Professional Documents

Culture Documents

Distance From Sprinkler To Hanger

Uploaded by

ahmaborashed100%(1)100% found this document useful (1 vote)

724 views1 pageDistance From Sprinkler to Hanger

Original Title

Distance From Sprinkler to Hanger

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDistance From Sprinkler to Hanger

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

724 views1 pageDistance From Sprinkler To Hanger

Uploaded by

ahmaborashedDistance From Sprinkler to Hanger

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

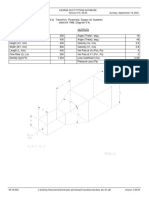

13314

INSTALLATION OF SPRINKLER SYSTEMS

maximum

36 in. (0.9 m) for 1 in. pipe

48 in. (1.2 m) for 1 in. pipe

60 in. (1.5 m) for 1 in. pipe

or larger

Greater than 36 in. (0.9 m) for 1 in. pipe

Greater than 48 in. (1.2 m) for 1 in. pipe

Greater than 60 in. (1.5 m) for 1 in. pipe or larger

Then extend here

FIGURE A.9.2.3.4 Distance from Sprinkler to Hanger.

For any pipe size:

12 in. (305 mm) maximum for steel pipe

6 in. (152 mm) maximum for copper pipe

For any pipe size:

Greater than 12 in. (305 mm) for steel pipe

6 in. (152 mm) for copper pipe

Then extend here

FIGURE A.9.2.3.4.4(a) Distance from Sprinkler to Hanger Where Maximum Pressure Exceeds

100 psi (6.9 bar) and Branch Line Above Ceiling Supplies Pendent Sprinklers Below Ceiling.

A.9.2.6 Examples include headers and horizontal runs of

pipe that need support from the floor.

Where applicable, the design of pipe stands should consider additional loading from other sources. Environmental

impacts, including water accumulation at the base, corrosion,

and wind should also be taken into account as appropriate.

A.9.3.1 Sprinkler systems are protected against earthquake

damage by means of the following:

(1) Stresses that would develop in the piping due to differential building movement are minimized through the use of

flexible joints or clearances.

(2) Bracing is used to keep the piping fairly rigid when supported from a building component expected to move as a

unit, such as a ceiling.

Areas known to have a potential for earthquakes have been

identified in building code and insurance maps.

Displacement due to story drift is addressed in 9.3.2 through

9.3.4.

A.9.3.2 Strains on sprinkler piping can be greatly lessened

and, in many cases, damage prevented by increasing the flexibility between major parts of the sprinkler system. One part of

the piping should never be held rigidly and another part allowed to move freely without provision for relieving the strain.

Flexibility can be provided by using listed flexible couplings,

by joining grooved end pipe at critical points, and by allowing

clearances at walls and floors.

Tank or pump risers should be treated the same as sprinkler

risers for their portion within a building. The discharge pipe of

tanks on buildings should have a control valve above the roof line

so any pipe break within the building can be controlled.

Piping 2 in. (51 mm) or smaller in size is pliable enough so

that flexible couplings are not usually necessary. Rigid-type

couplings that permit less than 1 degree of angular movement

at the grooved connections are not considered to be flexible

couplings. [See Figure A.9.3.2(a) and Figure A.9.3.2(b).]

A.9.3.2.3.1(1) Risers do not include riser nipples as defined

in 3.5.8.

A.9.3.2.3.1(4) A building expansion joint is usually a bituminous fiber strip used to separate blocks or units of concrete to

prevent cracking due to expansion as a result of temperature

changes. Where building expansion joints are used, the flexible coupling is required on one side of the joint by 9.3.2.3(4).

For seismic separation joints, considerably more flexibility

is needed, particularly for piping above the first floor. Figure

A.9.3.3(a) shows a method of providing additional flexibility

through the use of swing joints.

