Professional Documents

Culture Documents

Steel Deck 101

Uploaded by

arnoldistunoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Deck 101

Uploaded by

arnoldistunoCopyright:

Available Formats

Structural

Design

design issues for

structural engineers

U

T

E

R

t

Figure 1: rIn

ighits most basic form, a diaphragm behaves as if it were a short, deep beam.

y

Cop

Steel Deck Diaphragm

Design 101

By Kurt Voigt, P.E.

R

T

S

S

C

U

Steel roof and floor deck diaphragm design requires careful

attention to load paths, stiffness variations, fastener types,

and regional preferences

z

a

g

hear diaphragms are commonly used in

buildings as a means of transmitting lateral loads. In building design, these loads

are typically caused by wind and seismic

events, although earth and water can exert lateral

forces as well. Steel deck, plywood, and concrete

are all common materials utilized in diaphragm

applications. In its most basic form, i.e. a rectangular, uninterrupted plane, a diaphragm behaves

primarily as if it were a short, deep beam (Figure

1). Using this basic concept, the diaphragm shear

forces can be determined and generally the same

principles applied even with the introduction of

roof openings or irregular building geometry.

Lets start with the roof framing plan in Figure

2. Well use the same basic layout and service

level wind pressure as shown in Figure 1, with the

addition of (8) skylight openings in the roof. The

openings reduce the diaphragm stiffness in the

same manner that a beam web opening would

reduce the beam stiffness at the location of the

Figure 1 opening. Well need to ensure adequate

fastening and transfer elements are provided to

resist and transfer the design shear, including the

distributed shear around the openings.

For this example, we are only going to consider

wind in the direction shown, assuming half of the

net pressure shown is windward on AC and half is

leeward on BD. Constructing the shear diagram

(V) in Figure 3, using the free-body diagram of

Figure 1, shows us the maximum shear exists at

the ends of the building, along AB and CD. The

Figure 2 average shear (S) in the diaphragm is

Kurt Voigt, P.E., is an

Engineering Manager at New

Millennium Building Systems.

He can be reached at

kurt.voigt@newmill.com.

e

n

i

10 August 2013

determined by dividing the shear by the length

of the diaphragm at the location in question. The

maximum average shear (Smax) in this example

occurs both at the ends of the building, as well as

in the deck panels and fasteners just to the right

of the roof framing along AB (where average shear

length is reduced due to openings), where Smax =

0.292 kips per linear foot (klf ). Using the Steel

Deck Institute (SDI) Diaphragm Design Manual,

Third Edition, we can determine the required deck

fastening. Using 5/8-inch puddle welds for attaching deck to supports and #10 sidelap screws, we

find the nominal shear strength in the table for

0.0295-inch thick WR deck is 0.740 klf using a

36/4 (12-inch o.c.) support fastener pattern and

(4) sidelap screws per span (15-inch o.c.). For

ASD design, the wind factor of safety is 2.35,

yielding an allowable shear force of 0.315 klf. This

allowable shear force considers fastener strength

and panel distortion around the fasteners; however, an additional check for stability must be

made to ensure global buckling of the panel will

not occur. The allowable buckling shear from the

SDI table is 0.660 klf, so buckling will not occur.

Shear around Openings

The next step is to determine the shear around

the openings. Since the building, opening locations, and loading are all symmetrical, well

look only at the (2) openings nearest the left

end of the building (abcd and opening directly

below). The (2) openings at the opposite end

Figure 2: Skylight openings reduce diaphragm stiffness in the same manner

beam web openings do.

of the building will be the same, and the

(4) openings near the interior will have different shear, but would be calculated using

the same principles. From the average shear

diagram (S) in Figure 3, we know the shear

on the AB side of the openings is 0.219 klf

and the opposite side is 0.201 klf. To determine the shear along the other (2) sides of

each opening, we need to look at the rectangular deck areas directly above and below

each opening. By constructing free-body

E

R

Figure 3: Shear around openings is determined based on forces

diagrams of the

and moments above and below each opening.

areas in question,

t

igh

r

we can sum oforces

y

C p

and moments around the area perimeters. right side shear force is 0.267 klf x 30 ft.

