Professional Documents

Culture Documents

ATEX

Uploaded by

sagar_ovhal0 ratings0% found this document useful (0 votes)

113 views15 pagesATEX description

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentATEX description

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

113 views15 pagesATEX

Uploaded by

sagar_ovhalATEX description

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 15

There are two ATEX directives (one for the manufacturer and one

for the user of the equipment):

the ATEX 95 equipment directive 94/9/EC, Equipment and

protective systems intended for use in potentially explosive

atmospheres;

the ATEX 137 workplace directive 99/92/EC, Minimum

requirements for improving the safety and health protection of

workers potentially at risk from explosive atmospheres.

Mark for ATEX certified electrical equipment for explosive atmospheres

Explosion & Flame Proof

Protect your electrical equipment and

ensure the safety of your enclosures

This protection method assumes that the surrounding

explosive atmosphere can enter an enclosure intended

to protect electrical equipment and that there will be

internal explosions during the life of the protected

equipment.

In order to be certified as explosion or flame proof, the

enclosure must be strong enough not to fracture or

distort under the internal pressures generated in order to

contain explosions and prevent propagation. When

testing a product for Explosion proof protection, it will

have to undergo an actual explosion within simulated

environments.

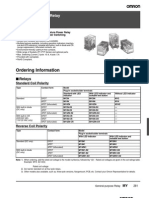

The chart below gives an overview of North

American and International Explosion and Flame

Proof protection standards:

There are differences between Explosion Proof

protection and Flame Proof protection that must be noted

and will have an impact on your projects depending on

where you intend to sell them. Generally, Explosion

Proof is utilized in the US while Flame Proof is utilized in

Canada and Europe.

EXPLOSIONPROOF or

FLAMEPROOF

A haunting question. Is it a dilemma or a complete solution

.does it require the NEC-IEC vision

Let us see We will use the following picture as a symbolic

representation of this situation.

Two tracks , of different colors ,operated by two different protocols

but leading to the same destination, which in our case is the Safe

Operation of the Electrical Equipments in the Hazardous Area .By

same analogy Explosion Proof & Flameproof are the two most

commonly used Hazardous Area Protection Techniques.

Historically, the first safety technique which was applied to

the electrical components was ENCASEMENT. Putting the

electrical components , capable ofelectrical spark or arc in a

sturdy metallic box and sealing it up with a heavy metallic lid,

was the most logical and practical solution. The object was two

fold.

1. To keep the insides isolated from the outer Hazardous

Atmosphere

2. If there is an ingress of outer explosive atmosphere resulting in

an explosion inside the box , the products of the explosion ,

namely, the high pressure, the fire,the smoke the hot gases and

the debris remain inside and is allowed to escape through (Not

the over-pressure value ) the joints .(The joints between the lid

and the enclosure , the conduits and the enclosure )

This was being done (at least) at two places in the world .

Europe & America

We will bypass the normal flow of history and land in 1957.

IEC 79 appears for flameproof enclosures of electrical apparatus.

The term Ex d appears many years later.

With the term Ex d comes the definition , as follows:

Flameproof Enclosure d . Enclosure in which the

parts which can ignite an explosive atmosphere are

placed and which can withstand the pressure developed

during an internal explosion of an explosive mixture,and

which prevents the transmission of the explosion to the

explosive atmosphere surrounding the enclosure. (IEC

60079-1

7th edition)

Now consider the definition of the Explosionproof

Article 100 of the National Electrical Code defines

explosionproof equipment as equipment enclosed in a

case that: (1) Is capable of withstanding an explosion of a

gas or vapor that may occur within the case, (2) Is

capable of preventing the ignition of a gas or vapor

surrounding the enclosure by sparks, flashes, or explosion

of the gas or vapor within the enclosure, and (3) Operates

at such an external temperature that a surrounding

flammable atmosphere will not be ignited by the outside

of the enclosure.

In designing explosionproof equipment, it is assumed that the

flammable gas or vapor will enter the equipment enclosure and be

ignited by a spark or arc within the enclosure. The threaded joints

provided by rigid metal conduit and intermediate metal conduit are

not gas-tight, so the gas can enter around these threads. In

addition, all electrical equipment intended to be connected to a

wiring system has a removable cover of some kind to permit

wiring and facilitate repair of the electrical parts. Some equipment

has external shafts to permit operation of internal switches or, as

in motors, to transmit mechanical motion through the enclosure.

