Professional Documents

Culture Documents

WPC120 PDF

Uploaded by

HamzaHashimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPC120 PDF

Uploaded by

HamzaHashimCopyright:

Available Formats

WPC120 Wrap-around Girth Weld Sleeve

Heat Shrinkable Products

The WPC120 with PCI (Permanent Change Indicator) is a two-layer field-joint coating

system for pipeline operating at 121C (250F) temperature.

Product description

WPC120 field-joint coating.

Construction: Two-layer system:

First layer: High shear-strength copolymer adhesive.

Second layer: Radiation cross-linked, high density polyethylene with PCI

(Permanent Change Indicator).

WPC120 is a wrap-around, heat-shrinkable sleeve designed for corrosion prevention and sealing on various types of piping systems (oil, gas, water, pipe-type cable, etc.), which operate

at temperatures up to 121C (250F). WPC120 is specially suited for higher stress conditions

caused both by elevated temperatures and by soils with severe contraction between wet-dry cycles. WPC120 is normally used for girth weld protection of steel pipes coated with Rayclad120 heat shrinkable tape. WPC120 may be cut to appropriate length to cover all pipe diameters.

The system is designed to be applied with minimum preheating of the pipe.

While installing, WPC120 is wrapped around the joint, a closure patch is then installed (already pre-attached if Uni-sleeve) forming a tube, and the sleeve is shrunk in

place. No epoxy primer is required. Upon heat exposure, the sleeve starts shrinking from its expanded size to form a tight fit around the substrate. During recovery,

the copolymer adhesive softens and flows to form a perfect bond with the pipe surface providing pipe protection against corrosion. The radiation cross-linked outer

layer forms a durable barrier to moisture and mechanical damage.

Product features/benefits

U

U

U

U

U

Product selection guide

Dimpled backing provides a permanent change" indicator for

application of heat

Ensures correct application heat & allows easy post-heat inspection.

Reliable inspectability at any time.

Available as a one-piece wrap-around unit or in roll form

Saves money by keeping inventory and logistics costs low.

High shear resistance

Provides high functional performance and safety.

High operating temperature rating

Top performance in demanding conditions.

No special equipment (standard gas torch & a roller) or skills required

Makes installation fast and easy.

Keeps installation costs low.

WPC120

Max operating temperature

121C (250F)

Compatible line coatings

PE, FBE, Rayclad120

Min preheat temperature

230C (446F)

Recommended pipe preparation

SA 2

Soil stress restrictions

None

DS-WPC120-REV-7-0309

Product thickness

WPC120 (/B)

0.030 in. (0.75 mm)

0.039 in. (1.0 mm)

0.039 in. (1.0 mm)

Backing (as supplied)

Backing (fully free recovered)

Adhesive (as supplied)

Product properties: WPC120 (1)

Property

Backing

Test method

Typical Value

Tensile strength

ASTM D-638

Elongation

ASTM D-638

Hardness, Shore D

Shrink force

Dielectric strength

ASTM D-2240

ASTM D-638

150C (302F)

ASTM D-149

2700 psi @ 23C (73F)

660 psi @ 121C (250F)

580% @ 23C (73F)

560% @ 121C (250F)

57

40 psi

Moisture absorption

ASTM D-570

800 volts/mil

31.5 kV/mm

0.06%

Adhesive

Softening point

Lap shear

ASTM E-28

ASTM D-1002

175C (347F)

1300 psi @ 23C (73F)

100 psi @ 121C (250F)

p 1 of 2

Product properties: WPC120 (2)

Property

Sleeve

Test method

Typical Value Property

Peel to Steel

ASTM D-1000

30 lbs/in.width @ 23C (73F)

Cathodic disbondment

Hot water immersion

Soil stress creep resistance

Low temperature flexibility

Impact resistance

Penetration resistance

ASTM G-42, 30 days

ASTM D-870, @ 90C (194F), 120 days

TP-206, @ 120C (248F), 24 hrs

ASTM D-2671-C

ASTM G-14

ASTM G-17

10 mm radius @ 121C (250F)

no delamination, no blisters or water under sleeves

0.002 inches (0.051 mm)

-50C (-58F)

90 in-lbs

no holiday with 12 kV detector @ 121C (250F)

(1)

Nominal width

Ordering information

WPC120 type products are available:

v� as cut piece (pre-cut sleeve and separate closure patch)

v� as Uni-sleeve (pre-cut sleeve with pre-attached closure patch)

v� as a roll (closure patches to be ordered separately)

Select sleeve width that will overlap onto the millapplied coating by 2 inches (50 mm) minimum on

each side of the weld joint.

