Professional Documents

Culture Documents

Behavior of Aluminum Alloy Castings Under Different Pouring Temperatures and Speeds From Leonardo Electronic Journal of Practices and Technologies

Uploaded by

Khin Aung ShweCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Behavior of Aluminum Alloy Castings Under Different Pouring Temperatures and Speeds From Leonardo Electronic Journal of Practices and Technologies

Uploaded by

Khin Aung ShweCopyright:

Available Formats

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesand

Speeds

MohammadB.NDALIMAN*andAkpanP.PIUS

MechanicalEngineeringDepartment,FederalUniversityofTechnology,Minna,Nigeria

mbndaliman@yahoo.com(*CorrespondingAuthor)

Abstract

The investigation studies the effect of pouring temperatures and rates on the

mechanical properties of Aluminum alloy castings. The castings were produced at

differentpouringtemperaturesandspeeds.Thespeedrangeis2.0cm/sto16.0cm/s,

whilethetemperaturerangefortheinvestigationis680oCto750oC.Thespecimens

were subsequently tested for quality and properties such as hardness and strength.

Observations and results indicated that lower pouring temperatures, nearer to the

meltingtemperaturesofthealloysproducedgoodqualitycastingswiththeoptimum

values of hardness and strength as 65.5 and 112 N/mm2 respectively. The optimum

pouringspeedisintherangeof2.2cm/sto2.8cm/s,wherethehardnessandstrength

were65.4and127N/mm2respectively.

Keywords

PouringTemperaturePouringSpeedUltimateTensileStrengthRockwellHardness

PercentageElongationPercentageReductioninArea.

Introduction

To an engineer, the knowledge and understanding of casting parameters in casting different

metalsandalloysisassignificantasthecastproducts.Metalcastingisbydefinitionanyprocessof

meltingmetalandpouringthemintomouldinordertoproducetherequiredshapes.Specificcasting

parameters such as pouring temperatures, rate of pouring, fluidity and composition of metals are of

topmostimportanceforconsiderationifsoundcastingistobeachieved.

Ithasbeenobserved[1]thatmeltingandpouringconditionsdirectlyorindirectlyaffectssuch

mechanical properties of cast materials as: hardness, percentage elongation, percentage reduction in

diameter,toughnessandsoon.Forinstanceaninvestigationonpouringrateofsomeferrousmetals

[2] revealed that metals such as steels have very high freezing rate compared to most other alloys

http://lejpt.academicdirect.org/A11/071_080.htm

1/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

castings.Theoptimumpouringspeedisalsofoundtobeafunctionofthecastingsizeandshape.

Theknowledgeofmeltingtemperatureofmetalsandalloysisnecessarytoestimatetheir

correspondingpouringtemperature[3].Aluminumalloycastinghasmeltingtemperatureof660C[4]

withitscorrespondingpouringtemperaturerangetobebetween700C750C.Itwasalsostatedby

Lindberg[5]thatthismeltingtemperaturemaybeaslowas649C.

Inthispaper,theeffortsmadeinsandcastingAluminumalloyofthesamesizeandshapeat

selectedpouringtemperaturesandratesispresented.Thecastalloyswereexaminedformechanical

properties. The aim is to determine the optimum points at which these parameters produce good

quality castings. It has been stated [6] that when pouring temperature is lower than optimum, the

mould cavity will not fill the gate or riser will solidify too rapidly and intercept directional

solidification. On the other hand, higher pouring temperature causes shrinkage of the casting and

mould warping [7]. Above all, many casting defects result because the optimum casting conditions

werenotusedduringthecastingprocess[7].

Experimentalmethods

For this investigation, the casting parameters varied were the pouring temperature and the

pouringrate.SpecimensofsandcastAluminumalloywereproducedwiththeaidofwoodenpattern.

Thestandardcastingprocedure,whichcomprisesofpatternmaking,molding,melting,pouringand

cleaning/fettling,wasfollowed.Aftermolding,scrapsofAluminumalloyweremeltedinanoilfired

crucible furnace. Charging and melting was for 1 hour. Temperature measurement was done with

thermocouple,andthealloywasalwaysheatedtoatemperatureof10oCabovethespecifiedpouring

temperature. This allows for temperature drops encountered during reloading and temperature loss

duringthetimerequiredforpouringofthecastingstobecompensatedfor.Thesamesizesandshapes

werecasttopresentuniformityinmeasurements.

Determinationofpouringspeed

Pouringspeedofmoltenmetal,Vmaybedefinedastheflowofthemetalperunittime.In

determine the pouring speed, the parameter, V, is expressed as the distance of the ladle above the

pouringbasinperunittimeofpouringthemetal.Thisisexpressedas:

where: V = pouring speed (cm/s) H = Height of ladle above pouring basin (cm) T = Time for

pouringthemoltenmetal(sec).

