Professional Documents

Culture Documents

Chiller Condensate System

Uploaded by

cesar luis gonzalez rodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chiller Condensate System

Uploaded by

cesar luis gonzalez rodriguezCopyright:

Available Formats

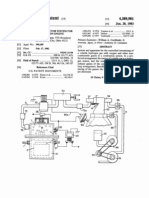

US 20110232313A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2011/0232313 A1

Chillar et al.

(54)

(43) Pub. Date:

CHILLER CONDENSATE SYSTEM

_

(75) Inventors.

(73) Assignee;

Publication Classi?cation

(51)

Rahul Chlllar, Atlanta, GA (US),

Julio Mestroni, Marietta, GA (US);

Steven Hartman, Marietta, GA

(Us); siddharth Upadhyays

(52)

Bangalore (IN)

(57)

Int. Cl.

F25D 21/14

(200601)

F28F 1/36

(200601)

US. Cl. ......................................... .. 62/285; 165/184

ABSTRACT

General Electric Company,

The present application provides a chiller condensate system.

Schnectady, NY (US)

The chiller condensate system may include a chiller that

produces a How of condensate, a condensate drain system

positioned about the chiller to collect the How of condensate,

and a heat exchanger in communication With the condensate

drain system for the How of condensate to How therethrough.

(21) Appl, No;

12/73 0,334

(22)

Mar, 24, 2010

Filed;

Sep. 29, 2011

/

89

_..

A/

r

~. g

i

r-

20o

.s

~~_____

/

h-

6'

T2316

\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\R

Patent Application Publication

Sep. 29, 2011 Sheet 1 0f 4

US 2011/0232313 A1

100

150

110

166/

17%

V193

yam

/

Fig. 2

T216

1 220

235

1.76

240

6y

K

220

210:

Fig. 3

4-525

Patent Application Publication

Sep. 29, 2011 Sheet 2 0f 4

WA

US 2011/0232313 Al

@6 Fig. 4

we

220

goo

6

210 :

235

230

319

176

320

250

T1

Fig. 6

\J

219

249 k

325

Patent Application Publication

Sep. 29, 2011 Sheet 3 0f 4

US 2011/0232313 A1

235

330

170

/

449

250

/

220

/Q

V

Fig. 8

3936

Patent Application Publication

Sep. 29, 2011 Sheet 4 0f 4

US 2011/0232313 A1

30

230

460

52%

K590

250

$49

220

476

>

G>

Sep. 29, 2011

US 2011/0232313 A1

CHILLER CONDENSATE SYSTEM

TECHNICAL FIELD

[0001]

BRIEF DESCRIPTION OF THE DRAWINGS

The present application relates generally to gas tur

bine engines and more particularly relates to a gas turbine

engine With a chiller condensate system used for cooling

purposes.

BACKGROUND OF THE INVENTION

[0002]

skill in the art upon revieW of the folloWing detailed descrip

tion When taken in conjunction With the several draWings and

the appended claims.

The poWer output of a gas turbine engine is directly

proportional to the inlet air mass ?oW rate. The inlet air mass

depends upon the density of the inlet air and hence the tem

perature of the air. As such, knoWn gas turbine engines may

use a chiller system to loWer the air temperature about the

compressor inlet. By loWering the inlet air temperature, the

density of the inlet air may be increased and the mass ?oW rate

to the compressor may increase. The poWer output of the gas

turbine engine thus increases due to the higher mass ?oW rate.

[0003] Chiller systems generally use a series of coils to cool

the inlet air. Sensible heat transfer from the inlet air to the loW

[0009] FIG. 1 is a schematic vieW of a gas turbine engine.

[0010] FIG. 2 is a schematic vieW of a portion of chiller

condensate system as is claimed herein With a condensate

collection and drainage system.

[0011]

FIG. 3 is a schematic vieW of a condensate heat

exchanger system.

[0012]

FIG. 4 is a schematic vieW of the condensate heat

exchanger system used With an air conditioning system.

[0013] FIG. 5 is a schematic vieW of the condensate heat

exchanger system used With a steam turbine condenser.

[0014] FIG. 6 is a schematic vieW of the condensate heat

exchanger system used With a turbine compartment.

