Professional Documents

Culture Documents

CO2 Depressurisation OLGA

Uploaded by

MaheshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CO2 Depressurisation OLGA

Uploaded by

MaheshCopyright:

Available Formats

Energy

Procedia

Energy Procedia 00 (2011) 000000

www.elsevier.com/locate/procedia

TCCS-6

Depressurization of CO2 a numerical benchmark study

Sigmund Clausena,c* and Svend Tollak Munkejordb

a

Gassco AS, P.O. Box 93, NO-5501 Haugesund, Norway

SINTEF Energy Research, P.O. Box 4761 Sluppen, NO-7465 Trondheim, Norway

c

Polytec, Srhauggt. 128, NO-5527 Haugesund, Norway

Abstract

A numerical benchmark study has been performed, comparing results from the OLGA pipeline simulator to data

obtained using the multi-stage (MUSTA) centred scheme. The case considered is a depressurization of a pipeline.

Care was taken to compare the same flow model and thermodynamic equation of state. The two methods appear to

converge on fine grids, but on coarse grids, the MUSTA method is more accurate.

2010 Published by Elsevier Ltd. Selection and/or peer-review under responsibility of [name organizer]

Keywords: CO2 pipeline transport; pipeline depressurization

1. Introduction

In CO2 transport, the development of safe procedures for e.g. injection into reservoirs, first fill and

depressurization of pipelines is an important issue. Pipeline integrity analyses are also gaining interest

[1,3]. A depressurization will normally lead to phase transition, which could cause a strong cooling of the

pipeline material. Due to the thermophysical properties, this effect is thought to be more pronounced for

CO2 than for e.g. natural gas. This motivates the study of single- and two-phase flow models for the flow

of CO2 in a pipeline. Furthermore, since the temperature is a function of pressure, there is a need for

numerical methods that are able to capture pressure waves in a robust and accurate manner.

For two-phase flow, such numerical methods are not an off-the-shelf commodity. Munkejord et al. [7]

discussed a drift-flux model for multi-component two-phase flows. The multi-stage (MUSTA) centred

scheme by Toro and coworkers [9,10] was chosen as numerical method, based on its good robustness and

accuracy properties, as well as its independence of the thermodynamic equation of state. The purpose of

the present study is to compare the MUSTA method to the solution scheme of commercially available

engineering tools.

* Corresponding author. Tel.: +4790981032; fax: +4752812946.

E-mail address: sigmund.clausen@gassco.no.

Clausen and Munkejord / Energy Procedia 00 (201111) 000000

As a pipeline simulation tool we have chosen OLGA, version 5.3.2. OLGA is a multiphase thermohydraulic simulation tool originally developed by IFE and later improved and further developed by SPT

Group. Our choice of OLGA was based upon availability, as well as the long track record within the

industry as the chosen tool for simulating transient multiphase pipeline transport. The OLGA version used

in this study is based upon a modified two-fluid model, i.e., separate continuity equations for the gas,

liquid bulk and liquid droplets are applied [2]. These may be coupled through interfacial mass transfer.

We believe that the ability of a CO2 pipeline simulation tool to predict pressure waves will be

important for developing safe procedures for injection into reservoirs, first fill and depressurization of

CO2 pipelines. For applications requiring high resolution, such as the simulation of water-hammer effects

and valve handling, it will be crucial that the chosen fluid model and numerical scheme is able to capture

the essential dynamics.

The rest of this paper is organized as follows. The considered flow model and thermodynamic equation

of state is briefly described in Section 2, while Section 3 presents our numerical simulations. Section 4

concludes the paper.

2. Model overview

When comparing different numerical models or tools, it is important to be able to distinguish between

any differences arising from different mathematical models and those due to different numerical methods.

