Professional Documents

Culture Documents

Sheet Metal Operations

Uploaded by

Parveen SainiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet Metal Operations

Uploaded by

Parveen SainiCopyright:

Available Formats

9/1/2011

SheetMetal

y Product has light weight and

versatile shape as

compared to forging/casting

SheetMetalOperation

p

y Most commonly used

low carbon steel sheet (cost,

strength,

g formability)

y

y Aluminium and titanium for aircraft and aerospace

y Sheet metal has become a significant material for,

automotive bodies and frames,

office furniture

BySKMondal

frames for home appliances

Piercing(Punching)andBlanking

Piercing(Punching)andBlanking

y Piercing and blanking are shearing operations.

y In blanking, the piece being punched out becomes

the workpiece and any major burrs or undesirable

features should be left on the remaining strip.

y In piercing (Punching), the punchout is the scrap

and the remaining strip is the workpiece.

y Both done on some form of mechanical press.

Clearance(VIMP)

y Die opening must be larger than punch and known as

clearance.

y Punching

Punch = size of hole

Die = punch size +2 clearance

y

Remember: In punching punch is correct size.

y Blanking

Die = size of product

Punch = Die size 2 clearance

y

Remember: In blanking die size will be correct.

9/1/2011

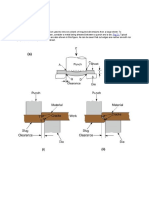

ClearanceContd.

Blanking

Punching

Example

Determine the die and punch sizes for blanking a circular

disc of 20mm diameter from a sheet whose thickness is 1.5

mm.

Shear strength of sheet material = 294 MPa

PunchingForceandBlankingForce

Fm ax = Lt

Thepunchingforceforholeswhicharesmallerthanthestock

thicknessmaybeestimatedasfollows:

Fmax =

dt

3

CapacityofPressforPunchingandBlanking

Presscapacitywillbe=

Fmax C

d

t

MinimumDiameterofPiercing

s d.t

c d2

Piercingpressure,=Strengthofpunch,

4

[WhereCisaconstantandequalto1.1to1.75depending

upontheprofile]

9/1/2011

Example

Estimate the blanking force to cut a blank 25 mm wide

and 30 mm long from a 1.5 mm thick metal strip, if the

ShearonPunch

y To reduce shearing force, shear is ground on the face of

the die or punch.

ultimate shear strength of the material is 450 N/mm2.

y It distribute the cutting action over a period of time.

Also determine the work done if the percentage

y Shear only reduces the maximum force to be applied but

penetration is 25 percent of material thickness.

total work done remains same.

ForcerequiredwithshearonPunch

F=

Fmax (tp) L t(tp)

=

S

S

Wherep=penetrationofpunchasafraction

S=shearonthepunchordie,mm

Example

y A hole, 100 mm diameter, is to be punched in steel plate

5.6 mm thick. The ultimate shear stress is 550 N/mm2 .

With normal clearance on the tools,, cutting

g is complete

p

at 40 per cent penetration of the punch. Give suitable

shear angle for the punch to bring the work within the

capacity of a 30T press.

Example

A washer with a 12.7 mm internal hole and an outside

diameter of 25.4 mm is to be made from 1.5 mm thick

strip. The ultimate shearing strength of the material of

the washer is 280 N/mm2.

((a)) Find the total cutting

g force if both p

punches act at

the same time and no shear is applied to either punch

or the die.

(b) What will be the cutting force if the punches are

staggered, so that only one punch acts at a time.

(c) Taking 60% penetration and shear on punch of 1

mm, what will be the cutting force if both punches act

together.

9/1/2011

FineBlanking

EnergyandPowerforPunchingandBlanking

Ideal Energy (E in J) = maximum force x punch travel = Fmax ( p t )

(Unit:Fmax in kJ and t in mm othrwise use Fmax in J and t in m)

Where p is percentage penetration required for rupture

EN

Ideal power in press ( P inW ) =

60

[Where N = actual number of stroke per minute]

Fine Blanking dies are designed that have small

clearances and pressure pads that hold the material

while it is sheared. The final result is blanks that have

extremely close tolerances.

Actual Energy ( E in J ) = Fmax ( p t ) C

Where C is a constant and equal to 1.1 to 1.75 depending upon the profile

EN

Actual power in press ( P inW ) =

60

WhereE is actual energy and is efficiency of the press

y Slitting moving rollers trace out complex paths during

cutting (like a can opener).

y Perforating: Multiple holes which are very small and

g

are cut in flat work material.

close together

y Notching: Metal pieces are cut from the edge of a sheet,

strip or blank.

y Trimming Cutting unwanted excess material from the

periphery of a previously formed component.

y Shaving Accurate dimensions of the part are obtained by

y Lancing A hole is partially cut and then one side is bent

down to form a sort of tab or louver. No metal removal, no

scrap.

removing a thin strip of metal along the edges.

y Squeezing Metal is caused to flow to all portions of a die

cavity under the action of compressive forces.