The sand mould for each specimen to be cast was placed on a mould board and the distance

betweenthepouringbasinandtheladlewasmeasuredas80cm.Themoltenmetalwasthenpoured

intothemouldandthepouringtimeforeachmouldtobefilledupwasvariedforeightspecimensso

as to obtain different pouring speeds for the castings. The pouring temperature was maintained at

700C.

http://lejpt.academicdirect.org/A11/071_080.htm

2/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

DeterminationofPouringTemperatures

ThepouringtemperaturesoftheAluminumalloycastingsweremeasuredbyathermocouple.

Inthepouringladle,thetipoftheinstrumentwasallowedtomakecontactwiththebaseofthemolten

metal contained in it. For each casting, two temperature readings were noted and recorded

accordingly.Thefirstbeingthetemperaturereadingatthebeginningofpouringofthemoltenmetal

intothemouldandthesecondbeingthetemperaturereadingimmediatelythemouldisfilledup.The

average of these two temperatures calculated were the temperatures for the particular casting. This

wasdoneforeightcastingsatdifferenttemperatures.Thepouringspeedwasmaintainedat2.5cm/s.

Thepouredmoltenmetalwereallowedtosolidifyandcool,andthenremovedfromthesand

andthefettlingoperationswereconductedonthemusingthenormalmethods.

TestoftheCastProducts

Standard specimen dimensions were prepared out of the castings for the test of mechanical

properties.Thetestsconductedaretensileandhardnesstests.AtensiletestingandRockwellhardness

testingmachineswereusedforthesetests.

ResultsandDiscussions

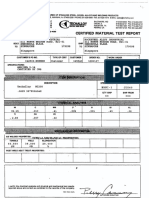

ThechemicalcompositionoftheAluminumalloycastingispresentedinTable1.

Table1.CompositionoftheAluminumAlloyCasting

Element

Composition(%) *StandardComposition(%)

Iron

0.5

0.5

Silicon

0.4

0.3

Copper

0.1

0.1

Nickel

0.1

0.1

Magnesium 4.2

3.06.0

Manganese 0.5

0.30.7

Zinc

0.1

Aluminum Balance

Balance

*Source[9]

ThecompositioninTable1canbeusedtocomparewiththepropertiesofatypicalAluminum

MagnesiumManganesealloyinascastcondition.Kempster[9]gavetheircompositionofsuch

analloytobeinthefollowingranges:Magnesium(3.06.0),andManganese(0.30.7).

The experimental results obtained for the mechanical properties of aluminum alloy casting

have been computed and plotted in graphs. A series of results were obtained for the properties at

different pouring speeds, with the pouring temperature kept constant at 700oC. From the tensile

testing,theultimatetensilestrength,percentageelongationandreductioninareawerecomputed.The

hardness values: both across and along the axis were also determined. The variations of these

propertieswithpouringspeedarepresentedinfigure1to3

http://lejpt.academicdirect.org/A11/071_080.htm

3/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

Similarpropertieswereinvestigatedwhenthepouringspeedwaskeptconstantat2.5cm/s,

while the pouring temperature was varied in the temperature range of 680.0C and 750.0C. The

behavioursofthepropertiesinthespecifiedrangearepresentedinfigures4to6.

CastingsPropertiesatDifferentPouringSpeeds

InFig.1,theRockwellhardnessnumberdeterminedforthecastingatdifferentpouringspeeds

ispresented.Thehardnessvalueacrossaxisincreasesinitiallywithpouringspeedfrom63.0.Itlatter

attaineditsmaximumvalueof65.4atthespeedof2.2cm/s.Thereafter,itfallssharplytoavalueof

58.0attherateof3.2cm/s.Itthenroseto62.0fromwhereitfinallyfallswithanyincreaseinpouring

speed.Forhardnessalongaxis,thehardnessvalueincreasesinitiallywithpouringspeedfrom60.0to

maximumvalueof63.1atthespeedof3.2cm/s,untilitfinallyfalltoavalueof50.0atthepouring

speedof16.0cm/s.

Figure1.VariationofHardnesswithPouringSpeed

Infigure2theultimatetensilestrengthdecreasesinitiallywithincreasingpouringspeedfrom

123.0N/mm2 to112.0N/mm2.Itreachesamaximumvalueof127.5N/mm2atthepouringspeedof

about2.8cm/s.Subsequentincreaseinpouringspeedreducesthetensilestrength.Thelowestvalueof

68.5N/mm2wasobtainedatthepouringrateof16cm/s.