Looking at the top 6-foot 3-inch wide x = 8.01 k (downward). Summing moments

30-foot long area, with base ac, we need about point (a) yields a shear force along

to ensure the forces around the perimeter the top (building perimeter above opening)

of that area are in equilibrium (Figure 4 , of (8.01 k x 6.25 ft. + 0.175 klf x (6.25

page 12). We know from the S diagram in ft.)2 / 2) / 30 ft. = 1.78 k (leftward). Then,

Figure 3 the left side shear force is 0.292 summing forces in the horizontal direction

klf x 30 ft. = 8.76 kips (k) (upward) and yields an equal and opposite force of 1.78

R

T

S

C

U

a

U

T

e

n

i

z

a

g

ADVERTISEMENT - For Advertiser Information, visit www.STRUCTUREmag.org

Take Your Place In

The CRSI Honors

RECOGNIZING INNOVATION

in the Design and Construction of

Reinforced Concrete Buildings by

creating value in any of several ways:

Collaborative Design

Lean Building Methods

Uniquely Inspiring Spaces

Planned Use Adaptability

Material or Systems Efficiency

Whole-Life Sustainability

Structural Resilience

ACKNOWLEDGING THE LEADERS

at Every Stage that Drive Great

Outcomes for Building Users:

Building Owners

Program Managers

Design Architects

Structural Engineers

Construction Managers

General Contractors

Construction Industries

Submittals will be accepted online from July 1, 2013 to November 1, 2013

Unlimited submittals per firm, entirely free to CRSI member organizations

HONORS

Presented by

2013

FOR FAST & EASY SUBMITTAL DETAILS VISIT

13070_CRSI_Honors_Structure_half_page_ad_2013.indd 1

STRUCTURE magazine

11

August 2013

honors.crsi.org TODAY!

6/10/13 12:17 PM

k (rightward) along ac. This force must be

transferred into the adjacent diaphragm

areas ( into each) immediately to the left

and right of the opening. Since this force is

in addition to the existing diaphragm shear

in those areas, care must be taken to provide

sufficient transfer length into those areas to

prevent crippling of the deck at the associated corners of the opening. Using A653

SS grade 33 steel, the allowable strength

of an arc spot weld can be determined by

the equation 2.2tFu(d-t)/ = 2.2(0.0295

in.)(45 ksi)(0.625 in.0.0295 in.)/(2.35) =

0.740k. The required number of fasteners to

distribute the additional shear into adjacent

diaphragms is (1.78 k)/(2 sides)/(0.740k/

weld) = 1.2 welds per side, rounded up to 2.

Since the diaphragm in the area in question

is capable of resisting a maximum allowable

shear of 0.315 klf, we should ensure that

the transfer length provided into adjacent

diaphragm areas is sufficient to limit the

average total shear to 0.315 klf. To the left

of the opening, the diaphragm is required to

resist 0.219 klf due to applied loads, so the

additional shear were introducing should

not exceed 0.315 klf 0.219 klf = 0.096 klf.

The minimum transfer length or connection length can be determined by dividing

the additional shear by the maximum additional shear calculated in previous step,

(1.78 k)/(2 sides)/(0.096 klf ) = 9.27 feet.

Since this length exceeds the roof framing

spacing, well need to provide a transfer

element, i.e. channel, angle, tube, etc., in

line with ac that extends (2) spaces out to

each side, upon which (2) 5/8-inch puddle

welds should be placed approximately 4 feet

6 inches and 9 feet from a and c. Practically

speaking in this example, since only (2)

additional welds are required on each side,

the deck could accommodate an additional

weld at each of the (2) supports adjacent to

a and c, in lieu of providing an additional

transfer element. Moving on to the 6-foot

3-inch x 30-foot diaphragm area between

the (2) leftmost openings, by inspection,

the additional shears along bd will be similar to those calculated previously, since the

area is the same size and shears are similar.

The shear would be slightly less, since the

applied load component is not present at

the top or bottom of the area.

Transfer of Lateral Loads

Designing and specifying diaphragms to transfer lateral loads is a fairly involved process,

becoming more complicated when openings

and irregular geometry are introduced. There

are many elements to be considered, including the interaction of the various structural

components with varying stiffness. How the

load travels from one part of the structure to

another is highlyrigdependent

upon the stiffht

y

Cop

ness of the components,

the fasteners chosen,

and the connection details in the areas where

the forces are intended to transfer from one

component to another. Careful consideration

of the load path is critical in maintaining an

economical, constructable diaphragm system.

Drag struts and collector elements are often

framed in the direction of the shear load, in

order to progressively collect the load and distribute it into the structural framing system.

In cases similar to the previous example,

where the lateral load is being resisted by a

horizontal diaphragm, a means of transferring

the force from the diaphragm above to the

structure below must be provided.

