Professional Documents

Culture Documents

Distance Protection System in Railway

Uploaded by

pavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distance Protection System in Railway

Uploaded by

pavanCopyright:

Available Formats

Proceedings of the 2006 IASME/WSEAS International Conference on Energy & Environmental Systems, Chalkida, Greece, May 8-10, 2006

(pp357-361)

Distance Protection Settings in Electrical Railway Systems

with Positive and Negative Feeder

Habil. Z. Styczynski

M. R. Ganjavi, R. Krebs

SIEMENS AG, PTD SE PT5

P.O.Box: 3220, D-91050 Erlangen

Germany

OTTO-VON-GUERICKE-UNIVERSITY MAGDEBURG

Faculty of Electrical & Information Technology

Universittsplatz 2, D-39106 Magdeburg

Germany

Abstract: - Electric railway systems have complex configurations of overhead lines, protected by distance

relays. The protection philosophy for this system considers low cost maintenance, control and protection in

autotransformer stations and advanced control and protection in supply stations.

The paper discusses some heuristic rules for settings of distance relays in railway systems with positive and

negative feeder configurations. The experience is formulated as a set of rules (if condition then effect) and stored

in an expert system for fast access.

Key-Words: - Expert System, Traction Supply, Catenary Protection

1 Introduction

Negative and positive feeder arrangement is an

overhead contact line system [2] for energizing trains

with AC voltage (see Fig. 1). In this system, there are

two traction supply station at the beginning and end

of each track and there are several autotransformer

stations between supply stations. There are two or

more main railway tracks between supply stations

and sometimes there are local tracks at each

autotransformer station. Supply stations provide

single-phase a.c. medium voltage to positive and

negative feeders with 180 degree phase difference.

At each autotransformer station all positive feeders,

all negative feeders and all railway tracks are

connected to an autotransformer via positive busbar,

negative busbar and earth busbar respectively. In

addition positive feeders are designed to provide

enough energy to trains but negative feeders are

designed to compensate voltage drop of positive

feeder via autotransformer stations. Therefore, the

current flows in positive and negative feeders are not

balanced during and after acceleration of trains.

As mentioned, in this system three sets of conductors

per railway track exist.

Positive Feeder: The positive feeder is the total

interconnected system consists of contact or catenary

wire and mechanical tension wires. Ii is directly

feeding the train via the contacted pantographs. It

operates with a voltage Vs for example 25kV and

50Hz.

Negative Feeder: The negative feeder operates with

voltage -Vs via the autotransformers according to the

Fig. 1. Most of the current feeding the train will

return to the supply station by the negative feeder and

not by the tracks.

Return Circuit: The return circuit is the total

interconnected system consists of the track,

earth-system conductor, earth grid and earth itself.

2 Electric Railway System Protection

The electric railway system consists of positive,

negative and return circuit will be protected by

distance relays in supply stations.

The trip command is connected to the double phase

circuit breaker, which disconnects both of the

positive and negative feeders.

The measuring quantities for the distance protection

relays installed in each supply station are as follows:

a) Voltage: positive busbar voltage according to the

Fig. 1.

b) Current: Sum of the positive and negative feeder

currents. The measured current will be summed

by secondary connection of the corresponding

current transformers. The relay current is as

follows:

I relay = I pos + I neg

(Eq. 1)

An example for an electric railway system with two

main tracks (Track 1 and Track 2) and two side tracks

Proceedings of the 2006 IASME/WSEAS International Conference on Energy & Environmental Systems, Chalkida, Greece, May 8-10, 2006 (pp357-361)

Fig. 1. Simplified Overhead Contact Line system with negative feeder arrangement

Fig. 2. Two traction supply stations and six autotransformer stations for energizing two railway tracks

Amper

TSS1

TSS1

Relay Input

Currents

Feeder E

Feeder G

AT 1a

AT1b

Feeder G, H

AT 2a

AT 3a

Feeder E,F

AT 4a

AT1b

TSS1

Feeder J, N

Feeder F

Feeder H

Feeder J, N

Fig.3. Distance relays measured currents for faults on the Track 2 in Fig. 2.