Take a 10% shrinkage during installation of sleeve

width into account when calculating the minimum

sleeve width.

6Z

Sleeve width

* Cut piece / Uni-sleeve

Example: WPC120-10750X17/B/UNI

Standard Ordering options

WPC...

10750

17

Product type

Outside pipe diameter in mils

Sleeve width in inches (Sw)

Thickness code

WPC120

2.375" 48.000" (DN50 DN 1200)

(1)

11" (11.25 or 285 mm) (1), 17" (17.75 or 450 mm)

(1)

(1)

24" (23.5 or 600 mm) , 34"(34.25 or 870 mm)

B

Designates pre-attached closure patch

optional

WPC...

17

Product type

Roll width in inches (Sw)

WPC120

100

Roll length in feet (Sl)

/UNI

(1)

DS-WPC120-REV-7-0309

* Roll form (closure patches to be ordered separately)

Nominal width

Example: WPC120-17x100-RL

Standard Ordering options

* Closure patch

(1)

(1)

11" (11.25 or 285 mm) (1), 17"(17.75 or 450 mm)

24" (23.5 or 600 mm) (1), 34"(34.25 or 870 mm)(1)

100 ft (30 m)

Nominal width

Example: WPCP-IV-4x17

4

17

Closure patch width in inches (Pw)

Closure patch length in inches (Pl)

4" (100 mm), 6" (150 mm)

11" (11.25 or 285 mm) (1), 17"(17.75 or 450 mm) (1)

24" (23.5 or 600 mm) (1), 34"(34.25 or 870 mm)(1)

(1)

Nominal width

Sleeve cut lengths and appropriate closure patch widths depend on the pipe size and product construction, see latest application table AT-GIRTHWELD

For proper product installation, see latest installation instruction.

Berry Plastics warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when used in compliance with Berry Plastics

written instructions. Since many installation factors are beyond the control of Berry Plastics, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities

in connection herewith. Berry Plastics liability is stated in the standard terms and conditions of sale. Berry Plastics makes no other warranty either expressed or implied. All information contained in

this technical data sheet is to be used as a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

Local Distributor / Representative:

For contact details of local Distributors / Representatives

Please visit www.berrycpg.com.

www.berrycpg.com

Headquarters : Berry Plastics Tapes & Coatings Division, Franklin MA, USA

Franklin, MA, USA

Tel: +1 508 918 1714

US Toll Free: +1 800 248 0149

Fax: +1 508 918 1910

CPG@berryplastics.com

Houston, TX, USA

Tel: +1 713 676 0085

US Toll Free: 01 888 676 7202

Fax:+1 713 676 0086

CPGH@berryplastics.com

Tijuana, Mexico

Tel USA +1 858 633 9797

Fax US: +1 858 633 9740

Tel Mexico: +52 664 647 4397

Fax Mexico: +52 664 647 4370

CPGTJ@berryplastics.com

Aarschot, Belgium

Tel: +32 16 55 36 00

Fax: +32 16 55 36 74

CPGE@berryplastics.com

Baroda, India

Tel: +91 2667 264721

Fax: +91 2667 264724

CPGIN@berryplastics.com

p 2 of 2

You might also like

- KRA List & Responsibility MatrixDocument1,158 pagesKRA List & Responsibility MatrixBheemeshwer Singh MouryaNo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 pagesDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- Polyken 2000 High TempDocument2 pagesPolyken 2000 High TempKyaw Kyaw AungNo ratings yet

- Rainwater DesignDocument64 pagesRainwater DesignarifzakirNo ratings yet

- Sea WaterDocument39 pagesSea WaterArun GuptaNo ratings yet

- DSI Bonded PT System Strands enDocument32 pagesDSI Bonded PT System Strands enElvisyuriNo ratings yet

- Viking Johnson ProductsDocument31 pagesViking Johnson ProductsAlvin MiraNo ratings yet

- Best Available Techniques (BAT) For Pulp and PaperDocument900 pagesBest Available Techniques (BAT) For Pulp and PaperHuy NguyenNo ratings yet

- Raychem-Cata MV TerminationDocument16 pagesRaychem-Cata MV TerminationKeshab ShresthaNo ratings yet