9/1/2011

Dinking

y Steel Rules soft materials are cut with a steel strip

shaped so that the edge is the pattern to be cut.

y Nibbling a single punch is moved up and down rapidly,

y Used to blank shapes from lowstrength materials, such as

rubber, fiber, or cloth.

y The shank of a die is either struck with a hammer or mallet or

the entire die is driven downward by some form of

p

mechanical press.

each time cutting off a small amount of material. This

allows a simple die to cut complex slots.

Elasticrecoveryorspringback

y Total deformation = elastic deformation + plastic

ElasticrecoveryorspringbackContd..

y More important in cold working.

deformation.

y It depends on the yield strength. Higher the yield

y At the end of a metal working operation, when the

strength, greater spring back.

pressure is released, there is an elastic recovery and the

total deformation will get reduced a little. This

phenomenon is called as "spring back".

y To compensate this, the cold deformation be carried

beyond the desired limit by an amount equal to the

spring back.

PunchandDiematerial

y

Commonlyused toolsteel

Forhighproduction carbides

PunchingPress

9/1/2011

Bolsterplate

BolsterplateContd....

y When many dies are to run in the same press at different

times, the wear occurring on the press bed is high. The

bolster plate is incorporated to take this wear.

y Relatively cheap and easy to replace.

y Attached to the press bed and the die shoe is then

attached to it.

Punchplate

Stripper

y Used to locate and hold the

punch in position.

y This is a useful way of

mounting,

especially

for

small punches.

StripperContd....

y The stripper removes the stock from the punch after a

piercing or blanking operation.

Ps = KLt

Knockout

y Knockout is a mechanism, usually connected to and

operated by the press ram, for freeing a work piece from

a die.

Where Ps =strippingforce,kN

L=perimeterofcut,mm

L i t f t

t=stockthickness,mm

K=strippingconstant,

=0.0103forlow carbonsteelsthinnerthan1.5mmwith

thecutattheedgeornearaprecedingcut

=0.0145forsamematerialsbutforothercuts

=0.0207forlow carbonsteelsabove1.5mmthickness

=0.0241forhardermaterials

9/1/2011

Pitman

Dowelpin

y It is a connecting rod which is used to transmit motion

from the main drive shaft to the press slide.

Drawing

y Drawing is a plastic deformation process in which a flat

sheet or plate is formed into a threedimensional part

with a depth more than several times the thickness of

the metal.

Drawing

y As a punch descends into a mating die, the metal

assumes the desired configuration.

Drawing

y Hot drawing is used for thickwalled parts of simple

geometries, thinning takes place.

y Cold drawing uses relatively thin metal, changes the

thickness very little or not at all, and produces parts in a

wide variety of shapes.

9/1/2011

BlankSize

D = d 2 + 4dh

Whend>20r

BlankHoldingForce

y Blank holding force required depends on the wrinkling

DrawingForce

P = dts C

d

DrawClearance

y Punch diameter = Die opening diameter 2.5 t.

tendency of the cup. The maximum limit is generally to

be onethird of the drawing force.

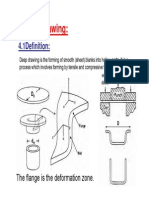

Deepdrawing

y Drawing when cup height is more than half the diameter is

termed deep drawing.

y Easy with ductile materials.

StressesonDeepDrawing

y Inflangeofblank:Biaxialtensionandcompression

y Inwallofthecup:simpleuniaxialtension

y Due to the radial flow

flo of material,

material the side walls

alls increase in

thickness as the height is increased.

y A cylindrical vessel with flat bottom can be deep drawn by

double action deep drawing.

y Deep drawing is a combination of drawing and stretching.

9/1/2011

DeepDrawability

y The ratio of the maximum blank diameter to the

diameter of the cup drawn . i.e. D/d.

y There is a limiting drawing ratio (LDR), after which the

punch will pierce a hole in the blank instead of drawing.

y This ratio depends upon material, amount of friction

present, etc.

y Limiting drawing ratio (LDR) is 1.6 to 2.3

LimitingDrawingRatio(LDR)

y Theaveragereductionindeepdrawing

d

= 0.5

D

d

Reduction = 1 100% = 50%

D

Thumb rule:

Example

y A symmetrical cup of 80 mm diameter and 250 mm

height is to be fabricated on a deep drawing die.

How many drawing operations will be necessary if

no intervening annealing is done.

y Also find the drawing force

First draw:Reduction = 50 %

Second draw:Reduction = 30 %

Third draw:Reduction = 25 %

Fourth draw:Reduction = 16 %

Fifth draw:Reduction = 13 %

DrawDieDesign

y Progressivedies

y Compounddies

y Combinationdies

C

bi ti di

Progressive dies

Perform two or more operations simultaneously in a single

stroke of a punch press, so that a complete component is

obtained for each stroke.