[0015] FIG. 7 is a schematic vieW of the condensate heat

exchanger system used With an exhaust frame and bearing

cooling system.

[0016]

FIG. 8 a schematic vieW of the condensate heat

temperature Water circulating through the chiller coils cools

the inlet air. During operation of the chiller, Water tends to

exchanger system used With a noZZle cooling system.

condense on the coils due to the cooling effect. The conden

tem.

sate is drained and collected so as to avoid carryover doWn

[0018] FIG. 10 a schematic vieW of the condensate spray

system used With a cooling toWer.

stream and into the compressor. The condensate generally is

discharged to the atmosphere or otherWise disposed. The

temperature of the condensate may be around about ?fty (50)

to about sixty (60) degrees Fahrenheit (about ten (10) to about

15.6 degrees Celsius) although other temperatures may be

used. If a typical chiller system is operating at full load, the

volume of the condensate may be at about 75 gallons per

minute (about 284 liters per minute). Other condensate vol

umes may be used.

[0004]

There is therefore a desire to obtain useful Work

from this existing condensate ?oW. Speci?cally, the use of

[0017]

FIG. 9 a schematic vieW of a condensate spray sys

DETAILED DESCRIPTION

[0019] Referring noW to the draWings, in Which like numer

als refer to like elements throughout the several vieWs, FIG. 1

shoWs a schematic vieW of a gas turbine engine 100. As is

knoWn, the gas turbine engine 100 may include a compressor

110 to compress an incoming How of air. The compressor 110

delivers the compressed How of air to a combustor 120. The

combustor 120 mixes the compressed How of air With a com

existing condensate may improve the overall ef?ciency of the

gas turbine engine and related equipment While still provid

pressed ?oW of fuel and ignites the mixture. Although only a

single combustor 120 is shoWn, the gas turbine engine 100

ing adequate inlet air cooling.

may include any number of combustors 120. The hot com

bustion gases are in turn delivered to a turbine 130. The hot

combustion gases drive the turbine 130 so as to produce

SUMMARY OF THE INVENTION

[0005] The present application thus provides a chiller con

densate system. The chiller condensate system may include a

chiller that produces a How of condensate, a condensate drain

system positioned about the chiller to collect the How of

condensate, and a heat exchanger in communication With the

condensate drain system for the condensate to How there

through.

[0006] The present application thus provides a chiller con

densate system. The chiller condensate system may include a

chiller that produces a How of condensate, a condensate drain

system positioned about the chiller to collect the How of

condensate, and a noZZle in communication With the conden

sate drain system for the condensate to spray therethrough.

[0007]

The present application further provides a cooling

toWer. The cooling toWer may include a chiller condensate

system With a noZZle to provide a spray of condensate and a

closed cooling circuit. The spray of condensate may chill the

closed cooling circuit.

[0008] These and other features and improvement of the

present application Will become apparent to one of ordinary

mechanical Work. The mechanical Work produced in the tur

bine 130 drives the compressor 110 and an external load 140

such as an electrical generator and the like. The gas turbine

engine 100 may use natural gas, various types of syngas, and

other types of fuels. Other gas turbine engine con?gurations

may be used herein.

[0020] The gas turbine engine 100 also may include a

chiller system 150. The chiller system 150 may be positioned

about the inlet of the compressor 110.As described above, the

chiller system 150 chills an incoming air?oW 160 to a desired

temperature. Various types of chiller systems 150 are knoWn.

[0021] FIG. 2 shoWs an improved chiller system 170 as is

described herein. The chiller system 170 may include a num

ber of coils 180. As described above, Water ?oWs through the

coils 180 so as to chill the incoming air?oW 160. The chiller

system 170 also may include a condensate drain system 190.

The condensate drain system may include a coil drain 200

positioned about each of the coils 180. A How of condensate

210 passes on to each coil drain 200. The coil drain 200 may

take the form of a trough or a similar structure to catch the

condensate. The coil drains 200 may lead to a condensate pipe

220 or other type of central basin. As described above, the

Sep. 29, 2011

US 2011/0232313 A1

How of condensate 210 may be at about 75 gallons per minute

(about 284 liters per minute). Other condensate volumes may

be used herein.