(The result is generated by SITRAS SIDYTRAC program.)

AT 5a

Proceedings of the 2006 IASME/WSEAS International Conference on Energy & Environmental Systems, Chalkida, Greece, May 8-10, 2006 (pp357-361)

(Track 3 and Track 4) with two supply station (TSS 1

and TSS 2) and six autotransformer station (AT 1a to

AT 5a and AT 1b) is shown in Fig. 2.

TSS 1 Feeders G and H supplies the Track 1 and

Track 2 toward right side of the TSS 1 station. These

feeders are equipped with negative feeders.

TSS 1 Feeders E and F supplies the Track 1 and

Track 2 toward left side of the TSS 1 station. These

feeders are equipped with negative feeders.

TSS1 Feeders J and N supplies the side tracks Trak 3

and Track 4 toward left side of the TSS 1.

The supply station TSS 1 is normally in operation.

The supply station TSS 2 comes into operation for

emergency situation alone or in parallel with TSS 1.

During normal operation, if a short-circuit between

Track 2 and positive feeder happens then all distance

relays at Feeder E, F, G, H, J and N measures

abnormal currents as all positive feeders, all negative

feeders, along with all autotransformers are in

parallel. Fig. 3 shows the measured current of Feeder

E, F, G, H, J, N as the short-circuit location moves

along the track 2.

The correct setting of distance relay should trip the

fault selectively with Zone 1 or Zone 2 of the distance

relays at relevant feeders according to the following

scheme:

For example for a fault on main track (Track 2)

between supply station TSS 1 and TSS 2 the distance

relay at Feeder G should trip with Zone 1 or Zone 2.

The distance relay at Feeder H should trip with Zone

2. In this way, the TSS 2 and autotransformer

stations AT 1a to AT 5a are de-energized. Then

undervoltage relay in these stations will disconnect

these stations from positive and negative feeders in

around 2.0 seconds. Later, the autoreclose function in

TSS 1 reenergizes the Feeder G and H. Now feeder G

feeds only the Track 2 and feeder H feeds only the

Track 1. If the fault still exists on the Track 2 then the

Feeder G trips again with Zone 1 or Zone 2 and

remains open. In addition all connection between

autotransformer stations and Track 2 remains open.

The connection between Track 1 and autotransformer

stations is closed by system operator so that Track 1

returns to normal operation.

Same scheme should be realized if a fault on a side

track (Track 3 or Track 4) between TSS 1 and

autotransformer station AT 1b happens.

the autotransformer stations. This leads to decrease in

the measured impedance by these relays. (see Fig. 4)

In addition, Fig. 3 shows that the measured fault

current of Feeder J and N becomes zero for a fault

location on the Track 2. Therefore the relays

measures very high impedance and will not pickup to

clear the fault.

During normal operation the measured current by the

relay is equal to the train load current. And during

short-circuit between positive or negative feeder to

ground, the relay current is equal to the short-circuit

current.

However the relay measured impedance is not

directly proportional to the distance-to-fault caused

by following facts [3]:

a) The current injection effect and impedance of

autotransformers along the tracks.

b) Parallel connection of positive feeders of all

parallel tracks.

c) Parallel connection of negative feeders of all

parallel tracks.

c) Back-infeed effect of autotransformers located

behind the regarded supply station.

d) Additional infeed effect of supply systems behind

or front of the regarded supply station.

e) Different impedances per line length for positive

and negative feeders.

f) Side tracks with lower priority are not equipped

with negative feeders. Therefore, the fault current

measured by side track relays becomes zero for

specific short-circuits located on the main track.