Compound dies

All the necessary operations are carried out at a single

station, in a single

g stroke of the ram. To do more than one set

of operations, a compound die consists of the necessary sets

of punches and dies.

Combination dies

A combination die is same as that of a compound die with

the main difference that here noncutting operations such as

bending and forming are also included as part of the

operation.

9/1/2011

Lubrication

y Indrawingoperation,properlubricationisessentialfor

1.

2.

3.

4.

Toimprovedielife.

Toreducedrawingforces.

Toreducetemperature.

Toimprovesurfacefinish.

DefectsinDrawing wrinkle

y An insufficient blank holder pressure causes wrinkles to

develop on the flange, which may also extend to the wall

of the cup.

DefectsinDrawing Fracture

DefectsinDrawingearing

y Further, too much of a blank holder pressure and friction

y While drawing a rolled stock, ears or lobes tend to occur

may cause a thinning of the walls and a fracture at the

flange, bottom, and the corners (if any).

because of the anisotropy induced by the rolling

operation.

DefectsinDrawing missstrike

DefectsinDrawing Orangepeel

y Due to the misplacement of the stock, unsymmetrical

y A surface roughening (defect) encountered in forming

flanges may result. This defect is known as miss strike.

products from metal stock that has a coarse grain size.

y It is due to uneven flow or to the appearance of the

overly large grains usually the result of annealing at too

high a temperature.

temperature

10

9/1/2011

Stretcherstrains(likeLuders Lines)

y Caused by plastic deformation due to inhomogeneous

Surfacescratches

y Dieorpunchnothavingasmoothsurface,insufficient

yielding.

y These lines can crisscross the surface of the workpiece and

lubrication

may be visibly objectionable.

objectionable

y Low carbon steel and aluminium shows more stretcher

strains.

Spinning

Spinning

y Spinning is a coldforming operation in which a

rotating disk of sheet metal is shaped over a male

form, or mandrel.

y Localized pressure is applied through a simple

roundended wooden or metal tool or small roller,

which traverses the entire surface of the part

Spinning

1. A mandrel (or die for internal pieces) is placed on a

rotating axis (like a turning center).

2. A blank or tube is held to the face of the mandrel.

3. A roller is pushed against the material near the

center

t off rotation,

t ti

and

d slowly

l l moved

d outwards,

t

d pushing

hi

the blank against the mandrel.

4. The part conforms to the shape of the mandrel (with

some springback).

5. The process is stopped, and the part is removed and

trimmed.

11

9/1/2011

tc = tb sin

HighEnergyRateForming(HERF)

Underwater

explosions.

HERF

y High Energy Rate Forming, also known as HERF or explosive

forming can be utilised to form a wide variety of metals, from

aluminum to high strength alloys.

y Applied a large amount of energy in a very sort time interval.

Electromagnetic

(theuseof

rapidlyformed

g

)

magneticfields).

Underwaterspark

discharge(electro

hydraulic)

hydraulic).

HERF

y HERF makes it possible to form large work pieces and

difficulttoform metals with lessexpensive equipment and

Internal

combustionof

gaseous

mixtures.

tooling required.

y No springback

UnderwaterExplosions

Pneumatic

mechanical

means

Underwaterexplosions

y A shock wave in the fluid medium (normally water ) is

generated by detonating an explosive charge.

y TNT and dynamite for higher energy and gun powder for

lower energy is used.

y Used for parts of thick materials.

y Employed

in

Aerospace,

aircraft

industries

and

automobile related components.

12

9/1/2011

ElectrohydraulicForming

y An operation using electric discharge in the form of

sparks to generate a shock wave in a fluid is called

electrohydrulic forming.

y A capacitor bank is charged through the charging circuit,

circuit

subsequently, a switch is closed, resulting in a spark

within the electrode gap to discharge the capacitors.

y Energy level and peak pressure is lower than underwater

explosions but easier and safer.

y Used for bulging operations in small parts.

ElectromagneticorMagneticPulseForming

y Based on the principle that the electromagnetic field of

an induced current always opposes the electromagnetic

field of the inducing current.

y A large

l

capacitor

it bank

b k is

i discharged,

di h

d producing

d i a currentt

surge through a coiled conductor.

y If the coil has been placed within a conductive cylinder,

around a cylinder, or adjacent the flat sheet of metal, the

discharge induces a secondary current in the workpiece,

causing it to be repelled from the coil and conformed to

a die or mating workpiece.

StretchForming

ElectromagneticorMagneticPulseForming

y The process is very rapid and is used primarily to expand

or contract tubing, or to permanently assemble

component parts.

y This process is most effective for relatively thin materials

(0.25 to 1.25 mm thick).

y Produce large sheet metal parts in low or limited

quantities.

y A sheet of metal is gripped by two or more sets of jaws

that stretch it and wrap it around a single form block.

y Because most of the deformation is induced by

y the

tensile stretching, the forces on the form block are far

less than those normally encountered in bending or

forming.

y There is very little springback, and the workpiece

conforms very closely to the shape of the tool.

y Because the forces are so low, the form blocks can often

be made of wood, lowmeltingpoint metal, or even

plastic.

