Professional Documents

Culture Documents

p355n NH Nl1 Nl2 Tubes

Uploaded by

Miclea Dragos-CostinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p355n NH Nl1 Nl2 Tubes

Uploaded by

Miclea Dragos-CostinCopyright:

Available Formats

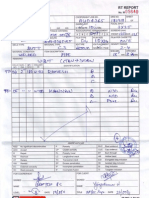

ThyssenKrupp Materials International

Alloy fine grain steel tubes

Material Data Sheet

Steel designation:

Name

Material No.

P355N

P355NH

P355NL1

P355NL2

1.0562

1.0565

1.0566

1.1106

Scope

This data sheet applies for seamless and welded alloy fine grain steel tubes with circular diameter.

Application

These normalized fine grain steels suit for pressure equipment for apparatus engineering, pressure pipe lines as well as for

hot worked construction parts.

This steels are specially suited for constructions, to which requirements regarding impact strength at low temperatures

and/or requirements regarding aging resistance are made.

Chemical composition (heat analysis in %)

Steel grade

Si

Mn

Al

Cr*

0,020

0,020

0,30

P355N

0,20

P355NH

0,020

0,50

0,90-1,70

0,025

P355NL1

0,18

P355NL2

Steel grade

0,015

Cu*

Mo*

Nb

Ni

Ti

Nb + Ti + V

0,30

0,08

0,05

0,50

0,03

0,10

0,12

P355N

P355NH

P355NL1

P355NL2

* The allowed total mass content of the three elements chromium, copper und molybdenum is 0,45 %.

Page 1 Material data sheet P355N/NH/NL1/NL2

09/2011

ThyssenKrupp Materials International

Mechanical properties at room temperature

Steel grade

Upper yield strength R eH or

proof strength R p0,2,min

N/mm

for wall thickness T in mm

Delivery

condition

355

> 12

20

P355N

P355NH

P355NL1

P355NL2

> 20

40

345

> 40

50

335

l = longitudinal

3)

t = transverse

22

20

> 50

65

325

> 65

80

315

> 20

40

490 bis 630

> 40

65

> 80

100

N = normalized; normalized rolled

t3)

20

490 bis 650

> 65

100

450 bis 590

2)

l2)

12

N1)

1)

Elongation

A

%

min.

Tensile Strength R m

N/mm

for wall thicknessn T in mm

305

Minimum values for impact test

Minimum average absorbed engery KV in J

Steel grade

Treatment

condition

Product

thickness

longitudinal

transverse

At a temperature of c

mm

- 40

- 20

+ 20

- 40

- 20

+ 20

P355N

40

40

47

55

27

35

39

P355NH

> 40 - 65

45

50

31

35

40

40

53

65

70

27

35

43

47

> 40 - 65

47

60

65

31

39

43

40

50

70

90

100

33

47

60

70

> 40 - 65

40

60

80

90

27

40

53

60

P355NL1

normalized

P355NL2

Page 2 Material data sheet P355N/NH/NL1/NL2

09/2011

ThyssenKrupp Materials International

Minimum proof strength Rp0,2 at elevated temperatures

Wall thickness

T

mm

Material

number

Steel grade

0,2 %-prrof strength at a temperature of C

100

150

200

250

300

350

400

in N/mm

P355NH

1.0565

20

304

284

255

235

216

196

167

> 20 bis 50

294

275

255

235

216

196

167

> 50 bis 65

284

265

245

226

206

186

157

> 65 bis 80

275

255

235

216

196

177

147

> 80 bis 100

265

245

226

206

186

167

137

Reference data for some physical properties

Density at

20 C

Modulus of elasticity

kN/mm at

Thermal conductivity

at 20 C

spec. thermal

capacity at 20 C

spec. electrical

resistivity at 20 C

Kg/dm

20 C

200 C

300 C

400 C

W/m K

J/kg K

mm/m

7,82

212

199

192

184

48,0

461

0,22

Linear coefficient 106 K-1 of thermal expansion between 20 C and

100 C

200 C

300 C

400 C

12,5

13,0

13,6

14,1

Hot forming / Heat treatment (for guidance only)

Hot forming

Heat treatment

Temperature C

Type of cooling

Normalizing 1)

Stress relieving anneal 2)

Type of cooling

1100 - 950

Air

890 - 950 C

570 - 620 C

Air

1)

Normalizing: Holding time 1 minute per mm plate thickness, minimum 30 minutes

2)

Stress relieving anneal: Holding time 1-2 minutes per mm plate thickness, minimum 30 minutes

Processing / Welding

Standard welding processes for these steel grades are:

TIG-welding

Arc welding (E)

MAG-welding solid wire

Submerged arec welding (SAW)

MAG-welding cored wire

Page 3 Material data sheet P355N/NH/NL1/NL2

09/2011

ThyssenKrupp Materials International

For these steel grades as filler metal the following electrodes and welding wires are recommended.