Failing to do so will hamper the development of both the models and the numerical methods. Therefore,

when the purpose is to compare different numerical schemes, the implemented models should ideally be

identical. However, for the time being, we do not have an implementation of the MUSTA method for the

two-fluid model found in OLGA. At the same time, there is no drift-flux model available in OLGA. On

the other hand, we know that by limiting the pressure to the single-phase region, the drift-flux model will

reduce to the Euler equations of single-phase flow. Without having access to the exact details of the

OLGA model, we assume that a similar thing will happen there. Hence in this work, we will study the

following model for single-phase one-dimensional compressible flow:

( u )

0,

t

x

( u ) ( u 2 ) p

4 u

Fw ,

(1)

t

x

x

3 x x

E ( E p)u

4 u

u uFw .

t

x

3 x x

Herein, is the density, u is the velocity, p is the pressure and is the dynamic viscosity. E = (e+1/2u2)

is the total energy and e is the specific internal energy. Fw is the wall friction,

f (Re, ) 1 2

Fw

u ,

(2)

d

2

where f(Re,) is the Darcy friction factor being a function of the Reynolds number, Re, and the relative

pipe roughness, . In the following calculations, the Colebrook-White formula will be used.

In the equation system (1), a thermodynamic equation of state (EOS) is required. Since this work is a

benchmark study, we have opted at using an EOS as simple as possible. Hence the stiffened-gas equation

of state [4,5] was employed. Herein, the pressure law is

p( , e) ( 1) e p

(3)

Clausen and Munkejord / Energy Procedia 00 (20111) 000000

and the temperature law is

1

p

T ( , e) e ,

(4)

cv

where the specific-heat ratio = cp/cv, the specific heat at constant pressure, cp, and the reference

pressure, p, are model constants. The stiffened-gas model can be seen as a linearization about a given

state. With p = 0, the ideal-gas law is recovered.

3. Numerical simulations

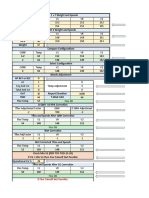

We consider the following benchmark case: A pipe of length 1000 m and inner diameter d = 0.3 m is

filled with initially motionless CO2, with a pressure of p = 20 MPa and a temperature of T = 300 K. The

pipe is closed at the left-hand side. At time t = 0 s, the pressure at the right-hand side is decreased to 10

MPa, and then set back to 20 MPa at t = 1 s. A rarefaction wave followed by a shock wave will propagate

to the left.

The EOS parameters are given in Table 1. They have been set using data from [8] at p = 15 MPa and

T = 300 K. The stiffened-gas equation of state is not implemented in OLGA. We have therefore supplied

the thermodynamic variables in the form of a fluid table. Further, a constant dynamic viscosity of = 8.4

105 Pa s has been employed, and the relative pipe roughness was = 1.67 104

Table 1. Equation-of-state parameters

Quantity

Symbol (unit)

Specific-heat ratio

()

1.4

Spec. heat at const. pres.

cp (J/(kg K))

2400

Reference pressure

p (Pa)

1.5 108

The MUSTA method is a first-order multi-stage centred scheme aimed at approaching the accuracy of

upwind schemes while retaining the simplicity of centred schemes [10]. The calculations performed using

the MUSTA method have been run with a CourantFriedrichsLewy (CFL) number of 0.9, employing the

two-stage MUSTA scheme with two local cells. Increased resolution can be obtained by increasing the

number of stages and cells, and by employing the MUSCL method to obtain second-order accuracy for

smooth solutions. These issues are described and discussed by Munkejord et al. [6]. In particular, for twophase flow models, a high number of stages is required before the accuracy of MUSTA can be compared

to that of e.g. the Roe scheme.

In the following, where noted, some reference solutions have been obtained using the MUSCLMUSTA scheme using a CFL number of 0.5

We do not have access to the details of the OLGA model and the numerical implementation of the

model. However, OLGA is known to utilize a semi-implicit integration scheme. This allows for taking

long time steps suitable for simulating rather slow mass transients and providing efficient run times for

long transport lines. However, limiting the time integration step based upon the mass transport will not

allow us to capture the essential dynamics of the pressure waves investigated in the present study.

Therefore, we have enabled a CFL criterion including the speed of sound, similar to that of the MUSTA

method, using a CFL number of 0.9.

Clausen and Munkejord / Energy Procedia 00 (201111) 000000

3.1. Effect of sub-models

We will start by investigating the effect of the terms on the right-hand side of the governing equations

(1). The first term on the right-hand side of the second and third equations represents the x component of

the viscous stress tensor. The rest of the viscous stress tensor is modelled by the wall-friction term. Since

we are interested in the model in itself, the high-resolution MUSCL-MUSTA scheme was employed with

a fine grid of 5000 cells. Pressure profiles calculated at time t = 1.51 s are displayed in Figure 1.

