Professional Documents

Culture Documents

Drive a 5 Watt CFL from 6V or 12V Using a Flyback Transformer Circuit

Uploaded by

John ApostleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drive a 5 Watt CFL from 6V or 12V Using a Flyback Transformer Circuit

Uploaded by

John ApostleCopyright:

Available Formats

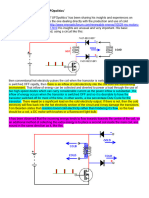

Drive a CFL from 6v or 12v

This

circuit will drive a 5 watt CFL tube from 6v or

12v.

For this project you need an old Compact Fluorescent

Lamp. Most faulty CFLs are due to a dry-joint or dry

electrolytic and the tube is perfect for re-cycling.

Only use a 5 watt Compact Fluorescent tube as each

wattage tube puts a different load on the circuit and higherwattage tube puts less load on the circuit and all the

magnetic flux is not converted to energy. This saturates

the core and overloads the transistor.

A high-wattage lamp will not be very bright and the

transistor will get very hot.

You can also use an 18 watt (or 20 watt) 2-foot normal

fluorescent tube.

You are only delivering 4 watts but it will be quite bright

and will give much more light than a CFL.

The secret to getting the tubes to strike is the high

voltage produced by the transformer.

The circuit is a fly-back design where the transistor is

turned off during part of the cycle and the magnetic flux in

the core of the transformer collapses and produces a very

high voltage.

This high voltage passes through the gas in the tube and

ionizes the gas molecules to create ultra-violet light. The

phosphorescent coating on the inside of the tube converts

the ultra-violet light to visible light.

Normally, small heaters at the end of the tube heat the gas

and this creates emissions so a fairly low voltage (about

400v) will strike the tube.

We are not supplying energy to the heaters and we need

over 1,000 volts to strike the tube - thats why we have 500

turns on the secondary. Because the voltage is very high,

we cannot wind the secondary as jumble-wound. You

can wind it in layers with insulation between the layers but

a simpler way is called PANCAKE winding.

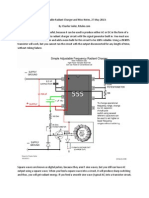

5 watt CFL Driver circuit

This consists of winding about 10 turns on top of each

other before advancing along the rod. The rod can be

by Colin Mitchell

round or flat, from an old AM radio. It is called a ferrite rod.

See photo for size. The 500 turns have to be added before

reaching the end and this means 100 turns has to take up

1/5th of the distance. This reduces the voltage between the

turns as the enamel will only withstand 100 volts.

Before you start winding, use at least 3 layers of stickytape to prevent the high voltage shorting to the rod.

The size of the wire is not important and anything 0.25mm

or thinner will be suitable. After winding the secondary, the

primary is 50 turns and the feedback is 10 turns.

The primary can be 0.5mm wire and the feedback

0.25mm.

Connect the transistor, components and tube and turn the

circuit ON very briefly. If the tube does not illuminate

immediately, reverse the wires to the feedback winding.

The transistor must be 2N 3055 (or the plastic version, TIP

3055). It will get warm when illuminating the lamp and

needs to be heatsinked. The lamp must not be removed as

the circuit will overload and damage the transistor.

The circuit takes 250mA when driving a 5 watt CFL (or 18

watt fluorescent tube) on 12v supply. The 1k base resistor

can be reduced to 820R and the brightness will increase

slightly but the current will increase to 500mA.

The circuit is more-efficient on 6v. The 1k base resistor is

reduced to 220R and the transistor remains cool.