Suppose the roof framing at 6-foot 3-inch o.c.

in the example (Figure 2, page 11) is an open

web steel joist system, where the ends of the

joists along walls AC and BD are bearing on a

ledger angle on precast walls. When the wind

is blowing on walls AB and CD, there must be

a path for the shear in the diaphragm above the

joists to transfer out into walls AC and AD. This

may be accomplished in many ways; one of

those would be via a deck bearing angle atop

the joist ends adjacent to the wall, into the

StruWare, Inc

joist seats, into the ledger angle, and then

Structural Engineering Software

into the wall; another being more direct via a

deck bearing angle that is attached to the wall

The easiest to use software for calculating

with sufficient fastening to directly transfer

wind, seismic, snow and other loadings for

the shear from the bearing angle and into

IBC, ASCE7, and all state codes based on

the wall; another would be to install channel

these codes ($195.00).

members or HSS tubing to the ledger angle

CMU or Tilt-up Concrete Walls with &

between the joist seats, such that the top of

without openings ($75.00).

the tubing is at the same elevation as top of

Floor Vibration for Steel Bms & Joists ($75.00).

joists, and would provide deck edge support

and a method for shear transfer into the

Concrete beams with torsion ($45.00).

ledger angle (eliminating the shear on the

joist seats which have limited capacity for

Demos at: www.struware.com

shear transfer), and into the wall.

ADVERTISEMENT - For Advertiser Information, visit www.STRUCTUREmag.org

R

T

S

C

U

a

STRUCTURE magazine

U

T

E

R

August 2013

Regional Preferences

So many choices how do you choose? The

answer lies in regional preferences, contractors and costs. Some erectors may prefer one

method over another, and precast wall manufacturers will have preferences and associated

costs as well. Steel joist seats have a fairly limited

rollover shear capacity of around 2.5 kips service

load at 21/2 inches deep. Thus, it is important

whenever possible to provide an alternate means

of shear transfer, such as the aforementioned

channel or tube members, when shear loads

begin to exceed the standard seat capacity. It

is critical to provide adequate load paths, and

for project teams to communicate with affected

trades to determine the best option for the

project. Similarly, deck fastening preferences

vary regionally, and even vary among erectors

within the same region. Diaphragm loads in the

western U.S. are generally considerably larger

than those present in the midwest. As such, a

particular deck fastening and transfer system

that typically works well in the western U.S.

may be very uncommon, and/or unnecessary,

in the midwest. Again, communication among

the project team is important.

In summary, the next time you design a

project with a diaphragm system, be sure to

give careful consideration to ALL the details,

from load paths, to stiffness variations, to

fastener types, and regional preferences. The

SDI Diaphragm Design Manual, Third Edition

is an excellent design reference every engineer

should utilize if designing with steel deck

diaphragms. The manual includes pertinent

design information, considerations, fastener

information, deck shear capacity tables, and

a plethora of highly relevant design examples,

stepping you through all the intricate details

and covering nearly any scenario you may

run across.

e

n

i

z

a

g

12

Figure 4: Forces

around the perimeter of an

opening must be brought into equilibrium.

You might also like

- C StrucDesign Voigt Aug13Document0 pagesC StrucDesign Voigt Aug13توان امتياس سامسدينNo ratings yet

- Truss Plus PurlinDocument6 pagesTruss Plus Purlinharshita singhNo ratings yet

- Bs5400 DesignDocument10 pagesBs5400 DesignMahesh Pokhrel67% (3)

- Unit 5Document42 pagesUnit 5ashok Pradhan0% (1)

- ACI - 318 - 05 Design of Slab PDFDocument24 pagesACI - 318 - 05 Design of Slab PDFtaz_taz3No ratings yet

- Life Sci. Special Issue Vol 3-3-67 2Document11 pagesLife Sci. Special Issue Vol 3-3-67 2jm11No ratings yet

- 105 Multi Layer Shotcrete Design TunnelDocument20 pages105 Multi Layer Shotcrete Design TunnelNuno FerreiraNo ratings yet

- CH 1Document49 pagesCH 1Gurinder PalsinghNo ratings yet

- Aci 318 05 PDFDocument24 pagesAci 318 05 PDFDavid BourcetNo ratings yet

- TB Lecture20 Example of PT Two Way SlabsDocument39 pagesTB Lecture20 Example of PT Two Way SlabsBridget Anne BenitezNo ratings yet

- 2 Principles of Roof Truss DesignDocument8 pages2 Principles of Roof Truss Designnaveenbaskaran1989No ratings yet

- Technical Note Wall Pier Flexural Design: S W D ACI 318-02Document19 pagesTechnical Note Wall Pier Flexural Design: S W D ACI 318-02tomxxx34No ratings yet

- Masara mosque-CALCULATION REPORTDocument115 pagesMasara mosque-CALCULATION REPORTmjnasar khan jamalNo ratings yet