20

No source

Viscous

Friction

p (MPa)

18

16

14

12

10

0

200

400

600

800

1000

x (m)

Figure 1: Depressurization case, effect of sub-models. MUSCL-MUSTA method on a 5000-cell grid. Pressure versus position at t =

1.51 s.

In the figure, no source denotes a right-hand side of 0 in the governing equations (1). The data labelled

viscous are calculated with the viscous term, but with zero wall friction. Friction means that the wallfriction term has been included. It can be seen from the figure that in this case, the x component of the

viscous stress tensor has nothing to say. Wall friction, on the other hand, has a clear effect on the pressure

drop, as expected. It can be noted, though, that wall friction causes practically no smearing of the

rarefaction and the shock wave. The results presented in the following are obtained using the wall-friction

model.

Clausen and Munkejord / Energy Procedia 00 (20111) 000000

3.2. Effect of second-order extension

The first-order MUSTA method and the high-resolution MUSCL-MUSTA method are compared in

Figure 2 using a grid of 100 cells. Data obtained using the first-order MUSTA method with a fine grid of

10000 cells are plotted as reference. The figure indicates a clear improvement in resolution by employing

the MUSCL-MUSTA method compared to the first-order MUSTA method.

20

Musta

Muscl-Musta

Ref.

p (MPa)

18

16

14

12

0

200

400

600

800

1000

x (m)

Figure 2: Depressurization case, effect of second-order extension (MUSCL). First-order MUSTA method and MUSCL-MUSTA are

compared using a grid of 100 cells, whereas data from the first-order MUSTA on a 10000-cell grid is used as reference. Pressure

versus position at t = 1.51 s.

Clausen and Munkejord / Energy Procedia 00 (201111) 000000

3.3. Comparison between OLGA and MUSTA

Figure 3 and Figure 4 display pressure profiles as a function of position and of time, respectively,

comparing results obtained using the MUSTA method and with OLGA. As can be seen, the two methods

give similar results, and the calculated wave-propagation speed agrees well. However, compared to the

OLGA results, the MUSTA method produces a sharper wave resolution. Indeed, the results of the two

methods appear to converge, but even for a fine grid of 10000 cells, there is a visible difference. This is

also an indication of what would happen in the two-phase region. If pressure waves are smeared out, an

underestimation of both the water hammer effect and the pipe cooling could be a result.

The wave-propagation speeds can be read off Figure 3. Both the centre of the rarefaction wave and

the shock wave have a speed of about 530 m/s. This agrees well with the speed of sound of 533 m/s at T =

300 K and p = 16 MPa [8].

20

Musta 100 cells

Musta 10k cells

Olga 100 cells

Olga 10k cells

p (MPa)

18

16

14

12

0

200

400

600

800

1000

x (m)

Figure 3: Comparison of OLGA and the MUSTA method, depressurization case. Pressure versus position at t = 1.51 s.

Clausen and Munkejord / Energy Procedia 00 (20111) 000000

20

Musta 100 cells

Musta 10k cells

Olga 100 cells

Olga 10k cells

p (MPa)

18

16

14

12

0.2

0.4

0.6

0.8

t (s)

1.2

1.4

Figure 4: Comparison of OLGA and the MUSTA method, depressurization case. Pressure versus time at x = 805 m.

Since, in the above calculations, the results have been obtained using the same kind of compressible

time-step restriction, and a first-order time-integration scheme, the differences are thought to be mainly a

function of the spatial discretization. There is possibly also a connection with the way the semi-implicit

time-integration method is implemented in OLGA, and it is expected that this will influence the results

providing less accurate prediction of the pressure waves, especially for low resolution grids. This means

that to obtain a given accuracy, a finer grid, and hence longer CPU times, would be required.

4. Conclusions

A benchmark case for depressurization of a CO2 pipeline in the single-phase region has been proposed.

Numerical results from the OLGA code have been compared to calculations using the multi-stage

(MUSTA) centred scheme. In particular, the stiffened-gas equation of state was employed in both cases.