The gases can enter through the interface between the removable

cover and the remainder of the enclosure, or through the shaft

and body interface. These interfaces are called joint surfaces,

or just joints and are commonly referred to as flame paths.

(KILLARK-2011 NEC code reviews)

The following common parameters are obvious:

1. STRONG Enclosure . Strong enough to withstand

the internal pressure of the explosion.

2.Special Design of the enclosure to isolate the

effects of the internal explosion and not to

transmit any of the effects to the outer

surrounding atmosphere.

3. The JOINTS or the interfaces are , however,

specially designed to control the expanding hot

gases in such a way so as to cool them and quench

the flame before letting some of the them escape

through the FLAME PATHS. A flame paths is

always long in proportion to its width.

IEC 60079-1 & NEC 501-1 describe the design principles of

these joints and we find a very elaborate description in IEC

60079-1.

One of the basic design parameter is the MESG -Maximum

Experimental Safe Gap (for an explosive mixture)

It is the Maximum gap of a joint of 25mm in width which prevents

any transmission of a explosion during TEN (10) tests made the

conditions specified in IEC 60079-1-1.

At this point let us examine the commercially available

Explosionproof & Flameproof enclosures.

Both the enclosures are made of the same alloyed material and

by the same manufacturer.

Markings:

Gas Explosion Protection Class I, Division 1, Groups B, C

&D

Gas explosion protection Ex d IIB + H2 , Europe (ATEX):

Explosion protection Ex d IIB + H2 T6T4, Ex.

SOwhat & where is the difference ?? .

Now let us use the NEC-IEC vision to finally get the clarity.

There is no difference between the Explosionproof &

Flameproof as far as following points are concerned:

a. The underlying Philosophy

b. The magnitude of the embedded safety

c. commercial availability and choice of material

d. technical library

The differences:

1. Specification protocols

Explosionproof follows the NEC Protocol

Flameproof follows the IEC Protocol

2. Testing parameters

Explosionproof are constructed to withstand 4 times the

explosive pressure of the gases Flameproof enclosures

are tested for over-pressure : 1.5 times the reference

pressure , with a minimum of 3.5 bars or 4 times the

reference pressure for enclosures not subjected to routine

overpressure testing Conclusion:

Designing my own Ex d (Explosion Proof / Flame Proof)

terminal box or a control station.

Empty Ex d Enclosures are available in the market.

An enthusiastic (not-so-Ex-PERT) person (like me) may have this

temptation of purchasing an empty Ex d Enclosure and making

a junction box or a control-station by installing industrial type

electrical components for operating it in a classified Hazardous

Area.

So what is wrong with this ECONOMICALLY BENEFICIAL

PRACTICE?

(See the details below )

You can do the Purchasing of an Empty Ex d box.

(After all you have purchased a branded Certified Empty Box and

you have downloaded the certificate from relevant web site)

You can carry out the installation of components

BUT You CANNOT take your designed terminal BOX

into a Hazardous Area and ENERGIZE it.

Because you are NOT ALLOWED by the Hazardous Area

Protection laws

(For you own safety,safety of the concerned staff and the safety

of the plant)

Just check the Certificate; it will have the following form

IECEx

Europe (ATEX)

IECEx KEM

KEMA ATEX

The letter U clearly indicates that the empty enclosure is a

component and NOT a COMPLETE ASSEMBLY and it

requires testing for the Hazardous Area once it takes the

form of an assembly (of components inside)

IEC 60079-0

Sec 3.28

Ex Component: Part of electrical equipment or a

module , marked with the Symbol U, which is not

intended to be used alone and requires additional

consideration when incorporated into electrical

equipment or systems for use in explosive

atmospheres.

And CERTAINLY your designed assembly of components

has never been tested in any laboratory of the world and

thus the Protection Level of the Junction Box / Control

Station is not known and thus DANGEROUS

Furthermore the Ex d enclosures are expected to

withstand the explosion-generated pressure of the

Assembly of the components installed in it. This scenario

can only be tested inside the factory or the certifying

body.

The Official way is to give details, to the manufacturer, of all the

components to be installed inside the enclosure and let them do

the designing , manufacturing and testing for you.

The purpose of an Ex Component ENCLOSURE certificate for

empty enclosures is to enable the manufacturer of

FLAMEPROOF enclosures to obtain a certificate without the

internal equipment being defined, so as to enable the empty

enclosure to be made available to third parties for

incorporation into a FULL EQUIPMENT Certificate without

the need for repetition of all the type tests for flameproof

enclosures d as required by IEC 60079-1 and IEC 600790.