- Design of RC Beams With OpeningsDocument8 pagesDesign of RC Beams With OpeningsVatsal GokaniNo ratings yet

- Seismic Design StepsDocument16 pagesSeismic Design StepsGopal MishraNo ratings yet

- Sesmic Structural Design StepsDocument16 pagesSesmic Structural Design StepsGeorge GeorgianNo ratings yet

- Environmental Engineering Concrete Structures: CE 498 - Design Project November 16, 21, 2006Document34 pagesEnvironmental Engineering Concrete Structures: CE 498 - Design Project November 16, 21, 2006Dory AzarNo ratings yet

- Structural Analysis of Transmission Structures: 1.problem DescriptionDocument69 pagesStructural Analysis of Transmission Structures: 1.problem DescriptionMahesh ANo ratings yet

- Anchor BoltsDocument8 pagesAnchor BoltsRalf SnellNo ratings yet

- Seismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineerDocument16 pagesSeismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineercivilsadiqNo ratings yet

- Composite Deck DesignDocument16 pagesComposite Deck DesignLatha MaNo ratings yet

- Composite Deck DesignDocument16 pagesComposite Deck DesignAhmad FitrahNo ratings yet

- Composite Deck DesignDocument16 pagesComposite Deck Designvejanidb100% (1)

- Project 2Document9 pagesProject 2nkjm rtdtNo ratings yet

- Design of Roof TrussesDocument24 pagesDesign of Roof TrussesAlam Mohammad Parvez Saifi69% (16)

- Unit 8 Roof Trusses: StructureDocument24 pagesUnit 8 Roof Trusses: StructureanbugobiNo ratings yet

- Composite Design PDFDocument23 pagesComposite Design PDFrameshbabu_1979No ratings yet

- Superstructure, Substructure and CostingDocument44 pagesSuperstructure, Substructure and Costingdear_tora100% (1)

- Reinforcedslab 100917010457 Phpapp02Document29 pagesReinforcedslab 100917010457 Phpapp02izyannn8950No ratings yet

- CEN210 - Chapter 1Document50 pagesCEN210 - Chapter 1Elie RizkNo ratings yet

- Ugur ErsoyDocument16 pagesUgur ErsoyTeknomdepo TeknomdepoNo ratings yet

- Design of One Way Slab-Basic Theory and Procedures-Dr. Latifee-16-Dec-2015v1Document18 pagesDesign of One Way Slab-Basic Theory and Procedures-Dr. Latifee-16-Dec-2015v1Ali M. MohammedNo ratings yet

- Appendix A: S.X., - , - He A RDocument53 pagesAppendix A: S.X., - , - He A RksshashidharNo ratings yet

- PCA Teoria-Rectangular Concrete TanksDocument27 pagesPCA Teoria-Rectangular Concrete TanksAlberto Muñoz Vizcarra100% (3)

- Truss DesignDocument16 pagesTruss DesignRabindraUpretiNo ratings yet

- Design Example For Beams With Web OpeningsDocument10 pagesDesign Example For Beams With Web OpeningsPeterNo ratings yet

- 3 2 2 A Loads TKDocument4 pages3 2 2 A Loads TKapi-272705534No ratings yet

- Assignmnet 2020-2021 HeviDocument59 pagesAssignmnet 2020-2021 HeviHEVINo ratings yet

- Time Saving-Two Way2Document9 pagesTime Saving-Two Way2Wanda Beasley100% (1)

- Design Analysis Beam ACI PDFDocument48 pagesDesign Analysis Beam ACI PDFAlbert DimayugaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Slab On Grade Reinforcing DesignDocument11 pagesSlab On Grade Reinforcing Designsantylat100% (1)

- Weekly Status ReportDocument1 pageWeekly Status ReportarnoldistunoNo ratings yet

- Intro To CFS FramingDocument52 pagesIntro To CFS FramingarnoldistunoNo ratings yet

- Intro To CFS FramingDocument52 pagesIntro To CFS FramingarnoldistunoNo ratings yet

- ACI Post Tension DesignDocument43 pagesACI Post Tension DesignDuaa Makki100% (3)

- Cheat Sheet Creator (/editor/?sport NFL) : Log Out (/logout)Document11 pagesCheat Sheet Creator (/editor/?sport NFL) : Log Out (/logout)arnoldistunoNo ratings yet

- HIT-HY 200 SupplementDocument56 pagesHIT-HY 200 SupplementarnoldistunoNo ratings yet

- Vessel Foundation Design PhilosophyDocument5 pagesVessel Foundation Design PhilosophyarnoldistunoNo ratings yet

