Professional Documents

Culture Documents

WTC Machinery Corporation WS-200 Track Press Specifications

Uploaded by

SENTHIL NATHANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WTC Machinery Corporation WS-200 Track Press Specifications

Uploaded by

SENTHIL NATHANCopyright:

Available Formats

WTC Machinery Corporation WS-200 Track Press

SPECIFICATIONS

SECTION 2 - WS-200 Track Press Specifications

DIMENSIONS

Weight ... 5916 lbs (2690 kg)

Length .... 88 inches (2,2 m)

Width (Depth) (without conveyors).... 48 inches (1,2 m)

Height ............................... 46 inches (1,1 m)

RAMS

Capacity 200 tons (182 t), each ram

Speeds Travel . 5-7/8 inches (149 mm)

50 Cycle

60 Cycle

Ram Diameter: 7.5 inches (190 mm)

Approach 63 IPM (1,6 m/min) 76 IPM (1,9 m/min)

Piston Diameter: 8 inches (203 mm)

Pressing

7 IPM (0,4 m/min) 21 IPM (0,5 m/min)

Return

45 IPM (3,7 m/min) 171 IPM (4,3 m/min)

JAW

The Retractable Jaw is raised and lowered hydraulically. Manual fine adjustment aligns the Jaw with tooling.

HYDRAULIC PUMP UNIT

Pumps High Pressure Pump 4.76 gpm (18,0 lpm)

7960 psi (545 atm.) max.

Low Pressure Pump 12.00 gpm (45.5 lpm)

2000 psi (136 atm) max.

Reservoir Total - 50 US gallons (190 l)

Usable - 35 US gallons (132 l)

POWER WINCH

Hydraulically operated power

winch has a 8,000 pound

(3640 kg) pulling capacity.

POWER CONVEYOR

Hydraulically operated power

conveyor moves track in and

out of work area.

Electric Motor 20 Hp (14.9 kW) 3 Phase electric.

Standard Voltages:

50 Hz (1500 rpm)

60 Hz (1800 rpm)

440V/29A,

460V/27A

380V/30A

230V/54A

220V/56A

208V/60A

Other voltages available

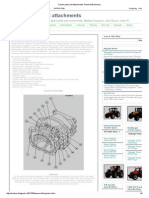

Equipment Identification

Power Conveyor

Winch (under Power Conveyor)

Retractable Jaw

Safety Door

Track Ramp

GRAVITY CONVEYORS

AND STANDS

Standard Duty Conveyor nine Conveyor Stands

support four Conveyor

Sections

Optional Shoe Lifting

Device - eleven Conveyor

Stands support five Conveyor

Sections

Gravity Conveyor ( X 4 )

Conveyor Stand ( X 9 )

Hydraulic Pump Unit

Track Press

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

WTC Machinery Corporation WS-200 Track Press

Control Identification

SPECIFICATIONS

Retractable Jaw Control

Conveyor Control

Right Ram Control

Winch Control

Left Ram Control

Retractable Jaw

Height Adjustment

Pump Start / Stop

Pressure Control

Sequence Valve

Motor Starter

Left Ram

Right Ram

Worktable

Support

Screws

Pressure Gauge

Worktable Height Adjustment

WTC Machinery Corporation WS-200 Track Press

SPECIFICATIONS

Control Identification

Left Ram Control - extends and retracts the Left Ram (or retracts both rams if the Sequence Valve is open)

With the Sequence Valve closed (fully clockwise), moving the Left Ram Control to the right extends

the Left Ram, and moving the Left Ram Control to the left retracts the Left Ram.

With the Sequence Valve open (fully counterclockwise), moving the Left Ram Control to the left

retracts both the Left Ram and the Right Ram.

Right Ram Control - extends and retracts the Right Ram (or extends both if the Sequence Valve is open)

With the Sequence Valve closed (fully clockwise), moving the Right Ram Control to the left extends

the Right Ram, and moving the Right Ram Control to the right retracts the Right Ram.

With the Sequence Valve open (fully counterclockwise), moving the Right Ram Control to the left

extends both the Left Ram and the Right Ram.

Sequence Valve - allows both rams controls to act separately (when closed) or together (when open)

With the Sequence Valve closed, the Left and Right Ram Controls act independently.

When the Sequence Valve is open, the Left Ram Control retracts both the Left and the Right Ram,

and the Right Ram Handle extends both the Left and the Right Ram.

Retractable Jaw Control - raises and lowers the Jaw for track chain movement

Pulling up on the Retractable Jaw Control lifts the Retractable Jaw.