(Ref: IEC 60079-1 (2014) Annex D)

So what is the use of the U certified enclosure?

Actually these empty enclosures with component certificates

are not intended for the end -users , in fact they are for other

manufacturers to install their products and then apply for

full equipment certificate , by-passing some or most of the

type tests.

Furthermore , since the production process is already

being monitored for the empty enclosures for quality

assessment, the third party is assured of the safety of the

purchased enclosure

Reference to IECEx OD 017 is worthwhile here.This Operational

Documents lists the documents & drawings to be submitted by the

manufacturers to the Ex testing laboratories when applying for

certification.

For the Flameproof Enclosures d (Flameproof because we

are using IEC) , some of the details to be shown in the

submitted drawings includes :

Area in which cable entries , switch operators , windows,

receptacles etc may be fitted

Layout and heat dissipation of internal component

showing location and approximate dimensions of each

component, including clearances between components

and the nearest sidewall. ( The purpose is to control)

Location of sources of heat, for temperature classification

purposes, for temperature withstand of plastic parts , window

cement, other potting materials, cable entries etc.

Cross check the pressure piling effects of the dimensions of the

enclosure.

be safe & consult the ex-perts

top

You might also like

- Hazardous Area Classification GuideDocument9 pagesHazardous Area Classification GuideVraja KisoriNo ratings yet

- General Information About Thermocouples: Working PrincipleDocument5 pagesGeneral Information About Thermocouples: Working Principlejha.sofcon5941No ratings yet

- UK ATEX IECEx Sensor CatalogueDocument26 pagesUK ATEX IECEx Sensor Cataloguedj22500No ratings yet

- Iec60079 18 2009Document35 pagesIec60079 18 2009Victor Castellanos AlegriaNo ratings yet

- Exhibit D3 Inspection and Test Plan (ITP)Document12 pagesExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNo ratings yet

- ATEX Advisory - Simple ApparatusDocument2 pagesATEX Advisory - Simple ApparatusPeter AllisonNo ratings yet

- Hazardous Area ClassificationDocument9 pagesHazardous Area ClassificationyogitatanavadeNo ratings yet

- New Atex Directive: Lars EkströmDocument23 pagesNew Atex Directive: Lars EkströmvalimironescuNo ratings yet

- Thermocouples and Resistance ThermometersDocument44 pagesThermocouples and Resistance Thermometersbrandy zavaletaNo ratings yet

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Document21 pages1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamNo ratings yet

- Distillation Column Equipment Category AssessmentDocument8 pagesDistillation Column Equipment Category Assessmentcgjp120391No ratings yet

- Checklist For Explosion-Proof GearmotorDocument10 pagesChecklist For Explosion-Proof Gearmotormarius_brkt6284No ratings yet

- FAT Procedure SafePlusDocument3 pagesFAT Procedure SafePlusharisNo ratings yet

- OFFSHORE FUNCTIONAL SPECDocument35 pagesOFFSHORE FUNCTIONAL SPECjtaylor2k1No ratings yet

- PROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFDocument8 pagesPROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFMohsin AliNo ratings yet

- PCD Hi-Pot Procedure TestingDocument2 pagesPCD Hi-Pot Procedure TestingMark HaizlipNo ratings yet

- Instrument Numbering Proceducer Rv05Document25 pagesInstrument Numbering Proceducer Rv05Aurelio Esquivia LopezNo ratings yet

- IEC Standards for Explosive AtmospheresDocument1 pageIEC Standards for Explosive AtmospheresMaahiNo ratings yet

- IEC 61439 Parts 1 & 2 Low-Voltage Switchgear and Controlgear AssembliesDocument35 pagesIEC 61439 Parts 1 & 2 Low-Voltage Switchgear and Controlgear AssembliesAlejandro Maturano100% (1)

- IEEE Seminar Hazardous ClassificationDocument39 pagesIEEE Seminar Hazardous ClassificationMochamad Aziz100% (1)

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- Rittal - Enclosure Heat Dissipation ManualDocument74 pagesRittal - Enclosure Heat Dissipation ManualExequiel RieterNo ratings yet

- Electrical Installation Requirements for Hazardous & Explosives AreasDocument34 pagesElectrical Installation Requirements for Hazardous & Explosives AreasmacodarvNo ratings yet

- LOTO Procedure TemplateDocument2 pagesLOTO Procedure TemplateMastur KuturNo ratings yet

- CompEx Course SyllabusDocument14 pagesCompEx Course SyllabusJoshuaNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area Guidescribd8421No ratings yet

