Professional Documents

Culture Documents

Power System Laboratory

Uploaded by

Bahadır AkbalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power System Laboratory

Uploaded by

Bahadır AkbalCopyright:

Available Formats

Power System Simulator PST 2200

PST 2200

Power System Simulator

Laboratory

Power System Simulator PST 2200

Power System Simulator PST 2200

CONTENTS

Introduction

General Information of the Power System Simulator PST 2200

Power Plant Module, PST 2210

Transmission Line & Distribution Module, PST 2220

Receiving Substation Module, PST 2230

Load Module, PST 2240

Measuring Details

10

Different set-ups of the Power System Simulator

11

SCADA system

12

List of Typical Experiments

12

Technical Information

13

Protective Relays

14

How to order

15

Power System Simulator, PSS 1200

16

Power System Simulator PST 2200

INTRODUCTION

Various kinds of simulation are used more often as an important aid to educate operating

and servicing personnel. With a simulator you can train people to make sensible decisions

and to act quickly and decisively under varying operating conditions. Moreover, you can

demonstrate efforts which previously have been covered in theory only.

The Terco Power System Simulator has been designed for practical training of power engineers and technicians

in realistic conditions, close to life situations in genuine environment.

A variety of training schemes programmed for:

power management staff

operators of power plants and substations

maintenance personnel

teaching of students

research in universities

can be realised.

The Terco Power System Simulator has been developed in close co-operation with ABB of Sweden one of the leading

suppliers of power facilities world-wide and Swedish State Power Board.

The result is, that a real power system has been copied for educational purposes.

All the Protective Relays (Static and Numerical) are supplied by ABB and are exactly the same as used in real

power installations.

Our comprehensive manuals have been both written and tested together with the engineers from Swedish State

Power Board, to reflect realistic conditions of operation as well as emergency situations, which may occur, and

do occur, in every-day life of a power engineer or technician.

What is the main difference between TERCO Power System Simulator and an industrial power system?

Apart from scaled down size, and much lower cost, the main difference consists of three major points:

The TERCO Power Simulator is prepared to stand human errors, performed by the students

during the training.

The TERCO Power Simulator includes facilities to produce simulated typical faults,

in order to drill the students in resolute and correct reactions.

The TERCO Power Simulator enables the students to survey both functions and malfunctions

in a complete power system, from generation to utilisation.

The TERCO Simulator is successfully used for training and education in universities and power companies

in 15 different countries throughout the world. The rich experience and know-how earned by us and our costumers

is now at your disposal.

The Equipment

A Terco Standard Simulator is based on four modules:

PST 2210 Power Plant Module

PST 2220 Transmission Line & Distribution Module

PST 2230 Receiving Substation Module

PST 2240 Load Module

The modules can be bought and operated individually and completed later with remaining modules.

The standard solution is equipped with high technology state of the art protective relays from ABB.

The Terco Standard Power System Simulator comprises 5 metallic frame works.

Each frame holds 2 rows of 19 inch racks each. The size and design of the frames is made to meet modern

ergonomical requirements, and it corresponds to modern industrial design.

From the rear side of the frames there is full access to the wiring and components for easy service.

Power System Simulator PST 2200

GENERAL INFORMATION

The picture above shows a 7 frame option with two complete and fully equipped turbine-generator sections, additional

transmission lines, an extended receiving substation and a standard load module.

TERCO POWER SYSTEM SIMULATOR

Standard configuration.

General lay-out of the standard Power System Simulator

Power System Simulator PST 2200

STANDARD CONFIGURATION

Module no. 1 PST 2210

POWER PLANT MODULE WITH HIGH VOLTAGE BUSBARS AND OUTGOING LINES.

Switchboard for the Power Plant Simulator including turbine + synchronous generator, rectifiers, instruments,

synchronising- and phasing devices, step-up transformer, current- and voltage transformers, protective relays, indications.

A-B-busbars, two outgoing lines (including protective relays, instruments and corresponding switchboard).

Two or more turbine-generator sections can be delivered as option.

Module no. 2 PST 2220

TRANSMISSION LINES & DISTRIBUTION MODULE

Seven different artificial 3-phase transmission lines with possibilities to change and combine impedance elements by

jumper positioning to constitute other OH HV-levels as well as cable models for distribution.

All models have coils, capacitors and resistors designed to withstand overload and surges for dynamic as well as

static experiments.

Module no. 3 PST 2230

RECEIVING SUBSTATION MODULE WITH HIGH VOLTAGE SIDE

Receiving substation with one incoming line and two outgoing lines including a complete switchboard with instruments

and corresponding protective relays. One step-down transformer including protective relays together with the corresponding

transformer. Two or more incoming lines, and three or more outgoing lines can be delivered as option.

Module no. 4 PST 2240

LOAD MODULE

Load unit with single-phase and three-phase combinations of resistive, inductive and capacitive loads to simulate

industrial as well as domestic loads of symmetrical as well as non-symmetrical types. An induction motor with a

flywheel is also included.

GENERAL

Necessary switches, instruments, and over-load protections are included.

On each module current- and voltage transformers as well as protective relay blocks are connected mainly by jumpers.

Protective relays etc. may be tested also together with external equipment.

On the transmission lines module, the impedance elements can be connected in different ways to design other main

characteristics of other transmission links suitable to try different settings of the protections. This possibility of changing

the structure of the impedance map is very useful when programming the distance protection.

PROTECTION

Full generator and transformer protection is provided for the simulated power plant and system protection for the

artificial lines, when ordering the standard simulator.

All protective relays are easily accessible from the control desk where settings can be done easily as well as

indications and tripping connections. All protections can be tried individually without interfering with the in-operation

simulator because of the test blocks into which test handles can be put. (CTs are automatically short circuited).

All modules / function blocks in the protective relays can easily be disassembled from the front.

All protective relays are of electronic type (Static and Numerical).