ZONE 2 Reach

12

10

AT 4a

435.89

km

O hm

AT 5a

440

km

AT 5a

440

km

AT 3a

424.24

km

AT 2a

418.80

km

AT 1a

412.89

km

Safety

Margin

TSS 1

407.4

km

TSS 2

431

km

Safety

Margin

TSS 2

431

km

ZONE 1 Reach

0

0

0. 5

1. 5

2. 5

3. 5

4. 5

O hm

Realization of this scheme confronted with following

difficulties:

As Fig. 3 shows the measured fault current of Feeder

E, F, G, H increases when the fault location is near to

a) Wi t hout A ut ot r ansf or mer s

b) Wi t h A ut ot r ansf or mer s

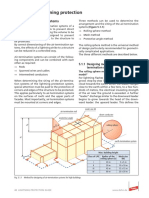

Fig.4. Proper selection of Zone 1 and Zone 2 for distance

relays at feeder G in Fig. 2 considering the effect of

parallel tracks and autotransformers current injection.

Proceedings of the 2006 IASME/WSEAS International Conference on Energy & Environmental Systems, Chalkida, Greece, May 8-10, 2006 (pp357-361)

Fig 5. Measured impedance of distance relays at feeder J and N in Fig. 2 considering the absence of negative feeders

3 Distance relays zone 1 settings

In case of fault on main tracks, for example Track 2,

in Fig. 2 with fault location between TSS 1 and TSS

2, the fault should be cleared by distance relay Zone 1

of Feeder G. Curve (a) in Fig. 4 shows the Feeder G

relay

measured impedance when a all

autotransformers are disconnected, positive and

negative feeders of the Track 1 and Track 2 are not

parallel to each other. Curve (b) in Fig. 4 shows the

measured impedance in normal operation when the

Track 1 and the Track 2 are parallel and

autotransformers are in operation.

As shown in Fig. 4, the observed impedance for a

given fault location in case (b) is approximately half

of the case (a) while the Track 1 and 2 are in parallel.

In addition, the current injection at each

autotransformer station results a saw-shape drop in

the impedance locus.

The measured relay impedance in the R-X plane like

Fig. 4, should be created for the following fault

scenarios by simulation methods (like SITRAS

SIDYTRAC program or [1]):

-

Fault between catenary to running rail

Fault between negative feeder and running rail

Fault between catenary and negative feeder

No fault but maximum load conditions

And also for following operation conditions:

-

All autotransformer are disconnected.

Track 1 and Track are not parallel.

All autotransformer are connected.

Supply station TSS1 is in operation

Supply station TSS2 is in operation

In order to have a selective protection for the distance

relay at Feeder G in Fig. 2, its Zone 1 reach should be

smaller than the supply station TSS2 impedance

reach measured by the relay.

Therefore all of the created R-X planes should be

analyzed for finding the minimum impedance reach

of the autotransformer station AT 4a after the

saw-shape impedance drop as shown in Fig. 4.

A safety margin of 10% to 20% can be applied to

have a safe value for Zone 1 reach.

Finding the Zone 1 reach for Feeder G distance relay

in Fig. 2, according to the above method, needs vast

amount of simulation for creation of R_X phase

plane diagram. During these analyses we have found

the following rule:

Zone 1reach = k Z TSS remote

(Eq. 2)

Proceedings of the 2006 IASME/WSEAS International Conference on Energy & Environmental Systems, Chalkida, Greece, May 8-10, 2006 (pp357-361)

Where:

Z TSS remote

: Impedance of one catenary between the

two supply stations (For example between TSS1 and

TSS2 in Fig. 2).

k : The reduction factor between 7010%. It

considers the autotransformers injection effect and

parallel impedances of positive feeders or negative

feeders between parallel tracks.

The Zone 1 needs no delay to send the trip command

to circuit breakers.

Same rule is valid for adjusting distance relay at

Feeder H, E, F, J, N in Fig. 2 when a fault on the main

tracks or on the side tracks of the left side of TSS 1

happens.

5 Distance relays zone 2 settings

In order to have a selective protection for the distance

relay at Feeder G in Fig. 2, its Zone 2 reach should be

higher than the supply station TSS2 impedance reach

observed by the relay.