- Uniform ForceDocument11 pagesUniform ForcearnoldistunoNo ratings yet

- HIT-HY 200 SupplementDocument56 pagesHIT-HY 200 SupplementarnoldistunoNo ratings yet

- Hilti 2008 Product Technical Guide r021 1Document452 pagesHilti 2008 Product Technical Guide r021 1shasta963No ratings yet

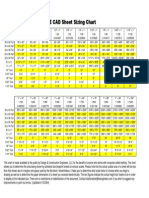

- CAD Sizing ChartDocument1 pageCAD Sizing ChartEdupuganti Sujith KumarNo ratings yet

- Checklists For Structural DesignDocument5 pagesChecklists For Structural DesignarnoldistunoNo ratings yet

- 142 Ward Avenue, Hamilton, May 29, 2012Document88 pages142 Ward Avenue, Hamilton, May 29, 2012miiszNo ratings yet

- Professional Deck Builder ArticleDocument2 pagesProfessional Deck Builder ArticlercNo ratings yet

- Roofs Building ConstructionDocument38 pagesRoofs Building Constructionisaacwabbi100% (3)

- Lean To PlanDocument7 pagesLean To PlandimfoNo ratings yet

- TB-820 Connecting 3-Ply TJI JoistsDocument6 pagesTB-820 Connecting 3-Ply TJI JoistsStevieNo ratings yet

- Manual - de - Inspección PUENTESDocument117 pagesManual - de - Inspección PUENTESjaijaj jajNo ratings yet

- Metal Roof PDFDocument15 pagesMetal Roof PDFJuan TorresNo ratings yet

- H+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductsDocument12 pagesH+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductspseudosilNo ratings yet

- Layers of A Floor - Anatomy, and Parts (Illustrated)Document8 pagesLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoNo ratings yet

- Example On Design of Timber Structure Part2 PDFDocument21 pagesExample On Design of Timber Structure Part2 PDFAnonymous 8f2veZf100% (3)

- ClarkDietrich Cold Formed Structural Framing Products Technical Design Guide Technical Notes 1530479Document100 pagesClarkDietrich Cold Formed Structural Framing Products Technical Design Guide Technical Notes 1530479Kris NauthNo ratings yet

- Construction Estimating Using ExcelDocument19 pagesConstruction Estimating Using ExcelEl Patron 167% (6)

- Lecture 06 Analysis and Design of RC SlabsDocument81 pagesLecture 06 Analysis and Design of RC SlabstyannottiNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Kirby Corporate BrochureDocument48 pagesKirby Corporate Brochurecpersels001No ratings yet

- Assessment of In-Place Wood Floor SystemsDocument6 pagesAssessment of In-Place Wood Floor SystemsdettyNo ratings yet

- Twelve-Fatality Hotel ArsonDocument56 pagesTwelve-Fatality Hotel ArsonKendric ShahidNo ratings yet

- Details For Conventional Wood Frame ConstructionDocument57 pagesDetails For Conventional Wood Frame ConstructionToni Qajani100% (1)

- GWS Open Web Joists - 1973Document36 pagesGWS Open Web Joists - 1973CESAR CANEO100% (1)

- Concrete Formwork SystemsDocument252 pagesConcrete Formwork SystemsAsraf KacakNo ratings yet

- MS 544-Part11-Sec1-2001 GCPDocument31 pagesMS 544-Part11-Sec1-2001 GCPGan Chin PhangNo ratings yet

- Wind Loading in Steel Joist Design PDFDocument95 pagesWind Loading in Steel Joist Design PDFnitroxx7No ratings yet

- Thumb Rules Steel DesignDocument7 pagesThumb Rules Steel DesignQazi Abdul MoeedNo ratings yet

- Main Street Fire - Cause and Origin ROI - DotDocument61 pagesMain Street Fire - Cause and Origin ROI - DotWGRZ-TV100% (1)

- Prefabricated ComponentsDocument9 pagesPrefabricated ComponentsvaishaliNo ratings yet

- FRAMECAD STRUCTURE Procedures OverviewDocument113 pagesFRAMECAD STRUCTURE Procedures OverviewDuc NguyenNo ratings yet

- CE 48-Timber Design SyllabusDocument3 pagesCE 48-Timber Design Syllabuspicefeati75% (4)

- Ayrshire Steel FramingDocument41 pagesAyrshire Steel FramingingdanbeloiuNo ratings yet

- Basic Steps For Building A DeckDocument5 pagesBasic Steps For Building A DeckRi SovannaphumiNo ratings yet