- Electrical Connectors and Tooling PDFDocument13 pagesElectrical Connectors and Tooling PDFWellington RamosNo ratings yet

- Kenexis FMEDA Worksheet Failure AnalysisDocument1 pageKenexis FMEDA Worksheet Failure AnalysisLuc SchramNo ratings yet

- Failure Modes and Mechanisms in Electronic Packages PDFDocument2 pagesFailure Modes and Mechanisms in Electronic Packages PDFDave0% (1)

- Area Classification: (IEC/EN 60529)Document1 pageArea Classification: (IEC/EN 60529)nestkwt1No ratings yet

- TLS-450PLUS Automatic Tank GaugeDocument5 pagesTLS-450PLUS Automatic Tank GaugeJamesNo ratings yet

- PC-J-95 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-95 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahNo ratings yet

- IEC61285 Analyser HouseDocument34 pagesIEC61285 Analyser HouseLuigi SergiNo ratings yet

- NEMA 4 & NEMA 4X Enclosures - Class 1, Div 2 Enclosure ProtectionDocument7 pagesNEMA 4 & NEMA 4X Enclosures - Class 1, Div 2 Enclosure Protectionvanselmetti1969No ratings yet

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDocument3 pagesDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellNo ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- AADvance Controller System BuildDocument161 pagesAADvance Controller System BuildFer EscalonaNo ratings yet

- Tech Specification For LT Power CableDocument23 pagesTech Specification For LT Power CablePramod B.Wankhade0% (1)

- Atex Marking and Meaning For HazardousDocument1 pageAtex Marking and Meaning For Hazardousact_rahul53No ratings yet

- ATEX Unit VerificationDocument16 pagesATEX Unit VerificationJairo WilchesNo ratings yet

- 3039 Type Test 66 KV 500sqmm Rev1 20060913Document8 pages3039 Type Test 66 KV 500sqmm Rev1 20060913renjithas2005No ratings yet

- 700XA Rev CDocument248 pages700XA Rev CMiguel I. Roman BarreraNo ratings yet

- 34-SAMSS-623 Programmable Controller Based ESD SystemsDocument31 pages34-SAMSS-623 Programmable Controller Based ESD Systemscherif yahyaouiNo ratings yet

- E839 ThermocoupleDocument17 pagesE839 ThermocouplefarhanNo ratings yet

- D1P7 IECEx CN Conference CoPC Scheme PDFDocument35 pagesD1P7 IECEx CN Conference CoPC Scheme PDFmadjadNo ratings yet

- Competence Criteria For SR S PDocument83 pagesCompetence Criteria For SR S Pmpendleton100% (2)

- 10-PLC Software Engineering Handbook 3QPL4H v1 4Document62 pages10-PLC Software Engineering Handbook 3QPL4H v1 4Anonymous dPUUgoNo ratings yet

- PCB HandlingDocument8 pagesPCB HandlingscanlonlNo ratings yet

- Modbus Point ListDocument4 pagesModbus Point Listcarlos alberto100% (1)

- Secondary Injection KitDocument9 pagesSecondary Injection KitSamundar KhanNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- Hazardous IEC PDocument6 pagesHazardous IEC PSaoloan NaiborhuNo ratings yet

- ISA Standards Committees ListDocument8 pagesISA Standards Committees ListAnonymous a19X9GHZNo ratings yet

- Compex Certification ProcessDocument1 pageCompex Certification ProcessMarkus_17No ratings yet

- Nonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsDocument46 pagesNonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsMahdy MazinyNo ratings yet

- AbbDocument170 pagesAbbManivannan100% (1)

- ESB Networks Electrical Safety Rules 2006Document36 pagesESB Networks Electrical Safety Rules 2006bdiaconu20048672No ratings yet

- Hazardous Area InformationDocument49 pagesHazardous Area Informationafic219473No ratings yet

- Lighting and Electrical EquipmentDocument11 pagesLighting and Electrical Equipmentadrian3591No ratings yet

- Operation Guide: Displaying The WaveformDocument2 pagesOperation Guide: Displaying The Waveformsagar_ovhalNo ratings yet

- User's Manual: Digital Manometer Firmware Update ProcedureDocument3 pagesUser's Manual: Digital Manometer Firmware Update Proceduresagar_ovhalNo ratings yet

