Professional Documents

Culture Documents

Impact of Cotton Parameters On Yarn Quality

Uploaded by

غلام جیلانیOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact of Cotton Parameters On Yarn Quality

Uploaded by

غلام جیلانیCopyright:

Available Formats

Cotton Fibre Characteristics

SCI

Min. 130

Length

Min. 1.06

Micronaire

3.9 -4.45

Strength

Min 28 GPT

Uniformity

Min 82

Maturity

0.92 1

SFI

Less than 8

Moisture

7-8

Trash Grade

3 4 points

(Trash Cnt + Trash Areas)

Elongation

Depends on the type of yarn

These cotton parameters are suitable for A-Grade yarn for all

counts.

Acro Textile Mills Pvt Ltd

Page 1

Impact of Cotton Parameters on

Yarn Quality

Spinning Consistency Index (SCI)

The spinning Consistency Index is a calculation for predicting the

spinnability of the fibres.

The Value for the SCI value is:

)+4.74Uniformity+0.65Rd+0.36(+b)

SCI =414.67+ 2.9 strength9.32 Micronaire+ 49.17 Length

Fibre Length (Len):

The fibre length influences:

1.

2.

3.

4.

5.

6.

Spinning limit

Yarn strength

Yarn hairiness

Process productivity

Yarn lustre

Yarn evenness

Productivity is influenced via the end-breakage rate, the quantity of waste

and the required turn of twist (T.P.I/T.M)

Micronaire (Mic):

It is a measure of cotton fineness. The fineness determines how many

fibres are present in the cross-section of a yarn of given thickness.

Additional fibres in the cross-section provide not only the additional

strength but also a better distribution in the yarn. Fibre maturity also has

an influence on micronaire value.

Fibre fineness influences primarily:

1.

2.

3.

4.

5.

Spinning Limit

Yarn Strength

Yarn evenness

Yarn Lustre

Productivity of the process

Acro Textile Mills Pvt Ltd

Page 2

Fibre Maturity (Mat):

The cotton fibre consists of cell wall and lumen. The maturity index is

dependent upon the thickness of this cell wall. The cotton fibre is

considered as ripe when the cell wall of the moisture-swollen fibre

represents 50-80% of the round cross-section, as unripe when it

represents 30-45% and as dead when it represents less than 25%. Unripe

fibres have neither adequate strength nor adequate longitudinal stiffness.

They therefore lead to:

1.

2.

3.

4.

5.

Loss of yarn strength

A high proportion of short fibres and increases the invisible loss.

Varying dyeability

Processing difficulties, mainly at Card machines

Causes nepps generation

Short Fibre Index (SFI):

The proportion of short fibre has an extremely influence on the following

parameters:

1.

2.

3.

4.

5.

6.

7.

8.

Spinning limit

Yarn strength

Yarn hairiness

Process productivity

Yarn lustre

Yarn evenness

Strong fly contamination

Strain on personnel, machine and workroom and on the air

conditioning

Fibre Strength (Str):

Strength of cotton fibres increases with increasing moisture content. The

higher the strength of cotton fibre, higher will be the CLSP of cotton yarn

and lower end breakage rate.

Elongation:

Higher elongation is needed in the production of sportswear and stretch

products. For weaving cotton yarns, higher elongations are neither

necessary nor desirable. Elongation should be around 7% for Pak cotton.

+B and Rd:

Acro Textile Mills Pvt Ltd

Page 3

+B is defined as the degree of yellowness. Rd is defined as degree of

whiteness. They both can influence the shade variations in yarn package

and dyeability.