More details on this circuit can be found on the website:

http://www.electronicsmaker.info

1

You might also like

- Drive A CFL From 6v or 12vDocument1 pageDrive A CFL From 6v or 12vJohn ApostleNo ratings yet

- 12 Volt Fluorescent Lamp DriversDocument8 pages12 Volt Fluorescent Lamp DriversDedy SuhendraNo ratings yet

- Our Solid-State Tesla Coil Can Produce Sparks As Long As 8 Inches With A Peak Output of About 100,000 Volts.Document8 pagesOur Solid-State Tesla Coil Can Produce Sparks As Long As 8 Inches With A Peak Output of About 100,000 Volts.Carlos Guzman100% (2)

- Build A Mini Tesla CoilDocument4 pagesBuild A Mini Tesla CoilPeerzada WahidNo ratings yet

- 12V fluorescent lamp driversDocument7 pages12V fluorescent lamp driversDiego García MedinaNo ratings yet

- Efficient 1.5V battery circuit produces over 50V and charges batteriesDocument5 pagesEfficient 1.5V battery circuit produces over 50V and charges batteriesJohn WestfieldNo ratings yet

- Cold ElectricityDocument10 pagesCold ElectricityPierre CorbeilNo ratings yet

- How ignition systems create sparks to light fuelDocument25 pagesHow ignition systems create sparks to light fuelNuno CunhaNo ratings yet

- Solar Panel Battery Charger: The ProblemDocument8 pagesSolar Panel Battery Charger: The Problemmijamin garcia faberioNo ratings yet

- Conventional Ignition SystemrevDocument20 pagesConventional Ignition SystemrevSuparman St0% (2)

- Experiment No.10213Document6 pagesExperiment No.10213nithinNo ratings yet

- Build Your Own Tesla Coil GuideDocument5 pagesBuild Your Own Tesla Coil GuideknthnpNo ratings yet

- Artificial Sources of LightDocument3 pagesArtificial Sources of LightjdipbhadraNo ratings yet

- HHO Pulse Charger 2.0 InfoDocument4 pagesHHO Pulse Charger 2.0 InfoAleksa Nataša Rančić100% (1)

- Solar Charger: A Great Kit For Self-SufficiencyDocument9 pagesSolar Charger: A Great Kit For Self-Sufficiencysekarmca89100% (1)

- Epic 1,000,000 Volt Tesla Coil InstructableDocument7 pagesEpic 1,000,000 Volt Tesla Coil Instructablesipdas 10aNo ratings yet

- R 07 Robots Page7Document4 pagesR 07 Robots Page7straf238No ratings yet

- Water As Fuel 2Document11 pagesWater As Fuel 2HaSophim100% (7)

- MODULE 1 Electrical InstallationDocument41 pagesMODULE 1 Electrical InstallationhmnzkonNo ratings yet

- Schema Pentru Tub NeonDocument2 pagesSchema Pentru Tub Neondanydymary100% (1)

- CFL RepairDocument6 pagesCFL RepairBulbtigerNo ratings yet

- Nalanda English Medium School: (Shewalwadi)Document18 pagesNalanda English Medium School: (Shewalwadi)Dipanshu Gawde100% (1)

- New Adjustable Frequency Radiant Charger PDFDocument5 pagesNew Adjustable Frequency Radiant Charger PDFlancerdoom1100% (6)

- A Practical Guide To Free Energy' Devices: Replication of Stanley Meyer's Demonstration ElectrolyserDocument0 pagesA Practical Guide To Free Energy' Devices: Replication of Stanley Meyer's Demonstration ElectrolyserTom TeraNo ratings yet

- Simple Free-Energy Devices: Chapter 21: A Perpetual LightDocument18 pagesSimple Free-Energy Devices: Chapter 21: A Perpetual LightbluesurviverNo ratings yet

- The Blocking OscillatorDocument2 pagesThe Blocking OscillatorJoseGarciaRuizNo ratings yet

- Fluorescent Lighting System BreakdownDocument38 pagesFluorescent Lighting System BreakdownkurmakkNo ratings yet

- Tube Light WordDocument21 pagesTube Light WordMuniyasamyNo ratings yet

- Water Fuel Cell - Build Manual - Tap Water (Daves Stanley Meyer Xogen Free Energy)Document10 pagesWater Fuel Cell - Build Manual - Tap Water (Daves Stanley Meyer Xogen Free Energy)andr3y767% (3)

