Professional Documents

Culture Documents

General Notes BRG at KM 103+500 (281299)

Uploaded by

Aziz ul HakeemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes BRG at KM 103+500 (281299)

Uploaded by

Aziz ul HakeemCopyright:

Available Formats

GENERAL NOTES FOR BRIDGES

GENERAL

SUB STRUCTURE

No of Spans

=

17

2.

Total Span Length

=

866 m

3.

Length of the Girder

=

49.9 m

4.

No. of Girders/Beams per Span

=

4

5.

Skew Angle

=

0

6.

No. of Lanes

=

2

7.

Road way width on the Bridge

=

8500 mm

8.

Pavement width of the Road

=

7300 mm

9.

Total width of the Bridge

=

10100 mm

10. No. of diaphragms per span

=

5

11.

The Specifications given in the drawings shall over

rule the general notes.

All dimensions are in millimeters unless specified otherwise.

All concrete joint surfaces (except girder and deck slab) shall be

roughened to full amplitude of 6 mm.

Dimensions mentioned on the drawings should be followed in

preference to scale measurements.

Contractor should study the drawings carefully before starting

work & mistakes (if any) in the drawings should be notified

to the Engineer.

Elastomeric bearing pads of hardness-60 (Shore A) and of size

mentioned on the drawings shall be provided.

Actual geo-technical investigation shall be carried out at the time of

construction.

Backfill behind the abutments shall be gravel sand mixture

(Granular).

Mini-clear covers for reinforcement steel shall be as given:

For pile caps and piles

= 75

mm

For all other sub structure elements

= 50

mm

Class-A concrete shall be used in all sub structure elements except

rolling blocks and pads under pile caps.

Lean concrete should be used in pads under pile caps.

Class-B concrete shall be used in rolling blocks.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Codes of practice are:

AASHTO LRFD code 1994

AASHTO Standard code 1996

Pakistan code of practice for highway bridges

(PCPHB), 1967

Live loads considered for design are:

Single lane of military class 70 loading (PCPHB

1967)

Class A loading (PCPHB 1967)

HS20-44 truck (AASHTO standard code 1996)

Design lane load plus design truck (HL 93,

AASHTO LRFD code 1994)

Design lane plus design Tandem (HL 93

AASHTO LRFD code 1994)

Unless otherwise shown on the drawing hooks shall be provided in

accordance with the Section 5.11 of

AASHTO LRFD Code 1994.

Concrete Specified as class A (20.6 MPa.) in the Contract Specifications shall be used for all Super-Structure elements except

prestressed girders for which concrete of 28 days cylinder crushing strength of 414 Kg/cm 2 (41.4 MPa.) shall be used.

Reinforcement steel indicated on drawings as 10, 6 etc, shall be deformed billet-steel bars conforming to ASTM A-615, AASHTO

M-31, Grade 40, (276 Mpa).

Reinforcement steel indicated on drawings as 12 and above, shall be deformed billet-steel bars conforming to ASTM A-615,

AASHTO M-31, Grade 60, (414 Mpa).

69 mm rigid type metal duct (sheath pipes) shall be used for tendons.

7 Tendons are used per girder and 12, 7 wire strands, of Grade 270 K, ASTM A 416 (1860 MPa.) and having modulus of elasticity

of 197,000 MPa., are used per tendon (84 Strands per girder).

Stronghold or equivalent system shall be used for stressing (Post tensioning) and stressing shall be performed from both ends.

System other than Stronghold and stressing from only one end can be performed only with approval of the Designing Firm.

Jacks shall be calibrated in laboratory before starting stressing of the tendons.

All the tendons shall be stressed simultaneously from both ends in the order specified on drawings.

Force/load per tendon and corresponding elongation should be achieved simultaneously, for each tendon.

G.I. pipes of dia 62.5 mm (or 25 Hooks) should be embedded in the girder at 300 mm (to center of G.I. pipe), for lifting/launching of

the girders.

Elongation and forces are given on the drawings, half of which should be applied/achieved at each end.

If the contractor, for any reason, wishes to adopt an alternative prestressing system for stressing of the girders, he can do so with

approval of the Engineer, in such case all design calculations & drawings shall be prepared by the contractor at his own expense and

submitted for Engineers approval.

Concrete cover of 40 mm shall be provided in deck slab and diaphragms, and 25 mm in girders and guard railings.

All materials & workmanship shall conform to the relevant AASHTO/ASTM standards.

200 dia. P.V.C. utility ducts shall be provided/installed at no extra cost.

100 mm dia-G.I. drain pipes shall be used.

MATERIALS

All materials and workmanship shall conform to the

relevant clauses of AASHTO & ASTM standards

except where modified below or in Particular

Specifications of Tender Documents.