Pushing down on the Retractable Jaw Control lowers the Retractable Jaw.

(Note: if the Retractable Jaw moves too quickly, adjust the Retractable Jaw Control Stops)

Conveyor Control - moves the Power Conveyor rollers which moves the track chain

Pulling up on the Conveyor Control moves the track chain toward the operator.

Pushing down on the Conveyor Control moves the track chain away from the operator.

Winch Control - pays out and reels in the winch cable, which pulls the track chain onto the Conveyor

Pulling up on the Winch Control retracts the Winch Cable.

Pushing down on the Winch Control pays out the Winch Cable.

Pump Start / Stop - starts and stops the Electric Motor which power the Track Press

Pressing the Start Push Button starts the Electric Motor.

Pressing the Stop Push Button stops the Electric Motor.

Remote Control Valve - sets the system pressure, and the ram force

Turning the Remote Control Valve's knob clockwise increases the operating pressure.

Turning the Remote Control Valve's knob counterclockwise decreases the operating pressure.

The jam nut behind the adjustment knob is used to lock the valve at a particular setting.

Pressure Gauge - shows the system pressure

The Track Chart shows the proper pressures for the assembly of selected types of track chain.

Retractable Jaw Height Adjustment - sets the height of the Retractable Jaw

Turning this (using a 5/8" wrench or socket) raises or lowers the Retractable Jaw and the track chain

it holds. Use this adjustment to bring the track chain into vertical alignment with the tooling.

Worktable Height Adjustment - raises and lowers the Worktables and the track chain links they support

Turning this (with a 5/8" wrench or socket) raises or lowers the Worktables. Use this during the

track chain's reassembly to bring track chain links into vertical alignment with the pins and bushings.

Worktable Support Screws - support the front end of the Worktable

Adjust these (using a 5/8" hex key or Allen wrench) to touch the Worktables' underside, whenever

changing the height of the Worktables. Always adjust these down before lowering the Worktables.

You might also like

- PDF The Ultimate Training Split Guide by Brian Decosta Compress 4Document23 pagesPDF The Ultimate Training Split Guide by Brian Decosta Compress 4Burcu Senol100% (1)

- Nikon Total Station DTM-502 ManualDocument226 pagesNikon Total Station DTM-502 ManualAzzahraNo ratings yet

- Grupo Herramienta de Reparacion de CadenasDocument28 pagesGrupo Herramienta de Reparacion de CadenasIsrael Miranda ZamarcaNo ratings yet

- Atkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDocument26 pagesAtkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDavid Kelly100% (1)

- Mower GuideDocument48 pagesMower GuidezexploNo ratings yet

- Code of Practice On Sewerage and Sanitary WorksDocument56 pagesCode of Practice On Sewerage and Sanitary Worksexlife86100% (2)

- 993k Wheel Loader Before Operation ManualDocument6 pages993k Wheel Loader Before Operation ManualGustavo VargasNo ratings yet

- 11 Lifting Blocking Clamping PDFDocument48 pages11 Lifting Blocking Clamping PDFEbied Yousif AlyNo ratings yet

- CASE 590 Super M PRELIMENARYDocument6 pagesCASE 590 Super M PRELIMENARYDian Sikumbang100% (1)

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- Spreader Training - EH5U & EH170UDocument43 pagesSpreader Training - EH5U & EH170UDavid Adeola Ogunyemi100% (3)

- GRW18 TCD2012L04 W V5 en-GBDocument2 pagesGRW18 TCD2012L04 W V5 en-GBFelix SandersNo ratings yet

- 70 kW Backhoe Loader with 1 m3 BucketDocument2 pages70 kW Backhoe Loader with 1 m3 BucketMarcio MotaNo ratings yet

- Grade 2 Classical Piano PDFDocument11 pagesGrade 2 Classical Piano PDFBruno VittoruzzoNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Albert Gafarov100% (1)

- TC5613-6 - Operation ManualDocument109 pagesTC5613-6 - Operation ManualSENTHIL NATHAN100% (4)

- Vtrack - ENGINESDocument64 pagesVtrack - ENGINESanderson cesconettoNo ratings yet

- Link Belt X4 Long Front FamilyDocument12 pagesLink Belt X4 Long Front FamilyYew LimNo ratings yet

- Kit de GatosDocument689 pagesKit de GatosRichardReveloNo ratings yet

- Pipeline EngineeringDocument32 pagesPipeline Engineeringvictorvikram100% (1)