- HTLP Heat Shrinkable SleeveDocument2 pagesHTLP Heat Shrinkable SleeveGanesh EshwarNo ratings yet

- WPCT Heat Shrink SleevesDocument4 pagesWPCT Heat Shrink SleevesHamzaHashimNo ratings yet

- DS Flex Rev7 0309 PDFDocument2 pagesDS Flex Rev7 0309 PDFDavid GonzaloNo ratings yet

- Covalence WPC100M Shrink Sleeves PDFDocument2 pagesCovalence WPC100M Shrink Sleeves PDFJMROMANTNo ratings yet

- Ds Dirax PP Rev8 0309 1Document2 pagesDs Dirax PP Rev8 0309 1Elias KapaNo ratings yet

- DENSO 50 Heat Shrink Sleeve (DENSO 50HSS)Document3 pagesDENSO 50 Heat Shrink Sleeve (DENSO 50HSS)jay2kay5793No ratings yet

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDocument5 pagesRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhNo ratings yet

- Wrapid BondDocument2 pagesWrapid BondgrtunaNo ratings yet

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- Cinta HVBTDocument2 pagesCinta HVBTFaVCMNo ratings yet

- Acw 0219Document2 pagesAcw 0219anna_malai078351No ratings yet

- 10-D1-VHightech (Very High Density Foam)Document1 page10-D1-VHightech (Very High Density Foam)GPNo ratings yet

- Dirax PDFDocument2 pagesDirax PDFTom Henry Bernabe Castro100% (1)

- Sika Plan 14.6Document3 pagesSika Plan 14.6the pilotNo ratings yet

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelDocument2 pagesCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzNo ratings yet

- HBR XL - Crosslink Closed Cell PDSDocument2 pagesHBR XL - Crosslink Closed Cell PDSHuy ThaiNo ratings yet

- Sika Plan 9.6Document3 pagesSika Plan 9.6the pilotNo ratings yet

- Trocal Stone Floor Sheet 1.2Document3 pagesTrocal Stone Floor Sheet 1.2the pilotNo ratings yet

- Afico Faceed InsulationDocument4 pagesAfico Faceed Insulationhello1230No ratings yet

- BR Polyken Rev11 Sep10Document8 pagesBR Polyken Rev11 Sep10diaccessltd_17172961No ratings yet

- Wrapid Sleeve PDSDocument2 pagesWrapid Sleeve PDSjayhuacat7743No ratings yet

- K-Flex Tapes BrochureDocument16 pagesK-Flex Tapes BrochuregetashishvaidNo ratings yet

- CamisaDocument2 pagesCamisaJuan Roberto López BetanzosNo ratings yet

- Tricosal KatalogasDocument32 pagesTricosal KatalogaschaubeyskcNo ratings yet

- Sika Tricomer (Eng)Document12 pagesSika Tricomer (Eng)ilijarskNo ratings yet

- 12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMDocument124 pages12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMhoangtinbkNo ratings yet

- 22 Ohm ResistorDocument11 pages22 Ohm ResistorDwp BhaskaranNo ratings yet

- Useholders: FuseholdersDocument18 pagesUseholders: FuseholdersVirginiaLaudaniNo ratings yet

- SikaWrap-230 CDocument3 pagesSikaWrap-230 CDac PiNo ratings yet

- Sika PDS - E - Sarnafil G 476 PDFDocument3 pagesSika PDS - E - Sarnafil G 476 PDFlwin_oo2435No ratings yet

- Visqueen Ultimate HC BLOK DatasheetDocument5 pagesVisqueen Ultimate HC BLOK Datasheetali aliNo ratings yet

- Model 1263 Model 1263: Tedea-HuntleighDocument3 pagesModel 1263 Model 1263: Tedea-HuntleighEong Huat Corporation Sdn BhdNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- Electrical TapeDocument2 pagesElectrical TapemmartincikNo ratings yet

- IsoTek Manual 8-18-14Document13 pagesIsoTek Manual 8-18-14usamazarifehNo ratings yet

- Rhodia - Tds - Technyl A 218 v30 Black 21ns - enDocument5 pagesRhodia - Tds - Technyl A 218 v30 Black 21ns - enrquaibiNo ratings yet

- Polyken 905 TapeDocument2 pagesPolyken 905 TapeKyaw Kyaw AungNo ratings yet

- SikaWrap-231 C PDFDocument3 pagesSikaWrap-231 C PDFDarwin SyahputraNo ratings yet