The advanced analysis method mentioned in section

four is applicable. However finding the Zone 2

reach, according to the above method, needs vast

amount of simulation for creation of R_X phase

plane diagram. During these analyses we have found

the following simple rule:

Zone 2 reach = k Z TSS remote

(Eq. 3)

Where:

Z TSS remote : Impedance of one catenary between the

two supply stations. (For example TSS1 and TSS2 in

Fig. 2)

k : A factor between 17020%

The Zone 2 should send the trip command to circuit

breakers with 0.4 to 1.0 second delay.

In practice some side tracks parallel to main track has

no negative feeders. Track 3 and 4 in Fig. 2 and 3 are

an example of such tracks.

As Fig. 3 shows, for a given fault location on main

Track 2, the distance relay on Track 3 observes zero

current or infinite impedance. Fig. 5 shows the

corresponding impedance locus of the distance relay

located at feeder J in Fig. 2.

In such a situation distance relays at feeder J will not

pick up. But the distance protection on the main track

at Feeder E and F trips with Zone 1 or 2 correctly and

then the distance relays at feeder J trips with Zone 1.

Therefore the suggested rule in Eq. 3 remains valid.

6 Conclusions

The configuration of electric railway systems,

especially if they are supplied with autotransformers

between positive and negative feeders, is very

complex.

The used and well known protection principle

distance protection is facing problems which could

lead to relay malfunction. The nonlinearity between

distance-to-fault and impedance-to-fault is described

in the paper. Rules for optimization of distance

protection Zone 1 and Zone 2 are proposed.

For future relay settings calculations, these rules will

be implemented in an existing expert system for

protection coordination.

References:

[1] E. Pilo, L. Rouco, A. Fernandez, and A.

Hernandez, A simulation tool for the design of

electrical supply system of high-speed railway

lines, presented at IEEE PES Summer meeting

2000, Seattle, USA.

[2] G. Varju, A comparison of the booster

transformer and auto transformer railway

feeding systems, feeding features and induction to

telecom lines, presented at EMC York 2004,

York, UK.

[3] Ganjavi M.R.; Krebs R.: Catenarys distance

protection in traction supply systems with

negative feeder arrangement, 14th International

Conference on Power System Protection (PSP

2004), pp. 201-210, Bled, Slovenia, September

2004

You might also like

- Distance Protection RelayDocument27 pagesDistance Protection RelaycallkalaiNo ratings yet

- Report On Tripping of Delta I Relay On Running of Wag12 LocosDocument3 pagesReport On Tripping of Delta I Relay On Running of Wag12 LocosrdkrdsoNo ratings yet

- ABB REF - Protection - RADHD-Notes PDFDocument8 pagesABB REF - Protection - RADHD-Notes PDFEBENo ratings yet

- HVDC ProtectionDocument10 pagesHVDC ProtectiondhrghamNo ratings yet

- 1MRK506340-UEN B en Commissioning Manual Line Distance Protection REL670 2.0 IECDocument270 pages1MRK506340-UEN B en Commissioning Manual Line Distance Protection REL670 2.0 IECAnonymous dH3DIEtzNo ratings yet

- Summation of Alternating CurrentsDocument3 pagesSummation of Alternating Currentsalexns84No ratings yet

- Chapter Four: Relay CoodinationDocument25 pagesChapter Four: Relay Coodinationmuaz_aminu1422No ratings yet

- Busbar ProtectionDocument10 pagesBusbar ProtectionMohd Taufiq IshakNo ratings yet

- Trip Circuit Supervision Relay Spec 0604Document5 pagesTrip Circuit Supervision Relay Spec 0604Sameera ChamingaNo ratings yet

- IEC 61850 Testing Tools ENUDocument4 pagesIEC 61850 Testing Tools ENUconst_nos100% (1)

- Distance Protection SchemesDocument11 pagesDistance Protection SchemesParichay GuptoNo ratings yet

- Differential Protection of Transformer Differential RelaysDocument2 pagesDifferential Protection of Transformer Differential RelaysHARIHARANNo ratings yet

- What Is Distance ProtectionDocument2 pagesWhat Is Distance Protectionboopathi1986No ratings yet