Any protective relay can be exchanged, combined or completed with other relays or relay functions because of the

COMBIFLEX connection system. A micro-processor-operated 1 + 3 zone distance protection relay can be installed

as option on one of the outgoing HV-lines of the HV-substation.

The distance protection can be programmed for different HV-levels and characteristics and operates for three-phase

short circuits, fault R-S, S-T, T-R, R-earth, S-earth, T-earth and with underimpedance start. There are separate time

settings for zone 2, 3 and 4. Each or all zones can be programmed for sensing in forward or reverse direction.

EXPERIMENTS

Experiments may be performed on the complete set-up of modules, on any of the four main modules individually

or on protective relays individually by using an external relay tester e.g. MV 1427 (optional).

The protective relays may also be tested in combination with individually chosen line models and loads to provide

experiment groups not to interfere with other experiments on protective relays on the remaining main modules.

Most protective relays are operated from individual set-ups of voltage- and current transformers included with terminals

accessible from the control pulpit.

4

Power System Simulator PST 2200

PST 2210, The Power Plant Simulator above is an extended version with two turbine-generator sections, fully equipped with

all protective relays and step-up transformers. The standard version has one fully equipped turbine-generator section.

Module no. 1

PST 2210 POWER PLANT MODULE

The power generation is represented by a three-phase 1.2 kVA synchronous generator driven by a separately excitated

2.0 kW DC motor as turbine.

As option, the turbine / generator can be manually set for different kW / Hz characteristics and for different start- and

stop ramps.

The operation mode of the turbine / generator can be chosen between manual- or automatic control regarding power

(frequency) and reactive power (voltage).

Digital instruments:

Armature (stator) current

Armature voltage

Field current

Revolutions per minute

Reactive power

Active power

Rotor current for turbine / DC-motor

Generator:

The reactance is referred to the nominal values of the

generator U and I.

The generator can be chosen either of the nominal power

1.2 kVA or 2.0 kVA as optional.

Both types are designed to be given parameters to simulate

the real size generators.

The smaller type (specified above) is designed with cylindrical rotor and the bigger one, as an option, with salient poles.

The field controller is a static rectifier, which settings can be

optimised by the student.

It can be used for automatic or manual control.

Transformer:

A 2 kVA transformer is used as a step-up transformer. The

ratio is 1:3. It is wound to withstand voltage surges without

saturation (and thus tripping the differential protection).

External impedance elements may be added as an option to

simulate different sizes / impedances of the transformer.

All windings are accessable externally to admit experiments

on the transformer alone.

The step-up main transformer is supplying a double-bus system to the outgoing HV-substation.

The transformer can be given a rating of 50% or 100% by

external resistive / inductive impedance elements, which are

connected by a contactor relay operation from the control

desk. Tappings on the secondary side of the transformer will

make it possible to change the voltage +/- 5 %.

The transformer has its windings accessible externally to

make it possible to perform tests like no-load test and shortcircuit test.

Primary as well as secondary voltages and currents can be

read on instruments.

Electronic Relay Protections:

The Electronic Relay Protections for turbine / generator /

step-up transformer comprises as a standard the following

facilities:

Differential protection for the generator

All-over differential relay for generator-transformer

Three-phase overcurrent relay for the generator

Over voltage relay

Rotor Earth-fault relay of injection type

95% Stator Earth-fault relay

Power System Simulator PST 2200

Optional protection:

Reverse power relay for the generator

Negative-sequence protection relay

Thermal overload relay for the generator

All protections are available for connecting

by 4 mm outlets via a testhandle.

All necessary current transformers are included

and the terminals are available from the desk.

Synchronising panel of the Power Plant Module.

HV Busbars

The HV busbars comprise an A-B system with interconnections for load transfer.

All breaker functions are operated by contactor relays.

The busbars are equipped with the following instruments:

Digital volt- and ammeters for all phases

Synchronising instruments including synchronoscope

Voltage selector switches.

HV Outgoing Substation

The HV outgoing substation comprises two outgoing lines

which can be connected to a radial network or a grid network

(depending on the connections of the transmission line

module).

The HV outgoing substation is equipped with the following

instruments:

Digital volt-, ampere- and power meters for both lines

Voltage selector switches

All switches / breakers are operated by contactor relays.

Electronic Relay Protections

for HV outgoing substation

The Electronic Relay Protections for HV outgoing substation

are constituted by:

One three-phase over current relay with directional earth

fault protection for Line 1

One three-phase over current relay with directional earth

fault protection for Line 2.

As options are available:

Static 3+1 zone distance protective relay

Static impedance protective relay.

All protections are available for connecting by 4 mm

outlets via a test handle. All necessary current transformers

and voltage transformers are included and the connections

available from the desk.

The control elements fitted are mostly of the same industrial

type as those used in control rooms of power plants and

substations.

Circuit breakers are push-button operated with lamp indications for the breaker status. Isolators are manually operated

and the physical position indicating open or closed position.

Turbine Generator Set: The power is generated by a 3-ph synchronous generator driven by a separately excitated DC-motor

as turbine. The electrical machines set is electrically fully connected and mechanically mounted on a machine bed.

Power System Simulator PST 2200

PST 2220 Transmission Line and Distribution Module.

Module no. 2

PST 2220 TRANSMISSION LINE & DISTRIBUTION MODULE

The Transmission Line and Distribution Module comprises:

Type

One HV double pi-link solid earth

One MV pi-link with

One double pi-link with resistive or solid earth

One double cable pi-link with resistive or solid earth

Voltage

130 kV

140 kV

111 kV

111 kV

Transmission ability

115 MVA

120 MVA

115 MVA

115 MVA

Length

100 km

150 km

115 km

110 km

All the different voltage levels can be adapted according to customers demands.

All line models (artificial transmission lines) have the same ratings in the model scale: 400 V, 2 A. This means, that it is easy

to compare the characteristics and typical behaviour of a high voltage, middle voltage and distribution voltage OH-line as well

as a distribution cable when for example running at 100 % transmission ability. The transmission models are built for both

static and dynamic experiments with overload / overvoltage ability.