13

9/1/2011

StretchFormingContd......

StretchFormingContd......

y Popular in the aircraft industry and is frequently used to

form aluminum and stainless steel

y Lowcarbon steel can be stretch formed to produce large

panels for the automotive and truck industry.

StretchFormingContd......

Ironing

y The process of thinning the walls of a drawn cylinder by

passing it between a punch and die whose separation is

less than the original wall thickness.

y The walls are thinned and lengthened, while the

thickness of the base remains unchanged.

y Examples of ironed products include brass cartridge

cases and the thinwalled beverage can.

IroningContd....

IroningForce

y Neglecting the friction and shape of the die, the ironing

force can be estimated using the following equation.

t

F = dt tt av ln o

tt

14

9/1/2011

Embossing

Coining

y It is a very shallow drawing operation where the depth of

y Coining is essentially a coldforging operation except for

the draw is limited to one to three times the thickness of

the fact that the flow of the metal occurs only at the top

the metal, and the material thickness remains largely

layers and not the entire volume.

unchanged.

y Coining is used for making coins, medals and similar

articles.

Bending

y Afterbasicshearingoperation,wecanbendaparttogiveitsome

shape.

y Bendingpartsdependsuponmaterialpropertiesatthelocationof

thebend.

y Atbend,biaxialcompressionandbiaxialtensionisthere.

,

p

Bending

Bendallowance,

Lb =(r+kt)

where

r=bendradius

k=constant(stretchfactor)

For r > 2t

k = 0.5

For r < 2t

k = 0.33

t=thicknessofmaterial

=bendangle(inradian)

BendingForce

Kl ut t 2

Bending

F=

y The strain on the outermost fibers of the bend is

1

=

2r

+1

t

Where l =Bend length = width of the stock, mm

ut = Ultimate tensilestrength, MPa (N/mm 2 )

t = blank

bl k thickness,

thi k

mm

w = width of die-opening, mm

K = die-opening factor , (can be used followin table)

Condition

V-Bending

U-Bending

Edge-Bending

W < 16t

1.33

2.67

0.67

W > = 16t

1.20

2.40

0.6

ForUorchannelbendingforcerequiredisdoublethanV bending

ForedgebendingitwillbeaboutonehalfthatforV bending

15

9/1/2011

Spanking

y During bending, the area of the sheet under the punch

has a tendency to flow and form a bulge on the outer

surface.

y The lower die should be provided with mating surfaces,

so that when the punch and die are completely closed on

the blank, any bulging developed earlier will be

completely presses or spanked out.

Methodformakingasimplewasherinacompoundpiercingand

blankingdie.Partisblanked(a)andsubsequentlypierced

(b)Theblankingpunchcontainsthedieforpiercing.

Progressivepiercingandblankingdiefor

makingasimplewasher.

Back

Back

16

9/1/2011

PowderMetallurgy

y Powder metallurgy is the name given to the

PowderMetallurgy

gy

process by which fine powdered materials are

blended,

bl d d

pressed

d

into

i t

desired

d i d

shape

h

(compacted), and then heated (sintered) in a

controlled atmosphere to bond the contacting

surfaces of the particles and establish the desired

properties.

BySKMondal

ManufacturingofPowder

Atomizationusingagasstream

Atomization/metal spraying low melting point

metals are sprayed to form irregular particles

Granulations as metals are cooled they are stirred

rapidly

Electrolytic

El t l ti deposition

d

iti

often

ft used

d for

f iron,

i

copper,

silver

Machining coarse powders such as magnesium

Milling crushers and rollers to break down metals

Shotting drops of molten metal are dropped in water

Reduction metal oxides are turned to powder when

exposed to below melting point gases.

y Powders often come in elemental forms and must be

blended in correct ratios for metallurgical purposes.

y Lubricants may also be added to increase powder flow,

and to reduce mold adhesion during and after

compaction.

compaction

y During sintering the metal parts are put in ovens with

temperatures just below the melting point. (These ovens

also have controlled atmospheres). As the parts are

heated the compacted particles melt slightly and bond.

There is a reduction in part size.

9/1/2011

Blending

y Blending or mixing operations can be done either dry or wet.

y Lubricants such as graphite or stearic acid improve the flow

characteristics and compressibility at the expense of reduced

y Powder is pressed into a green compact

y 40 to 1650 MPa pressure (Depends on materials,

p

p

y)

product complexity)

st

e gt .

strength.

y Binders

Compacting

produce

the

reverse

effect

of

lubricants.