- Behavior of Current Transformers (CTS) Under Severe Saturation ConditionDocument5 pagesBehavior of Current Transformers (CTS) Under Severe Saturation ConditionAdianto Ari PurwanaNo ratings yet

- 3 - Busbar Protection Scheme Explained - Electrical ConceptsDocument18 pages3 - Busbar Protection Scheme Explained - Electrical Conceptsabu sayedNo ratings yet

- Induction Disc & Time-Overcurrent RelaysDocument30 pagesInduction Disc & Time-Overcurrent Relayssherif ahmed moussaNo ratings yet

- NSD 50&mcdDocument25 pagesNSD 50&mcdkrishnamanikandanNo ratings yet

- Distance Protection SchemeDocument8 pagesDistance Protection Schemesajjad ramezanzadehNo ratings yet

- Carrier Aidded ProtectionDocument4 pagesCarrier Aidded ProtectionThirumalNo ratings yet

- EE35T - Transformer Differential ProtectionDocument4 pagesEE35T - Transformer Differential ProtectionTanveer Ul HaqNo ratings yet

- Automatic Load Sharing of TransformerDocument7 pagesAutomatic Load Sharing of TransformerSarang AbadagireNo ratings yet

- Busbar Protection Philedelphia Edu LibreDocument90 pagesBusbar Protection Philedelphia Edu Libreprakasa88No ratings yet

- 12 Pulse Rectifier For MeaDocument6 pages12 Pulse Rectifier For MeaJeevan KalraNo ratings yet

- Knee Point Voltage of Current Transformer PS ClassDocument4 pagesKnee Point Voltage of Current Transformer PS ClassMang PorongNo ratings yet

- 01 UTM ProtectionDocument105 pages01 UTM ProtectionrajimuruganNo ratings yet

- DC Time Constant EstimationDocument6 pagesDC Time Constant Estimationrasheed313No ratings yet

- Technical Specification For Earthing of Power Supply Installations of 25kV & 2X25kV, AC 50Hz, Traction SystemDocument37 pagesTechnical Specification For Earthing of Power Supply Installations of 25kV & 2X25kV, AC 50Hz, Traction SystemAnubhav Hem Kumar JainNo ratings yet

- REL 531-1-0 Line Distance Protection TerminalDocument20 pagesREL 531-1-0 Line Distance Protection Terminalsenthil kumarNo ratings yet

- Introduction To System Protection - Protection BasicsDocument94 pagesIntroduction To System Protection - Protection Basicsdaniel_2MNo ratings yet

- Earth Fault RelayDocument1 pageEarth Fault RelayAliu AlaoNo ratings yet

- Traction - PKPattanaik-2019Document7 pagesTraction - PKPattanaik-2019Guru MishraNo ratings yet

- 1 DC System DC AC Circuit at The Sub StationDocument19 pages1 DC System DC AC Circuit at The Sub Stationapi-258852000% (1)

- Experiment No: 1 19bee069 Date: 20/01/2022 Aim: To Determine Magnetization Characteristics of A Given Current TransformerDocument11 pagesExperiment No: 1 19bee069 Date: 20/01/2022 Aim: To Determine Magnetization Characteristics of A Given Current TransformerR.D Sutariya100% (1)

- Capacitive Voltage Transformers CVT For HV MeasurementsDocument4 pagesCapacitive Voltage Transformers CVT For HV Measurementshossam_24_6_722542No ratings yet

- P220 PDFDocument12 pagesP220 PDFSatya VasuNo ratings yet

- PLCC Tech Specification SummaryDocument23 pagesPLCC Tech Specification SummaryVirgo PremNo ratings yet

- Mr902 Stab ResistorsDocument5 pagesMr902 Stab Resistorsraj151857No ratings yet

- SWGR PresentationDocument86 pagesSWGR PresentationManirupa SinhaNo ratings yet

- MMLG 01-02-03 - 04 Manual GBDocument8 pagesMMLG 01-02-03 - 04 Manual GBethan625No ratings yet