- Tle 9Document3 pagesTle 9Lilian Laurel Cariquitan50% (2)

- Secret High Power Free Energy Circuit (AECDocument2 pagesSecret High Power Free Energy Circuit (AECvladcoinstal100% (2)

- Low Anode 2Document3 pagesLow Anode 2dusan1962No ratings yet

- Simple DIY Induction Heater CircuitDocument8 pagesSimple DIY Induction Heater CircuitPramillaNo ratings yet

- Illumination 2Document20 pagesIllumination 2Waqas AhmadNo ratings yet

- Plate No. 4Document10 pagesPlate No. 4Junrey BelandoNo ratings yet

- Simple Free-Energy Devices: Chapter 2: The "Joule Thief"Document5 pagesSimple Free-Energy Devices: Chapter 2: The "Joule Thief"Rafat KashoomNo ratings yet

- Slayer Exciter CircuitDocument2 pagesSlayer Exciter CircuitRalph VaronNo ratings yet

- Joule Thief CircuitDocument8 pagesJoule Thief CircuitTariq PatelNo ratings yet

- Applications of Tesla CoilsDocument12 pagesApplications of Tesla CoilsNitin Daswani100% (1)

- Emailing AC - Exp - 05 - StudentDocument8 pagesEmailing AC - Exp - 05 - StudentNafiul BariNo ratings yet

- Powered With Solar PanelDocument2 pagesPowered With Solar PanelalejandroNo ratings yet

- SF6 Circuit Breakers AdvantagesDocument4 pagesSF6 Circuit Breakers Advantagessekhar_ntpcNo ratings yet

- Induction Heater Tutorial 10kw and 3kw PDFDocument39 pagesInduction Heater Tutorial 10kw and 3kw PDFpichaidv80% (5)

- A Self-Powered GeneratorDocument16 pagesA Self-Powered Generatorkwag100% (1)

- The Development of LED Technology Has Caused Their Efficiency and Light Output To Rise ExponentiallyDocument14 pagesThe Development of LED Technology Has Caused Their Efficiency and Light Output To Rise ExponentiallyOsim LeeNo ratings yet

- Solid State Tesla CoilDocument9 pagesSolid State Tesla CoilSatadru HalderNo ratings yet

- Met 2Document10 pagesMet 2Ářvíňď PřášáďNo ratings yet

- Purpose of A BallastDocument14 pagesPurpose of A BallastKARAM ZAKARIANo ratings yet

- 5496770-HTBARBC-Best Radiant Charging CircuitsDocument12 pages5496770-HTBARBC-Best Radiant Charging Circuitslightingfastno808No ratings yet

- Have You Ever Wondered How A Fluorescent Light Works? Even Though They're Nearly AsDocument4 pagesHave You Ever Wondered How A Fluorescent Light Works? Even Though They're Nearly AsMarlon BoucaudNo ratings yet

- Reverse Tesla CoilDocument17 pagesReverse Tesla Coilmarin_marin88100% (1)

- Enercon Finals Assignment 5Document18 pagesEnercon Finals Assignment 5Ezekiel Brizuela100% (2)

- Alexkor's battery charging circuit guideDocument11 pagesAlexkor's battery charging circuit guideOlaNo ratings yet

- 100 IC CircuitsDocument60 pages100 IC CircuitssabNo ratings yet

- How to Wire a Doll's House for Electricity - An Illustrated GuideFrom EverandHow to Wire a Doll's House for Electricity - An Illustrated GuideRating: 5 out of 5 stars5/5 (1)