Thermoplastics or a watersoluble methylcellulose binder is

used.

y Still very porous, ~70% density

y May be done cold or warm (higher density)

y Most lubricants or binders are not wanted in the final

product and are removed ( volatilized or burned off)

Compacting

Sintering

y Controlledatmosphere:nooxygen

y Heatto0.75*Tmelt

y Particlesbindtogether

y Partshrinksinsize

y Densityincreases,upto95%

y Strength~=~Density

ColdIsostatic Pressing(CIP)

y The powder is contained in a flexible mould made of

rubber or some other elastomer material

y The flexible mould is then pressurized by means of

highpressure water or oil. (same pressure in all

directions)

y No lubricant is needed

y High and uniform density can be achieved

9/1/2011

HotIsostatic Pressing(HIP)

y Is carried out at high temperature and pressure using a

gas such as argon.

y 50:50FeAlalloysisusedformagneticparts

y AlNiFeisusedforpermanentmagnets

y The flexible mould is made of sheet metal. (Due to high

y Sinteringisdoneinawirecoiltoalignthemagnetic

polesofthematerial

p

)

temperature)

y Compaction

Productionofmagnets

and

sintering

are

completed

y H2 isusedtorapidlycoolthepart(tomaintainmagnetic

alignment)

y Totalshrinkageisapproximately37%(foraccurateparts

simultaneously.

y Used in the production of billets of superalloys, high

speed steels, titanium, ceramics, etc, where the integrity

anextrasinteringstepmaybeaddedbeforemagnetic

alignment)

y Thesinteringtemperatureis600CinH2

of the materials is a prime consideration

Advantages

y Goodtolerancesandsurfacefinish

y Highlycomplexshapesmadequickly

y Canproduceporouspartsandhardtomanufacture

materials(e.g.cementedoxides)

y Poresinthemetalcanbefilledwithother

materials/metals

y Surfacescanhavehighwearresistance

y Porositycanbecontrolled

y Lowwaste

y Automationiseasy

AdvantagesContd.

y Physicalpropertiescanbecontrolled

y Variationfromparttopartislow

y Hardtomachinemetalscanbeusedeasily

y Nomoltenmetals

y Noneedformany/anyfinishingoperations

y Permitshighvolumeproductionofcomplexshapes

y Allowsnontraditionalalloycombinations

y Goodcontroloffinaldensity

Disadvantages

y Metalpowdersdeterioratequicklywhenstored

improperly

y Fixedandsetupcostsarehigh

y Partsizeislimitedbythepress,andcompressionofthe

powderused.

d d

y Sharpcornersandvaryingthicknesscanbehardto

produce

y Nonmoldablefeaturesareimpossibletoproduce.

Applications

y Oilimpregnated bearings made from either iron or

copper alloys for home appliance and automotive

applications

y P/M filters can be made with pores of almost any size.

y Pressure or flow regulators.

regulators

y Small gears, cams etc.

y Products where the combined properties of two or more

metals (or both metals and nonmetals) are desired.

y Cementedcarbidesareproducedbythecold

compactionoftungstencarbidepowderinabinder,such

ascobalt(5to12%),followedbyliquidphasesintering.

9/1/2011

Pre Sintering

Repressing

y If a part made by PM needs some machining, it will be

y Repressing is performed to increase the density and

rather very difficult if the material is very hard and

strong. These machining operations are made easier by

improve the mechanical properties.

y Further improvement is achieved by resintering.

the presintering operation which is done before

sintering operation.

Infiltration

y Component is dipped into a low meltingtemperature

alloy liquid

y The liquid would flow into the voids simply by capillary

action, thereby decreasing the porosity and improving

the strength of the component.

y The process is used quite extensively with ferrous parts

using copper as an infiltrate but to avoid erosion, an alloy

Impregnation

y Impregnation is similar to infiltration

y PM component is kept in an oil bath. The oil penetrates

into the voids by capillary forces and remains there.

y The oil is used for lubrication of the component when

necessary. During

D i the

th actual

t l service

i conditions,

diti

th oil

the

il is

i

released slowly to provide the necessary lubrication.

y The components can absorb between 12% and 30% oil by

volume.

y It is being used on P/M selflubricating bearing

components since the late 1920's.

of copper containing iron and manganese is often used.

OilimpregnatedPorousBronzeBearings

ConventionalQuestions

1. Explain why metal powders are blended. Describe what

happens during sintering.

[IES2010, 2 Marks]

9/1/2011

ConventionalQuestions

1. Discuss

the terms fineness and particle size

distribution in powder metallurgy. [IES2010, 2 Marks]

Ans.

Fineness: Is the diameter of spherical shaped particle

p

p p

and mean diameter of nonspherical

shaped

particle.

ConventionalQuestions

Enumerate the steps involved in powder metallurgy

process. Discuss these steps. Name the materials used

in powder metallurgy. What are the limitations of

powder metallurgy?

[IES2005, 10 Marks]

Particle size distribution:

Geometric standard

deviation (a measure for the bredth or width of a

distribution), is the ratio of particle size diameters

taken at 84.1 and 50% of the cumulative undersized

weight plot, respectively and mean mass diameter

define the particle size distribution.

