Professional Documents

Culture Documents

15.05.10 Span Gases

Uploaded by

Trịnh Đức HạnhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15.05.10 Span Gases

Uploaded by

Trịnh Đức HạnhCopyright:

Available Formats

Wilhelmsen Ships Service

SPAN GASES

Text:

Thomas

Jacobsen

Span

Gases

What are Span gases?

Span gases are special gas mixtures used for testing gas detection equipment, which

requires regular checking and calibration (bump testing). Calibration is an important

issue for all testing instruments and is done by means of exposing the sensor to a

known concentration of a contaminant. The gases are used as a reference point to

ensure correct readings after calibration. The gases supplied by Wilhelmsen Ships

Service are suitable for calibration and testing of almost any type of gas detection

equipment presently used on board vessels.

The span gases supplied by Wilhelmsen Ships Service are subjected to strict quality

controls. The composition of each cylinder is tested and certified, usually for 3 years,

which reflects the guarantied stability of the gas.

We supply span gases in 3 different cylinder types: a 10 litre refillable cylinder and two

disposable cylinders called a Scotty cylinder and Minimix cylinder. The 10 litre is

recommended for gases that are used often while the disposable cylinders are perfect

for less frequently used gas types or when working in difficult locations on board.

Wilhelmsen Ships Service supplies around 60 different mixtures and pure gases to the

marine market, split into the following main groups:

Hydrocarbons & Air mixtures so called LEL mixtures

Hydrocarbons & Nitrogen mixtures mainly LEL mixtures

Carbon monoxide or Hydrogen sulfide mixtures

Oxygen & Nitrogen mixtures

Pure gases such as Nitrogen, Propane and Methane

How are the gases produced?

The gas mixtures are produced by two basic methods; gravimetric and volumetric.

Wilhelmsen Ships Service span gases are in most cases mixed using the gravimetric

process which ensures precise gas mixtures.

The gravimetric method is based on using finely calibrated scales to weigh the amount

of gas put into the cylinder. By adding components and subsequent weighing, the

composition can be set very accurately. The accuracy of the mix and the quality of the

filling are of vital importance as impurities can result in incorrect calibration.

A prerequisite for a stable mixture is a perfectly clean cylinder. The span gas cylinders

are cleaned by purging with high purity nitrogen followed by vacuuming. The strength of

the vacuum and the holding time of the vacuum are two factors determining the level of

cleanliness. For critical mixtures (i.e. ppm mixtures), the vacuuming is performed while

the cylinders are slightly heated to ensure that any product adhering to the inner surface

is removed.

Wilhelmsen Ships Service

After filling, the gas mixture must be thoroughly mixed to ensure that all components are

evenly distributed throughout the cylinder contents. Gases have a tendency not to mix

as easy as people might think, and when not properly mixed, the composition can vary

along the length of the cylinder. The commonest way of mixing gases is to place the

cylinders on horizontal rollers and rolling them for 2-4 hours.

After the mixing the gas cylinder content is ready to be certified. This means a sample of

the gas cylinder content is analysed to ensure the stated composition is actually inside

the cylinder. Wilhelmsen Ships Service uses an accuracy of 5% of the nominal

composition.

For example: 2.5% Methane in nitrogen is the nominal composition. The certified

composition will then be 2.5% 5% relative = 2.5% 0.125%. This is standard for

calibration and bump testing of gas detection equipment.

How long can I use the same gas cylinder?

Fairly small volumes of gas are used for span testing, which means that, in theory,

cylinders could be used for a long time. However, in practice this is not the case. Most

gases have a shelf life of 3 years after the actual filling and certifying, but in some cases

the shelf-life can be as low as 6-12 months, as is the case for mixtures containing

hydrogen sulphide.

Information on the shelf-life and filling date can always be found on the certificate of

analysis that comes with each refillable cylinder or on the label of disposable cylinders.

How much gas is there in a cylinder?

Refillable 10 litre 150/200 bar cylinder:

Most mixtures based on flammable gases are filled to around 100 bars. Higher

pressures are not possible because of the required stability of the mixture. The

total amount of gas is therefore approx 1000 litres. Using a flow rate of 1.5 litre min

(the maximum recommended for most sensors) this will give approximately 660

minutes of usage.

Disposable MINIMIX cylinder:

Usually contain 16 litres of gas, giving approximately 10 minutes of gas flow.

Disposable Scotty IV cylinder:

Usually contain 50 litres of gas giving approximately 30 minutes of gas flow.

Disposable Scotty 28 cylinder used for a 4-component mixture:

Usually contain 27 litres of gas giving approximately 18 minutes of gas flow.

Not only from an economical point of view but also from an environmental point of view,

it is preferable, where possible, to use the refillable cylinders over the disposable ones.

In some cases where there may be corrosive reactions in the cylinder wall, only

disposable cylinders are available.