[0022] FIG. 3 shoWs an example of a chiller condensate

system 230 as is claimed herein. In this example, the chiller

condensate system 230 may be in the form of a condensate

heat exchange system 235. Speci?cally, the condensate heat

exchange system 235 includes the chiller system 170 With the

condensate drain system 190. The How of condensate 210

from the coil drains 200 is forWarded to a heat exchanger 240

by the condensate pipe 220. The heat exchanger 240 may be

any type of heat exchange device including shell and tube heat

[0026] FIG. 7 shoWs use of the condensate heat exchanger

system 235 With an exhaust frame and bearing system 330.

The exhaust frame and bearing system 330 may include a

bearing housing 340 supporting a rotor 350. The bearing

housing 340 may be positioned Within an exhaust frame 360

With a hot gas path 370 extending therethrough. The exhaust

frame and bearing system 330 also may include a cooling air

pathWay 380 extending therethrough to cool the bearing

housing 340 and the exhaust frame 3 60 With an incoming How

of air 385. The heat exchanger 240 of the condenser heat

exchanger system 235 may be positioned about the cooling

exchangers, plate heat exchangers, plate and ?n heat

exchangers, air coils, direct contact, adiabatic heat exchang

air pathWay 380 to cool the incoming air?oW 385. Further, the

heat exchanger 240 may be positioned elseWhere Within the

exhaust frame and bearing system 330. Cooling may increase

ers, etc. The heat exchanger 240 exchanges heat With any type

the lifespan of the bearing housing 340, the exhaust frame

of load 245 such as an air?oW, a turbine component, or other

structure in a manner similar to those examples described

360, and the other components therein. Other exhaust frame

and bearing system con?gurations may be used herein.

beloW. A pump 250 may be positioned about the condensate

pipe 220. The How of condensate 210 may then How to

additional heat exchangers 240, discharged, or otherWise

[0027]

FIG. 8 shoWs the use of the condensate heat

exchanger system 235 With a noZZle cooling system 390. Air

extracted from, for example, a ninth stage 400 and the elev

used.

[0023] FIG. 4 shoWs use of the condensate heat exchanger

system 235 With an example of a load 245, an air conditioning

system 260. Speci?cally, the heat exchanger 240 of the con

enth stage 410 of the compressor 110 may be used to cool a

stage three noZZle 420 and a stage tWo noZZle 430 of the

turbine 130 via a number of extraction lines 440. The heat

densate heat exchanger system 235 may be positioned about

exchanger 240 of the condensate heat exchanger system 235

a fan 270 or other type of air movement device of the air

may be positioned about the extraction lines 440 so as to cool

an air extraction 450 therein. Better cooling of the noZZles

conditioning system 260. The heat exchanger 240 may cool

an air conditioning How 280 therethrough. The condensate

heat exchanger system 235 thus uses the How of condensate

210 to provide cooling in the form of air conditioning. More

420, 430 thus may increase component lifetime. The heat

exchanger 240 also may be positioned elseWhere about the

noZZle cooling system 390. Likewise, other types of extrac

tions may be used. Other types of noZZle cooling con?gura

over, the use of the condensate heat exchanger system 235

tions also may be used herein.

thus reduces the need for externally generated chilled Water

that may be used exclusively for air conditioning purposes.

Other air conditioning con?gurations and systems may be

used herein.

[0024] FIG. 5 shoWs the use of the condensate heat

exchanger system 235 With a steam turbine condenser 290.

The heat exchanger 240 thus may take the form of tubes or

other types of pathWays through the condenser 290. Gener

ally described, a vacuum is maintained in the steam turbine

condenser 290 by expanding a How of steam passing through

a steam pathWay 300 therein. By reducing the temperature

inside the condenser 290 via the heat exchanger 240, the

expansion may maintain the vacuum. As such, the back pres

sure in the condenser 290 may be reduced. With loWer back

pressure, the steam may expand to a loWer temperature and

thus provide more output. The How of condensate 210 also

may be added to an existing ambient ?oW through the con

denser 290. Other steam turbine condenser con?gurations

and other structures may be used herein.