You might also like

- 04 Cutting ClearanceDocument18 pages04 Cutting Clearancegaurav deshmukhNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Shearing Process GuideDocument29 pagesShearing Process GuideSriram MuruganNo ratings yet

- Sheet Metal FormingDocument25 pagesSheet Metal Formingankushkapoor2003No ratings yet

- Sheet MetalDocument21 pagesSheet MetalRam Janm Singh100% (2)

- Sheet Forming Processes: Shearing & BendingDocument50 pagesSheet Forming Processes: Shearing & Bendingsudharsans88No ratings yet

- MP SheetMetal PDFDocument48 pagesMP SheetMetal PDFNhan LeNo ratings yet

- 03 Cutting ForceDocument3 pages03 Cutting ForceAhmad Mustaghfiri Asrar100% (1)

- Deep Drawing Process GuideDocument26 pagesDeep Drawing Process Guidemck_medo100% (1)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Module2: Design and Calculations of Piercing & Blanking DieDocument89 pagesModule2: Design and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- 3 Die CuttingDocument41 pages3 Die CuttingNarendrareddy RamireddyNo ratings yet

- Press Tool CalculationDocument76 pagesPress Tool CalculationPrashant AmbadekarNo ratings yet

- Selection of Material and Hardware Used in Press ToolDocument22 pagesSelection of Material and Hardware Used in Press ToolVipul MetaNo ratings yet

- Lecture 8 Sheet Metal Working PDFDocument6 pagesLecture 8 Sheet Metal Working PDFluisimtzNo ratings yet

- CH03. Sheet Metal ProcessesDocument73 pagesCH03. Sheet Metal ProcesseshizanorhudaNo ratings yet

- 5 Strip LayoutDocument28 pages5 Strip LayoutNarendrareddy Ramireddy67% (3)

- 01 Introduction To Press ToolsDocument31 pages01 Introduction To Press ToolsNiranjan HalgarNo ratings yet

- Strip LayoutDocument35 pagesStrip LayoutJay PatelNo ratings yet

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDocument17 pages15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- Selection of Presses and Its SettingDocument21 pagesSelection of Presses and Its SettingVipul MetaNo ratings yet

- Computing Die Thickness and MarginsDocument3 pagesComputing Die Thickness and MarginsAnand PrajapatiNo ratings yet

- Types of Press Tools Classified and ExplainedDocument24 pagesTypes of Press Tools Classified and ExplainedAvula VinayNo ratings yet

- Chapter 4 Tool and Die DesignDocument70 pagesChapter 4 Tool and Die Designdawit solomonNo ratings yet

- Press ToolDocument71 pagesPress Toolamolnjainajgmail.com 7507254906No ratings yet

- Sheet Metal Design Services ConsiderationsDocument3 pagesSheet Metal Design Services ConsiderationsVino KumarNo ratings yet

- PRESSTOOL MASTER 1st SemDocument111 pagesPRESSTOOL MASTER 1st Semmathapatikumar56No ratings yet

- Press Tool Theory - 1Document144 pagesPress Tool Theory - 1Abhishek AbhiNo ratings yet

- DieDocument6 pagesDieAditya GoelNo ratings yet

- Formula For Press Tool DesignDocument2 pagesFormula For Press Tool DesignJimmy Clavel100% (2)

- Report Press ToolDocument61 pagesReport Press ToolAvinash BorgaonkarNo ratings yet

- Lab10 Final Progressive Die PDFDocument7 pagesLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Metal Stamping Dies GuideDocument7 pagesMetal Stamping Dies GuideedpsousaNo ratings yet

- Die Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingDocument30 pagesDie Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingAmitNo ratings yet

- Press Tool Operation and FunctionsDocument25 pagesPress Tool Operation and Functionsjagan89% (9)

- Sheet Metal Form Vinay 1226927986919169 9Document83 pagesSheet Metal Form Vinay 1226927986919169 9Nhan LeNo ratings yet

- Bending Die DesignDocument46 pagesBending Die DesignSujit Mule83% (6)

- Elements of Press Tool: Base PlateDocument3 pagesElements of Press Tool: Base PlateSujay AvatiNo ratings yet

- Cutting ClearanceDocument50 pagesCutting ClearanceVinayak Aryan100% (16)

- Cutting ClearanceDocument2 pagesCutting ClearancevinodNo ratings yet

- Punch and DieDocument16 pagesPunch and DieNani DatrikaNo ratings yet

- SHT Metal EstimatorDocument7 pagesSHT Metal Estimatorkarthikkumarfeb6No ratings yet

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينNo ratings yet

- Types of Stoppers Used in Press Working ToolsDocument44 pagesTypes of Stoppers Used in Press Working ToolsSubodh KumarNo ratings yet

- Sheet Metalworking 1 - Chapter 19Document99 pagesSheet Metalworking 1 - Chapter 19xharpreetxNo ratings yet