The two methods appear to converge on fine grids, but on coarse grids, the method in OLGA produced

more smeared-out results.

We believe that the ability of a CO2 pipeline simulation tool to predict pressure waves will be

important for developing safe procedures for injection into reservoirs, first fill and depressurization of

CO2 pipelines. For applications requiring high resolution, such as the simulation of water-hammer effects

and valve handling, it will be crucial that the chosen fluid model and numerical scheme is able to capture

the essential dynamics.

Future work will include a benchmark case accounting for phase transition.

Clausen and Munkejord / Energy Procedia 00 (201111) 000000

Acknowledgements

This work of the first author was financed by Gassco AS.

This work of the second author was financed through the CO2 Dynamics project, and the support from the

Research Council of Norway (189978), Gassco AS, Statoil Petroleum AS and Vattenfall AB is

acknowledged.

References

1.

Aihara, S. And Misawa, K. Numerical simulation of unstable crack propagation and arrest in CO2 pipelines, The First

international Forum on the Transportation of CO2 in Pipelines, Newcastle, UK, 2010.

2. Bendiksen, K.H., Malnes, D., Moe, R. and Nuland, S. The Dynamic Two-Fluid Model OLGA: Theory and Application,

SPE Production Engineering, 1991; 6:171180.

3. Berstad, T., Drum, C., Jakobsen, J.P., Kragset, S., Li, H., Lund, H., Morin, A., Munkejord, S.T., Mlnvik, M.J.,

Nordhagen, H.O. and stby, E. CO2 pipeline integrity: A new evaluation methodology. Energy Procedia, 2011; 4:3000

3007.

4. Menikoff, R. Empirical EOS for Solids, Shock Wave Science and Technology Reference Library, Volume 2 Solids,

Berlin: Springer-Verlag, Berlin; 2007, 143188.

5. Menikoff, R. and Plohr, B.J. The Riemann problem for fluid flow of real materials, Rev. Mod. Phys, 1989; 88:75130.

6. Munkejord, S.T., Evje, S. and Fltten, T. The multi-stage centred-scheme approach applied to a drift-flux two-phase flow

model. Int. J. Numer. Meth. Fluids, 2006; 52:679705.

7. Munkejord, S.T., Jakobsen, J.P., Austegard, A. and Mlnvik, M.J. Thermo- and fluid-dynamical modelling of two-phase

multi-component carbon dioxide mixtures. Int. J. Greenh. Gas Con, 2010; 4:589596.

8. National Institute of Standards and Technology (NIST) Chemistry WebBook, http://webbook.nist.gov/. Accessed

November 2010.

9. Titarev, V.A and Toro, E.F. MUSTA schemes for multi-dimensional hyperbolic systems: Analysis and improvements.

Int. J. Numer. Meth. Fluids, 2005; 49:117147.

10. Toro, E.F. MUSTA: A multi-stage numerical flux. Appl. Numer. Math, 2006;56:14641479.

You might also like

- OLGA 6.2 Release NoteDocument33 pagesOLGA 6.2 Release NoteelvithafNo ratings yet

- Tips OlgaDocument15 pagesTips OlgaArlen ZapataNo ratings yet

- OLGA2000 TransientSimulationDocument89 pagesOLGA2000 TransientSimulationesraates44No ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- Flare Radiation 1.3: User ManualDocument10 pagesFlare Radiation 1.3: User ManualLazaro Hernandez GallegosNo ratings yet

- Investigating Slug Flow Characteristics of A Pipline Riser System Using Olga Simulation ToolDocument10 pagesInvestigating Slug Flow Characteristics of A Pipline Riser System Using Olga Simulation ToolmNo ratings yet

- FLARENETDocument19 pagesFLARENETrohmanNo ratings yet

- 2003 Cochran RP Hydrate Control Remediation PDFDocument8 pages2003 Cochran RP Hydrate Control Remediation PDFArsénioNo ratings yet

- Flare Sweep GasDocument5 pagesFlare Sweep GasChem.EnggNo ratings yet

- Aspentech Course Catalog Fy18Document27 pagesAspentech Course Catalog Fy18LION_FIRENo ratings yet