Storage and safety

As span gases are supplied in pressurized containers there are certain rules and

precautions one must observe when handling and storing the cylinders. The cylinders

Disposable Scotty IV cylinder:

Usually contain 50 litres of gas giving approximately 30 minutes of gas flow.

Disposable Scotty 28 cylinder used for a 4-component mixture:

Usually contain 27 litres of gas giving approximately 18 minutes of gas flow.

Wilhelmsen Ships Service

Not only from an economical point of view but also from an environmental point of view,

it is preferable, where possible, to use the refillable cylinders over the disposable ones.

In some cases where there may be corrosive reactions in the cylinder wall, only

disposable cylinders are available.

Storage and safety

As span gases are supplied in pressurized containers there are certain rules and

precautions one must observe when handling and storing the cylinders. The cylinders

must always be handled with great care and stored vertically and secured to the

bulkhead to prevent tipping over or accidental damage. They must be placed in a

separate room which must be well ventilated and clearly marked with gas under

pressure signs. The disposable cylinders, when empty, must be disposed properly and

with care to both the crew and the environment.

Availability

As mentioned above, strict cylinder cleaning and filling procedures are vital for the

quality of the end product. This limits the number of filling stations capable of delivering

span gases in the quality we require. The other consideration when stocking the span

gases is the shelf life of the gas. In view of these limitations, Wilhelmsen Ships Service

ensures global coverage using major ports such as Singapore, Rotterdam or Houston.

For other ports all span gases can be made available given sufficient lead time in order

to produce or mix the gas or transport it from the major hubs.

In addition, a limited selection of span gases can be found in several smaller ports to

meet customer demand.

Wilhelmsen Ships Service has a broad understanding of customers needs with regards

to the application and use of span gases. The range of gases covers most applications

on board and is guaranteed both in terms of quality of filling and the cylinder itself. In

addition to the span gas range Wilhelmsen Ships Service offers a wide range of

peripheral equipment such as regulators, flow meters and brackets in order to supply the

vessel with a complete solution and satisfy the customer needs and demands.

Next issue: Safe handling of cylinders

Wilhelmsen Ships Service supplies regulatory products and services, Unitor marine products,

Nalfleet marine chemicals, maritime logistics and ships agency.

Wilhelmsen Ships Service has the worlds largest maritime services network, with 4,600 marine

professionals servicing 2 200 ports in 125 countries. Wilhelmsen Ships Service supplies regulatory

products and services, Unitor marine products, Nalfleet marine chemicals, maritime logistics and

ships agency to the maritime industry. Last year the company made 214 000 product deliveries

to 23 000 vessels and handled 54 000 port calls.

For more information, see www.wilhelmsen.com/shipsservice or contact

wss.marketing@wilhelmsen.com

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Maximo in Oil and GasDocument29 pagesMaximo in Oil and GasDia Putranto Harmay100% (1)

- IMI Purchasing Maintenance Repair and Operations ProcedureDocument23 pagesIMI Purchasing Maintenance Repair and Operations ProcedureSaikumar SelaNo ratings yet

- Supor 0904Document12 pagesSupor 0904sealion72No ratings yet

- BDSLT Method Statement - BT Maung PDFDocument39 pagesBDSLT Method Statement - BT Maung PDFSuhaidi Alias100% (2)

- 03 Calibration Standards Pgs 39-84 Date 17-06-10 WebDocument46 pages03 Calibration Standards Pgs 39-84 Date 17-06-10 WebGert ten Brink100% (1)

- SP203-1 Version 7.1 May 2019Document39 pagesSP203-1 Version 7.1 May 2019Anonymous eKcAx8ixs4No ratings yet

- E1409 13Document7 pagesE1409 13senthilNo ratings yet

- TEC Novatop Terminal GBDocument79 pagesTEC Novatop Terminal GBahmedNo ratings yet

- SAC Technical Guide 3-V1Document117 pagesSAC Technical Guide 3-V1shahrilzainul77No ratings yet

- EURAMET-020 Calibration Guide No. 20Document12 pagesEURAMET-020 Calibration Guide No. 20Alexander MartinezNo ratings yet

- En 10246-1 PDFDocument13 pagesEn 10246-1 PDFRajan SteeveNo ratings yet

- Abrasive Materials For Industrial Valve Grinding - LarsLap®Document9 pagesAbrasive Materials For Industrial Valve Grinding - LarsLap®Trịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 170 Cells UP1L 325 1 X ESGL3-3450 STD 2 Tier 3 Step RackDocument4 pagesNi-Cd Battery 170 Cells UP1L 325 1 X ESGL3-3450 STD 2 Tier 3 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 96 Cells UP1M 48 1 X ESGL2-1500 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 96 Cells UP1M 48 1 X ESGL2-1500 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- P 28may21 Trinh Duc A SYS 00001Document4 pagesP 28may21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- P 17may21 Trinh Duc A SYS 00001Document4 pagesP 17may21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- P 04aug21 Trinh Duc A SYS 00001Document4 pagesP 04aug21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- P 08sep21 Trinh Duc A SYS 00001Document4 pagesP 08sep21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 180 Cells SBLE 300 1 X ESGL4-2700 STD 2 Tier 4 Step RackDocument4 pagesNi-Cd Battery 180 Cells SBLE 300 1 X ESGL4-2700 STD 2 Tier 4 Step RackTrịnh Đức HạnhNo ratings yet