--`,,`,,,``,`,,,`,`,,``,,,

2013 Edition

Copyright National Fire Protection Association

4/2012

You might also like

- LEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYDocument30 pagesLEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYTomaszNo ratings yet

- DK9322 0810 0036Document9 pagesDK9322 0810 0036Alex David EliNo ratings yet

- Virbyg J-1Document6 pagesVirbyg J-1Anonymous xFV7bg7Q100% (1)

- Catalogue General enDocument31 pagesCatalogue General enzhyhhNo ratings yet

- Cadprofi 2021 enDocument67 pagesCadprofi 2021 enPetru CorduneanuNo ratings yet

- NordCAD 3.1Q User ManualDocument24 pagesNordCAD 3.1Q User ManualsundarNo ratings yet

- Donaldson Torit - Easy Duct Master Cataloguel PDFDocument32 pagesDonaldson Torit - Easy Duct Master Cataloguel PDFtylerstearnsNo ratings yet

- Equest Tutorial v364 PDFDocument151 pagesEquest Tutorial v364 PDFRaniPaviNo ratings yet

- TRACE3DPlus - Standard - 140 - Results PDFDocument146 pagesTRACE3DPlus - Standard - 140 - Results PDFMelvin SanchezNo ratings yet

- Energy-efficient gas heaters for commercial spacesDocument66 pagesEnergy-efficient gas heaters for commercial spacesdfsddsNo ratings yet

- Ashrae DatabaseDocument81 pagesAshrae Databasesam100% (1)

- CYPEFIRE Sprinklers ManualDocument33 pagesCYPEFIRE Sprinklers Manualrukesh104100% (2)

- 4MCAD-EN ManualDocument404 pages4MCAD-EN ManualolgfNo ratings yet

- Basic Training Workbook SettingsDocument8 pagesBasic Training Workbook SettingsIvonn OchoaNo ratings yet

- Autocad Mep 2009Document132 pagesAutocad Mep 2009haneefaparokot100% (1)

- English Book A4 Final UpdateDocument221 pagesEnglish Book A4 Final UpdateVinay PallivalppilNo ratings yet

- Thermal Comfort in Green BuildingDocument22 pagesThermal Comfort in Green BuildingThắm PhạmNo ratings yet

- Pipe Spooling in Fabrication CADmepDocument3 pagesPipe Spooling in Fabrication CADmepsambasivammeNo ratings yet

- How To Import Data From Template Projects: QB Tip 001Document3 pagesHow To Import Data From Template Projects: QB Tip 001maheshNo ratings yet

- Iti Bcu 570 GBDocument116 pagesIti Bcu 570 GBJos AngelNo ratings yet

- Daikin AHU Integration KitDocument4 pagesDaikin AHU Integration Kiterdo mandanaNo ratings yet

- For Modelling LEED (Version-1)Document11 pagesFor Modelling LEED (Version-1)Zaw Moe KhineNo ratings yet

- LEED V4 - BDC - Reference Guide - EA p2 - Minimum Energy PerformanceDocument3 pagesLEED V4 - BDC - Reference Guide - EA p2 - Minimum Energy PerformanceTrần TùngNo ratings yet

- AViCAD UserManual PDFDocument690 pagesAViCAD UserManual PDFbrutuseczekNo ratings yet

- Tuto Pyrosim Hvac Room PDFDocument14 pagesTuto Pyrosim Hvac Room PDFgilles arzulNo ratings yet

- DampersDocument7 pagesDampersPrasath SivaNo ratings yet

- ATTMA TSL2 Issue 1 PDFDocument32 pagesATTMA TSL2 Issue 1 PDFDenise Koh Chin HuiNo ratings yet

- VHX 1420 Hfs PDFDocument2 pagesVHX 1420 Hfs PDFCarlos Eberhard Diaz TorresNo ratings yet

- KB Duct 2019 CatalogDocument60 pagesKB Duct 2019 CatalogRajendraPrajapat100% (1)

- PB32We - 04 FSX PDFDocument2 pagesPB32We - 04 FSX PDFAnonymous 3q9fOpWt9vNo ratings yet