- Water Dewpoint Calculation of Natural GasDocument5 pagesWater Dewpoint Calculation of Natural GasSrinivas BobbyNo ratings yet

- Flare NetDocument2 pagesFlare NetPetrol SollyNo ratings yet

- Modeling wax deposition in crude oil pipelinesDocument9 pagesModeling wax deposition in crude oil pipelinesEleonoraNo ratings yet

- PSV Selection For BeginnersDocument1 pagePSV Selection For BeginnersVishal SoniNo ratings yet

- K.O DrumDocument7 pagesK.O DrumsaririskihasibuanNo ratings yet

- User's GuideDocument30 pagesUser's GuideAnonymous Wd2KONNo ratings yet

- Burial of Pipes in OLGADocument2 pagesBurial of Pipes in OLGAVictor YuzhaninNo ratings yet

- OlgaDocument18 pagesOlgaSEEDEIG GROUPNo ratings yet

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionaytihdaNo ratings yet

- Process Heat Transfer Hof MasterDocument327 pagesProcess Heat Transfer Hof MastersdrtfgNo ratings yet

- EastmanDocument37 pagesEastmanKrishnananth SajuNo ratings yet

- Dresser Italia S.r.l. Safety Relief Valve ReportDocument4 pagesDresser Italia S.r.l. Safety Relief Valve Reportwinlugue3059No ratings yet

- V Cone Flowmeter PDFDocument16 pagesV Cone Flowmeter PDFRajesh KrishnamoorthyNo ratings yet

- HAT Horiz Vessel VolDocument1 pageHAT Horiz Vessel VolAnonymous JWI6rqtNo ratings yet

- Ácido TereftalicoDocument9 pagesÁcido TereftalicoIvan GuerreroNo ratings yet

- Process Design Engineering Test-1Document6 pagesProcess Design Engineering Test-1Vague FruitsNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- Need To Get Stream Data From Your Aspen Hysys Simulation Into Another FormatDocument3 pagesNeed To Get Stream Data From Your Aspen Hysys Simulation Into Another FormatCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- AT 03943 JSG Acid Gas Cleaning Aspen HYSYS PDFDocument17 pagesAT 03943 JSG Acid Gas Cleaning Aspen HYSYS PDFAkhmadi WaridyantoNo ratings yet

- A Robust SRU Waste Heat Boiler DesignDocument21 pagesA Robust SRU Waste Heat Boiler DesignsheenNo ratings yet

- Getting Start Hysys UnisimDocument38 pagesGetting Start Hysys UnisimBassem BalghouthiNo ratings yet

- Datasheet SimSci HEXTRAN PDFDocument3 pagesDatasheet SimSci HEXTRAN PDFHector ReNo ratings yet

- Finger Type Slug CatcherDocument41 pagesFinger Type Slug CatcherIrfaan Taufiiqul Rayadi100% (1)

- Rules of Dynamic SimulationDocument1 pageRules of Dynamic SimulationImtihan KomahateeNo ratings yet

- As Built: Data Sheet FOR FLARE STACK V-219-03Document9 pagesAs Built: Data Sheet FOR FLARE STACK V-219-03Rafael Reyno Raditya0% (1)

- PSV Sizing OrificeDocument4 pagesPSV Sizing OrificeRupak PatilNo ratings yet

- Dynamic Depressuring PDFDocument16 pagesDynamic Depressuring PDFAsimNo ratings yet

- Integration of Design & ControlDocument23 pagesIntegration of Design & ControlRachele PiovanelliNo ratings yet

- 521taaai 2Document7 pages521taaai 2Erwin FerdianNo ratings yet

- Natural Gas Liquids Recovery Processes in Natural Gas ProcessingDocument27 pagesNatural Gas Liquids Recovery Processes in Natural Gas ProcessingVictor Ali MentaNo ratings yet

- 2017CHE003 FinalPaper Draft 8 1Document90 pages2017CHE003 FinalPaper Draft 8 1Evan DulayNo ratings yet