- Mccormick c60 c75 c85 c95 c105 C Max Workshop ManualDocument8 pagesMccormick c60 c75 c85 c95 c105 C Max Workshop ManualdingleberryspotifyNo ratings yet

- Motor Basico C9Document9 pagesMotor Basico C9GerardoNo ratings yet

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 5th PartDocument26 pagesEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 5th Partthan zaw win100% (1)

- PGP PGM 500 600 Uk 845Document36 pagesPGP PGM 500 600 Uk 845Jorge Andres PozoNo ratings yet

- Rodamientos SKFDocument1,380 pagesRodamientos SKFSebastian Lobos OpitzNo ratings yet

- Prescribed Books FrenchDocument7 pagesPrescribed Books Frenchplaaspaddas3No ratings yet

- 塔顶组件材质(性能等级)Material备注Remark1Tower Head Assembly滑轮轴(1)1Pulley Shaft (1)螺栓 BoltM12×3044.8级B.03A.8滑轮组(A)1Pulley Assembly (A)330020103A0500TC5013B.03A.5滑轮组(B)1Pulley Assembly (B)34Document65 pages塔顶组件材质(性能等级)Material备注Remark1Tower Head Assembly滑轮轴(1)1Pulley Shaft (1)螺栓 BoltM12×3044.8级B.03A.8滑轮组(A)1Pulley Assembly (A)330020103A0500TC5013B.03A.5滑轮组(B)1Pulley Assembly (B)34SENTHIL NATHAN100% (1)

- 塔顶组件材质(性能等级)Material备注Remark1Tower Head Assembly滑轮轴(1)1Pulley Shaft (1)螺栓 BoltM12×3044.8级B.03A.8滑轮组(A)1Pulley Assembly (A)330020103A0500TC5013B.03A.5滑轮组(B)1Pulley Assembly (B)34Document65 pages塔顶组件材质(性能等级)Material备注Remark1Tower Head Assembly滑轮轴(1)1Pulley Shaft (1)螺栓 BoltM12×3044.8级B.03A.8滑轮组(A)1Pulley Assembly (A)330020103A0500TC5013B.03A.5滑轮组(B)1Pulley Assembly (B)34SENTHIL NATHAN100% (1)

- Caterpillar d7f Crawler Parts Manual S N 93n1175Document11 pagesCaterpillar d7f Crawler Parts Manual S N 93n1175Hugo Cordero RuizNo ratings yet

- T630 Web Manual Cat-Perkins Engine Auburn HubsDocument87 pagesT630 Web Manual Cat-Perkins Engine Auburn Hubsjesus silvaNo ratings yet

- Accessories CatalogueDocument36 pagesAccessories Cataloguekra062No ratings yet

- CATERPILLAR SIS + Price List (10.2015) MultilanguageDocument1 pageCATERPILLAR SIS + Price List (10.2015) MultilanguageIRENENo ratings yet

- JT30AT Operator Manual (3152)Document243 pagesJT30AT Operator Manual (3152)Luke FosterNo ratings yet

- Specs CASE 821E SeriesDocument6 pagesSpecs CASE 821E SeriesDian SikumbangNo ratings yet

- 03-Senr3130!08!01-All Torque SpecificationsDocument16 pages03-Senr3130!08!01-All Torque Specificationsgustavoespinosam100% (1)

- Tractor Parts and Attachments: Powershift GearboxDocument6 pagesTractor Parts and Attachments: Powershift Gearboxaritmetics100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Lhsan Rajawi100% (1)

- HATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMDocument39 pagesHATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMEdmundas ŽemaitisNo ratings yet

- Airlinx CatalogDocument22 pagesAirlinx CatalogjcNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Bulldog Cat 3056 Engine KitsDocument1 pageBulldog Cat 3056 Engine KitsDavid Fernando Castillo NisttahuzNo ratings yet

- L350F 21D1002740Document28 pagesL350F 21D1002740dalibor_bogdanNo ratings yet

- SENR3255 - D5 GB System Operation-1Document49 pagesSENR3255 - D5 GB System Operation-1frgmanNo ratings yet

- Valtra ANTS Concept Design de Um TratorDocument13 pagesValtra ANTS Concept Design de Um TratorDaniel FerrariNo ratings yet

- Cub Cadet 3185 Operators Manual 163730Document36 pagesCub Cadet 3185 Operators Manual 163730mamamNo ratings yet

- New Holland B80B Backhoe Loader Service Repair ManualDocument31 pagesNew Holland B80B Backhoe Loader Service Repair ManualggjjjjotonesNo ratings yet