Each artificial line model consists of a three-phase pi-link and an earth link. The models are set up on the line model

board of the module where the internal connections are chosen by the means of jumpers and lab.-leads. All line models are

accessible not only on the line model board, but also in parallel as four + four pole blocks in the desk section to give

possibilities to arrange radius, grid or mixed networks in a very simple way.

All line models also have parallel four + four pole blocks to provide easy facilities of connecting to Receiving Substation in

Module 3 and the distribution networks with load banks of the low voltage switchgear in Module 4.

A fault simulator is also built-in as a separate panel in the Transmission Line and Distribution Module.

It has push button operated contactor relays which together with built in resistors can be used to simulate faults of the types:

Three-phase short circuits

Two-phase short circuits

Short circuits with limited over current

Isolation Earth fault with limited current.

On the transmission lines modules, the impedance elements can be connected in different ways to design other main

characteristics of other transmission links suitable e.g. to try different settings of a distance protection.

Power System Simulator PST 2200

PST 2230 Receiving Substation Module: This picture is an optional version of two incoming lines, HV-busbars, step down

transformers (as incoming standard it is one of each), middle voltage busbar and two outgoing lines.

Module no. 3 PST 2230 RECEIVING SUBSTATION MODULE

The receiving substation comprises one incoming line, HV-busbars, transformer, middle voltage busbars, and two outgoing

lines. Other combinations are optional.

Digital instruments:

Voltage, current and power meters for incoming power

Voltage between busbars of incoming power

Voltage selector switches for incoming line

Voltage, current and power meters for outgoing power

Voltage between busbars of outgoing power

Voltage selector switches for outgoing lines

Electronic Relay Protections:

Busbar overcurrent protection

Transformer differential protection

HV / MV overcurrent protection

Neutral point voltage earth fault protection

Overcurrent (three-phase) and directional earth fault protection for outgoing Line 1

Overcurrent (three-phase) and directional earth fault protection for outgoing Line 2

Multifunction motor protection relay for outgoing Line 2 (optional)

Auto-reclosing relay in combination with the protection for outgoing Line 1 (optional).

All protections are available by 4 mm outlets via a test handle. All current- and voltage transformers are included

and most terminals are available from the desk.

The step down transformer can be operated individually and all the terminals are available from the desk. All breakers

are operated by contactor relays.

Possible earthing methods are:

a) solid or resistive earth

b) insulated earth

c) Petersen coil

Power System Simulator PST 2200

Module no. 4

PST 2240 LOAD MODULE

Low Voltage Distribution

The Low Voltage Distribution is constituted

by a busbar to which the substation can be

connected by the outgoing lines or by one or

more transmission models.

From the busbar there are 6 outgoing groups to

which loads can be connected. Each outgoing

group is equipped with manually operated

switches or selector switches.

All distribution groups are available by 4 mm

safety outlets to which loads can be connected

with or without external instruments.

Instruments as optional:

Voltage and frequency on incoming busbars

Voltage selector switch

Ammeter on each outgoing group

kWh-meter

PST 2240 Load Module.

The picture shows an option with two motor protections.

Load Group

The load module consists of groups of single phase and three-phase industrial and domestic loads.

The loads are of resistive, capacitive, inductive and active (motor) types: Three 3-phase groups can be varied in

small steps which together with the other loads will cover load possibilities from 0150 % of nominal power.

By jumpers and switches it is possible to create single phase loads as well as other non-symmetrical loads.

One motor with flywheel is enclosed to the load module. Several motors can be added as optionals to make it

possible to study the dynamics of the system as well as the mechanical load sharings between two or more machines.

The motor together with the flywheel will constitute a suitable load for the microprocessor operated motor protection

(optional) on the outgoing line of the middle-voltage substation.

The Load Module comprises:

6 resistive 1-phase load groups connectable by switches

6 capacitive 1-phase load groups connectable by switches

6 inductive 1-phase load groups connectable by switches

2 three-phase controllable resistive loadbanks

2 three-phase controllable capacitive loadbanks

2 three-phase controllable inductive loadbanks

1 induction motor with flywheel and mechanical brake, 0,25 kW

One induction motor Dahlander with flywheel and mechanical brake, 0,25/0,12kW (optional).

Other optional machines may be mounted on a metal basement or can be delivered on an external machine bed.

Power System Simulator PST 2200

MEASURING DETAILS

Logic Blocking Unit

The logical blocking unit uses a microprocessor to determine whether an isolator can

be operated or not. All isolators and circuit

breakers in the simulator are assigned to a

form where the user gives the conditions for

operation or not. The corresponding contactor

relays give status to the microprocessor which

in less than a msec compares all conditions

with the demand of the user turning the switch

on the front. When upgrading the simulator

with more circuit breakers and isolators, the

user simply has to reprogramme the microprocessor to fit the new constellation.

Circuits: A 24 Channel Logical Blocking Unit.

Digital Instruments

The simulator contains, depending on options,

normally 60 instrument amplifiers of which

8 are spares for upgrading.

A typical group of instruments will consist

of one wattmeter, one VAr meter one

ammeter and one voltmeter which by means

of a selector switch can be connected for

measuring line to line voltages or line to

neutral voltages.

Picture showing some of the instruments.

Channel Measuring Unit

Each measuring module has six signal

amplifiers, all of them galvanically isolating

the power side from the signal side. All

channels are easily adapted for measuring

AC or DC or mixed quantities. Calculation of

power and reactive power is performed by

multipliers and addition circuits. On the

output terminals all signals are available as

instant values and as buffered mean values

within +/-10V. This will simplify future

upgrading of the simulator for computer

control.

Circuits: A 6 Channel Measuring Module.

10

Power System Simulator PST 2200

DIFFERENT SET-UPS OF AN EXTENDED POWER SYSTEM SIMULATOR

Different set ups of the Power System Simulator. Due the modular system, the system can be arranged in different ways

depending on the available space.