- Flammable Gas Mixing and Detection in HVAC Ducts - Industrial Fire Journal - Fire & Rescue - Hemming Group LTDDocument3 pagesFlammable Gas Mixing and Detection in HVAC Ducts - Industrial Fire Journal - Fire & Rescue - Hemming Group LTDAnonymous 1AAjd0No ratings yet

- Josam SS Drain GuideDocument28 pagesJosam SS Drain GuidetuzlucayirNo ratings yet

- Hap Ehelp 024Document6 pagesHap Ehelp 024Abed NaemNo ratings yet

- Installation Guide V1.3: Intrinsic Safety Box: Serial Isolator and Power Supply For CorusDocument13 pagesInstallation Guide V1.3: Intrinsic Safety Box: Serial Isolator and Power Supply For CorusOmar Orlando KranevitterNo ratings yet

- Add An Optional Design Standard Property To Flanges in Plant 3DDocument3 pagesAdd An Optional Design Standard Property To Flanges in Plant 3DgeorgD2010No ratings yet

- Agregar Componentes AutoCAD Plant 3DDocument8 pagesAgregar Componentes AutoCAD Plant 3DystasvNo ratings yet

- 'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineDocument6 pages'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineAnonymous NGXdt2BxNo ratings yet

- Viking Post Indicator PDFDocument12 pagesViking Post Indicator PDFpequenita34No ratings yet

- Basic Concepts of Stairwell PressurizationDocument4 pagesBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNo ratings yet

- FHCDocument6 pagesFHCyunying21No ratings yet

- Hap Ehelp 009 1Document3 pagesHap Ehelp 009 1maheshNo ratings yet

- Module 2 Start System PDFDocument20 pagesModule 2 Start System PDFIvonn OchoaNo ratings yet

- LunaCel VBX H13 FilterDocument1 pageLunaCel VBX H13 FilterKurkuma PlusNo ratings yet

- Online Enclosure Integrity Training PDFDocument6 pagesOnline Enclosure Integrity Training PDFsujiNo ratings yet

- Hi-Fog For Buildings: Technical IntroductionDocument16 pagesHi-Fog For Buildings: Technical IntroductionEsther TapiaNo ratings yet

- (SR4-2) Transition, Pyramidal, Supply Air Systems (Idelchik 1986, Diagram 5-4) Inputs OutputsDocument20 pages(SR4-2) Transition, Pyramidal, Supply Air Systems (Idelchik 1986, Diagram 5-4) Inputs Outputscollins014100% (1)

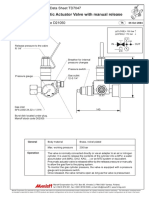

- Pneumatic Actuator Valve With Manual Release: Hi-FogDocument1 pagePneumatic Actuator Valve With Manual Release: Hi-FogGutsavoNo ratings yet

- FTS004 Deep Fat FryersDocument3 pagesFTS004 Deep Fat FryersWissam JarmakNo ratings yet

- Pyro Sim ManualDocument180 pagesPyro Sim Manualcrow250No ratings yet

- Low Heating Costs: QB Tip 001Document8 pagesLow Heating Costs: QB Tip 001maheshNo ratings yet

- WRD Ot Clarifier Calculations 445211 7Document118 pagesWRD Ot Clarifier Calculations 445211 7royal inNo ratings yet

- BR PDF Ad B1 2013Document84 pagesBR PDF Ad B1 2013twinpixtwinpixNo ratings yet

- Maximum Distance Between HangersDocument2 pagesMaximum Distance Between HangersAhmed Ali100% (1)

- Armover LengthDocument2 pagesArmover Lengthjo100% (1)

- Nfpa 13 (Acceptable Axial Loading and Unacceptable Loading)Document3 pagesNfpa 13 (Acceptable Axial Loading and Unacceptable Loading)design sseNo ratings yet

- DuctworkDocument5 pagesDuctworkducatti996chNo ratings yet

- Sway Bracing:: PW P P, P PDocument3 pagesSway Bracing:: PW P P, P PShafiullah AmanNo ratings yet