[0025] FIG. 6 shoWs the use of the condensate heat

exchanger system 235 With a turbine compartment 310. The

turbine compartment 310 may be an enclosure of any shape

With turbine equipment therein. Heat from the turbine casing

and other components may cause safety and lifetime issues

for the equipment therein. The turbine compartment 310 thus

may include a cooling air pathWay 320 extending there

through. The heat exchanger 240 of the condensate heat

exchanger system 235 may be positioned about the cooling

air pathWay 320 or otherWise to chill an incoming How of air

325 along the cooling air pathWay 320. Alternatively, the heat

exchanger 240 may be positioned about any of the speci?c

pieces of equipment therein. Other turbine compartment con

?gurations may be used herein.

[0028]

Referring again to FIG. 3, the chiller condensate

system 230 also may be usedWith a fuel moisturizer 455. Fuel

moisturiZation systems have been used in combined cycle

poWer plants in an attempt to increase poWer output and

thermodynamic ef?ciency. In such systems, natural gas is

saturated With Water and the moisturized fuel is heated to

saturation conditions at the design gas pressure. The

increased gas mass ?oW due to the addition of moisture may

result in increased poWer output from gas and steam turbines.

In this example, the How of condensate 210 may be directed

to the saturator 455 to saturate a How of fuel therein. The How

of condensate 210 may ?oW directly to the saturator 445,

exchange heat With the heat exchanger 240, or otherWise be

Warmed. Such moisturiZation may improve the overall e?i

ciency of the gas turbine engine 100. The pump 250 also may

be used herein.

[0029] FIG. 9 shoWs a further example of the chiller con

densate system 230. The chiller condensate system 230 may

be in the form of a condensate spray system 460 as may be

described herein. The condensate spray system 460 may

include one or more spray noZZles 470 so as to provide a spray

480 of the condensate 210 for cooling purposes to a load 490

in a manner similar to the heat exchanger 240. The spray

noZZles 470 may be any type of device that provides the spray

480 in any form. For example, the spray 480 may take the

form of a mist, a stream, or any type of output. The spray

noZZles 470 also may be positioned doWnstream of the heat

exchanger 240 for use thereWith. Other positions and compo

nents may be used herein. The pump 250 also may be used

herein.

[0030] FIG. 10 shoWs the use of the condensate spray sys

tem 460 With a cooling toWer 500. The cooling toWer 500 may

include a Water tube bundle 510 extending therethrough. (Al

Sep. 29, 2011

US 2011/0232313 Al

though only one Water tube is shown herein, the Water tube

bundle 510 may have any number of tubes.) The Water tube

bundle 510 may be part of a closed cooling circuit 520. The

closed cooling circuit 520 may include one or more heat

exchangers 530. Any type of heat exchanger or heat exchange

device may be used herein.

[0031] The Water tube bundle 510 may be cooled by an

incoming air?oW 540 draWn in by a number of fans 550 or

other types of air movement devices positioned Within the

cooling toWer 500. One or more noZZles 470 of the conden

sate spray system 460 may be positioned about the air?oW

540 so as to provide the spray 480 to the air?oW 540. Cooling

the air?oW 540 With the spray 480 of the condensate 210 may

further cool the Water tube bundle 510. As such, the overall

operation of the heat exchanger 530 and the closed cooling

circuit 520 may be improved.

[0032] The heat exchanger 530 of the closed cooling circuit

520 may be used to cool any type of further load 560 such as

a ?uid How, a component, and the like. For example, the heat

exchanger 530 may be a lube oil heat exchanger, a generator

heat exchanger or cooler, a steam condenser, or any type of

component for heat exchange thereWith. Better cooling of the

lube oil may increase the lube oil life and varnishing may be

avoided. Likewise, additional cooling for the generator may

raise the ef?ciency of the generator. Similarly, better cooling

of the condenser may increase output due to better expansion

of the steam. Other bene?ts of additional (and free) cooling

may be found herein.

[0033]

In summary, the condensate heat exchanger system

235 and/or the condensate spray system 460 of the chiller

condensate system 230 thus may be used to cool any compo

nent Within the gas turbine engine 100 as Well as related

components such as poWer plant air conditioning and other

types of loads 245. Such cooling provided by otherWise dis

carded condensate thus serves to improve the overall e?i

ciency of the gas turbine engine system 100.

[0034] It should be apparent that the foregoing relates only

to certain embodiments of the present application and that

numerous changes and modi?cations may be made herein by

one of ordinary skill in the art Without departing from the

general spirit and scope of the invention as de?ned by the

folloWing claims and the equivalents thereof.