Process

Filler metal

TIG

Union I 1,2 Ni

MAG solid wire

Union K5 Ni

MAG cored wire

Union RV Ni 1

Arc welding (E)

SAW

Phoenix SH V 1

(Phoenix 120K)

Union S 2 Ni 370 - UV 421 TT

These steels can be welded within all thickness ranges according to the afore mentioned welding processes considering

the general rules of technology by hand and automatically welding.

The mentioned filler metals apply for highest demands. The details in brackets are for lower demands.

Hot and cold forming can be performed without and difficulties.

The material suits well for machining

For outside temperatures below +5 C and for wall thicknesses larger than 30 mm a preheating up to 50 to 150 C is

recommended for flame cutting and welding.

The tube surface should be free from condensation water in any case.

Burning, preheating, welding and stress relieving annealing should occur under consideration of Stahl-Eisen-Material

bulletin 310.

Specifications and standards concerning stress relieving anneal have to be observed.

Remark

The material is magnetizable.

Editor

THYSSENKRUPP MATERIALS INTERNATIONAL GMBH

Technical Sales / Quality Management

Am Thyssenhaus 1

45128 Essen

References

DIN EN 10216-3:2004-07

Beuth Verlag GmbH, Postfach, D-10772 Berlin

DIN EN 10217-3:2005-05

Stahl-EISEN-Bulletin 310:1992-08

Verlag Stahleisen GmbH, Postfach 10 51 64, D-40042 Dsseldorf

Bhler Schweisstechnik Deutschland GmbH, Hamm

Important Hint

Information given in this data sheet about property or applicability of materials respective products are no

assurance of characteristics but serve for description.

Information, with which we like to advise you, relate to the experience of the producers and our own.

Warranty for the results of the treatment and application of the products cannot be granted.

Page 4 Material data sheet P355N/NH/NL1/NL2

09/2011

You might also like

- Iso 12952 10 2021Document20 pagesIso 12952 10 2021Jim Frenken100% (1)

- Application Form For CSWIP 10 Year Re-Certification (Overseas) With LogbookDocument4 pagesApplication Form For CSWIP 10 Year Re-Certification (Overseas) With LogbookapkramjiNo ratings yet

- Leakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Document5 pagesLeakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Ashfaq AnwerNo ratings yet

- Pressure Vessels and EquipmentDocument16 pagesPressure Vessels and EquipmentwenigmaNo ratings yet

- HAZOP Study Checklist (26092011) - 6 PDFDocument1 pageHAZOP Study Checklist (26092011) - 6 PDFHina ImranNo ratings yet

- WQT For CSDocument5 pagesWQT For CSkumar08686No ratings yet

- DIN 2460 Steel Pipes WaterDocument5 pagesDIN 2460 Steel Pipes WaterAhmed BoussoffaraNo ratings yet

- Closure Data PEDocument2 pagesClosure Data PEjowarNo ratings yet

- ASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesDocument1 pageASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesJose Rodrigo Salguero DuranNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- En 10028 2 Non Alloy and Alloy Steels For Pressure PurposesDocument2 pagesEn 10028 2 Non Alloy and Alloy Steels For Pressure PurposesPatilea DanielaNo ratings yet

- Valve Leakage Rates Test STDDocument5 pagesValve Leakage Rates Test STD윤병택No ratings yet

- Iso 12952 2 2021Document46 pagesIso 12952 2 2021Jim FrenkenNo ratings yet

- Nikopol Steel Pipe Plant Yutist Seamless Steel TubesDocument2 pagesNikopol Steel Pipe Plant Yutist Seamless Steel Tubesvishal.nitham100% (1)

- Atex Eng PDFDocument1 pageAtex Eng PDFENo ratings yet

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- 21Document6 pages21Dannis AnantoNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- 39NiCrMo3 steel technical cardDocument2 pages39NiCrMo3 steel technical cardLokesh Krishnappa100% (1)