- UntitledDocument3 pagesUntitledalexander quinterosNo ratings yet

- Obstructions in SprinklerDocument28 pagesObstructions in SprinklerMd Rafat ArefinNo ratings yet

- StandardDocument3 pagesStandardAnonymous m4MF1gNo ratings yet

- Condensing Boiler Plant CPVSDocument10 pagesCondensing Boiler Plant CPVSahmaborashedNo ratings yet

- Condensing Boiler Plant VPDocument10 pagesCondensing Boiler Plant VPMelvin MagbanuaNo ratings yet

- PV Panels and Cables SubsystemDocument4 pagesPV Panels and Cables SubsystemahmaborashedNo ratings yet

- 1 Hvac Fundamentals 160216143402Document55 pages1 Hvac Fundamentals 160216143402ahmaborashedNo ratings yet

- Boiler Spec SheetDocument1 pageBoiler Spec SheetahmaborashedNo ratings yet

- LEED Version 4 For Building Design and Construction (IMPORTANTE)Document154 pagesLEED Version 4 For Building Design and Construction (IMPORTANTE)Carlos L. Oyuela100% (1)

- Charge Controllers SubsystemDocument9 pagesCharge Controllers SubsystemahmaborashedNo ratings yet

- All Variable Water Cooled Chiller PlantDocument10 pagesAll Variable Water Cooled Chiller PlantahmaborashedNo ratings yet

- Battery SubsystemDocument7 pagesBattery SubsystemahmaborashedNo ratings yet

- Battery SubsystemDocument7 pagesBattery SubsystemahmaborashedNo ratings yet

- M Elec Solar Lights Brochure 2016Document10 pagesM Elec Solar Lights Brochure 2016ahmaborashedNo ratings yet

- Solar Indoor SystemsDocument10 pagesSolar Indoor SystemsahmaborashedNo ratings yet

- Measurement of GasDocument6 pagesMeasurement of GasahmaborashedNo ratings yet

- Installing and Testing Fiber Optics: NECA/FOA 301-2009Document38 pagesInstalling and Testing Fiber Optics: NECA/FOA 301-2009shiningstar619No ratings yet

- Heat Load Calculation PsychometricDocument69 pagesHeat Load Calculation Psychometricahmaborashed100% (6)

- WiloStarST20 6Document9 pagesWiloStarST20 6ahmaborashedNo ratings yet

- Drainage Fixture Units For Fixtures and GroupsDocument1 pageDrainage Fixture Units For Fixtures and GroupsahmaborashedNo ratings yet

- Residential Streetlight Engineering PracticesDocument41 pagesResidential Streetlight Engineering PracticesvisitakcNo ratings yet

- Condensate Drain SizingDocument1 pageCondensate Drain SizingahmaborashedNo ratings yet

- Piping ColdDocument4 pagesPiping ColdahmaborashedNo ratings yet

- ISOVERDocument35 pagesISOVERMadhu RaghuNo ratings yet

- Condensate Drain SizingDocument1 pageCondensate Drain SizingahmaborashedNo ratings yet

- Open Wiring On InsulatorsDocument1 pageOpen Wiring On InsulatorsahmaborashedNo ratings yet

- Petroleum GlossaryDocument20 pagesPetroleum GlossaryegyinspectoryahooNo ratings yet

- Syrian Insulation CodeDocument124 pagesSyrian Insulation CodeahmaborashedNo ratings yet

- Fire Sprinklers and WaterDocument8 pagesFire Sprinklers and WaterahmaborashedNo ratings yet

- Fire StopDocument49 pagesFire StopJavier OrnaNo ratings yet

- Installation of Sprinkler Systems: 2013 EditionDocument1 pageInstallation of Sprinkler Systems: 2013 EditionahmaborashedNo ratings yet

- Floor Control ValveDocument1 pageFloor Control Valveahmaborashed100% (3)