11

Power System Simulator PST 2200

SCADA System for Power System Simulator

Terco SCADA system (Supervisory Control and Data Aquisition) is a computerized supervisory, control and display system

to be used with Terco Power System Simulators (PSS and PST program).

It will display all main instruments either as readouts or as graphs. All breakers and isolators belonging to the simulated power

system can be operated from the PC.

Operational status of the simulator is followed on a one-line diagram on the monitor, where the status of each breaker and

each isolator is indicated together with all instrument readouts.

Please ask for our separate SCADA leaflet.

List of Some Typical Experiments

Under normal conditions

Settings of field control parameters, settings of turbine control rectifier parameters, settings of start- and stop ramps

(=intake gate opening and closing)

Checking AC-supply, DC supply, alarm indications, acknowledge- and cancel procedures, status indications of isolators

and breakers. Start order.

All performance diagrams of the generator can be studied.

Vector group of system transformer is checked.

Differential relays can be tested by resistive faults or trim faults caused inside the protective zones.

Load distribution can be varied using auxiliary transformers to keep the currents within certain limits.

This can also be studied by use of parallel lines where the line parameters are different.

(Arranged for example by jumper connectors in the transmission module).

Generator performance under steady state and dynamic conditions can be studied for different types of loads.

Difference between manual and automatic control of voltage = reactive power control.

Difference between manual and automatic control of speed = active power control.

Rapidity of field control v.s. stability. Optimizing gain and time constants of voltage and current controllers.

Feedback systems.

Voltage differences, frequency differences, phase difference, timing, instruments, blockings (synchronising).

The dynamic characteristics of the controller can be examined.

All protective relays can be tried individually with or without load with a relay testing unit of injection type (optional)

where tripping levels are checked together with operating characteristics in the complex RX-plane as well as pick-up

and tripping times by a built-in six digit timer.

Characteristics of overcurrent and underimpedance starting elements can be obtained by means of loads and system feed

provided underimpedance protection is included..

The tripping characteristics of a modified impedance relay can be determined by experiment (optional choice).

Impedance maps can be calculated easily to give information for an optimised selectivity plan of protection.

By means of a ring main feed from one end various methods of protection can be studied, e.g. employing directional

overcurrent relays or non-directional relays with instantaneous opening of the main grid.

Under fault conditions:

The reactances and time constant of the synchronous generator are of decisive importance for its transient behaviour.

This can easily be studied in several ways. Also symmetrical and asymmetrical faults can be studied.

Different types of system earthing methods can be studied: isolated, high resistance, low resistance and Petersen coil.

Connecting the infinite busbar system in different parts of the network. Influence on fault currents and short circuit

currents.

Influence on fault currents and short circuit currents and relay protections. Settings of relays. Selectivity.

Transient behaviour of generator can be shown when it is not correctly synchronised with the system.

Single-phase and three-phase fault interruptions can be demonstrated for different lengths of transmission lines and

different values of power transmitted.

The generator protection scheme is checked under conditions of deliberate maloperation of the generator and especially

introduced faults.

12

Power System Simulator PST 2200

Overcurrent and under-voltage relays for motor protection operating in conjunction with the system relays can also be

shown.

Signalling, indications warnings, trippings, actions in the fault announciator system.

The list of experiments can be made much longer but these are a selection of experiments.

Regarding Protective Relays

Connecting current and voltage transformers in different single- and three-phase configurations.

Overcurrent protection

Overcurrent protection with time lag overcurrent relays

Over- and under voltage relays

Neutral point protection

Independent time characteristics

Directional overcurrent protection

Earth fault protection

Directional earth fault protection

Differential protections

Design principles

Instantaneous measuring relay

Influences of the DC-component

Directional relay for power

Signal relays + Auxiliary relays

A typical feeder protection.

Microprocessor operated 1 + 3 zones distance protection, programmable for low / high impedance isolated / impedance

earthing, under impedance tripping, phase-phase, earth fault etc (optional).

Auto-reclosing, high speed or time delayed, 1 or several shots, memory functions, counter etc (optional).

Technical information:

Standards

All units, included in the Terco Power System Simulator,

correspond, in all significant points, to IEC recommendations.

Power input : 3-phase 400 / 230 V, 50 & 60 Hz

The turbine / generator / step-up transformer:

Generator data:

DC-machine 2.0 kW, simulating turbine

4-pole synchronous generator, 1.2 kVA, cos phi 0,8

Static rectifier for speed control

Static rectifier for voltage / VAr control

Step-up transformer 230 / 400 V, 2.0 kVA

Voltage

Nominal current

Frequency

Speed

Synchronous reactance

Transient reactance

Subtransient reactance

Transmission Line

Type

Transmission

Voltage Aibility Length

HV double pi-link solid earth 130 kV

MV pi-link

140 kV

Double pi-link with

resistive or solid earth

111 kV

Double cable pi-link with

resistive or solid earth

111 kV

115 MVA 100 km

120 MVA 150 km

115 MVA 115 km

115 MVA 110 km

3 x 230 V

3,5 A

50 Hz/60Hz

1500 rpm / 1800 rpm

97 %

17 %

8%

Single-phased Load groups

Resistive

6x200 W

Capacitive

6x200 VAr

Inductive

6x200 VAr

3-phase Loadbanks controllable in 6 steps

Resistive

2x3-ph 0900 W

Capacitive

2x3-ph 0900 VAr

Inductive

2x3-ph 0900 VAr

1 induction motor with flywheel and mechanical

brake 0,25 kW

Optional

1 induction motor Dahlander with flywheel and

mechanical brake 0,25/0,12 kW

13

Power System Simulator PST 2200

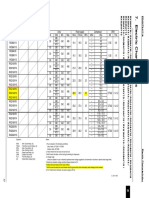

STATIC PROTECTIVE RELAYS

Level 2

Level 3 (standard)