________________________________________

Acro Textile Mills Pvt Ltd

Page 4

You might also like

- Basic Engineering Circuit Analysis 8th Ed SolutionsDocument1,254 pagesBasic Engineering Circuit Analysis 8th Ed SolutionsAndrew David Bushner87% (188)

- Effect of Twist On Yarn PropertiesDocument5 pagesEffect of Twist On Yarn PropertiesAbdulqadeerNo ratings yet

- Yarn Faults and ClearingDocument8 pagesYarn Faults and Clearingsitu_tex8594100% (7)

- IPI Stands For Imperfection Index of YarnsDocument1 pageIPI Stands For Imperfection Index of YarnsShoreless Shaikat100% (5)

- FormulasDocument20 pagesFormulasRishit MevadaNo ratings yet

- Classimat Yarn Fault AnalysisDocument4 pagesClassimat Yarn Fault AnalysisMitu Chowdhury75% (4)

- Yarn Faults: Types Causes RemediesDocument20 pagesYarn Faults: Types Causes Remediesஹரி கிருஷ்ணன் வாசு71% (7)

- Case AnalysisDocument5 pagesCase Analysisغلام جیلانی67% (3)

- Lecture 09 Value Chain AnalysisDocument29 pagesLecture 09 Value Chain AnalysisDavid HermanNo ratings yet

- A Control System For DC Arc Furnaces For Power Quality ImprovementsDocument8 pagesA Control System For DC Arc Furnaces For Power Quality ImprovementsgtgreatNo ratings yet

- Textile in DepthDocument59 pagesTextile in DepthBoopathi Sadasivam50% (2)

- Quailty Control in SpinningDocument30 pagesQuailty Control in SpinningRounoque ShishirNo ratings yet

- Yarn Clearing SystemsDocument11 pagesYarn Clearing SystemsLohit MohapatraNo ratings yet

- Clearer Cuts Summary ReportDocument34 pagesClearer Cuts Summary ReportTowfic Aziz Kanon100% (1)

- CV CalculationDocument7 pagesCV CalculationNirbhay Sharma71% (7)

- Process Parameters in SimplexDocument3 pagesProcess Parameters in SimplexTanvir Alam100% (5)

- Session 7 - Hosiery Yarn Quality RequirementsDocument68 pagesSession 7 - Hosiery Yarn Quality Requirementsselvakumar100% (2)

- LRTDocument5 pagesLRTAnish akNo ratings yet

- Cotton Process ParametersDocument54 pagesCotton Process ParametersBhaskar Mitra100% (9)

- Auto Cone ComparisonDocument8 pagesAuto Cone ComparisonMuhammad Talha100% (1)

- Calculation of Draft and Twist in Ring SpinningDocument3 pagesCalculation of Draft and Twist in Ring Spinningbmsali100% (2)

- RKM DetailsDocument7 pagesRKM DetailsDurairaj.N90% (10)

- Uster StandardsDocument3 pagesUster Standardsselvapdm86% (7)

- Spin Plan For A Cotton MillDocument10 pagesSpin Plan For A Cotton MillRobotrix84% (19)

- Spinning CalculationsDocument40 pagesSpinning Calculationsrajasekarmca100% (2)

- TPMDocument2 pagesTPMVijay Shirole83% (6)

- Standard Parameters of Cotton Yarns of Different TypesDocument3 pagesStandard Parameters of Cotton Yarns of Different TypesRezaul Karim Tutul80% (5)

- Twist MultiplierDocument1 pageTwist MultiplierAniket Mahajan100% (5)

- Finisher Draw Frame AutolevellerDocument30 pagesFinisher Draw Frame AutolevellerRuhi gnext100% (1)

- Calculation of Draft ConstantDocument10 pagesCalculation of Draft ConstantVinay Kumar Tripathi100% (4)

- Spinning CalculationDocument5 pagesSpinning CalculationKarthik Manic100% (1)

- Classification of Yarn Faults and Possible SourceDocument4 pagesClassification of Yarn Faults and Possible SourceNagarajan Sivathanu Pillai50% (2)

- Spinning Maths-4 PDFDocument9 pagesSpinning Maths-4 PDFSantoshNo ratings yet

- HVI Measurement Principles - by - AbuBakkar MarwatDocument33 pagesHVI Measurement Principles - by - AbuBakkar MarwatAbu Bakkar100% (6)

- Cone Density Formula On Different DegreesDocument15 pagesCone Density Formula On Different Degreesgymadni50% (2)