- Presstool MasterDocument111 pagesPresstool MasterRajesh Kumar100% (2)

- Blank CalculationDocument4 pagesBlank CalculationSatish Zle100% (5)

- Cold and Hot Stamping Dies eDocument12 pagesCold and Hot Stamping Dies eajaygupta.af3919No ratings yet

- Unit 4Document135 pagesUnit 4Akeju AyodeleNo ratings yet

- LO 03 - BendingDocument61 pagesLO 03 - Bendingladyinred90No ratings yet

- Tool Design Data Book PDFDocument124 pagesTool Design Data Book PDFbmvinay74% (19)

- Formulas For Designing Press ToolsDocument21 pagesFormulas For Designing Press ToolsKarthik Gopal86% (35)

- Design of DieDocument41 pagesDesign of DieKarthik ACNo ratings yet

- Presentation On Sheet Metal DesignDocument27 pagesPresentation On Sheet Metal Designniloy_67No ratings yet

- Casting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingDocument26 pagesCasting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingkiransideasNo ratings yet

- Bending DiesDocument31 pagesBending DiesTamirat Nemomsa100% (1)

- Bending ProcessDocument32 pagesBending ProcessdfdsNo ratings yet

- Sheet Metal Working (Compatibility Mode)Document75 pagesSheet Metal Working (Compatibility Mode)PrinceVegetaNo ratings yet

- Me Diva L India History by SNDocument71 pagesMe Diva L India History by SNprem kumarNo ratings yet

- Curriculum Vitae: Kulshearstha PundirDocument2 pagesCurriculum Vitae: Kulshearstha PundirParveen SainiNo ratings yet

- Paper 2Document1 pagePaper 2Parveen SainiNo ratings yet

- HindiDocument4 pagesHindiParveen SainiNo ratings yet

- Document AvksDocument1 pageDocument AvksParveen SainiNo ratings yet

- Week 2 Test: Q.1-Consider The Following Statements in Regard ToDocument7 pagesWeek 2 Test: Q.1-Consider The Following Statements in Regard ToParveen SainiNo ratings yet

- THE EXAMS MADE SIMPLE PRESENTS THE HINDU AND PIB PLUS OTHER IMPORTANT WEBSITE’S CURRENT AFFAIRS FOR THE MONTHS OF MAY-JUNE-JULY 2017Document18 pagesTHE EXAMS MADE SIMPLE PRESENTS THE HINDU AND PIB PLUS OTHER IMPORTANT WEBSITE’S CURRENT AFFAIRS FOR THE MONTHS OF MAY-JUNE-JULY 2017Parveen SainiNo ratings yet

- Upsc Capf Ac Physical 2016Document2 pagesUpsc Capf Ac Physical 2016Parveen SainiNo ratings yet

- Upsc Ac 2018Document22 pagesUpsc Ac 2018Parveen SainiNo ratings yet

- Test 1Document10 pagesTest 1Parveen SainiNo ratings yet

- Test 4: TelanganaDocument8 pagesTest 4: TelanganaParveen SainiNo ratings yet

- 10 Largest Lakes of WorldDocument6 pages10 Largest Lakes of WorldParveen SainiNo ratings yet

- Historical Monuments Ebook OliveboardDocument9 pagesHistorical Monuments Ebook OliveboardsriNo ratings yet

- Week 3 Test: (A) Hydrogen Cyanide (B) Hydrogen Methyl IsobutaneDocument5 pagesWeek 3 Test: (A) Hydrogen Cyanide (B) Hydrogen Methyl IsobutaneParveen SainiNo ratings yet

- CDS 2 2017Document2 pagesCDS 2 2017Parveen SainiNo ratings yet

- Indian Air Force Aircraft GuideDocument15 pagesIndian Air Force Aircraft GuideParveen SainiNo ratings yet

- 2016 Test - 5 Answer PaperDocument19 pages2016 Test - 5 Answer PaperMangeshNo ratings yet

- Upsc Ac Change1Document7 pagesUpsc Ac Change1Parveen SainiNo ratings yet

- NCERT Science Fodder Material For UpscDocument22 pagesNCERT Science Fodder Material For UpscMd Afsar HussainNo ratings yet

- Disaster and Disaster Management - Udita GauravDocument33 pagesDisaster and Disaster Management - Udita GauravParveen SainiNo ratings yet

- Daily Quiz Jun Jul 2016 1 PDFDocument20 pagesDaily Quiz Jun Jul 2016 1 PDFParveen SainiNo ratings yet

- List of Famous International Awards, World Famous Awards in Literature, Science, Films EtcDocument17 pagesList of Famous International Awards, World Famous Awards in Literature, Science, Films EtcParveen SainiNo ratings yet

- Major Crops - Prelims - 16-07-12 - Single ColumnDocument48 pagesMajor Crops - Prelims - 16-07-12 - Single ColumnParveen SainiNo ratings yet