- Same Laser 125 150 2009Document2 pagesSame Laser 125 150 2009Silvia De Pedro CamoeirasNo ratings yet

- ULTRA Linear Operators Manual PDFDocument101 pagesULTRA Linear Operators Manual PDFIov IftodeNo ratings yet

- Manual de Parte Bulldozer d8t Volumne 3Document28 pagesManual de Parte Bulldozer d8t Volumne 3henotharenasNo ratings yet

- Caterpillar CS44B Specifications - 4 PDFDocument2 pagesCaterpillar CS44B Specifications - 4 PDFTaha GargoumNo ratings yet

- D4EDocument11 pagesD4EMantenimiento U.C.O.100% (1)

- 695SR 26061062GBDocument16 pages695SR 26061062GBwalk111No ratings yet

- AG150 250 Part 3Document6 pagesAG150 250 Part 3aritmeticsNo ratings yet

- Dodge Speed Reducers Parts Replacement ManualDocument9 pagesDodge Speed Reducers Parts Replacement Manuala04205No ratings yet

- 277C, 287C, 297C MTL English PDFDocument12 pages277C, 287C, 297C MTL English PDFJuan n cadenaNo ratings yet

- Butee EmbrayageDocument2 pagesButee EmbrayagewoulkanNo ratings yet

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- SakaiDocument2 pagesSakaiariNo ratings yet

- WA380 7 BrochureDocument24 pagesWA380 7 BrochureAvaa Amgaa100% (1)

- Tecumseh Model Hm80 155128e Parts ListDocument11 pagesTecumseh Model Hm80 155128e Parts ListAndy TuranskyNo ratings yet

- SCZ Cheetah Manual Book 03363Document87 pagesSCZ Cheetah Manual Book 03363rob sullivan100% (1)

- 6 Speed Transmission Gears & Related PartsDocument5 pages6 Speed Transmission Gears & Related PartsMarcela Liliana MolnarNo ratings yet

- TR-500EX: Tadano LTDDocument6 pagesTR-500EX: Tadano LTDMuhammadFaridNo ratings yet

- Doosan EXC QuickCoupler ENDocument2 pagesDoosan EXC QuickCoupler ENFelipe HernandezNo ratings yet

- M318S-Steering PumpDocument88 pagesM318S-Steering Pumpzeck28No ratings yet

- Harvesters: 703JH 753JH 759JHDocument18 pagesHarvesters: 703JH 753JH 759JHrossini_danielNo ratings yet

- AGRIA HISPANIA DH-160 Dumper Parts CatalogDocument97 pagesAGRIA HISPANIA DH-160 Dumper Parts CatalogEdin Raul Yalle RafaelNo ratings yet

- Fuel Lift Pump Remote Mounting Kit RevisionDocument2 pagesFuel Lift Pump Remote Mounting Kit RevisionMike PerryNo ratings yet

- MSeries RevB2Document7 pagesMSeries RevB2Guillermo MartínezNo ratings yet

- 3500watt 3 5kw 48 72v 3000rpm BLDC MotorDocument19 pages3500watt 3 5kw 48 72v 3000rpm BLDC MotorOscar Dominguez LunaNo ratings yet

- Bajaj Pulsar 150 Dts IDocument75 pagesBajaj Pulsar 150 Dts IErick100% (1)

- 2021 Integration Manual: Tested - Proven - TrustedDocument28 pages2021 Integration Manual: Tested - Proven - TrustedSENTHIL NATHANNo ratings yet

- Safety Check ListDocument1 pageSafety Check ListSENTHIL NATHANNo ratings yet

- Catalogue of GeneratorsDocument13 pagesCatalogue of GeneratorsSENTHIL NATHANNo ratings yet

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaNo ratings yet

- Deep Well De-WateringDocument14 pagesDeep Well De-WateringSENTHIL NATHAN100% (1)

- Safety Measures PresentationDocument26 pagesSafety Measures PresentationSENTHIL NATHANNo ratings yet

- Igc3 Nebosh Guidance 2014 v.2Document21 pagesIgc3 Nebosh Guidance 2014 v.2Cezar DumitriuNo ratings yet

- Geho PumpsDocument5 pagesGeho PumpsSENTHIL NATHANNo ratings yet

- Hydraulic PressDocument1 pageHydraulic PressSENTHIL NATHAN100% (1)

- Sample HS ReportDocument5 pagesSample HS ReportAnas ShoaibNo ratings yet

- Poster Dont Overload SocketsDocument1 pagePoster Dont Overload SocketsSENTHIL NATHANNo ratings yet