- Protect 7VH60 High-Impedance Busbar RelayDocument7 pagesProtect 7VH60 High-Impedance Busbar RelayMohamed TalebNo ratings yet

- Theoretical Fundamentals and Implementation of Novel Self-Adaptive Distance Protection Resistant To Power SwingsDocument12 pagesTheoretical Fundamentals and Implementation of Novel Self-Adaptive Distance Protection Resistant To Power SwingsSubhadeep PaladhiNo ratings yet

- Bus Switching Scheme PDFDocument6 pagesBus Switching Scheme PDFJAYKUMAR SINGHNo ratings yet

- EE466 C5 Distance Protection of Transmission Lines PDFDocument7 pagesEE466 C5 Distance Protection of Transmission Lines PDFSaisreeNo ratings yet

- Northern Region protection philosophy implementationDocument1 pageNorthern Region protection philosophy implementationsandeepy_27No ratings yet

- Generation Transmission & Distribution of Electrical PowerDocument42 pagesGeneration Transmission & Distribution of Electrical PowerMinale BirlieNo ratings yet

- Electric Traction Systems ExplainedDocument19 pagesElectric Traction Systems ExplainedNishchal MurdiaNo ratings yet

- Busbar Differential Protection SchemeDocument9 pagesBusbar Differential Protection SchemeGourav KumarNo ratings yet

- Transmission Line Protection 2Document28 pagesTransmission Line Protection 2sebsbie zewduNo ratings yet

- 7VK61xx Manual A3 V041100 enDocument332 pages7VK61xx Manual A3 V041100 enthilakkumaeee100% (1)

- Everything You Need to Know About Battery Systems at 220kV SubstationsDocument20 pagesEverything You Need to Know About Battery Systems at 220kV SubstationsManu JosephNo ratings yet

- 24V 40AH Battery and Charger Technical SpecsDocument10 pages24V 40AH Battery and Charger Technical Specsramana3339No ratings yet

- Protection Scheme For 132kV and 22kV Busbar Configurations PDFDocument6 pagesProtection Scheme For 132kV and 22kV Busbar Configurations PDFABHINAV SAURAVNo ratings yet

- WSEASDocument6 pagesWSEASrajesh kannanNo ratings yet

- Transients Analysis of Unbalanced Faults in The Power Distribution System With Two FeedersDocument6 pagesTransients Analysis of Unbalanced Faults in The Power Distribution System With Two FeedersherberthfabricioNo ratings yet

- Optimizing neutral reactors reduces secondary arc currentsDocument8 pagesOptimizing neutral reactors reduces secondary arc currentsCarlos Lino Rojas AgüeroNo ratings yet

- Eh1 Rdso 04Document1 pageEh1 Rdso 04pavanNo ratings yet

- Pages From CBIP Substation Manual 2006Document1 pagePages From CBIP Substation Manual 2006pavanNo ratings yet

- 23 Letter 66kv EquipmentDocument2 pages23 Letter 66kv EquipmentpavanNo ratings yet

- Tower Wagon Shed-G.e Drawing-ModelDocument1 pageTower Wagon Shed-G.e Drawing-ModelpavanNo ratings yet

- California High-Speed Train Project Traction Power 2x25kV Autotransformer Electrification System Design Manual CriteriaDocument20 pagesCalifornia High-Speed Train Project Traction Power 2x25kV Autotransformer Electrification System Design Manual CriteriapavanNo ratings yet

- Observations On GA DrawingsDocument2 pagesObservations On GA DrawingspavanNo ratings yet

- Protective Relaying Philosphy and Design GuidelinesDocument81 pagesProtective Relaying Philosphy and Design GuidelinesairtarlacNo ratings yet

- Schneider Protection GuideDocument76 pagesSchneider Protection GuideahmedhamzehNo ratings yet

- BBP E Chapter 05Document99 pagesBBP E Chapter 05pavanNo ratings yet

- Complete The Conversation by Choosing The Correct Form in BracketsDocument3 pagesComplete The Conversation by Choosing The Correct Form in BracketsJesús Alexander MejíazNo ratings yet