We claim:

3. The chiller condensate system of claim 1, Wherein the

condensate drain system comprises a plurality of coil drains

and a condensate pipe.

4. The chiller condensate system of claim 1, further com

prising a pump in communication With the condensate drain

system.

5. The chiller condensate system of claim 1, further com

prising a load in communication With the heat exchanger.

6. The chiller condensate system of claim 5, Wherein the

load comprises an air conditioning system.

7. The chiller condensate system of claim 5, Wherein the

load comprises a condenser.

8. The chiller condensate system of claim 5, Wherein the

load comprises a turbine compartment.

9. The chiller condensate system of claim 5, Wherein the

load comprises an exhaust frame and bearing system.

10. The chiller condensate system of claim 5, Wherein the

load comprises a noZZle cooling system.

11. The chiller condensate system of claim 5, Wherein the

heat exchanger comprises a spray noZZle.

12. The chiller condensate system of claim 11, Wherein the

load comprises a closed cooling circuit.

13. The chiller condensate system of claim 12, Wherein the

closed cooling circuit is in communication With a further

load.

14. The chiller condensate system of claim 5, Wherein the

load comprises a How of air.

15. The chiller condensate system of claim 5, Wherein the

load comprises a How of steam.

16. The chiller condensate system of claim 5, Wherein the

load comprises a How of ?uid.

17. The chiller condensate system of claim 1, further com

prising a moisturizer.

18. A chiller condensate system, comprising:

a chiller;

Wherein the chiller produces a How of condensate;

a condensate drain system positioned about the chiller to

collect the How of condensate; and

a noZZle in communication With the condensate drain sys

tem for the condensate to spray therethrough.

19. The chiller condensate system of claim 18, further

comprising a load in communication With the noZZle.

1. A chiller condensate system, comprising:

20. A cooling toWer, comprising:

a chiller;

a chiller condensate system;

Wherein the chiller produces a How of condensate;

a condensate drain system positioned about the chiller to

collect the How of condensate; and

a heat exchanger in communication With the condensate

drain system for the condensate to How therethrough.

2. The chiller condensate system of claim 1, Wherein the

chiller comprises a plurality of coils.

Wherein the chiller condensate system comprises a noZZle

to provide a spray of condensate; and

a closed cooling circuit;

Wherein the spray of condensate chills the closed cooling

circuit.

You might also like

- HVAC outlet temperature calculation correction from ambient and water temperaturesDocument8 pagesHVAC outlet temperature calculation correction from ambient and water temperaturesnavatejaNo ratings yet

- Gicc Us8631660Document9 pagesGicc Us8631660Ricardo RamsesNo ratings yet

- Thermoelectric Cooling and Heating SystemDocument7 pagesThermoelectric Cooling and Heating SystemBurak PalaNo ratings yet

- United States Patent (19) : Coffinberry Et AlDocument10 pagesUnited States Patent (19) : Coffinberry Et AlKrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,145,294: Traver Et Al. (45) Date of Patent: Nov. 14, 2000Document9 pagesUnited States Patent (19) (11) Patent Number: 6,145,294: Traver Et Al. (45) Date of Patent: Nov. 14, 2000Siva SubramaniyanNo ratings yet

- Optimizing Turboexpander Efficiency Using Compressor Inlet Guide VanesDocument15 pagesOptimizing Turboexpander Efficiency Using Compressor Inlet Guide Vaneschemsac2No ratings yet

- Vacuum Distillation System with Auxiliary Ejector for Lower Column Pressurerate, Will negatively impact the yield and quality of thedesired vacuum distillation productsDocument10 pagesVacuum Distillation System with Auxiliary Ejector for Lower Column Pressurerate, Will negatively impact the yield and quality of thedesired vacuum distillation productsdollarrbillNo ratings yet

- Us 20080005966Document5 pagesUs 20080005966trinasariNo ratings yet

- Tori Patent Complete SpecificationDocument13 pagesTori Patent Complete SpecificationajaypaltaNo ratings yet

- Hydrogen Gas Injector System for Internal Combustion EnginesDocument14 pagesHydrogen Gas Injector System for Internal Combustion EnginesMarkerter60100% (2)