- Application Form For CSWIP 10 Year Assessment (Overseas) No LogbookDocument10 pagesApplication Form For CSWIP 10 Year Assessment (Overseas) No LogbookKarthikeyanNo ratings yet

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- Failure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresDocument10 pagesFailure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresGECJNo ratings yet

- Iso 12952 6 2021Document38 pagesIso 12952 6 2021Jim FrenkenNo ratings yet

- ASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1Document23 pagesASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1John PaulNo ratings yet

- SSSS RequirementDocument15 pagesSSSS RequirementWanping TangNo ratings yet

- Class P15A6Document7 pagesClass P15A6SalimNo ratings yet

- Unstiffened Cylinders en 13445-3 - 8.5.2Document4 pagesUnstiffened Cylinders en 13445-3 - 8.5.2met-calcNo ratings yet

- Brochure HPX1 PLUS 201601Document8 pagesBrochure HPX1 PLUS 201601Serkan KılıçaslanNo ratings yet

- ASME Section 1 and Pressure Equipment DirectiveDocument5 pagesASME Section 1 and Pressure Equipment DirectivealextentwentyNo ratings yet

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- En 13445 WPS PQR WPQDocument5 pagesEn 13445 WPS PQR WPQmuhammad hadiNo ratings yet

- Pressure Vessel Design RequirementsDocument6 pagesPressure Vessel Design RequirementsLDM Man. e Mont. Ind. EIRELINo ratings yet

- Steam Power Plant and CoalDocument74 pagesSteam Power Plant and CoalRahul SoniNo ratings yet

- Blind Flange Test Flange API 6a Spec SheetDocument1 pageBlind Flange Test Flange API 6a Spec SheetahnafNo ratings yet

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- Radiographic Examination Procedure For Asme CodeDocument33 pagesRadiographic Examination Procedure For Asme CodeEdAlmNo ratings yet

- Destructive testing query for gathering pipelinesDocument10 pagesDestructive testing query for gathering pipelinesZaidiNo ratings yet

- Gantrail Welded Base Fixing: SpecificationsDocument2 pagesGantrail Welded Base Fixing: Specificationsaandueza_1No ratings yet

- l7 AngDocument9 pagesl7 AngAnonymous SLI4aGNo ratings yet

- Installation of Distribution-to-Utilization Voltage TransformersDocument7 pagesInstallation of Distribution-to-Utilization Voltage TransformersadauNo ratings yet

- Cen TR 13480-7 (2002) (E)Document6 pagesCen TR 13480-7 (2002) (E)g9g9No ratings yet

- 186-19 Wpqc-W162-2''-Asme XiDocument1 page186-19 Wpqc-W162-2''-Asme Xibouchoucha jebaliNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Firefighting KksDocument63 pagesFirefighting KksLeonardo Ernesto Cornejo PinoNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- HAZOP Study Checklist (26092011) - 3Document1 pageHAZOP Study Checklist (26092011) - 3Hina ImranNo ratings yet

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDocument2 pagesTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanNo ratings yet

- PED Presentation - Client Animation1 (Compatibility Mode)Document11 pagesPED Presentation - Client Animation1 (Compatibility Mode)shabbir626No ratings yet

- TRD 301 Annex 1 Design PDFDocument14 pagesTRD 301 Annex 1 Design PDFarjun prajapatiNo ratings yet

- Gouging ProcedureDocument11 pagesGouging Procedurealizadeh222275% (4)

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- Pressure Gauge Calibration TG13 Version 2 December 2017Document6 pagesPressure Gauge Calibration TG13 Version 2 December 2017iptNo ratings yet

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsNo ratings yet

- ThyssenKrupp Steel Data Sheet P235GHDocument4 pagesThyssenKrupp Steel Data Sheet P235GHjaseerkannothNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- 1.4462 EN-material Duplex PDFDocument3 pages1.4462 EN-material Duplex PDFtien100% (1)

- P460ML1Document2 pagesP460ML1Christiam Bernal MurilloNo ratings yet

- Hot-Rolled Coils For The Manufacture of Large-Diameter PipesDocument2 pagesHot-Rolled Coils For The Manufacture of Large-Diameter PipesismailinesNo ratings yet

- My career and vision for improving engineering processesDocument14 pagesMy career and vision for improving engineering processesMiclea Dragos-CostinNo ratings yet

- Piping Isometric TutorialDocument45 pagesPiping Isometric Tutorialcepong89100% (1)