- How to Install Electric Bells, Annunciators, and AlarmsFrom EverandHow to Install Electric Bells, Annunciators, and AlarmsNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Motion Picture Operation, Stage Electrics and Illusions: A Practical Hand-book and Guide for Theater Electricians, Motion Picture Operators and Managers of Theaters and ProductionsFrom EverandMotion Picture Operation, Stage Electrics and Illusions: A Practical Hand-book and Guide for Theater Electricians, Motion Picture Operators and Managers of Theaters and ProductionsNo ratings yet

- Nutritious Value of CornDocument4 pagesNutritious Value of CornJohn ApostleNo ratings yet

- Caiar: Nutritional ProfileDocument2 pagesCaiar: Nutritional ProfileJohn ApostleNo ratings yet

- Carrots As NutritionDocument3 pagesCarrots As NutritionJohn ApostleNo ratings yet

- Cabbage As NutritionDocument5 pagesCabbage As NutritionJohn ApostleNo ratings yet

- Beef Nutritional ProfileDocument6 pagesBeef Nutritional ProfileJohn ApostleNo ratings yet

- Nutritious Broccoli Provides Many Health BenefitsDocument5 pagesNutritious Broccoli Provides Many Health BenefitsJohn ApostleNo ratings yet

- Blueberries Nutrition ProfileDocument3 pagesBlueberries Nutrition ProfileJohn ApostleNo ratings yet

- Carob As NutritionDocument3 pagesCarob As NutritionJohn ApostleNo ratings yet

- Carob As NutritionDocument3 pagesCarob As NutritionJohn ApostleNo ratings yet

- Butter Nutrition FactsDocument3 pagesButter Nutrition FactsJohn ApostleNo ratings yet

- Beets As NutritionDocument3 pagesBeets As NutritionJohn ApostleNo ratings yet

- Beans: A Nutritious LegumeDocument5 pagesBeans: A Nutritious LegumeJohn ApostleNo ratings yet

- Brussels Sprouts As NutritionDocument4 pagesBrussels Sprouts As NutritionJohn ApostleNo ratings yet

- Blackberries As NutritionDocument3 pagesBlackberries As NutritionJohn ApostleNo ratings yet

- Nutritional Profile of BreadDocument4 pagesNutritional Profile of BreadJohn ApostleNo ratings yet

- Barley Nutritional ProfileDocument3 pagesBarley Nutritional ProfileJohn ApostleNo ratings yet

- Nutrition Facts and Health Benefits of AvocadosDocument4 pagesNutrition Facts and Health Benefits of AvocadosJohn ApostleNo ratings yet

- Nutritional Profile of BananasDocument4 pagesNutritional Profile of BananasJohn ApostleNo ratings yet

- Artichoke Globe Nutritional ProfileDocument3 pagesArtichoke Globe Nutritional ProfileJohn ApostleNo ratings yet

- Asparagus Nutritional ProfileDocument3 pagesAsparagus Nutritional ProfileJohn ApostleNo ratings yet

- Dynamic Model of IGBTDocument1 pageDynamic Model of IGBTJohn ApostleNo ratings yet

- Artichoke Jerusalem - Sunchoke Nutritional ProfileDocument2 pagesArtichoke Jerusalem - Sunchoke Nutritional ProfileJohn ApostleNo ratings yet

- Working With Flip-FlopsDocument6 pagesWorking With Flip-FlopsJohn ApostleNo ratings yet

- A Simplified Spice Model For IgbtDocument2 pagesA Simplified Spice Model For IgbtJohn ApostleNo ratings yet

- A Spice Circuit of IGBTDocument1 pageA Spice Circuit of IGBTJohn ApostleNo ratings yet

- A Simplified Spice Model For IgbtDocument2 pagesA Simplified Spice Model For IgbtJohn ApostleNo ratings yet

- Altering Camera and Workspace Views in Anime StudioDocument3 pagesAltering Camera and Workspace Views in Anime StudioJohn ApostleNo ratings yet

- Altering Camera and Workspace Views in Anime StudioDocument3 pagesAltering Camera and Workspace Views in Anime StudioJohn ApostleNo ratings yet