- Hawo Hd680de Dev Deiv - enDocument4 pagesHawo Hd680de Dev Deiv - enSertgio Zapata EspinosaNo ratings yet

- HVBT - Bus Bar Insulation Tape - 25 KVDocument2 pagesHVBT - Bus Bar Insulation Tape - 25 KVLakshmi NarayananNo ratings yet

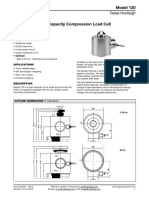

- Model 120 Model 120: Tedea-HuntleighDocument3 pagesModel 120 Model 120: Tedea-HuntleighEong Huat Corporation Sdn BhdNo ratings yet

- Gall5231328512232fip PDFDocument15 pagesGall5231328512232fip PDFAndres CortezNo ratings yet

- Section - 079129 - Penetration SealsDocument6 pagesSection - 079129 - Penetration SealsBikash BhattaraiNo ratings yet

- Sika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneDocument3 pagesSika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneSouvik DasNo ratings yet

- SikaWrap-230 C PDFDocument3 pagesSikaWrap-230 C PDFMatteo BreveglieriNo ratings yet

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDocument14 pagesITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengNo ratings yet

- Data Sheet SSG4600Document8 pagesData Sheet SSG4600Anonymous OnzJpzNo ratings yet

- Vibradamp DC30 122IPMDocument3 pagesVibradamp DC30 122IPMtrublu260112No ratings yet

- Tremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031Document12 pagesTremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031ali razaNo ratings yet

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- PE Yellow Gas - WebDocument16 pagesPE Yellow Gas - WebGavin KwanNo ratings yet

- Research On Performance Management Practices in PakistanDocument1 pageResearch On Performance Management Practices in PakistanHamzaHashimNo ratings yet

- Hadmaxjqwoij 2222Document9 pagesHadmaxjqwoij 2222HamzaHashimNo ratings yet

- Camp Areauyyhiu7Document1 pageCamp Areauyyhiu7HamzaHashimNo ratings yet

- Sulphide Scavengers in Oil and Gas Industry - A ReviewDocument8 pagesSulphide Scavengers in Oil and Gas Industry - A ReviewMartín Diego MastandreaNo ratings yet

- Valve Pressure-Temperature Ratings SWAGELOKDocument32 pagesValve Pressure-Temperature Ratings SWAGELOKBsSrinivas SriniNo ratings yet

- Tjy 56 y 45 y 34 T 34 TDocument1 pageTjy 56 y 45 y 34 T 34 THamzaHashimNo ratings yet

- 14th EPE Result (For Website)Document9 pages14th EPE Result (For Website)HamzaHashimNo ratings yet

- Camp AreaDocument1 pageCamp AreaHamzaHashimNo ratings yet

- 8 Employer Survey Feedback Form Rev 01 MEnggDocument1 page8 Employer Survey Feedback Form Rev 01 MEnggHamzaHashimNo ratings yet

- 2 R 7 FHFDocument1 page2 R 7 FHFHamzaHashimNo ratings yet

- Camp AreaDocument1 pageCamp AreaHamzaHashimNo ratings yet

- Calculation of Acquired CPD Points by Candidate Please Enter Acquired CPD Points in Respective Red Boxes OnlyDocument1 pageCalculation of Acquired CPD Points by Candidate Please Enter Acquired CPD Points in Respective Red Boxes OnlyHamzaHashimNo ratings yet

- TorDocument3 pagesTorHamzaHashimNo ratings yet

- Taxpayer Guide For EnrolmentDocument18 pagesTaxpayer Guide For EnrolmentMuhammad IbrahimNo ratings yet

- GdawqdDocument1 pageGdawqdHamzaHashimNo ratings yet

- T-04 T-5 T-06 T-35 T-13 T-39 28mm Tube 30 29 30 15mm Tube Connector, Male, 28Mm 2 2 2 Connector, Male, 15Mm 5 5 5 28mm Threaded Flange 1Document2 pagesT-04 T-5 T-06 T-35 T-13 T-39 28mm Tube 30 29 30 15mm Tube Connector, Male, 28Mm 2 2 2 Connector, Male, 15Mm 5 5 5 28mm Threaded Flange 1HamzaHashimNo ratings yet