- Piping Isometric TutorialDocument45 pagesPiping Isometric Tutorialcepong89100% (1)

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- 2014 PTQ q1Document156 pages2014 PTQ q1coolvishal2003100% (1)

- Royalene 301T TDSDocument1 pageRoyalene 301T TDSMohamed BendoudouchNo ratings yet

- Jsabuilder: Job Safety AnalysisDocument5 pagesJsabuilder: Job Safety Analysisandika eka putraNo ratings yet

- 4th Question Experimental TechniquesDocument10 pages4th Question Experimental TechniquesHayaa KhanNo ratings yet

- Gas Tungsten Arc WeldingDocument1 pageGas Tungsten Arc WeldingabhibawaNo ratings yet

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument184 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingDivya Soni0% (1)

- AlcoTec Alloy Filler ChartDocument1 pageAlcoTec Alloy Filler CharttxspacecadetNo ratings yet

- TW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Document17 pagesTW BF 01 - Barstock Flanged Type Thermowell (Straight) : TWBF - 01Mangesh MohiteNo ratings yet

- R 141 BDocument5 pagesR 141 BBuilt InNo ratings yet

- Sutton Tools Black Books CatalogueDocument4 pagesSutton Tools Black Books CatalogueAitor Miguel SobrevillaNo ratings yet

- Gulf Precast GRCDocument12 pagesGulf Precast GRCmujeebscribdNo ratings yet

- Adhesive Bonding 2Document67 pagesAdhesive Bonding 2Saud Aidrus100% (1)

- Degreasers Program Eng 0 PDFDocument8 pagesDegreasers Program Eng 0 PDFtopguitarNo ratings yet

- Review Paper Abpout TiO2 For Food Packaging - 2022Document12 pagesReview Paper Abpout TiO2 For Food Packaging - 2022Nguyễn SơnNo ratings yet

- Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Inert Gas Fusion TechniquesDocument22 pagesDetermination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Inert Gas Fusion Techniquessoobee khanNo ratings yet

- Mendina, Camille D 11-Stem CuriosityDocument4 pagesMendina, Camille D 11-Stem CuriosityBryan Philip BejeranoNo ratings yet

- A Brief History of Indian Alchemy Covering Transi-Tional and Tantric Periods (Circa 800 A.D. - 1300 A. D)Document27 pagesA Brief History of Indian Alchemy Covering Transi-Tional and Tantric Periods (Circa 800 A.D. - 1300 A. D)neelakantasiddaNo ratings yet

- Bio ElementsDocument28 pagesBio ElementsBioinformatics Biotechnology100% (1)

- Chemistry Lab - 15 - Solubility Curve For KNO3Document4 pagesChemistry Lab - 15 - Solubility Curve For KNO3Nader AwadNo ratings yet

- A Detailed Lesson Plan in Chemical ReactionsDocument7 pagesA Detailed Lesson Plan in Chemical Reactionsgorio98% (52)

- Reactions of Keten. Part Kinetics of The Gas-Phase Reaction With Acetic AcidDocument2 pagesReactions of Keten. Part Kinetics of The Gas-Phase Reaction With Acetic AcidRafli ZulfikarNo ratings yet

- 4 Chemical Accidents Emergency Planning Preparedness and Response Rules 1996Document27 pages4 Chemical Accidents Emergency Planning Preparedness and Response Rules 1996siddhrathNo ratings yet

- ASTM E353-93 Standard Test Methods For Chemical Analysis ofDocument33 pagesASTM E353-93 Standard Test Methods For Chemical Analysis ofAvishek guptaNo ratings yet

- PolyacetalDocument16 pagesPolyacetalChakma SHIMULNo ratings yet

- Chapter2-Campuran Pada Tingkat MolekulerDocument73 pagesChapter2-Campuran Pada Tingkat MolekulerAnnisah MardiyyahNo ratings yet

- Gram Equivalent Concept: Sunil Kumar SinghDocument9 pagesGram Equivalent Concept: Sunil Kumar Singhnitesh004No ratings yet

- 17 Inspissator FinthfhgDocument6 pages17 Inspissator FinthfhgArchieDuqueNo ratings yet

- Introduction To Cost Estimating Lec 1Document146 pagesIntroduction To Cost Estimating Lec 1Arwa HusseinNo ratings yet

- PPTDocument28 pagesPPTRaj KumarNo ratings yet

- Phase Rule PDFDocument42 pagesPhase Rule PDFAnonymous LGaFI1No ratings yet