- Back To Basics - Pump Specific Speed and Suction Specific Speed - WaterWorldDocument7 pagesBack To Basics - Pump Specific Speed and Suction Specific Speed - WaterWorldTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 20 Cells UP1L 800 1 Tier 4 Rows: Customer Information Ref1: P - 29jun21 - Trinh Duc - A Ref2: SYS - 00001Document4 pagesNi-Cd Battery 20 Cells UP1L 800 1 Tier 4 Rows: Customer Information Ref1: P - 29jun21 - Trinh Duc - A Ref2: SYS - 00001Trịnh Đức HạnhNo ratings yet

- Features: 1-Channel 151Mhz ReceiverDocument8 pagesFeatures: 1-Channel 151Mhz ReceiverTrịnh Đức HạnhNo ratings yet

- 1769 Compact Power Supplies, Expansion Cables, and End CapsDocument1 page1769 Compact Power Supplies, Expansion Cables, and End CapsTrịnh Đức HạnhNo ratings yet

- Specific Speed (NS) Definition - Pump Terms - Intro To PumpsDocument3 pagesSpecific Speed (NS) Definition - Pump Terms - Intro To PumpsTrịnh Đức HạnhNo ratings yet

- How To Find The Best Efficiency Point For Your Pump - All Pumps BlogDocument3 pagesHow To Find The Best Efficiency Point For Your Pump - All Pumps BlogTrịnh Đức HạnhNo ratings yet

- User Manual: ATEQ Leak/Flow Calibrator (CDF)Document78 pagesUser Manual: ATEQ Leak/Flow Calibrator (CDF)BrigitteNo ratings yet

- Brosur Conductivity Orion 2225 by SAKADocument2 pagesBrosur Conductivity Orion 2225 by SAKAduanda oktoraNo ratings yet

- Clean Oil GuideDocument139 pagesClean Oil GuideHINANo ratings yet

- GB 235+ User Manual PDFDocument76 pagesGB 235+ User Manual PDFTechno Genisys100% (1)

- Price List September 2019: Make Sure It'S SecureDocument11 pagesPrice List September 2019: Make Sure It'S SecureDavid Jimena FernandezNo ratings yet

- Fed STD 191a., Method 4108Document4 pagesFed STD 191a., Method 4108itsFRNCsNo ratings yet

- LC QuickDocument46 pagesLC QuickLauro AraripeNo ratings yet

- AABC Specifications For Testing and Balancing HVAC Systems: Revised February 2007Document11 pagesAABC Specifications For Testing and Balancing HVAC Systems: Revised February 2007sreejeshkeralamNo ratings yet

- DataPRO1.9 Manual V14Document219 pagesDataPRO1.9 Manual V14Victor OsorioNo ratings yet

- TVOC Manual V4.5Document32 pagesTVOC Manual V4.5viktor_gligorovNo ratings yet

- Basler Pilot Pia Camera Brochure - enDocument6 pagesBasler Pilot Pia Camera Brochure - enKUMA1999No ratings yet

- Bulletin: PULSE Order AnalysisDocument1 pageBulletin: PULSE Order AnalysisBrianna Daniela VARGAS MERMANo ratings yet

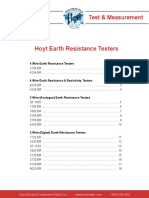

- 1120 Er 3 Wire Digital Earth Resistance Tester 1619095478Document19 pages1120 Er 3 Wire Digital Earth Resistance Tester 1619095478Asaad ChughtaiNo ratings yet

- Operations Manual Te2000psDocument13 pagesOperations Manual Te2000pssuko winartiNo ratings yet

- Astm D7208 - 06Document6 pagesAstm D7208 - 06Black GokuNo ratings yet

- What Is SAP PMDocument47 pagesWhat Is SAP PMPrakash Sawant100% (1)

- Checklist CPCDocument14 pagesChecklist CPCkhajaimadNo ratings yet

- ISO 17034 S4 Technical and Production Requirements 1Document29 pagesISO 17034 S4 Technical and Production Requirements 1saotrangnguyenNo ratings yet

- Transmisor Coriolis CFT51Document218 pagesTransmisor Coriolis CFT51WILDREN100% (1)