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- Piping Design Engineer Interview Questions Part-13 - OilandgasclubDocument1 pagePiping Design Engineer Interview Questions Part-13 - OilandgasclubneerajNo ratings yet

- Tray-Type Deaerator: A. Parallel DownflowDocument4 pagesTray-Type Deaerator: A. Parallel DownflowMuhammad Fakhriy IndallahNo ratings yet

- Pc35r-8 S - N F21701-Up - Control Valve (11 - 17)Document2 pagesPc35r-8 S - N F21701-Up - Control Valve (11 - 17)Husika HusikaaNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Bomba DekkerDocument4 pagesBomba Dekkerjverdejop100% (1)

- ASME/ANSI B16 Standards For Pipes and FittingsDocument14 pagesASME/ANSI B16 Standards For Pipes and FittingsEquilibrium EngineersNo ratings yet

- Sebapo Stock Material DrillcoDocument7 pagesSebapo Stock Material Drillcogandhi_wirawanNo ratings yet

- LSPC 3PCDocument16 pagesLSPC 3PCVictor Acuña100% (3)

- nrcs142p2 - 024468 (Autoguardado)Document1 pagenrcs142p2 - 024468 (Autoguardado)Luis RamirezNo ratings yet

- GP 03 19 01Document12 pagesGP 03 19 01Anonymous fvO1W3100% (2)

- Non Dimensional NumbersDocument16 pagesNon Dimensional NumbersSharath ChandraNo ratings yet

- Fluid Mechanics Formula SheetDocument2 pagesFluid Mechanics Formula SheetRahulNo ratings yet

- PH HCS TB-0001 Parker Solenoid EvolutionDocument2 pagesPH HCS TB-0001 Parker Solenoid Evolutionjohn deereNo ratings yet

- P3E Choke: Valve SpecificationsDocument4 pagesP3E Choke: Valve SpecificationsJairo andres Guarnizo SuarezNo ratings yet

- FlowconME Valves Catalogue 32Document1 pageFlowconME Valves Catalogue 32mohansafNo ratings yet

- Ivc Valves PDFDocument4 pagesIvc Valves PDFNaveen ReddyNo ratings yet

- Twin-turbo System Troubleshooting GuideDocument4 pagesTwin-turbo System Troubleshooting GuideDesiderio Leonel Epullan LlanquileoNo ratings yet

- ASG-30R / RD, ASG-60R, ASG-130R / RDF, ASG-210R Silent Grapple SpecificationsDocument1 pageASG-30R / RD, ASG-60R, ASG-130R / RDF, ASG-210R Silent Grapple Specifications江文泽No ratings yet

- Aplicaciones Valvulas de ControlDocument45 pagesAplicaciones Valvulas de ControlLOPEZCRG100% (1)

- P Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValvesDocument1 pageP Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValveskrishnakumarsistNo ratings yet

- Valve Sizing - Flow RateDocument19 pagesValve Sizing - Flow RateMohammed AzeemNo ratings yet

- Water-Driven Foam Pumps For The Fire Industry: Albany PDocument2 pagesWater-Driven Foam Pumps For The Fire Industry: Albany Pkhalidwy6342No ratings yet

- Centrifugal and Axial Compressor 2Document48 pagesCentrifugal and Axial Compressor 2mbabar81100% (4)

- NPSH Pump OperatingDocument4 pagesNPSH Pump OperatingJanneth Herrera FloresNo ratings yet

- Chapter 8Document21 pagesChapter 8mohamedbadawyNo ratings yet

- CS533E Hydraulic Schematic KENR3668 PDFDocument2 pagesCS533E Hydraulic Schematic KENR3668 PDFLenin Gullapalli100% (1)

- EvaporatorDocument2 pagesEvaporatorDe JavuNo ratings yet

- Nominal Pipe SizeDocument3 pagesNominal Pipe SizeNAYEEMNo ratings yet

- Esquema de Tubos FabiusDocument1 pageEsquema de Tubos FabiusRobson BarrosNo ratings yet