Infigure3,thepercentageelongationincreasewithincreaseinpouringspeedfrom1.6%tothe

maximum of 2.8% at 2.8cm/s. Subsequence increase in pouring speed reduces the percentage

elongation. It can be observed that the lowest value obtained is 0.1% at 16.0cm/s. The percentage

reduction in diameter also follows the same trend, except that the values are lower than that

percentageelongationforanygivenrateofpouring.

http://lejpt.academicdirect.org/A11/071_080.htm

4/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

Figure2.VariationofUTSwithPouringSpeed

From these results, the maximum values obtained for the properties are consistent with the

existingstandards[9]whenthepouringrateisintherangeof2.22.8cm/s.Thus,thehardnessvalue

of 65.4 compares well with 50.0 [10], as obtained in standards. Similarly, the maximum tensile

strengthandelongationareinclosecomparisonwith140.0N/mm2and2.0respectivelyasfoundin

standards[9,10].Therefore,allthediscussionsonthevariationtrendswouldbetakentobevalid.

PropertiesofCastingatDifferentPouringTemperatures

Figure 4 shows the variation of Rockwell hardness with pouring temperature. Generally the

hardnessacrosstheaxisisshowntobealwayshigherthanthatalongaxis.Thehardnessacrossthe

axisincreasesinitiallywithpouringtemperaturetoamaximumof65.5attemperatureof688C.

Themaximumhardnessattainedalongtheaxisis62.8atthepouringtemperatureof688C.

Thebehaviorofthetwohardnesstypesfollowswaveforms,butgenerallydecreasesathigherpouring

temperatures. For instance, at the pouring temperature of 760C, the Rockwell hardness across the

axisis51.0,whilethatalongtheaxisis40.0.

http://lejpt.academicdirect.org/A11/071_080.htm

5/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

Figure3.EffectofPouringSpeedonDeformationofAluminumAlloyCasting

It has been observed [5] that pinholes in aluminum castings are caused by the absorbed

hydrogen. This can be minimised by pouring the alloy at temperatures just necessary for casting.

Therefore,oncethisoptimumpouringtemperatureisidentified,itshouldbeproperlyapplied.

Figure4.VariationofHardnesswithPouringTemperature

Figure5.VariationofUTSwithTemperature

http://lejpt.academicdirect.org/A11/071_080.htm

6/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

The ultimate tensile strength decreases with increasing pouring temperature (fig 5). The

minimumvalueattainedis79.5N/mm2atthepouringtemperatureof740C.

InFigure6,thepercentageelongationisseentoincreasewithpouringtemperaturefrom2.8%

toamaximumvalueof3.1%.

Figure6.EffectofPouringTemperatureonDeformation

Furtherincreasesinpouringtemperaturereducethepercentageelongation.Ontheotherhand,

thepercentagereductionindiameterincreasesinitiallywithpouringtemperaturefrom2.0%to2.5%

atthetemperatureof700C.Itthendecreasesto2.2%afterwhichitincreasestoamaximumvalueof

2.5%. Thereafter it falls sharply to 1.0%. Since these properties compared favorably well with the

castingsofsimilaralloycompositions,theproductscanbeusedinareassuchasfoodandchemical

industriesaswellasmarineandarchitecturalworks.

QualityAssessmentoftheCastings

For aluminum alloys, the optimum pouring temperature range is 700C to 750C. At

temperatures higher than this range, the casting results in large crystals, low strength and gases are

entrappedinthecastings,leadingtodefectsknownasblowholes.

ResultofVisualInspectionoftheCastings

Fromcastings,thebestsurfacefinishwasobtainedatthepouringtemperaturerangeof680C

700C.Athighertemperatures,castingswithstickysandandveryroughsurfaceswereobtained.

Pouringspeedalsoaffectsthequalityofcastings.Thespeedrangeof2.0cm/s2.7cm/sgave

http://lejpt.academicdirect.org/A11/071_080.htm

7/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

thebestsurfacefinish.Thedegreeofsurfacefinishdeterioratedasthespeedincreases.

InternalDefects

Thecastingsproducedatpouringtemperatureslessthan730Cwerefreefrominternaldefect.

This implied that the temperature were sufficient. Also castings at different pouring speeds on

machiningshowedvariationininternaldefectswithcastspecimens.Thecastingsproducedathigher

speeds {8.0cm/s to16.0cm/s} were found to have either inclusions or dross and gas holes. These

defectsmaybeasaresultofturbulenceflowconditionofthemoltenmetalasitispouredthroughthe

gatingsystemintothemould.