- FCASDCDocument1 pageFCASDCHamzaHashimNo ratings yet

- ContentsDocument1 pageContentsHamzaHashimNo ratings yet

- C PDFDocument1 pageC PDFHamzaHashimNo ratings yet

- H PDFDocument1 pageH PDFHamzaHashimNo ratings yet

- H PDFDocument1 pageH PDFHamzaHashimNo ratings yet

- EscwefcasDocument1 pageEscwefcasHamzaHashimNo ratings yet

- H PDFDocument1 pageH PDFHamzaHashimNo ratings yet

- DcxasdDocument1 pageDcxasdHamzaHashimNo ratings yet

- AaaxdDocument1 pageAaaxdHamzaHashimNo ratings yet

- PlottingDocument1 pagePlottingHamzaHashimNo ratings yet

- SFWFDocument1 pageSFWFHamzaHashimNo ratings yet

- CccascDocument1 pageCccascHamzaHashimNo ratings yet

- Contents SepDocument1 pageContents SepHamzaHashimNo ratings yet

- WDDDDDDocument3 pagesWDDDDDHamzaHashimNo ratings yet

- 39 MeisingerDocument11 pages39 MeisingerBaru SomisettyNo ratings yet

- Multiple-Unit Material Balances I: Cheme 101 - 6.4 Worksheet 1 Semester Ay 2020-2021 Department of Chemical EngineeringDocument6 pagesMultiple-Unit Material Balances I: Cheme 101 - 6.4 Worksheet 1 Semester Ay 2020-2021 Department of Chemical EngineeringAcademicBMNo ratings yet

- MUJ - Hostel B8, B9 & B10Document12 pagesMUJ - Hostel B8, B9 & B10GanjaNo ratings yet

- GLR EstimateDocument2 pagesGLR EstimateanbujeNo ratings yet

- Position: Reduced Runway Separation Minima For Night OperationsDocument2 pagesPosition: Reduced Runway Separation Minima For Night OperationsHENIGUEDRINo ratings yet

- Quantum Multiport PackerDocument1 pageQuantum Multiport Packersmithyry2014No ratings yet

- Robotic CafeDocument13 pagesRobotic CafeRana SaqlainNo ratings yet

- Assignment Payment 1Document5 pagesAssignment Payment 1Mohamad SafwanNo ratings yet

- SANS Institute: Unix Security ChecklistDocument9 pagesSANS Institute: Unix Security ChecklistRufino UribeNo ratings yet

- Croker Test & DrainDocument1 pageCroker Test & Drainjhoger2012No ratings yet

- AMIA Definition of Biomedical InformaticsDocument15 pagesAMIA Definition of Biomedical InformaticsAndre FrancoNo ratings yet

- Scheduled Power Interruption For April 23-24, 2019Document1 pageScheduled Power Interruption For April 23-24, 2019glaiNo ratings yet

- IMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicDocument10 pagesIMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicatommotaNo ratings yet

- Cylinder Valve Assembly Series: CV Series PCV SeriesDocument2 pagesCylinder Valve Assembly Series: CV Series PCV SeriesAli OsmanNo ratings yet

- Sizing Columns in HysysDocument4 pagesSizing Columns in HysysemebusamuelNo ratings yet

- Rohit Bebarta CVDocument1 pageRohit Bebarta CVRohit BebartaNo ratings yet

- Abrasive Cleaning SystemDocument4 pagesAbrasive Cleaning SystemSulfikar SalimNo ratings yet

- Imp25 PDFDocument8 pagesImp25 PDFEng Marwa ElsherifNo ratings yet

- Manual Daiwa Tanacom 500 PDFDocument37 pagesManual Daiwa Tanacom 500 PDFHenrique BelliniNo ratings yet

- VGP - Book1Document94 pagesVGP - Book1Chirag DesaiNo ratings yet

- LBS SchneiderDocument20 pagesLBS SchneiderTien Dang ThanhNo ratings yet

- Science 6 Week 2Document3 pagesScience 6 Week 2Ma. Jennifer MapanooNo ratings yet

- Parts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachineDocument39 pagesParts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachinePericoNo ratings yet

- CraftDocument15 pagesCraftImamMukhri100% (1)

- Instrumentation - Aeroplanes: 22.01. Flight InstrumentsDocument27 pagesInstrumentation - Aeroplanes: 22.01. Flight InstrumentsveenadivyakishNo ratings yet

- Line Protection: Return To Main IndexDocument44 pagesLine Protection: Return To Main IndexAli RazaNo ratings yet