- Siemens Switchboard and Protection ManualDocument472 pagesSiemens Switchboard and Protection Manual1wocker1100% (1)

- Sheet No 12Document30 pagesSheet No 12Falgon IslamNo ratings yet

- Ts of 33 KV in Door Switch Board-IDocument29 pagesTs of 33 KV in Door Switch Board-ISunil SinghNo ratings yet

- Prelim Forward Complete Book AgrawalDocument27 pagesPrelim Forward Complete Book Agrawaljgonzalez19615268No ratings yet

- UCE Physics Papers 1987-2012Document185 pagesUCE Physics Papers 1987-2012Ochaka HerbertNo ratings yet

- Introduction To Power World SimulatorDocument34 pagesIntroduction To Power World SimulatorMuhammadNo ratings yet

- GAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFDocument24 pagesGAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFBudi SantonyNo ratings yet

- International CodeDocument2 pagesInternational CodeTushar Shah100% (1)

- PT Cipta Tapak SejahteraDocument8 pagesPT Cipta Tapak SejahteraAnakBawangNo ratings yet

- Group-3 - (Battery Charging Circuit Using SCR)Document15 pagesGroup-3 - (Battery Charging Circuit Using SCR)Nayem IslamNo ratings yet

- Lsa GeneralDocument20 pagesLsa GeneralMohamad JadoNo ratings yet

- Transmission LineDocument84 pagesTransmission Linemiguel itsonNo ratings yet

- K-Factor Defined: AN102 Application NoteDocument2 pagesK-Factor Defined: AN102 Application NoteDenyNo ratings yet

- Cable FittingsDocument108 pagesCable FittingspvkrishnajiNo ratings yet

- Power Quality: Project ON Grid Connected PV SystemsDocument22 pagesPower Quality: Project ON Grid Connected PV SystemsRahul Radhakrishnan100% (1)

- Current Sensing Techniques-Hall EffectDocument18 pagesCurrent Sensing Techniques-Hall EffectsanilNo ratings yet

- Khabat Power Plant Auto Transformer Test ReportsDocument11 pagesKhabat Power Plant Auto Transformer Test ReportsUtku Can KılıçNo ratings yet

- Transducers Engineering Notes PDFDocument110 pagesTransducers Engineering Notes PDFThamilarasan VNo ratings yet

- Lecture 3.2 Control Circuits With Single Line DiagramDocument42 pagesLecture 3.2 Control Circuits With Single Line Diagrammuaz_aminu1422No ratings yet

- Book IV Table of Contents SchedulesDocument5 pagesBook IV Table of Contents SchedulesVin Fiyanthi TyaswarieNo ratings yet

- Typical Bill For A 2x15MVA Transformer Substation ConstructionDocument6 pagesTypical Bill For A 2x15MVA Transformer Substation ConstructionRajeshYadav100% (1)

- FN - Engineering Guide - 115.26-EG3Document28 pagesFN - Engineering Guide - 115.26-EG3Michael FutolNo ratings yet

- Level I Questions Eddy Current TestingDocument24 pagesLevel I Questions Eddy Current TestingBAWAg PİNDĪNo ratings yet

- PDFDocument12 pagesPDFALBERTONo ratings yet

- Current Transformer: Current Transformers I IDocument10 pagesCurrent Transformer: Current Transformers I IraghavNo ratings yet

- Electrical Power Transmission Distribution OverviewDocument27 pagesElectrical Power Transmission Distribution OverviewWRHKNo ratings yet

- Don Smith Theory I-1Document2 pagesDon Smith Theory I-177nicuNo ratings yet

- How To Calculate Ferrite Core TransformersDocument14 pagesHow To Calculate Ferrite Core TransformersAhmed HeskolNo ratings yet

- Technical SpecificationDocument22 pagesTechnical SpecificationWilliam RuizNo ratings yet

- MT P 20160901Document173 pagesMT P 20160901pfalencar0% (1)