Concrete

Special concrete will be used in prestressed

concrete girders with a minimum 28 days cylinder

crushing strength of 414 Kg/cm2 (41.4 MPa.).

Class A concrete shall be used having minimum

28 days (15 x 30 cm). Cylinder strength of 210

Kg/Cm2 (20.6 MPa)

Class B concrete shall be used having minimum

28 days (15 x 30 cm). Cylinder strength of 170

Kg/Cm2 (16.66 MPa)

Lean concrete shall be used as shown on drawings

of 28 days cylinder crushing strength of 100

Kg/cm2 (9.8 MPa)

Sulphate resisting cement shall be used in concrete

work for all sub-structure elements (i.e. piles, pile

caps, abutments piers, transoms, approach slabs,

wing walls etc.). No additional payment for

Sulphate resisting cement shall be made.

Reinforcing Steel

As given in construction drawings

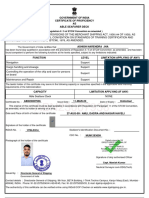

GOVERNMENT OF PAKISTAN

MINISTRY OF COMMUNICATIONS

NATIONAL HIGHWAY

AUTHORITY ISLAMABAD

KHYBER

CONSULTING

ENGINEERS

94/E-1, STREET 8, PHASE 1, HAYATABAD PESHAWAR PAKISTAN.

Phones: ++92 91 819101 5 Fax: ++92 91 819106

Website: http/www.khybers.com

E-mail: khybers@khybers.com

SURFACE RENDERING

All faces of concrete shall receive surface rendering

(Bitumen Coating) when becoming in contact with

backfill or pavement, cost of which will not be paid

separately.

EMBEDDED ITEMS

All Embedded items shall be secured in position

according to the drawings before concreting is done

DISMANTLING OF EXISTING

STRUCTURE

Existing structure(s) shall be dismantled, where

required, and removed as specified and as directed by

the Engineer.

STANDARD HOOKS

SUPER STRUCTURE

1.

DESIGN PARAMETERS

DETAILED BAR BENDING SCHEDULE

Detailed Bar Bending schedule shall be prepared by the

Contractor and submitted for Engineers Approval.

ABBREVIATIONS

B, BOTT.

CL

C/C

C.J, C.Jt

Dia

Exp.Jt.

EL.

G.I.

I.D.

Kg.

KN

m

mm

MPa

NGL

O.D

PCPHB

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Symm.

Typ.

TH.

T

Var.

=

=

=

=

=

=

Bottom

Center Line

Center to Center

Construction Joint

Diameter

Expansion Joint

Elevation

Galvanized Iron

Internal Diameter

Kilogram

Kilo Newton

Meter

Millimeter

Maga Pascal

Natural Ground Level

Outer diameter

Pakistan code of practice for

Highway bridges

Symmetrical

Typical

Thickness

Top

Varies

Skew Angle in degrees

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Annexure - IDocument3 pagesAnnexure - IAziz ul HakeemNo ratings yet

- Steel Weight and PercentagesDocument1 pageSteel Weight and PercentagesAziz ul HakeemNo ratings yet

- Retaining Wall Analysis & Design (ACI318Document13 pagesRetaining Wall Analysis & Design (ACI318Aziz ul HakeemNo ratings yet

- Dangers of Binge Drinkin PDFDocument19 pagesDangers of Binge Drinkin PDFAziz ul HakeemNo ratings yet

- Foundation Bearing Capacity (SPT BasedDocument8 pagesFoundation Bearing Capacity (SPT BasedAziz ul HakeemNo ratings yet

- Gravity Wall Calculator TADocument13 pagesGravity Wall Calculator TAAdibowoWicaksonoNo ratings yet

- Penstock Painting - As Per Indian StandardsDocument3 pagesPenstock Painting - As Per Indian StandardsAziz ul HakeemNo ratings yet

- Scour CalcsDocument9 pagesScour CalcsAziz ul HakeemNo ratings yet

- Singer Sewing Machine Model White 2220 ManualDocument40 pagesSinger Sewing Machine Model White 2220 ManualAziz ul Hakeem50% (2)

- PEDO Private Sector ProjectsDocument11 pagesPEDO Private Sector ProjectsAziz ul HakeemNo ratings yet

- Pile Load CapacityDocument2 pagesPile Load CapacityAziz ul HakeemNo ratings yet

- Pashtun Tribes - Wikipedia, The Free Encyclopedia PDFDocument6 pagesPashtun Tribes - Wikipedia, The Free Encyclopedia PDFAziz ul HakeemNo ratings yet

- Slab and Buttress DamDocument10 pagesSlab and Buttress DamAziz ul HakeemNo ratings yet