Conclusions

Fromboththequalityandmechanicalpropertyassessments,itwasfoundthatforAluminum

alloystheoptimumpouringtemperaturerangeisbetween700oCand750oC.Thisistheregionwhere

goodqualitycastsareproducedwithgoodmechanicalproperties.

Thepouringspeedrange,whichgavethebestsurfacefinish,isbetween2.0cm/sand2.8cm/s.

Optimum values of hardness, tensile strength and deformations were obtained at this temperature

range.

Furtherstudiesonthemetallurgicalinvestigationsonthecastingsproducedatvariedrangesof

these parameters {temperature & speed} are currently in progress. This is to check the grain sizes,

nonmetallicinclusionsandsubmicroscopicpinholes.

References

1. PiusA.P.,EffectofSomeCastingParametersontheMechanicalPropertiesofAluminumAlloy

and Medium Carbon Steel, Unpublished B. Eng Project Submitted to the Dept. of Mechanical

Engineering,FederalUniversityofTechnology,Minna,2000.

2.WarrendaleJ.L.,PouringRateofSomeFerrousandNonFerrousMetals,PaperPresentedatthe

FourthFifthPittsburghAnnualMeetingofAmericanSocietyofMetallurgicalEngineers,April

20,1981,p.3745.

3.JainP.L.,PrincipleofFoundryTechnology,MIRPublicationsMoscow,1986,p.2264.

4. Lindberg R. A., Processes and Materials for Manufacture, 2nd Edition, Allyn and Bacon Inc.

Boston,London,SydneyandToronto,1997,p.9096.

5.ASME,PouringTemperatureRangesforMetalsandAlloys,PublicationofAmericanSocietyof

MechanicalEngineering,Vol.III,ChicagoUSA,1996.

6.LancerN.C.,GuidelinesforEstablishmentofFoundry,MIRPublishersMoscow,1981,p.7275.

7. GrillP.L.,PrincipleofMetalCasting,McGrawHillBookCompany,NewYork,1982,p.160

166.

8.AdelekeO.P.,EffectofPouringTemperatureonSolubilityofGases,B.EngProjectSubmittedto

http://lejpt.academicdirect.org/A11/071_080.htm

8/9

2/2/2016 BehaviorofAluminumAlloyCastingsunderDifferentPouringTemperaturesandSpeedsfromLeonardoElectronicJournalofPracticesandTechnolo...

MechanicalEngineeringDepartment,F.U.T.Minna,1992,p.1718.

9. KemsterM.H.A.,MaterialforEngineers,HodderandStoughton,London, Sydney, Auckland

andToronto,1976,p.161170.

10. SpottsM.F.,DesignofMachineElements,6thEdition,PrenticeHallofIndiaPrivateLimited,

NewDelhi110001,1988,p.705709.

http://lejpt.academicdirect.org/A11/071_080.htm

9/9

You might also like

- Experimental Investigation On Weld Ability of Cast IronDocument5 pagesExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweNo ratings yet

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDocument4 pagesFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweNo ratings yet

- Microscopy With Light and ElectronsDocument36 pagesMicroscopy With Light and ElectronsCORE Materials100% (1)

- JK Stereo1Document26 pagesJK Stereo1Yongliang LiuNo ratings yet

- Austenitic Ductile Iron For Low Temperature ApplicationDocument6 pagesAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweNo ratings yet

- Fracture and Crack Propagation in WeldmentsDocument66 pagesFracture and Crack Propagation in WeldmentsKhin Aung ShweNo ratings yet

- ERNI-1 Cast Iron ElectrodeDocument1 pageERNI-1 Cast Iron ElectrodeKhin Aung ShweNo ratings yet

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaNo ratings yet

- Mo SteelDocument0 pagesMo SteelSamsi B HanifNo ratings yet

- Lab Exericise 3 For MicroscopeDocument9 pagesLab Exericise 3 For MicroscopeKhin Aung ShweNo ratings yet

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDocument10 pagesInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweNo ratings yet

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Document68 pagesTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweNo ratings yet

- Manual de Servicio Olympus SZ-IIIDocument18 pagesManual de Servicio Olympus SZ-IIIcarlosibaNo ratings yet

- Safety of Machinery - Principles of Risk AssessmentDocument27 pagesSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweNo ratings yet

- Welding of Nonferrous Metal and Their AlloysDocument62 pagesWelding of Nonferrous Metal and Their AlloysKhin Aung ShweNo ratings yet

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Lampiran PQR 003Document3 pagesLampiran PQR 003Khin Aung ShweNo ratings yet