- Ref Review ProblemsDocument3 pagesRef Review ProblemsGiancarlo SantosNo ratings yet

- Diesel Engineering Handbook Cooling SystemsDocument14 pagesDiesel Engineering Handbook Cooling Systemsmartin.ruben100% (1)

- Vapour Compression SystemDocument15 pagesVapour Compression SystemAnonymous 5HYsyrddpNo ratings yet

- Engineering Manual Evaporative CondensersDocument16 pagesEngineering Manual Evaporative Condenserstulamst100% (2)

- Basic Design Vapor-Compression Refrigeration SystemDocument20 pagesBasic Design Vapor-Compression Refrigeration Systemscarmathor90No ratings yet

- Maintaining Optimal Engine TemperatureDocument11 pagesMaintaining Optimal Engine TemperatureBird JacquesNo ratings yet

- United States Patent (19) : (73) AssigneeDocument7 pagesUnited States Patent (19) : (73) AssigneechenguofuNo ratings yet

- Jurnal Teknologi: T P M E A C CDocument6 pagesJurnal Teknologi: T P M E A C CmhdmkNo ratings yet

- ac&refDocument6 pagesac&refManoharan PilshanNo ratings yet

- TEPZZ 7785 4A - T: European Patent ApplicationDocument12 pagesTEPZZ 7785 4A - T: European Patent ApplicationThang Cao DaiNo ratings yet

- Vapor Compression Refrigeration CycleDocument10 pagesVapor Compression Refrigeration CycleArpit ThakurNo ratings yet

- Hydronic SystemsDocument5 pagesHydronic SystemsValentinNo ratings yet

- 11 AirconditioningDocument19 pages11 AirconditioningRohit AgrawalNo ratings yet

- Freezer with Liquid Cryogen Refrigerant and Purge Valve MethodDocument7 pagesFreezer with Liquid Cryogen Refrigerant and Purge Valve Methodingeniomeca8800No ratings yet

- Reduce Fouling Air PreheaterDocument13 pagesReduce Fouling Air Preheaterdhio bagusNo ratings yet

- Solar Energy ChillerDocument4 pagesSolar Energy Chilleraniketkulkarni1509No ratings yet

- Carrier HVAC Handbook Part 7 Refrigeration EquipmentDocument71 pagesCarrier HVAC Handbook Part 7 Refrigeration EquipmentTanveer100% (3)

- Sample QuestionsDocument2 pagesSample QuestionsnakatsuswanNo ratings yet

- Water Cooled Vacuum CondensersDocument2 pagesWater Cooled Vacuum CondensersRana Mubbashir IqbalNo ratings yet

- Selecting Refrigeration EquipmentDocument71 pagesSelecting Refrigeration Equipmentlyly20983% (6)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1Document5 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1shamsNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Mcquay Chiller FundamentalsDocument20 pagesMcquay Chiller FundamentalsSajith MenonNo ratings yet

- EME2146 Tutorial 6Document2 pagesEME2146 Tutorial 6iwqb0% (1)

- RAC AssignmentDocument7 pagesRAC AssignmentSoumikSabyasachi50% (2)

- Patent for Inverter-Aided Multi-System Air Conditioner with Refrigerant and Superheating ControlsDocument11 pagesPatent for Inverter-Aided Multi-System Air Conditioner with Refrigerant and Superheating ControlsAazuela RvnNo ratings yet

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Block 15 DesuperheatingDocument42 pagesBlock 15 DesuperheatingBabu Aravind100% (1)

- RAC Refrigeration System ExplainedDocument7 pagesRAC Refrigeration System ExplainedMuhammad AkhtarNo ratings yet

- CH 12 PDFDocument63 pagesCH 12 PDFswami061009No ratings yet

- RAC MCQ Guide for SSC JE ExamsDocument121 pagesRAC MCQ Guide for SSC JE ExamsYash Shah100% (1)

- Cooling hydraulic systemsDocument2 pagesCooling hydraulic systemsGustavo CuatzoNo ratings yet

- ME405 RAC Question BankDocument8 pagesME405 RAC Question BankDeepakNo ratings yet

