Chain Quality in Roanoke VA Resume Laurence GilLaurenceGilNo ratings yet

- LEAN Manufacturing Engineer in Santa Ana Orange County CA Resume Brent YamamotoDocument2 pagesLEAN Manufacturing Engineer in Santa Ana Orange County CA Resume Brent YamamotoBrentYamanotoNo ratings yet

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonDocument2 pagesVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2No ratings yet

- Senior Director Software QA in Dallas FT Worth TX Resume James CanterDocument3 pagesSenior Director Software QA in Dallas FT Worth TX Resume James CanterJamesCanterNo ratings yet

- Richard Newman ResumeDocument2 pagesRichard Newman ResumeRichNo ratings yet

- Sample Resume - GKN AerospaceDocument2 pagesSample Resume - GKN AerospaceRolndoNo ratings yet

- Automotive Quality Director Bilingual in Tyler Texas Resume Cesar Ruiz de ChavezDocument2 pagesAutomotive Quality Director Bilingual in Tyler Texas Resume Cesar Ruiz de ChavezCesar Ruiz de ChavezNo ratings yet

- EHubbert Resume2Document3 pagesEHubbert Resume2ehubbNo ratings yet

- VP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaDocument3 pagesVP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaJoelCamardaNo ratings yet

- Senior Director Software QA in Dallas FT Worth TX Resume James CanterDocument4 pagesSenior Director Software QA in Dallas FT Worth TX Resume James CanterJamesCanter2No ratings yet

- Quality ManualDocument45 pagesQuality Manualhmp90100% (1)

- Frank Resume 2014Document2 pagesFrank Resume 2014api-249007095No ratings yet

- Abhishek Consultant ResumeDocument4 pagesAbhishek Consultant ResumeAbhishek SrivastvaNo ratings yet

- ASD CV Jan 21Document4 pagesASD CV Jan 21Anil DesaleNo ratings yet

- Richard Ray - QA - CI ResumeDocument3 pagesRichard Ray - QA - CI ResumeRick RayNo ratings yet

- Director Operations Apparel Textiles Worldwide Resume Michael Marazzo JRDocument2 pagesDirector Operations Apparel Textiles Worldwide Resume Michael Marazzo JRMichaelMarazzoJrNo ratings yet

- Shubailat - Omar - Quality and MBA Leadership Resume (June 09)Document3 pagesShubailat - Omar - Quality and MBA Leadership Resume (June 09)Omar ShubailatNo ratings yet

- Quality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaDocument4 pagesQuality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaArunNo ratings yet

- Curri Carlos 3ene2011Document3 pagesCurri Carlos 3ene2011carlosNo ratings yet

- HP Laserjet Pro MFP M127 Series: Handle The Essentials With One Affordable, Networked MFPDocument2 pagesHP Laserjet Pro MFP M127 Series: Handle The Essentials With One Affordable, Networked MFPAndrew MarshallNo ratings yet

- 1 P&ID Diagram D - 10MAG1CSD422837 Martina Lengert Martina Lengert 2013-11-06Document2 pages1 P&ID Diagram D - 10MAG1CSD422837 Martina Lengert Martina Lengert 2013-11-06Baltasar BuchiniNo ratings yet

- Sip Group 4 Chapter 1Document6 pagesSip Group 4 Chapter 1markism RNNo ratings yet

- VoLTE 1Document28 pagesVoLTE 1raad79No ratings yet

- Tracer AN Series Solar Charge Controller User ManualDocument44 pagesTracer AN Series Solar Charge Controller User ManualtalibanindonesiaNo ratings yet

- Class 11 Computer Science (Society Law and Ethics)Document19 pagesClass 11 Computer Science (Society Law and Ethics)prateekurmaliya5No ratings yet

- Virtual Gym Trainer App Tracks Your WorkoutsDocument6 pagesVirtual Gym Trainer App Tracks Your Workouts6581 Amaan ShaikhNo ratings yet

- Case Study II - RoffDocument3 pagesCase Study II - RoffNikhil MaheshwariNo ratings yet

- Quiz Questions on Internet ConceptsDocument3 pagesQuiz Questions on Internet Conceptsjohn100% (1)

- Chap5 - Samsung LTE-LSM Overview and PracticeDocument221 pagesChap5 - Samsung LTE-LSM Overview and Practiceabhay100% (2)

- Alseca Innovation Mar2021 15Document20 pagesAlseca Innovation Mar2021 15Gabriel BodeaNo ratings yet

- PCS-9705 Bcu - V1.00Document29 pagesPCS-9705 Bcu - V1.00Bharath ErNo ratings yet

- PMDG 737 Checklist 2.0 LightDocument6 pagesPMDG 737 Checklist 2.0 LightHenry O'sunaNo ratings yet

- Buffering in Operating System - JavatpointDocument7 pagesBuffering in Operating System - JavatpointkkkkNo ratings yet

- Solartility LED Emergency Light Catalogue 201608Document1 pageSolartility LED Emergency Light Catalogue 201608Dhawn Aciong TaoaguenNo ratings yet

- Azure ML DocumentationDocument731 pagesAzure ML DocumentationkewlgeekNo ratings yet

- 07 DiagnosticsDocument124 pages07 DiagnosticsManuel KusminskyNo ratings yet

- GPS World 2020-01Document54 pagesGPS World 2020-01Diego FrancoNo ratings yet

- Transient Performance of CVTsDocument3 pagesTransient Performance of CVTsajaysitaula8478No ratings yet

- Adcmxl1021-1 - Sensor Analogic 1 Eixos FFT - Ideia de Fazer Do Acell Analog Um Digital Usando Adxl1002Document42 pagesAdcmxl1021-1 - Sensor Analogic 1 Eixos FFT - Ideia de Fazer Do Acell Analog Um Digital Usando Adxl1002FabioDangerNo ratings yet

- MS-RPC UUID Mappings - Juniper NetworksDocument4 pagesMS-RPC UUID Mappings - Juniper NetworksMobileDickNo ratings yet

- Design and Construction Standards For Kiosk Type SubstationsDocument37 pagesDesign and Construction Standards For Kiosk Type SubstationsFlo MircaNo ratings yet

- Difference Between ECN, ECR, ECODocument3 pagesDifference Between ECN, ECR, ECOmkumarshahiNo ratings yet

- Operation Manual of REDLIFT R Series IC ForkliftDocument153 pagesOperation Manual of REDLIFT R Series IC Forkliftroberto_robledo_6No ratings yet

- Capstan c500hDocument13 pagesCapstan c500hakbar muslimNo ratings yet

- Accenture B2B Customer Experience InfographicDocument1 pageAccenture B2B Customer Experience Infographicmahesh_mirle100% (2)

- CEC3010 - DATA-PRIVACY-AND-SECURITY-IN-BUSINESS - LT - 1.0 - 41 - Data Privacy and Security in BusinessDocument3 pagesCEC3010 - DATA-PRIVACY-AND-SECURITY-IN-BUSINESS - LT - 1.0 - 41 - Data Privacy and Security in BusinessRevanta ChoudharyNo ratings yet

- 4800 Baud Modem Daughter Board PDFDocument12 pages4800 Baud Modem Daughter Board PDFpalahobaraNo ratings yet

- 2017 - 746 in Vitro Diagnostic Medical Devices - Summary List of Harmonised Standards - Generated On 12.5.2022 PDFDocument3 pages2017 - 746 in Vitro Diagnostic Medical Devices - Summary List of Harmonised Standards - Generated On 12.5.2022 PDFsaberNo ratings yet

- CNS-9101 SM PDFDocument70 pagesCNS-9101 SM PDFhadiiir pal100% (1)