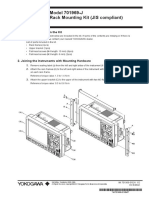

- User's Manual: Model 701969-J Rack Mounting Kit (JIS Compliant)Document2 pagesUser's Manual: Model 701969-J Rack Mounting Kit (JIS Compliant)sagar_ovhalNo ratings yet

- User's Manual: Model VJA5 Distributor (With Square Root Extractor)Document4 pagesUser's Manual: Model VJA5 Distributor (With Square Root Extractor)Alvaro Quinteros CabreraNo ratings yet

- Instruction Manual: Small-And Laboratory - Rotameters Ragk, RaglDocument2 pagesInstruction Manual: Small-And Laboratory - Rotameters Ragk, Raglsagar_ovhalNo ratings yet

- PH and ORP Sensors: User's ManualDocument23 pagesPH and ORP Sensors: User's Manualsagar_ovhalNo ratings yet

- User's Manual: Precautions on the Use of the JUXTA Series JUXTA シリーズご使用上の注意Document4 pagesUser's Manual: Precautions on the Use of the JUXTA Series JUXTA シリーズご使用上の注意sagar_ovhalNo ratings yet

- Symbol Editor: User's ManualDocument24 pagesSymbol Editor: User's Manualsagar_ovhalNo ratings yet

- User's Manual: Model 735371 AQ6370 Viewer Installation ManualDocument2 pagesUser's Manual: Model 735371 AQ6370 Viewer Installation Manualsagar_ovhalNo ratings yet

- User's Manual: Model 709821 Additional Option License For The DLM5000Document2 pagesUser's Manual: Model 709821 Additional Option License For The DLM5000sagar_ovhalNo ratings yet

- User S Manual: Model 701949 Miniature Passive ProbeDocument24 pagesUser S Manual: Model 701949 Miniature Passive Probesagar_ovhalNo ratings yet

- User's Guide to the VJQ8 Pulse to Analog ConverterDocument6 pagesUser's Guide to the VJQ8 Pulse to Analog Convertersagar_ovhalNo ratings yet

- Instruction Manual: FAST/TOOLS R10.04 Service Pack 2 Release NotesDocument18 pagesInstruction Manual: FAST/TOOLS R10.04 Service Pack 2 Release Notessagar_ovhalNo ratings yet

- Im33k25b40 01e PDFDocument4 pagesIm33k25b40 01e PDFsagar_ovhalNo ratings yet

- 110 Omron Datasheet 10910125Document20 pages110 Omron Datasheet 10910125rikku9791No ratings yet

- User's Manual: DX1000/DX1000N/DX2000 PLC Communication Protocol Communication InterfaceDocument22 pagesUser's Manual: DX1000/DX1000N/DX2000 PLC Communication Protocol Communication Interfacesagar_ovhalNo ratings yet

- d4gs-n Ds e 7 5 csm1236 PDFDocument11 pagesd4gs-n Ds e 7 5 csm1236 PDFRiski SuhardinataNo ratings yet

- User S Manual: Rota Total Insight Addendum To Instruction Manuals For Phase-Out of Product DVDDocument1 pageUser S Manual: Rota Total Insight Addendum To Instruction Manuals For Phase-Out of Product DVDsagar_ovhalNo ratings yet

- Omron Photo Ellectric Sensor PDFDocument28 pagesOmron Photo Ellectric Sensor PDFsagar_ovhalNo ratings yet

- Fluke Electric Motor AnalisisDocument8 pagesFluke Electric Motor AnalisisedgardoboieroNo ratings yet

- EOQDocument4 pagesEOQHassan Ali100% (2)

- Pert CPM GoodDocument54 pagesPert CPM GoodHiền Lại Thị DiệuNo ratings yet

- EtiquetteDocument19 pagesEtiquettesagar_ovhalNo ratings yet

- SIS PDS LogicSolver PDFDocument14 pagesSIS PDS LogicSolver PDFsagar_ovhalNo ratings yet

- Safety ReliefDocument38 pagesSafety Reliefsagar_ovhal100% (1)

- Working Capital ManagementDocument20 pagesWorking Capital ManagementSoni Parag Bharatbhai0% (1)

- Basic ConceptsDocument8 pagesBasic Conceptsbabajan_4No ratings yet

- Guidelines For The Operation of Digital FM Radio BroadcastDocument3 pagesGuidelines For The Operation of Digital FM Radio BroadcastmiyumiNo ratings yet

- CONSOLA MOTOR Stryker CROSSFIREDocument48 pagesCONSOLA MOTOR Stryker CROSSFIREJose M SNo ratings yet