- Aspen HysysDocument314 pagesAspen HysysAntonio VargasNo ratings yet

- PSVDocument1 pagePSVsalman ahmedNo ratings yet

- PVTsim - The powerful fluid properties tool for OLGA simulationsDocument24 pagesPVTsim - The powerful fluid properties tool for OLGA simulationssterling100% (1)

- Well Test Standards Section 3.30 Chemical Injection Pumps: Global StandardDocument8 pagesWell Test Standards Section 3.30 Chemical Injection Pumps: Global StandardEmmanuelNo ratings yet

- Titas Production System Analysis PDFDocument144 pagesTitas Production System Analysis PDFনাঈমআহমেদNo ratings yet

- Pipesys TutorialDocument62 pagesPipesys TutorialNatalia Prieto JimenezNo ratings yet

- Purge Gas OptimizationDocument7 pagesPurge Gas OptimizationVangapanduSrinivasarao100% (2)

- Case 1. Gas Lift System DesignDocument10 pagesCase 1. Gas Lift System DesignDaniel ChiriacNo ratings yet

- Acentric Factor EoSDocument10 pagesAcentric Factor EoSdesertflowNo ratings yet

- Pig OlgaDocument24 pagesPig OlgaCitlalli QuetzalcoatlNo ratings yet

- Need of Flow Assurance For Crude Oil PropertiesDocument8 pagesNeed of Flow Assurance For Crude Oil Propertiesvande852001No ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Kinetics of Hydrocarbon AdsorptionDocument16 pagesKinetics of Hydrocarbon Adsorptionali105No ratings yet

- A Comparison Study On Fin Surfaces in Finned-Tube Heat ExchangersDocument15 pagesA Comparison Study On Fin Surfaces in Finned-Tube Heat ExchangerssantoshkumarvenuNo ratings yet

- Invoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketDocument2 pagesInvoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketMahesh0% (1)

- BOILERDocument6 pagesBOILERapi-26570979100% (3)

- Pulanche Patralekhan PDFDocument1 pagePulanche Patralekhan PDFMaheshNo ratings yet

- 2012christiansen PDFDocument116 pages2012christiansen PDFMaheshNo ratings yet

- How To Get A Job - 57 TacticsDocument36 pagesHow To Get A Job - 57 TacticsShemin T JohnNo ratings yet

- 1101.0969 2 PDFDocument10 pages1101.0969 2 PDFMaheshNo ratings yet

- PH Coagulant DosageDocument6 pagesPH Coagulant Dosageromdhan88No ratings yet

- 05.0 Operating ProceduresDocument8 pages05.0 Operating ProceduresMaheshNo ratings yet

- OLGA Link User GuideDocument51 pagesOLGA Link User GuideekabudiartiNo ratings yet

- VishakhaDocument3 pagesVishakhaMaheshNo ratings yet

- ArachchigeEJSR86 3Document12 pagesArachchigeEJSR86 3MaheshNo ratings yet

- Bendik Sen 1991Document10 pagesBendik Sen 1991MaheshNo ratings yet

- Rigorously Size Relief Valves For Critical FluidsDocument10 pagesRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Noc - Frequently Asked QuestionsDocument6 pagesNoc - Frequently Asked QuestionsMaheshNo ratings yet

- 02 - Heat ExchangersDocument107 pages02 - Heat ExchangersMaheshNo ratings yet

- View PDFDocument2 pagesView PDFMaheshNo ratings yet

- Comparison To WorkbenchDocument5 pagesComparison To WorkbenchMaheshNo ratings yet

- O Hydrate Formation ReportDocument10 pagesO Hydrate Formation ReportMaheshNo ratings yet

- Control Valve Sizing for Viscous Crude Oil FlowDocument1 pageControl Valve Sizing for Viscous Crude Oil Flowmaulana_madridistaNo ratings yet

- REfrigeration CO2 GuidelinesDocument7 pagesREfrigeration CO2 GuidelinesMaheshNo ratings yet

- Aspen Plus Simulation of CO2 Removal From Coal and Gas Fired Power PlantsDocument9 pagesAspen Plus Simulation of CO2 Removal From Coal and Gas Fired Power Plantstaufany99No ratings yet

- Strategic Investment Analysis - PINSDocument10 pagesStrategic Investment Analysis - PINSMaheshNo ratings yet