- Essay by BhupiDocument46 pagesEssay by BhupiBeing Humane50% (2)

- Major Warships of the Indian NavyDocument13 pagesMajor Warships of the Indian NavyParveen SainiNo ratings yet

- List of Conventional and Nuclear Submarines of IndiaDocument7 pagesList of Conventional and Nuclear Submarines of IndiaParveen SainiNo ratings yet

- Important Amendments of the Indian ConstitutionDocument9 pagesImportant Amendments of the Indian ConstitutionParveen SainiNo ratings yet

- Haryana Staff Selection Commission, Government of HaryanaDocument3 pagesHaryana Staff Selection Commission, Government of HaryanaParveen SainiNo ratings yet

- GS 1700 Full Test 8 Jan Questions PDFDocument32 pagesGS 1700 Full Test 8 Jan Questions PDFParveen SainiNo ratings yet

- India's internal and external security challengesDocument19 pagesIndia's internal and external security challengesParveen SainiNo ratings yet

- Workman GTX: Utility VehicleDocument36 pagesWorkman GTX: Utility VehicleDaniel Carrillo BarriosNo ratings yet

- How To Read Architect DrawingDocument32 pagesHow To Read Architect DrawingKutty Mansoor50% (2)

- Solar Powered Automatic Toilet LightDocument10 pagesSolar Powered Automatic Toilet LightarwinNo ratings yet

- Scoring Rubric For Oral Presentations Total Points ScoreDocument2 pagesScoring Rubric For Oral Presentations Total Points ScoreLezia pagdonsolanNo ratings yet

- AbzenoDocument7 pagesAbzenojykhgpdrc5No ratings yet

- Abstract Substructure Conc - Frame Westgate RealDocument4 pagesAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniNo ratings yet

- Aqm Mallcom ReportDocument12 pagesAqm Mallcom ReportHarshita TiwariNo ratings yet

- Sevice Manual BOBCAT S630 PDFDocument890 pagesSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- Cyclopedia of Architecture Carpentry & Building Vol VIIIDocument422 pagesCyclopedia of Architecture Carpentry & Building Vol VIIIbootsola100% (2)

- Clarion Technologies: at A GlanceDocument7 pagesClarion Technologies: at A GlanceChetan PrasadNo ratings yet

- IT Act 2000 overview objectives featuresDocument3 pagesIT Act 2000 overview objectives featuresalpanshiNo ratings yet

- Grand Rapids Controls LPA Checksheet AuditDocument7 pagesGrand Rapids Controls LPA Checksheet Auditalliceyew100% (3)

- 218477these Stufy of An in Vehicule Infotainement SystemDocument79 pages218477these Stufy of An in Vehicule Infotainement SystemKhaled GharbiNo ratings yet

- SR.11.10961 - Sour Well Design GuideDocument52 pagesSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- Numeric To Numeric Encryption of Databases Using 3kDES AlgorithmDocument5 pagesNumeric To Numeric Encryption of Databases Using 3kDES AlgorithmSwathi VasudevanNo ratings yet

- Task #2 SIA-309 Perancangan Fondasi 2: Retaining WallsDocument1 pageTask #2 SIA-309 Perancangan Fondasi 2: Retaining WallsDesti Santi PratiwiNo ratings yet

- Riveting vs. WeldingDocument5 pagesRiveting vs. WeldingNikhilVinay100% (1)

- Gordon M. Pugh Davidg - RasmussenDocument2 pagesGordon M. Pugh Davidg - RasmussenKuroKy KrausserNo ratings yet

- Lancashire BoilerDocument28 pagesLancashire BoilerDr. BIBIN CHIDAMBARANATHANNo ratings yet

- Civilstrips Installation NotesDocument3 pagesCivilstrips Installation NotesKoeswara SofyanNo ratings yet

- Service Accessories: CatalogDocument32 pagesService Accessories: CatalogdummaNo ratings yet

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDocument332 pages(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLNo ratings yet

- L .. Eee - .: Distribution Voltage RegulatorsDocument11 pagesL .. Eee - .: Distribution Voltage RegulatorsSirajulNo ratings yet

- Abrasive Cleaning SystemDocument4 pagesAbrasive Cleaning SystemSulfikar SalimNo ratings yet

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDocument3 pagesBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaNo ratings yet

- Average Waiting Time at Dental ClinicDocument12 pagesAverage Waiting Time at Dental ClinicJonas Ciabis100% (1)

- How To Build A 43 Note CalliopeDocument14 pagesHow To Build A 43 Note CalliopeBrad SommersNo ratings yet

- OTC13998Document15 pagesOTC13998Raifel MoralesNo ratings yet

- Jumeirah Group Future IssuesDocument3 pagesJumeirah Group Future Issueshaelstone100% (1)

- Fossa FO 0015 0035 A Technical Data en 9aaDocument2 pagesFossa FO 0015 0035 A Technical Data en 9aaFatih YAŞARNo ratings yet