- Ed5 5Document8 pagesEd5 5Anonymous 4e7GNjzGWNo ratings yet

- Rosendal1943 SkinDocument22 pagesRosendal1943 SkinEdwin CallejasNo ratings yet

- Beckercom: Welcome To The Becker ElectronicsDocument68 pagesBeckercom: Welcome To The Becker ElectronicsMichael Erdis50% (2)

- Power Quality ProblemsDocument2 pagesPower Quality ProblemsKT MENONNo ratings yet

- PDK 205481 Kw26-S5-Fse-4q enDocument114 pagesPDK 205481 Kw26-S5-Fse-4q enMostafa MagdyNo ratings yet

- Basics of Electrical SwitchesDocument3 pagesBasics of Electrical SwitchesHsein WangNo ratings yet

- 32kx8bit CMOS SRAM: HY62256A SeriesDocument9 pages32kx8bit CMOS SRAM: HY62256A SeriesHernan KisielNo ratings yet

- IL230x-B110 Fieldbus Box Modules For EtherCATDocument2 pagesIL230x-B110 Fieldbus Box Modules For EtherCATmicaNo ratings yet

- Mid ExamDocument3 pagesMid ExamAbdulhakim heboNo ratings yet

- 12V Battery Charger-cum-Variable Power SupplyDocument11 pages12V Battery Charger-cum-Variable Power SupplyLOLO ISMUNASIBNo ratings yet

- Receiver: Service ManualDocument76 pagesReceiver: Service ManualheladiomontesdeocaNo ratings yet

- Syncon Webinar 2020 Dec Presented 2020DECDocument34 pagesSyncon Webinar 2020 Dec Presented 2020DECmassimocalviNo ratings yet

- Five Renowned Scientists in The WorldDocument3 pagesFive Renowned Scientists in The WorldJulius Raphael RoxasNo ratings yet

- Panasonic SA-AK960 Mini ComboDocument121 pagesPanasonic SA-AK960 Mini Comboppstone100% (3)

- Diagrama Electrico Exc.Document2 pagesDiagrama Electrico Exc.Becker Orlando Perez FIallos100% (1)

- Tomasi Full Reviewer PDFDocument159 pagesTomasi Full Reviewer PDFAdriane Patrick QuirosNo ratings yet

- PAC E100 110 Technical SpecV2 00 (060320)Document24 pagesPAC E100 110 Technical SpecV2 00 (060320)mkarimiloloNo ratings yet

- SSI Series Inverter Manual: Setup, Operation and Safety InstructionsDocument24 pagesSSI Series Inverter Manual: Setup, Operation and Safety InstructionsBrandon CatronNo ratings yet

- Hybrid PEM Fuel-Cell-Diesel-Solar Power System Design for Electric BoatsDocument7 pagesHybrid PEM Fuel-Cell-Diesel-Solar Power System Design for Electric BoatsBernardo ReyesNo ratings yet

- GPD 205 Technical Manual: Magne TekDocument88 pagesGPD 205 Technical Manual: Magne TekUsman ShahNo ratings yet

- TR5 ArcWelding AlonzoDocument7 pagesTR5 ArcWelding AlonzoIsaiah Benjamin AlonzoNo ratings yet

- Trouble Shooting-Diagram Tank Level Measuring system-EL-TDocument5 pagesTrouble Shooting-Diagram Tank Level Measuring system-EL-TEtl OdessaNo ratings yet

- 6305-El-Etp-7010-A00 Ac DBDocument18 pages6305-El-Etp-7010-A00 Ac DBvicesuza87No ratings yet

- Soft-switching active snubbers reduce losses in DC-DC convertersDocument13 pagesSoft-switching active snubbers reduce losses in DC-DC convertersashish_rewaNo ratings yet

- NEC Article 620: Elevators, Part 1: Continuing Education: Codes & StandardsDocument10 pagesNEC Article 620: Elevators, Part 1: Continuing Education: Codes & StandardsMenaNo ratings yet

- The Right Choice, For Your Power EquipmentsDocument48 pagesThe Right Choice, For Your Power EquipmentsJuan LeeNo ratings yet

- How To Make DTMF Decoder MINI-PROJECT - MyClassBookDocument9 pagesHow To Make DTMF Decoder MINI-PROJECT - MyClassBookVamsi VangaraNo ratings yet

- Submittal For Al Barsha 1451 Rev0 PDFDocument55 pagesSubmittal For Al Barsha 1451 Rev0 PDFGokulNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesFrom EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo ratings yet