POWER PLANT MODULE PST 2210-2

Turbine / Generator / Step-up Transformer:

POWER PLANT MODULE PST 2210-3

Turbine / Generator / Step-up Transformer:

All-over Differential Protection

Three-phase O/C Protection

Power Plant Substation outgoing HV-lines:

Three-phase O/C and Directional Earth Fault

Protection, Line 1

Three-phase O/C and Directional Earth Fault

Protection, Line 2

Power Plant Substation outgoing HV-lines:

RECEIVING SUBSTATION MODULE PST 2230-2

Busbar Overcurrent Protection

Transformer Differential Protection

Three-phase O/C and Directional Earth Fault

Protection, Line 1

Three-phase O/C and Directional Earth Fault

Protection, Line 2

Differential Generator Protection

All-over Differential Protection

Three-phase O/C Protection

Over Voltage Protection

Rotor Earth Fault Protection

95 % Stator Earth Fault Protection

Three-phase O/C and Directional Earth Fault

Protection, Line 1

Three-phase O/C and Directional Earth Fault

Protection, Line 2

RECEIVING SUBSTATION MODULE PST 2230-3

Busbar Overcurrent Protection

Transformer Differential Protection

HV / MV Overcurrent Protection

Neutral Point Earth Fault Protection

Three-phase O/C and Directional Earth Fault

Protection, Line 1

Three-phase O/C and Directional Earth Fault

Protection, Line 2

Customer adapted protections

At customers request more sophisticated protections

can be chosen in addition to e.g. level 3.

POWER PLANT MODULE

Turbine / Generator / Step-up Transformer:

Reverse Power Relay for the Generator

Negative-sequence Protection Relay

Thermal Overload Relay for the Generator

Busbar Overcurrent Protection

Power Plant Substation outgoing HV-lines:

3 + 1 Zone Distance Protection

Impedance Relay

RECEIVING SUBSTATION MODULE

14

Auto Reclosing Relay

Distance Protection for Incoming Line

Busbar Overcurrent Protection

Multifunction Motor Protection

Picture showing some of the Static Protective Relays in the

Power Plant Module.

Power System Simulator PST 2200

Weights and Dimensions

Approx net weights

400 kg

275 kg

310 kg

275 kg

How to order:

Power Plant Module

Transmission Line

& Distribution Module

Receiving Substation Module

Load Module

PST 2210-1

PST 2210-2

PST 2210-3

PST 2220

PST 2230-1

PST 2230-2

PST 2230-3

PST 2240

Level 1.

Without static relay protections (normal protection by fusing included).

Level 2.

A minimum level when the simulator has a choice of the most important

types of static protective relays built-in.

Level 3.

(standard)

Includes a standard set-up of static protective relays typical for small size real

power plants and substations.

More sophisticated protections can be chosen as optional and adapted to customers request.

Of course, it is also possible to deliver Transmission Line Modules specially designed for the customers demand.

The simulator may be upgraded from level to level and also in between.

Guarantee & Terms

Turn-Key Delivery

and After-Sales Back-Up

The complete Power System Simulator is supplied on

turn-key basis, with supervision of installation,

commissioning and on-site training to be performed by

Terco engineers.

Further training in Sweden or on site can be arranged on

request, subject to a separate agreement.

Individual item specified in this catalogue, can also be

delivered on request.

The GUARANTEE is valid 12 months from delivery.

The guarantee covers repair or exchange of defective parts,

due faulty design or workmanship at our factory.

Detailed conditions of guarantee are specified in our Terms

of Guarantee.

All overseas deliveries are effected in special, madeto-order wooden crates, extremely sturdy and damageresistent.

Sets of spare parts for 23 years of normal operations are

included in the moduls, whereever necessary. The regular

after-sales service is performed by the worldwide network

of Terco representatives, with the advice and support of

our engineers.

TERCO reserves the right to make changes in the design, modifications or

improvments of the products at any time without incurring any obligations.

15

Power System Simulator PST 2200

GENERATION

TRANSMISSION

DISTRIBUTION

CONSUMPTION

POWER SYSTEM SIMULATOR PSS 1200

TERCO also manufactures another power system simulator, the PSS 1200.

This simulator has the same mimic structure but all components are built-in into industrial racks which are possible

to open at the front.

Please ask for our special brochure.

High Voltage Power System Model

1. Power Station Simulator incl. Turbine-Generator

2. Basic Loads and Measurements

3. Advanced Loads and Measurements

4. Substation Simulator

Industrial Power Distribution Model

5. Oil Immersed Transformer

6. Low Voltage Switchgear with industrial load models.

The modular system was chosen due to its flexibility

and adaptability, both to the size of student groups and to

available laboratory space.

Power Station Simulator

This is a model of a typical power station, containing a

turbine-generator unit, transformer, high-voltage switch-gear

and two outgoing lines. It is made up of two sep. sections:

Power Station

Simulator MV 1231

The Turbine-Generator Model, consisting of a converter

controlled DC-Machine, which simulates the turbine, and an

ordinary, small size synchronous generator.

The Control Room Section, consisting of five cubicles, with

mimic diagrams and laboratory terminals on front panels.

This section contains advanced equipment of exactly the

same type, as used in real power stations:

All protective relays are of modern, electronic (solid state)

type and belong to the ABB Combiflex system.

Substation Simulator

This is a model of a simple substation, designed for one incoming high voltage line, connected to duplicate busbars,

a transformer, low voltage dubplicate busbars and two

outgoing feeders. The Substation Simulator contains also

advanced equipment of the same type as used in real

substations:

Substation

Simulator MV 1220

All equipment, including the transformer and the protective

relays, are located in two cubicles, with mimic diagrams and

laboratory terminals on front panels.

Education and training

It is our belief that a good result in training power people,

etc. is only achieved by well trained teachers / instructors,

good curricula with sufficient time for hands-on training

and relevant equipment.