- United States of The Dead - Joseph TallutoDocument145 pagesUnited States of The Dead - Joseph TallutofelipetenpranoNo ratings yet

- Timed Egress Requirements For Transit and Passenger Rail Station Evacuation As Described in NFPA 130Document9 pagesTimed Egress Requirements For Transit and Passenger Rail Station Evacuation As Described in NFPA 130Sakshi BhatiaNo ratings yet

- Silicomanganese Production at Transalloys in The Twenty-TensDocument13 pagesSilicomanganese Production at Transalloys in The Twenty-TensjoyNo ratings yet

- PR Pakistan Railways Test ResultsDocument212 pagesPR Pakistan Railways Test Resultssaeed jamalNo ratings yet

- Civil Design Criteria for Road and Rail ProjectsDocument351 pagesCivil Design Criteria for Road and Rail ProjectsGeorge V0% (2)

- Bus Operator Restroom Use Interactive)Document4 pagesBus Operator Restroom Use Interactive)transportlngctrNo ratings yet

- London Travel PlanDocument4 pagesLondon Travel PlanTushar KesarwaniNo ratings yet

- Amazon On The T Somerville Ma DigitalDocument81 pagesAmazon On The T Somerville Ma DigitalAlex NewmanNo ratings yet

- Iloilo City Regulation Ordinance 2013-344Document6 pagesIloilo City Regulation Ordinance 2013-344Iloilo City CouncilNo ratings yet

- The Case of Failed TransformerDocument84 pagesThe Case of Failed Transformerlbk50100% (1)

- Check List For Safety Inspection at Crew LobbyDocument3 pagesCheck List For Safety Inspection at Crew LobbyHanuma Reddy100% (1)

- Case Study of Ropar BridgeDocument45 pagesCase Study of Ropar BridgeEr Raj Kamal0% (2)

- EPB-TBM WorkingPhaseDocument3 pagesEPB-TBM WorkingPhaseLyndaNo ratings yet

- PNR1Document45 pagesPNR1Christian NicolNo ratings yet

- SurabayaDocument20 pagesSurabayaAnonymous D4W9rAjIVDNo ratings yet

- Alberta Driving Basic Handbook 2009Document161 pagesAlberta Driving Basic Handbook 2009Ilie BricicaruNo ratings yet

- 2743 FullDocument10 pages2743 FullIvica BudrovacNo ratings yet

- Pre Stressed Concrete: Modular Construction Technology: Prepared byDocument28 pagesPre Stressed Concrete: Modular Construction Technology: Prepared byindian royalNo ratings yet

- Meccano Race Car ManualDocument24 pagesMeccano Race Car ManualalberhidaNo ratings yet

- Transpo ReviewerDocument108 pagesTranspo ReviewerSui100% (1)

- The Sunny Side OF Ireland.: John O'MahonyDocument210 pagesThe Sunny Side OF Ireland.: John O'MahonyGutenberg.org100% (1)

- International Case Studies On Delivery and Finacing - A Report For HS2Document50 pagesInternational Case Studies On Delivery and Finacing - A Report For HS2HighSpeedRailNo ratings yet

- Transport PDFDocument5 pagesTransport PDFMercedes López PortilloNo ratings yet

- No NPH FinalDocument13 pagesNo NPH Finalanand singhNo ratings yet

- Monorail Capital Construction CostsDocument3 pagesMonorail Capital Construction CostsErnest Christian Nanola0% (1)

- Finding the Third LevelDocument2 pagesFinding the Third LevelLini DasanNo ratings yet

- Scale Military Modeller International - Issue 594 - September 2020Document86 pagesScale Military Modeller International - Issue 594 - September 2020Chris W. Balmer100% (2)

- The Use of Lattice Girders in The Construction of TunnelsDocument7 pagesThe Use of Lattice Girders in The Construction of TunnelsyedidiNo ratings yet

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)