- 400T Press Link MachineDocument3 pages400T Press Link MachineSENTHIL NATHANNo ratings yet

- Summit 20-24-28 ManualLathesDocument4 pagesSummit 20-24-28 ManualLathesSENTHIL NATHANNo ratings yet

- Yacht Week PR ProposalDocument16 pagesYacht Week PR ProposalDayaram Panday0% (1)

- ReflectionDocument2 pagesReflectionAfrah IzzatiNo ratings yet

- Rhapsody On A Theme by Paganini: Violin IDocument15 pagesRhapsody On A Theme by Paganini: Violin IDoris TkalčevićNo ratings yet

- DND - 5E - CharacterSheet - Form FillableDocument3 pagesDND - 5E - CharacterSheet - Form FillableSimon ParkNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryNo ratings yet

- ETSI TS 102 819: Digital Video Broadcasting (DVB) Globally Executable MHP Version 1.0.2 (GEM 1.0.2)Document94 pagesETSI TS 102 819: Digital Video Broadcasting (DVB) Globally Executable MHP Version 1.0.2 (GEM 1.0.2)Daniel Martinez CollazoNo ratings yet

- Kentucky Derby Odds As of Feb. 3, 2016Document2 pagesKentucky Derby Odds As of Feb. 3, 2016Anonymous HduTOVdgQNo ratings yet

- Animation PresentationDocument13 pagesAnimation Presentationdin2kxpNo ratings yet

- Disney Luxury Homes in Hyderabad's Financial DistrictDocument21 pagesDisney Luxury Homes in Hyderabad's Financial DistrictKota RavichandNo ratings yet

- Editing Guide SE102 enDocument168 pagesEditing Guide SE102 enzomb_killerNo ratings yet

- Datasheet of DS 7716NXI K4 - V4.71.100 - 20220723Document5 pagesDatasheet of DS 7716NXI K4 - V4.71.100 - 20220723David Lazo PallautaNo ratings yet

- CJ2+ Supplement 16 GPWSDocument10 pagesCJ2+ Supplement 16 GPWSCAPT RAJA NALLURINo ratings yet

- Phil Parker Bye PDFDocument5 pagesPhil Parker Bye PDFMarc MorehouseNo ratings yet

- WHD_Reference_Sheet_v4.3Document17 pagesWHD_Reference_Sheet_v4.3juan antonioNo ratings yet

- Anthology: Something Exploded in The KitchenDocument38 pagesAnthology: Something Exploded in The KitchendaphnehoNo ratings yet

- Lab Project WoDocument121 pagesLab Project Woravindra erabattiNo ratings yet

- Debugging Steps of XBee Sensor Expansion BoardDocument14 pagesDebugging Steps of XBee Sensor Expansion BoardsoliddigiNo ratings yet

- COURT MUSIC OF VIETNAM and SINGAPOREDocument1 pageCOURT MUSIC OF VIETNAM and SINGAPOREChardnys EmpinadoNo ratings yet

- HirePro Video Proctored Assessment System RequirementsDocument1 pageHirePro Video Proctored Assessment System RequirementsKrishna RockNo ratings yet

- Datasheet of THC-D320-VF V1.0.1 20181008 PDFDocument3 pagesDatasheet of THC-D320-VF V1.0.1 20181008 PDFIT.COMPany Intelligent SolutionsNo ratings yet

- Seminar On Contemprary ArchitectureDocument15 pagesSeminar On Contemprary ArchitectureGunjan UttamchandaniNo ratings yet

- Airline Designator Airline DesignatorDocument1 pageAirline Designator Airline Designatornikhil sharmaNo ratings yet

- NewChallenges Workbook Level4 PDFDocument18 pagesNewChallenges Workbook Level4 PDFNatalia AstorgaNo ratings yet

- Marxist Film TheorywordDocument19 pagesMarxist Film Theorywordapi-299624824No ratings yet

- Rigging Manual Club 420 Class: Performance Sailcraft 2000 Inc 2555 Dollard Lasalle, Quebec, H8N 3A9 Tel: 514 363 5050Document11 pagesRigging Manual Club 420 Class: Performance Sailcraft 2000 Inc 2555 Dollard Lasalle, Quebec, H8N 3A9 Tel: 514 363 5050Cesar Arango GomezNo ratings yet

- 1-Gma Annual Report - 2020 1621409182Document86 pages1-Gma Annual Report - 2020 1621409182RonEljun Medalla-EnopiaNo ratings yet

- Exercises About Simple Past TenseDocument4 pagesExercises About Simple Past TenseDavid CastilloNo ratings yet