16

TERCO has the possibility to offer training, in Sweden

or at site, of technical people in POWER SYSTEMS,

INDUSTRIAL ELECTRONICS, POWER ELECTRONICS,

ELECTRICAL MACHINES, and MOTOR DRIVES.

Please contact us for further information.

Power System Simulator PST 2200

Power System Simulator PST 2200

Terco Headoffice

Terco headoffice and factory outside Stockholm, Sweden.

EL. INSTALL. &

CONTACTORS

INDUSTRIAL

ELECTRONICS

MATERIAL

TESTING

CLASSIC

ELECTRICAL

MACHINES

1 kW

POWER STATION SIMULATOR (PST)

SCAN DRIVE

400 W

SCAN LAB

ELECTRICAL

MACHINES

PROTECTION RELAYS

POWER STATION SIMULATOR (PSS)

TERCO AB P.O. Box 5014 SE-141 05 HUDDINGE STOCKHOLM SWEDEN

Telephone: + 46 8 506 855 00 Telefax: + 46 8 506 855 01 www.terco.se e-mail: export@terco.se

You might also like

- Weighbridge Preventive Maintenance ChecklistDocument12 pagesWeighbridge Preventive Maintenance ChecklistKrishna Jasha80% (5)

- Protection of SubstationDocument21 pagesProtection of SubstationARVIND100% (2)

- Tutuka PS MV Switchgear Protection SchemesDocument33 pagesTutuka PS MV Switchgear Protection SchemesAdhyartha KerafNo ratings yet

- Lec # 10 Earthing and GroundingDocument68 pagesLec # 10 Earthing and GroundingSaddam jatt786No ratings yet

- Psse System Test For Voltage Collapse Analysis PDFDocument22 pagesPsse System Test For Voltage Collapse Analysis PDFDalessandroNo ratings yet

- Terco PST2200 ENGDocument28 pagesTerco PST2200 ENGWak TacuNo ratings yet

- Electrical Cable Fault LocatingDocument41 pagesElectrical Cable Fault LocatingKARAM ZAKARIA100% (1)

- GenieEvo MVP 5320 v4Document46 pagesGenieEvo MVP 5320 v4sulemanchNo ratings yet

- History Spring08Document7 pagesHistory Spring08Anonymous 9VcxlFErfNo ratings yet

- Distance ProtectionDocument24 pagesDistance ProtectionJulio AristizabalNo ratings yet

- Lucy Ring MainDocument12 pagesLucy Ring MainfndprojectNo ratings yet

- UniMasr.com 79e3983af376cc3e0a3c7adef354815eDocument60 pagesUniMasr.com 79e3983af376cc3e0a3c7adef354815eBala MNo ratings yet

- GER 3178 LBB ProtectionDocument20 pagesGER 3178 LBB ProtectionsureshnfclNo ratings yet

- Studying No-Load Operation of Transmission LineDocument44 pagesStudying No-Load Operation of Transmission Lineeaf1No ratings yet

- Exercise - Setting An SEL-751A To Replace An Existing Electromechanical RelayDocument8 pagesExercise - Setting An SEL-751A To Replace An Existing Electromechanical RelayDavidNo ratings yet

- 6.1-Busbar Protection PDFDocument54 pages6.1-Busbar Protection PDFMohammed Bashri100% (7)

- TechInfo01 IT System FA enDocument6 pagesTechInfo01 IT System FA encarrot123456No ratings yet

- Earthing in Electrical Network - Purpose, Methods and MeasurementDocument33 pagesEarthing in Electrical Network - Purpose, Methods and Measurementmsaadi717No ratings yet

- Distance Protection: 1 Import ProjectDocument12 pagesDistance Protection: 1 Import ProjectJuan David RamírezNo ratings yet

- Differential Protection 8Document42 pagesDifferential Protection 8Noli OtebaNo ratings yet

- EATON Protection and Control RelaysDocument8 pagesEATON Protection and Control RelaysRazvan MaresNo ratings yet

- Broken Conductor Protection PDFDocument4 pagesBroken Conductor Protection PDFRandhir KumarNo ratings yet

- Improve Reliability with Numerical RelayingDocument49 pagesImprove Reliability with Numerical RelayingBhargav PandyaNo ratings yet

- 6.1-Busbar Protection PDFDocument54 pages6.1-Busbar Protection PDFmubarakkirkoNo ratings yet

- What Is The Difference Between MCB, MCCB, ELCB, and RCCBDocument7 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCBYousif_AbdalhalimNo ratings yet

- 3 - Transformer FaultDocument4 pages3 - Transformer FaultJoseph FaresNo ratings yet

- Bus Bar Protection REV 1Document18 pagesBus Bar Protection REV 1Jai GuptaNo ratings yet

- ELR: ABB Range of Front Panel Residual Current Relays: Protection Device According To IEC/EN 60947-2 Annex MDocument12 pagesELR: ABB Range of Front Panel Residual Current Relays: Protection Device According To IEC/EN 60947-2 Annex MNgọc Nguyễn Thanh100% (1)

- Energy Meter Test ReportDocument4 pagesEnergy Meter Test ReportHumayun AhsanNo ratings yet

- Substation Automation Basics - The Next GenerationDocument8 pagesSubstation Automation Basics - The Next GenerationAlly RaxaNo ratings yet

- Ground fault protection for high voltage busbarsDocument40 pagesGround fault protection for high voltage busbarshaichau199No ratings yet

- Protection SchemesDocument20 pagesProtection SchemesMohamed Wahid100% (1)

- Busbar Differential ProtectionDocument2 pagesBusbar Differential Protectionnomy158No ratings yet

- Ferroresenance Phenomena of A Station Service Transformer During Black Start and Its Investigatio1Document4 pagesFerroresenance Phenomena of A Station Service Transformer During Black Start and Its Investigatio1pongpumNo ratings yet

- Schneider Ect128 - Design and Use of Current-Limiting Fuse - 1Document30 pagesSchneider Ect128 - Design and Use of Current-Limiting Fuse - 1lbk50100% (1)