- CVGASDocument1 pageCVGASrarunr1No ratings yet

- Heat Transfer Excel Calculations 1Document39 pagesHeat Transfer Excel Calculations 1Sharon LambertNo ratings yet

- BOG CalDocument6 pagesBOG CalSook Thiam LeeNo ratings yet

- 1 s2.0 S0957582096706262 MainDocument10 pages1 s2.0 S0957582096706262 MainMaheshNo ratings yet

- 05.0 Operating ProceduresDocument8 pages05.0 Operating ProceduresMaheshNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- TFT-LCD TV/MONITOR SERVICE MANUALDocument54 pagesTFT-LCD TV/MONITOR SERVICE MANUALhimkoNo ratings yet

- Fuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DDocument2 pagesFuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DMar WilkNo ratings yet

- 942 FullDocument9 pages942 FullZulfah MidahNo ratings yet

- C ProgDocument29 pagesC ProgaishwaryaNo ratings yet

- POOJA TRADING CO. Price List for FRP Manhole CoversDocument1 pagePOOJA TRADING CO. Price List for FRP Manhole Coversmitesh20281No ratings yet

- Systems Analyst Interview Questions GuideDocument3 pagesSystems Analyst Interview Questions GuidehassanshoaibNo ratings yet

- Off-Highway 6600 Series Transmission SpecsDocument2 pagesOff-Highway 6600 Series Transmission SpecsIng Dimatiguz0% (1)

- Independent University, Bangladesh: Term Paper (Group Assignment)Document16 pagesIndependent University, Bangladesh: Term Paper (Group Assignment)Johan Tausifur RahmanNo ratings yet

- Multiple Choice Bubble Sheet Template Customize This WordDocument3 pagesMultiple Choice Bubble Sheet Template Customize This WordAl Bin0% (1)

- Instructions: Hmems80 2020 Semester 1 Assignment 01 (Unique Number: 873964) Due Date: 9 March 2020Document8 pagesInstructions: Hmems80 2020 Semester 1 Assignment 01 (Unique Number: 873964) Due Date: 9 March 2020Matshele SerageNo ratings yet

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- UniSim Heat Exchangers User Guide PDFDocument22 pagesUniSim Heat Exchangers User Guide PDFzhangyiliNo ratings yet

- Educ 61 Module 5 ActivityDocument4 pagesEduc 61 Module 5 ActivityMitchille GetizoNo ratings yet

- SATA Product Manual: Standard ModelsDocument32 pagesSATA Product Manual: Standard ModelsEdy AprilyantoNo ratings yet

- Fire Risk Assessment FormDocument16 pagesFire Risk Assessment Formmukamat safiiNo ratings yet

- Organizational Structure and ProfilesDocument178 pagesOrganizational Structure and ProfilesImran Khan NiaziNo ratings yet

- Industrial Applications of Olefin MetathesisDocument7 pagesIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- A320 Flex CalculationDocument10 pagesA320 Flex CalculationMansour TaoualiNo ratings yet

- Noritz N-063 Installation ManualDocument66 pagesNoritz N-063 Installation ManualbondsupplyNo ratings yet

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocument15 pagesPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisNo ratings yet

- (Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFDocument128 pages(Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFMarcos EstevamNo ratings yet

- Safety Steering System Alarm Code GuideDocument43 pagesSafety Steering System Alarm Code GuideIsrael Michaud84% (19)

- Checklist of Bats From Iraq-Mammalian Biology 2020Document14 pagesChecklist of Bats From Iraq-Mammalian Biology 2020Adil DalafNo ratings yet

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDocument42 pagesCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- Chapter 3Document12 pagesChapter 3Raymond LeoNo ratings yet

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Document6 pagesWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNo ratings yet

- Regulation of AlternatorDocument6 pagesRegulation of Alternatorkudupudinagesh100% (1)

- Planets Classification Malefic and BeneficDocument3 pagesPlanets Classification Malefic and Beneficmadhu77No ratings yet

- Discrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebraDocument6 pagesDiscrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebralakkajaoNo ratings yet

- Karl Marx AssignmentDocument1 pageKarl Marx Assignmenthanunarabella1No ratings yet