- Angelo CombinesDocument9 pagesAngelo CombinesJan LerNo ratings yet

- SVCRCDocument32 pagesSVCRCmesfn derbNo ratings yet

- Assignment 1, RAC - KME 601Document3 pagesAssignment 1, RAC - KME 601ANSH VERMANo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattFrom EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Downloaded From Manuals Search EngineDocument42 pagesDownloaded From Manuals Search Enginecesar luis gonzalez rodriguezNo ratings yet

- NN-T695 NN-T685SF: Microwave OvenDocument49 pagesNN-T695 NN-T685SF: Microwave Ovencesar luis gonzalez rodriguezNo ratings yet

- Troubleshooting Compressor Faults V4Document5 pagesTroubleshooting Compressor Faults V4Tawafuq FmNo ratings yet

- Operating Instructions: Microwave Oven Models: NN-T695/T785/T795/ T985/T995/SD696/SD986Document60 pagesOperating Instructions: Microwave Oven Models: NN-T695/T785/T795/ T985/T995/SD696/SD986cesar luis gonzalez rodriguezNo ratings yet

- Forsthoffer's Rotating Equipment Handbooks Vol 3 CompressorsDocument411 pagesForsthoffer's Rotating Equipment Handbooks Vol 3 CompressorskarthickmectrNo ratings yet

- THG (DF) C 0712 ManDocument16 pagesTHG (DF) C 0712 Mancesar luis gonzalez rodriguezNo ratings yet

- Si 0187Document5 pagesSi 0187cesar luis gonzalez rodriguez75% (4)

- Norris Brochure Series200Document12 pagesNorris Brochure Series200cesar luis gonzalez rodriguezNo ratings yet

- PID ControlDocument5 pagesPID Controlcesar luis gonzalez rodriguezNo ratings yet

- Hvac Eqpt SizingDocument46 pagesHvac Eqpt SizingSharon Lambert100% (1)

- TD 1000Document468 pagesTD 1000cesar luis gonzalez rodriguezNo ratings yet

- VALVES - 23 - Butteryfly - Cast IronDocument6 pagesVALVES - 23 - Butteryfly - Cast Ironcesar luis gonzalez rodriguezNo ratings yet

- Flushing and Cleaning (EN) PDFDocument5 pagesFlushing and Cleaning (EN) PDFcesar luis gonzalez rodriguezNo ratings yet

- Effector IOMDocument19 pagesEffector IOMcesar luis gonzalez rodriguezNo ratings yet

- Wyatt Earp WikipediaDocument25 pagesWyatt Earp Wikipediacesar luis gonzalez rodriguezNo ratings yet

- All Wiring DiagramsDocument58 pagesAll Wiring DiagramsFrank Graham100% (4)

- Compaq Evo n610c Service ManualDocument217 pagesCompaq Evo n610c Service ManualdarreljNo ratings yet

- PL 806aDocument45 pagesPL 806acesar luis gonzalez rodriguezNo ratings yet

- 1SFC101044M0201Document16 pages1SFC101044M0201cesar luis gonzalez rodriguezNo ratings yet

- EductorsDocument1 pageEductorscesar luis gonzalez rodriguez100% (1)

- Effector IOMDocument19 pagesEffector IOMcesar luis gonzalez rodriguezNo ratings yet

- Imm WGZ 2Document60 pagesImm WGZ 2cesar luis gonzalez rodriguezNo ratings yet

- Microsoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesDocument35 pagesMicrosoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesPaneendra Kumar0% (1)

- MWCP 2007Document72 pagesMWCP 2007cesar luis gonzalez rodriguezNo ratings yet

- Install flow monitor with sensor tip immersion detectionDocument6 pagesInstall flow monitor with sensor tip immersion detectioncesar luis gonzalez rodriguezNo ratings yet

- Compressor Danfoss SM185S4CC SpecsDocument96 pagesCompressor Danfoss SM185S4CC SpecsDan C In-IraqNo ratings yet

- I&M Manual - WGZ-1Document72 pagesI&M Manual - WGZ-1cesar luis gonzalez rodriguezNo ratings yet

- Epa Bum Ch9 HvacDocument23 pagesEpa Bum Ch9 Hvaccesar luis gonzalez rodriguezNo ratings yet

- Optimising of Water-Cooled Chiller-Cooling Towers Combinations PDFDocument8 pagesOptimising of Water-Cooled Chiller-Cooling Towers Combinations PDFanescuveronicaNo ratings yet