- Restricted Earth Fault Protection of Transformer - REF ProtectionDocument4 pagesRestricted Earth Fault Protection of Transformer - REF Protectionpoornak47No ratings yet

- Partial Discharge Analysis in High-Frequency Transformer Based On High-Frequency Current TransducerDocument13 pagesPartial Discharge Analysis in High-Frequency Transformer Based On High-Frequency Current TransducerKaiba SetoNo ratings yet

- Characteristics of Inrush Current of Present Designs of Power Transformers PDFDocument6 pagesCharacteristics of Inrush Current of Present Designs of Power Transformers PDFbpchimeraNo ratings yet

- Distance Protection of Series-Compensated Lines – Problems and Solutions ExplainedDocument36 pagesDistance Protection of Series-Compensated Lines – Problems and Solutions ExplainedfreddyriveraNo ratings yet

- Electrical Power SystemsDocument14 pagesElectrical Power SystemsEternalOOOSunshine100% (1)

- Technical Specification of 6 6kV Capacitor Bank-1Document7 pagesTechnical Specification of 6 6kV Capacitor Bank-1saturasatuNo ratings yet

- Protective Relays RelaysDocument14 pagesProtective Relays RelaysPaul Sunny100% (1)

- Disturbance AnalysisDocument20 pagesDisturbance AnalysisArliel John GarboNo ratings yet

- Feeder Protection - Distance System PDFDocument49 pagesFeeder Protection - Distance System PDFAndrea MaurillaNo ratings yet

- Ferroresonance Suppression in Voltage TransformersDocument6 pagesFerroresonance Suppression in Voltage TransformersmmshtNo ratings yet

- CT Current Transformer GuideDocument9 pagesCT Current Transformer Guidesonu200186100% (1)

- Mason-The Art & Science of Protective Relaying (002-010)Document9 pagesMason-The Art & Science of Protective Relaying (002-010)Marian ArjonaNo ratings yet

- Power System Protection - Part 08Document16 pagesPower System Protection - Part 08Rahul MandalNo ratings yet

- Upgrading The ProtectionDocument4 pagesUpgrading The ProtectionMukesh KumarNo ratings yet

- Power System Protection PDFDocument12 pagesPower System Protection PDFBala MNo ratings yet

- Over-Head Conductors IN Transmission LineDocument33 pagesOver-Head Conductors IN Transmission LineSubhashree SahuNo ratings yet

- Different Types of RelaysDocument34 pagesDifferent Types of RelayssupriyarakshitNo ratings yet

- Directional RelayDocument86 pagesDirectional Relaysamarth krNo ratings yet

- Auto Transformer Insulation Coordination StudyDocument6 pagesAuto Transformer Insulation Coordination StudyrajfabNo ratings yet

- Transformer Protections: by Alok RaiDocument8 pagesTransformer Protections: by Alok RaiAlok RaiNo ratings yet

- Transformer Differential Protection ANSI Code 87 TDocument7 pagesTransformer Differential Protection ANSI Code 87 TPierre Enrique Carrasco FuentesNo ratings yet

- Unit & Non-Unit Type ProtectionDocument1 pageUnit & Non-Unit Type ProtectionDEEPAK MITTAL67% (3)

- SFRA impedance analysis under 40 charsDocument22 pagesSFRA impedance analysis under 40 charsAnonymous zzMfpoBxNo ratings yet

- CENG 104 Programming II CourseDocument1 pageCENG 104 Programming II CourseBahadır AkbalNo ratings yet

- Vilnius Bus Station to Airport Shuttle ScheduleDocument1 pageVilnius Bus Station to Airport Shuttle ScheduleBahadır AkbalNo ratings yet

- Is 808-1989 Steel TableDocument24 pagesIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- PQ Network Fscan and Harm Distortion NewDocument4 pagesPQ Network Fscan and Harm Distortion NewBahadır AkbalNo ratings yet

- Template of IREEDocument3 pagesTemplate of IREEBahadır AkbalNo ratings yet

- Application Note - Investigating Possible Induction Generator Effects Due To SSR - No Background ColourDocument6 pagesApplication Note - Investigating Possible Induction Generator Effects Due To SSR - No Background ColourBahadır AkbalNo ratings yet

- Power Substation Automation & Communication - IEC 61850Document27 pagesPower Substation Automation & Communication - IEC 61850boeingAH64No ratings yet

- Iet Epa CFP MvpeteegcsDocument1 pageIet Epa CFP MvpeteegcsBahadır AkbalNo ratings yet

- DL GTU102-S Power Trasmission and DistributionDocument4 pagesDL GTU102-S Power Trasmission and DistributionBahadır AkbalNo ratings yet

- Kahramanmaras Sutcu Imam University Journal of Engineering Sciences Journal DergiParkDocument2 pagesKahramanmaras Sutcu Imam University Journal of Engineering Sciences Journal DergiParkBahadır AkbalNo ratings yet

- Comparison of Neutral Earthing MethodsDocument5 pagesComparison of Neutral Earthing MethodsBahadır AkbalNo ratings yet

- DaskPoliceBasim8pt YeniDocument1 pageDaskPoliceBasim8pt YeniBahadır AkbalNo ratings yet

- Halil DergiDocument3 pagesHalil DergiBahadır AkbalNo ratings yet

- HAKEMLER IJITCS - International Journal of Information Technology & Computer ScienceDocument2 pagesHAKEMLER IJITCS - International Journal of Information Technology & Computer ScienceBahadır AkbalNo ratings yet

- YAYININ IJITCS - International Journal of Information Technology & Computer ScienceDocument5 pagesYAYININ IJITCS - International Journal of Information Technology & Computer ScienceBahadır AkbalNo ratings yet

- EDİTOR IJITCS - International Journal of Information Technology & Computer ScienceDocument5 pagesEDİTOR IJITCS - International Journal of Information Technology & Computer ScienceBahadır AkbalNo ratings yet

- Nexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFDocument25 pagesNexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFnicesreekanthNo ratings yet

- YAYININ IJITCS - International Journal of Information Technology & Computer ScienceDocument5 pagesYAYININ IJITCS - International Journal of Information Technology & Computer ScienceBahadır AkbalNo ratings yet

- Barcelona Conferences Abstracts December 2016Document82 pagesBarcelona Conferences Abstracts December 2016Bahadır AkbalNo ratings yet

- ReservedDocument1 pageReservedSiddarthan AnnamalaiNo ratings yet

- CSA-Kapur Method To Determine Ice Load Amount On Electric Transmission Line ConductorsDocument4 pagesCSA-Kapur Method To Determine Ice Load Amount On Electric Transmission Line ConductorsBahadır AkbalNo ratings yet

- Distribution Automation Handbook ABB - Electrical SafetyDocument12 pagesDistribution Automation Handbook ABB - Electrical SafetyEduardo Zapata100% (1)

- Paper Template 2009 05 21 V 9 Updated 1 31 12Document4 pagesPaper Template 2009 05 21 V 9 Updated 1 31 12Bahadır AkbalNo ratings yet

- ABB XLPE Cable Systems Users Guide Rev 3Document28 pagesABB XLPE Cable Systems Users Guide Rev 3vijaypshindeNo ratings yet

- Nexans High Voltage UndergroundDocument64 pagesNexans High Voltage UndergroundBahadır AkbalNo ratings yet

- Ab Power Cable AnalysisDocument2 pagesAb Power Cable AnalysisBahadır AkbalNo ratings yet

- Filter inductor and transformer design using the Kg methodDocument63 pagesFilter inductor and transformer design using the Kg methodBahadır AkbalNo ratings yet

- 2004 Int Ansys Conf 36Document8 pages2004 Int Ansys Conf 36Bahadır AkbalNo ratings yet

- Pad Mounted TransformerDocument14 pagesPad Mounted Transformeraryans143sNo ratings yet

- Turk Indutive Speed Sensor PDFDocument3 pagesTurk Indutive Speed Sensor PDFAhmad DagamsehNo ratings yet

- Multi-Product Calibrator: Getting StartedDocument40 pagesMulti-Product Calibrator: Getting StartedPham Ngoc HaiNo ratings yet

- 3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsDocument12 pages3 A, 2 MHZ Buck-Regulating Led Driver: Description Features and BenefitsElizabet VallejoNo ratings yet

- Swinburne's Test of DC Machine - Electrical4uDocument7 pagesSwinburne's Test of DC Machine - Electrical4uM Kumar Marimuthu0% (1)

- Indoor or Outdoor Current Transformer: Type CMFDocument4 pagesIndoor or Outdoor Current Transformer: Type CMFKatty CachagoNo ratings yet

- Power Electronics & Drives: Unit: 1 Power Semiconductor DevicesDocument24 pagesPower Electronics & Drives: Unit: 1 Power Semiconductor DevicesTapobroto ChatterjeeNo ratings yet

- DC Motor Guide: How Motors Convert Electrical Energy to MotionDocument25 pagesDC Motor Guide: How Motors Convert Electrical Energy to MotionYaron SaksNo ratings yet

- SAIKAT252Document30 pagesSAIKAT252nikcsitNo ratings yet

- PCC3100 02Document98 pagesPCC3100 02Lan Nguyen67% (3)

- ELSGS01Document13 pagesELSGS01Ariel Anibal AparicioNo ratings yet

- P1 - (JLD 3.0) - Capacitor - PYQsDocument45 pagesP1 - (JLD 3.0) - Capacitor - PYQsChiranjivi.S GowdaNo ratings yet

- X Ray GeneratorDocument70 pagesX Ray Generatorub17075% (4)

- Implementation and Validation of The Nordic Test System in Digsilent PowerfactoryDocument6 pagesImplementation and Validation of The Nordic Test System in Digsilent PowerfactoryDiego J. AlverniaNo ratings yet

- Operation of MicrogridDocument52 pagesOperation of Microgridketan bhere100% (1)

- Fyp Final Year Report Solar ThermalDocument34 pagesFyp Final Year Report Solar ThermalFaiq AhmedNo ratings yet

- Pyramid DSP Series UpsDocument66 pagesPyramid DSP Series UpsЮрий КуликNo ratings yet

- Golf Variant Edition March 2011Document3 pagesGolf Variant Edition March 2011Anonymous vQewJPfVXaNo ratings yet

- EeeDocument13 pagesEeesiddharthNo ratings yet

- 004 - Power Fuse (LS)Document16 pages004 - Power Fuse (LS)HungPhanNo ratings yet

- 6EP14372BA20 Datasheet enDocument4 pages6EP14372BA20 Datasheet enBastián Hernández VarelaNo ratings yet

- Catalogue Pages of S200C Circuit BreakersDocument20 pagesCatalogue Pages of S200C Circuit BreakersLucas MorenoNo ratings yet

- On Load Tap Changers Abb PDFDocument12 pagesOn Load Tap Changers Abb PDFKushtrim MalaNo ratings yet

- Ericsson Universal Cable EngDocument1 pageEricsson Universal Cable EngMuhammad Afrizal HidayatNo ratings yet

- Extracted Pages From Daikin VRV-A Engineering DataDocument2 pagesExtracted Pages From Daikin VRV-A Engineering Datalilama45-1No ratings yet

- Chapter 8 (3-Phase AC Circuits)Document47 pagesChapter 8 (3-Phase AC Circuits)Conde RomelNo ratings yet

- SPD Selection GuideDocument8 pagesSPD Selection GuideLorenzo GuidaNo ratings yet

- GATE EE 2001 Section A Resonance and Inductively Coupled CircuitsDocument15 pagesGATE EE 2001 Section A Resonance and Inductively Coupled CircuitsJohnfinn CaddickNo ratings yet