- Simplex FrameDocument38 pagesSimplex Framedrskathirrvelu0% (1)

- Yarn Evenness CVDocument10 pagesYarn Evenness CVRanganatham Ummadisetty100% (1)

- Textilecalculations 131030144207 Phpapp01Document15 pagesTextilecalculations 131030144207 Phpapp01jazzlovey100% (1)

- Auto Levelling in SpinningDocument81 pagesAuto Levelling in SpinningArihara Sudhan73% (11)

- Spinning Calculation WDocument7 pagesSpinning Calculation Wgrsenthil3100% (1)

- Improving Productivity of Ring FramesDocument8 pagesImproving Productivity of Ring FramesAmrit virkNo ratings yet

- Process Control in SpinningDocument31 pagesProcess Control in Spinningapi-2649455553% (15)

- USTERDocument5 pagesUSTERchiragNo ratings yet

- Investigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisDocument59 pagesInvestigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisJuan Cubas100% (1)

- Top Arm LoadingDocument5 pagesTop Arm LoadingGautam Sootgirni100% (1)

- Conversion of Weight Units: Useful Informations To The SpinnersDocument5 pagesConversion of Weight Units: Useful Informations To The SpinnersGautam SootgirniNo ratings yet

- Ring FrameDocument9 pagesRing FrameArabinda ChandNo ratings yet

- yarn-II NoteDocument118 pagesyarn-II NoteMoshiur Rahman Kayes100% (1)

- Spin PLanDocument3 pagesSpin PLanntunewspoint100% (4)

- LRT HandbookDocument41 pagesLRT HandbookAshok Kumar60% (5)

- Yarn HairinessDocument11 pagesYarn HairinessEngr Parvez Hasan0% (3)

- Slub Yarn Base Count CalculationDocument1 pageSlub Yarn Base Count Calculationselvakumar100% (1)

- Blow Room Production Calculations Formula With ExampleDocument23 pagesBlow Room Production Calculations Formula With ExampleAbel TayeNo ratings yet

- Mathematics of Yarn IIDocument5 pagesMathematics of Yarn IIRobotrix100% (1)

- Process Control SpinningDocument25 pagesProcess Control SpinningNessre Zeine100% (2)

- Spinning Norms: Prof. R. Chattopadhyay IIT, DelhiDocument39 pagesSpinning Norms: Prof. R. Chattopadhyay IIT, Delhiapi-26494555100% (5)

- Short Fiber SpinningDocument111 pagesShort Fiber Spinningnminhtuan883116100% (1)

- Textile FibersDocument60 pagesTextile Fiberssathish_20102010No ratings yet

- Uster Analysis of Cotton/polyester Blended Spun Yarns With Different CountsDocument14 pagesUster Analysis of Cotton/polyester Blended Spun Yarns With Different CountsQuocHuynhNo ratings yet

- Yarn QualityDocument4 pagesYarn Qualityalireza vahabi100% (1)

- Materi PTT NewDocument25 pagesMateri PTT NewMark Riha JrNo ratings yet

- Friction SpinningDocument8 pagesFriction SpinningVenkat Prasanna50% (2)

- TestingDocument36 pagesTestingMd.Milon HossainNo ratings yet

- Book DL DeBrito Case Study Review 2004Document36 pagesBook DL DeBrito Case Study Review 2004غلام جیلانیNo ratings yet

- Chapter 8 Answers To ExercisesDocument12 pagesChapter 8 Answers To ExercisesSaroj Kumar RaiNo ratings yet

- An Exploratory Analysis of Reverse Logistics in FlandersDocument2 pagesAn Exploratory Analysis of Reverse Logistics in Flandersغلام جیلانیNo ratings yet

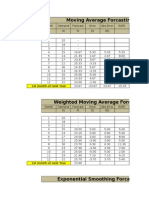

- Moving Average Forcasting: 1st Month of Next YearDocument8 pagesMoving Average Forcasting: 1st Month of Next Yearغلام جیلانیNo ratings yet