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDocument1,080 pagesအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Effect of Pouring Temperature and Stirring Speed OnDocument6 pagesEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- DryerDocument80 pagesDryerAaron Paulo Bernardo100% (2)

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDocument33 pagesBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweNo ratings yet

- Braze Cast Iron - Videos, Tips and ProceduresDocument5 pagesBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweNo ratings yet

- The Crucible Arthur Miller Play AllegoryDocument11 pagesThe Crucible Arthur Miller Play AllegoryKhin Aung Shwe100% (1)

- Boiler Furnace TheoryDocument8 pagesBoiler Furnace TheoryArun YogaNo ratings yet

- Fundamentals of Metal CastingDocument14 pagesFundamentals of Metal CastingKhin Aung ShweNo ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- UeeDocument4 pagesUeeAditya ShrivastavNo ratings yet

- Assignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Document1 pageAssignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Nishant PatilNo ratings yet

- Experiment No. 1 Consistency Test On CementDocument8 pagesExperiment No. 1 Consistency Test On CementAjinkya Shendarkar0% (1)

- 4140 HTDocument2 pages4140 HTwillys8No ratings yet

- The Guiding Star Free of Charge Special Coaching Class Pre-ExaminationDocument4 pagesThe Guiding Star Free of Charge Special Coaching Class Pre-ExaminationSANLU HTUTNo ratings yet

- 17.11.2016 - Päikesekiirgusega Seotud Aspektide Analüüsivõimalustest Hoonete KavandamiselDocument137 pages17.11.2016 - Päikesekiirgusega Seotud Aspektide Analüüsivõimalustest Hoonete KavandamiselJaanus HallikNo ratings yet

- Matter - Its States, Classification, Changes, and TransitionsDocument20 pagesMatter - Its States, Classification, Changes, and TransitionsShayne Nicole . AndradeNo ratings yet

- Deep Beam-1Document14 pagesDeep Beam-1mohammed04149778No ratings yet

- Geometric Geodesy Geometric GeodesyDocument10 pagesGeometric Geodesy Geometric GeodesyKismet100% (1)

- Introduction To Stress Linearization - FEA For AllDocument10 pagesIntroduction To Stress Linearization - FEA For AllpajadhavNo ratings yet

- Damped Free VibrationDocument9 pagesDamped Free VibrationAdeoti OladapoNo ratings yet

- OlympiadDocument2 pagesOlympiadRajeev GangwarNo ratings yet

- 5054 w16 QP 11 PDFDocument20 pages5054 w16 QP 11 PDFMuhammad SaifNo ratings yet

- Aluminum A413Document2 pagesAluminum A413Fabio Miguel RodriguesNo ratings yet

- EX. US-19 Inclined SupportsDocument8 pagesEX. US-19 Inclined Supportsblisscutest beagleNo ratings yet

- Sonoluminescence by F. Ronald YoungDocument256 pagesSonoluminescence by F. Ronald Youngbennhallett100% (1)

- Cu-Psha A Matlab Software For PshaDocument26 pagesCu-Psha A Matlab Software For PshaPartha Sarathi ParhiNo ratings yet

- Chapter 3 PDFDocument46 pagesChapter 3 PDFRG RAJNo ratings yet

- Vibration and Shock Isolation-Advanced Antivibration ComponentsDocument55 pagesVibration and Shock Isolation-Advanced Antivibration Componentshiginio.moro6182No ratings yet

- Alberti PhdthesisDocument234 pagesAlberti PhdthesisUsman AliNo ratings yet

- Hexane and WaterDocument4 pagesHexane and WaterFrancis Adu-marfoNo ratings yet

- 3D Blade Analysis v1.0Document12 pages3D Blade Analysis v1.0DUVAN FELIPE MUNOZ GARCIANo ratings yet

- Sliver On Rolled AlluminiumDocument1 pageSliver On Rolled AlluminiumPEEYUSH MISHRANo ratings yet

- Reference Phthalic AcidDocument2 pagesReference Phthalic AcidBeningNo ratings yet

- Huang Et AlDocument9 pagesHuang Et AlSai Theja KandakurthiNo ratings yet

- EOR NotesDocument53 pagesEOR NotesArpit PatelNo ratings yet

- Carbon Fibre ReportDocument14 pagesCarbon Fibre ReportyoyotoyoNo ratings yet

- PP, PE, PVC, POM, PET, PA6G material characteristicsDocument1 pagePP, PE, PVC, POM, PET, PA6G material characteristicsandytuorNo ratings yet

- How fiber addition affects properties of low cement castablesDocument4 pagesHow fiber addition affects properties of low cement castablesAndrian Hadiana100% (1)