- SQL DBA Mod 1 IntroDocument27 pagesSQL DBA Mod 1 IntroDivyaNo ratings yet

- FINAL Session 3 Specific GuidelinesDocument54 pagesFINAL Session 3 Specific GuidelinesBovelyn Autida-masingNo ratings yet

- BR18 Mechanical Engineering Robotics Semester VIDocument2 pagesBR18 Mechanical Engineering Robotics Semester VIPRAVEeNo ratings yet

- Pic32mx1xx2xx283644-Pin Datasheet Ds60001168lDocument350 pagesPic32mx1xx2xx283644-Pin Datasheet Ds60001168lR khanNo ratings yet

- 2012 NAPTIN DocumentDocument48 pages2012 NAPTIN DocumentbenaikodonNo ratings yet

- University of Texas at Arlington Fall 2011 Diagnostic Exam Text and Topic Reference Guide For Electrical Engineering DepartmentDocument3 pagesUniversity of Texas at Arlington Fall 2011 Diagnostic Exam Text and Topic Reference Guide For Electrical Engineering Departmentnuzhat_mansurNo ratings yet

- Capital Asset Pricing ModelDocument11 pagesCapital Asset Pricing ModelrichaNo ratings yet

- Dr Nael Qtati's E-Commerce Business Models Week 1 CourseDocument28 pagesDr Nael Qtati's E-Commerce Business Models Week 1 CourseMohammed LubbadNo ratings yet

- Payment Solutions For Travel Platform: SabreDocument2 pagesPayment Solutions For Travel Platform: Sabrehell nahNo ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- November 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE StudentsDocument19 pagesNovember 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE Studentssatish gordeNo ratings yet

- SMG Wireless Gateway ManualV2.2.0Document95 pagesSMG Wireless Gateway ManualV2.2.0shahedctgNo ratings yet

- Model 200-30A200P-31-21A Solenoid ValveDocument4 pagesModel 200-30A200P-31-21A Solenoid Valveemuno008No ratings yet

- MEETING OF THE BOARD OF GOVERNORS Committee on University Governance April 17, 2024Document8 pagesMEETING OF THE BOARD OF GOVERNORS Committee on University Governance April 17, 2024Jamie BouletNo ratings yet

- Medhat CVDocument2 pagesMedhat CVSemsem MakNo ratings yet

- Soft SkillsDocument117 pagesSoft Skillskiran100% (1)

- Outdoor Composting Guide 06339 FDocument9 pagesOutdoor Composting Guide 06339 FAdjgnf AANo ratings yet

- Chapter 6 Performance Review and Appraisal - ReproDocument22 pagesChapter 6 Performance Review and Appraisal - ReproPrecious SanchezNo ratings yet

- Design of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI UnitDocument41 pagesDesign of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI Unityoga arkanNo ratings yet

- Recent Advances in Mobile Robotics - TopalovDocument464 pagesRecent Advances in Mobile Robotics - TopalovBruno MacedoNo ratings yet

- GeM Bidding 2568310Document9 pagesGeM Bidding 2568310SICURO INDIANo ratings yet

- Spec 2 - Activity 08Document6 pagesSpec 2 - Activity 08AlvinTRectoNo ratings yet

- LK BMHS 30 September 2021Document71 pagesLK BMHS 30 September 2021samudraNo ratings yet

- Math30.CA U1l1 PolynomialFunctionsDocument20 pagesMath30.CA U1l1 PolynomialFunctionsUnozxcv Doszxc100% (1)

- Product Datasheet ASSA ABLOY DL6120T enDocument28 pagesProduct Datasheet ASSA ABLOY DL6120T enAbin RajuNo ratings yet

- Ermac vs. MedeloDocument1 pageErmac vs. MedeloJessa F. Austria-CalderonNo ratings yet

- Lessee Information StatementDocument1 pageLessee Information Statementmja.carilloNo ratings yet

- Cache Memory in Computer Architecture - Gate VidyalayDocument6 pagesCache Memory in Computer Architecture - Gate VidyalayPAINNo ratings yet

- Kj1010-6804-Man604-Man205 - Chapter 7Document16 pagesKj1010-6804-Man604-Man205 - Chapter 7ghalibNo ratings yet