- Warehouse DiagramDocument1 pageWarehouse Diagramغلام جیلانیNo ratings yet

- Demand Forcast For Flexman: Month Routers SwitchesDocument9 pagesDemand Forcast For Flexman: Month Routers Switchesغلام جیلانیNo ratings yet

- Question 2Document3 pagesQuestion 2غلام جیلانیNo ratings yet

- D Praveen Kumar ChaubeyDocument2 pagesD Praveen Kumar ChaubeyyouvsyouNo ratings yet

- Bearing Detail PDFDocument1,152 pagesBearing Detail PDFJayesh MachhiNo ratings yet

- Odi2-065r16m18s02-Q DS 0-0-0Document3 pagesOdi2-065r16m18s02-Q DS 0-0-0leolima trustitNo ratings yet

- Tps 53014Document27 pagesTps 53014nebiyu mulugetaNo ratings yet

- Training CoursesDocument16 pagesTraining CoursesFeroz KhanNo ratings yet

- Transistor IRFP350Document7 pagesTransistor IRFP350MiguelAngelCedanoBurrolaNo ratings yet

- How To Draw and Read Line Diagrams Onboard Ships?: ShareDocument9 pagesHow To Draw and Read Line Diagrams Onboard Ships?: ShareShaif uddin rifatNo ratings yet

- Catalog C60H-DCDocument6 pagesCatalog C60H-DCNae MocioiNo ratings yet

- Production Support ProcessDocument15 pagesProduction Support ProcesssantoshNo ratings yet

- Se MeterDataProcessingDocument83 pagesSe MeterDataProcessingbzkxtNo ratings yet

- Hydraulics - Civil Engineering Questions and Answers Page 3Document6 pagesHydraulics - Civil Engineering Questions and Answers Page 3umairNo ratings yet

- GC120 Outline Rev SGDocument2 pagesGC120 Outline Rev SGsong perezNo ratings yet

- Highway Engineering B 1Document8 pagesHighway Engineering B 1Angelica TolentinoNo ratings yet

- Croatia: Approved Port Facilities in CroatiaDocument1 pageCroatia: Approved Port Facilities in CroatiaАлександрNo ratings yet

- Weld Fitting Flange Astm SpecsDocument1 pageWeld Fitting Flange Astm SpecsAZU-OKPONo ratings yet

- Lab 2Document8 pagesLab 2Hamid SaeedNo ratings yet

- Six Sigma Report Out TemplateDocument55 pagesSix Sigma Report Out Templatevijayasarathy201325350% (2)

- BoyapatyDocument5 pagesBoyapatylalalallalalaaluuuNo ratings yet

- 3000w Inverter Parts ListDocument6 pages3000w Inverter Parts ListayoowuyeNo ratings yet

- Agc-4 DRH 4189340686 UkDocument222 pagesAgc-4 DRH 4189340686 UkGiangDoNo ratings yet

- CharanDocument25 pagesCharanCharan KumarNo ratings yet

- Material Handling System and ASRS PDFDocument13 pagesMaterial Handling System and ASRS PDFHarsh PatelNo ratings yet

- OE Spec MTU16V4000DS2250 3F FC 50Hz 1 14Document6 pagesOE Spec MTU16V4000DS2250 3F FC 50Hz 1 14YasirSwatiNo ratings yet

- Tech. Specs. For 11 KV DP StructureDocument7 pagesTech. Specs. For 11 KV DP StructureSaraswatapalitNo ratings yet

- SampleDocument2 pagesSamplesaurabhverma08No ratings yet

- NEMA Premium CatalogDocument38 pagesNEMA Premium CatalogPedro SanchezNo ratings yet

- Sumanta Chowdhury - CLS Aipmt-15-16 XIII Phy Study-Package-7 Set-1 Chapter-27Document32 pagesSumanta Chowdhury - CLS Aipmt-15-16 XIII Phy Study-Package-7 Set-1 Chapter-27Rohit Raj0% (1)