- Using Turbines in Bentley HAMMER - Haes... Cs and Hydrology - Bentley CommunitiesDocument13 pagesUsing Turbines in Bentley HAMMER - Haes... Cs and Hydrology - Bentley CommunitiesAziz ul HakeemNo ratings yet

- Slab Walls Design Aashto LRFDDocument2 pagesSlab Walls Design Aashto LRFDAziz ul HakeemNo ratings yet

- IPD Final Report Form: Candidate Name: Membership Number: Date of Report: Core Objective: Standard Achieved A K E BDocument1 pageIPD Final Report Form: Candidate Name: Membership Number: Date of Report: Core Objective: Standard Achieved A K E BAziz ul HakeemNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EIAC-RQ-IB-002 I1 Rev 2 1aWaExODocument15 pagesEIAC-RQ-IB-002 I1 Rev 2 1aWaExOMidhun BabyNo ratings yet

- Malkhedi To Khurai Lopcsd KM 986Document1 pageMalkhedi To Khurai Lopcsd KM 986santosh iyerNo ratings yet

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDocument100 pagesOwner'S Manual: Read This Manual Carefully Before Operating This Vehicleigor petrovskiNo ratings yet

- CODE3013 Course Outline 2021Document13 pagesCODE3013 Course Outline 2021Grier KershawNo ratings yet

- EASA Air Law PDFDocument17 pagesEASA Air Law PDFMiyachita Tagahachi100% (4)

- Volkswagen TransporterDocument3 pagesVolkswagen TransporterTasawar ShahNo ratings yet

- ID F FT NN0 TQD FP 11 0005 - R3 - Technical Query To Change Driven Pile To Drag Anchor AwcDocument20 pagesID F FT NN0 TQD FP 11 0005 - R3 - Technical Query To Change Driven Pile To Drag Anchor AwcmutadiNo ratings yet

- C-TPAT Partner Appl2Document7 pagesC-TPAT Partner Appl2Cheo HitchensNo ratings yet

- 8120-8520 SerieDocument1 page8120-8520 Serieinfo7879No ratings yet

- HD2 PAP GB Otokar Gamme-Interurbain PLQ 19Document28 pagesHD2 PAP GB Otokar Gamme-Interurbain PLQ 19JimJakNo ratings yet

- BS 7121-2-12012 AbstractDocument7 pagesBS 7121-2-12012 AbstractPrasanth Varrier0% (1)

- Fe42rl GBR EngDocument4 pagesFe42rl GBR EngaaNo ratings yet

- Final Project Report 3Document86 pagesFinal Project Report 3Muhammad Talha Khan100% (1)

- AAR Safety Fact SheetDocument2 pagesAAR Safety Fact Sheetrogelio mezaNo ratings yet

- North Carolina: Driver's License Format, Issuance, and RenewalDocument10 pagesNorth Carolina: Driver's License Format, Issuance, and Renewalannaliese faverNo ratings yet

- Q 117R2Document2 pagesQ 117R22791957No ratings yet

- Product Guide: FeaturesDocument16 pagesProduct Guide: FeaturesJavier Ignacio MacíasNo ratings yet

- Exterior & Interior: SectionDocument30 pagesExterior & Interior: SectionDozer KamilNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument129 pagesAdvisory Circular: U.S. Department of TransportationMohammed AlsbeayNo ratings yet

- Letter of IntentDocument5 pagesLetter of IntentTokimemoto Lustre ReidNo ratings yet

- Consulting ServicesDocument1 pageConsulting ServicesTimu OvidiuNo ratings yet

- Msd80/81 Dme Flash Instructions: Please Read The Following NotesDocument10 pagesMsd80/81 Dme Flash Instructions: Please Read The Following NotesBolinha's Wash ClubNo ratings yet

- A Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUDocument92 pagesA Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUOner AltınsoyNo ratings yet

- Ashish Jha (Cop)Document1 pageAshish Jha (Cop)ashishjha6067No ratings yet

- IATA Resolution 700 (From IATA Website)Document9 pagesIATA Resolution 700 (From IATA Website)akosistella100% (1)

- Word FileDocument26 pagesWord FileSeph InfanteNo ratings yet

- The Royal Canadian Navy and The Cuban Missile CrisisDocument16 pagesThe Royal Canadian Navy and The Cuban Missile CrisisSean CampbellNo ratings yet

- Arada VS CaDocument6 pagesArada VS CaNFNLNo ratings yet

- SPC - Bajaj Re2S CompactDocument54 pagesSPC - Bajaj Re2S CompactRafael FelixNo ratings yet

- CHP - V Sight DistancerDocument26 pagesCHP - V Sight Distancerሽታ ዓለሜ0% (1)