Professional Documents

Culture Documents

Aisc Edition Member Dimensions and Properties Viewer

Uploaded by

Roberto CatalaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisc Edition Member Dimensions and Properties Viewer

Uploaded by

Roberto CatalaniCopyright:

Available Formats

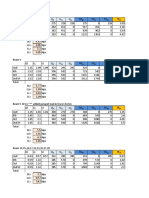

"AISC 14.1 Properties Viewer.

xls" Program

Version 1.0

AISC 14th EDITION MEMBER DIMENSIONS AND PROPERTIES VIEWER

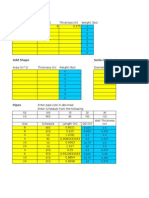

W, S, M, HP Shapes

C, MC Shapes

Single Angles

Y

k1=0.8125

tf=0.45

WT, ST, MT Shapes

bf=6.5

A=

d=

tw =

bf =

tf =

k(des) =

k(det) =

k1 =

T=

gage =

wt./ft. =

bf/(2*tf)

h/tw =

Ix =

Sx =

rx =

Zx =

Iy =

Sy =

ry =

Zy =

rts =

ho =

J=

Cw =

a=

W no =

Sw =

Qf =

Qw =

AW =

V=

N=

hW /tw=

N=

R=

R=

R=

W21X44

13

20.7

0.35

6.5

0.45

0.95

1.125

0.8125

18.375

3.5

44

7.22

53.6

843

81.6

8.06

95.4

20.7

6.37

1.26

10.2

1.6

20.3

0.77

2110

84.23

32.9

24.1

14

46.8

7.245

144.9

6.24875

54.5

x(bar)=0.854

t=0.375

d=3.5

X

d=3.5

in.

in.

in.

in.

in.

in.

in.

in.

in.

plf.

in.^4

in.^3

in.

in.^3

in.^4

in.^3

in.

in.^3

in.

in.

in.^4

in.^6

in.

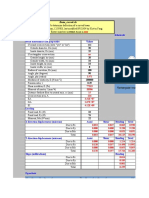

A=

d=

tw =

bf =

tf =

k(des) =

k(det) =

T=

gage =

rts =

ho =

wt./ft. =

eo =

Ix =

Sx =

rx =

Zx =

Iy =

Sy =

ry =

x(bar) =

Zy =

xp =

J=

Cw =

a=

in.^2

ro(bar) =

in.^4

H=

C10X15.3

4.48

10

0.24

2.6

0.436

1

1

8

1.5

0.868

9.56

15.3

0.796

67.3

13.5

3.88

15.9

2.27

1.15

0.711

0.634

2.34

0.224

0.209

45.5

23.74

4.19

0.884

tw=0.24

b=5

y(bar)=1.6

(0, 3/8, or 3/4

gap)

A=

d=

tw =

bf =

tf =

k(des) =

k(det) =

in.^2

in.

in.

in.

in.

in.

in.

in.

gage =

wt./ft.

bf/(2*tf)

in.

d/tw

plf.

Ix =

Sx =

rx =

y(bar) =

Zx =

yp =

Iy =

Sy =

ry =

Zy =

Qs =

in.

in.

in.

in.^4

in.^3

in.

in.^3

in.^4

in.^3

in.

in.

in.^3

in.^4

J=

Cw =

in.^6

a=

in.

in.

ro(bar) =

in.

H=

WT5X11

3.24

5.09

0.24

5.75

0.36

0.66

0.9375

2.75

11

7.99

21.2

6.88

1.72

1.46

1.07

3.02

0.282

5.71

1.99

1.33

3.05

0.834

0.119

0.107

1.53

2.16

0.83

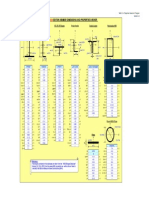

L5X3-1/2X3/8

in.^2

in.

in.

in.

in.

in.

in.

in.

plf.

in.^4

in.^3

in.

in.

in.^3

in.

in.^4

in.^3

in.

in.^3

in.^4

in.^6

in.

in.

A=

d=

b=

t=

k(des) =

k(det) =

wt./ft. =

Ix =

Sx =

rx =

y(bar) =

Zx =

yp =

Iy =

Sy =

ry =

x(bar) =

Zy =

xp =

Iz =

Sz =

rz =

TAN() =

Qs =

J=

Cw =

a=

ro(bar) =

H=

in.^3

3.05

3.5

5

0.375

0.813

0.8125

10.4

7.75

2.28

1.59

1.6

4.09

0.933

3.15

1.19

1.02

0.854

2.12

0.305

1.73

0.985

0.755

0.485

0.983

0.15

0.217

1.94

2.45

in.^3

end bearing length

otherwise not applicable

middle bearing length

int web crippling

end web crippling

0.302

end web crippling

N/D<0.2

55.37109123

53.31284117

W/ N=

W/N=

6

6

b=6

2L5X3-1/2X3/8LLBB

in.^2

in.

in.

in.

in.

in.

plf.

in.^4

in.^3

in.

in.

in.^3

in.

in.^4

in.^3

in.

in.

in.^3

A=

d=

b=

t=

wt./ft. =

Ix =

Sx =

rx =

y(bar) =

Zx =

yp =

Iy =

Sy =

ry =

Zy =

ro(bar) =

H=

Qs =

6.1

3.5

5

0.375

20.8

15.5

4.56

1.59

1.6

8.18

0.933

10.8

3.09

1.33

5.21

2.51

0.683

1

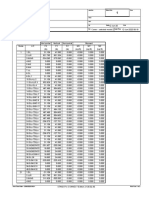

HSS8X6X3/8

in.^2

in.

in.

in.

plf.

in.^4

in.^3

in.

in.

in.^3

in.

in.

in.

in.

A=

h=

b=

t(des) =

wt./ft. =

Ix =

Sx =

rx =

Zx =

Iy =

Sy =

ry =

Zy =

h(flat) =

b(flat) =

J=

C=

A(surf) =

8.97

8

6

0.349

32.58

79.1

19.8

2.97

24.1

50.6

16.9

2.38

19.8

6.3125

4.3125

100

30

2.23

in.^2

in.

in.

in.

plf.

in.^4

in.^3

in.

in.^3

in.^4

in.^3

in.

in.^3

in.

in.

in.^4

in.^3

ft^2/ft

in.

Round HSS & Pipes

Y

in.^4

in.^3

t(nom)=0.322

in.

Plates

Y

in.^4

in.^6

t=0.375

in.

in.

O.D.=8.63

I.D.=7.98

X

b=12

Pipe8STD

in.^3

in

<54

4.2175

in

94.79074448 k

56.47214435 k

54.13863101 k

h=8

y(bar)=1.6

bf=2.6

in.^2

t(des)=0.349

b=5

d=5.09

tw=0.24

tw=0.35

t=0.375

bf=5.75

y(bar)=1.07

tf=0.36

d=10

Rectangular HSS

tf=0.436

x(bar)=0.634

d=20.7

Double Angles

t=

b=

wt./ft. =

A=

0.375

12

15.31

4.50

in.

Ix =

Sx =

rx =

Iy =

Sy =

ry =

0.053

0.281

0.108

54.00

9.00

3.46

54.05

in.^4

J=

in.

plf.

in.^2

in.^3

in.

in.^4

in.^3

in.

in.^4

A=

O.D. =

I.D. =

t(nom) =

t(des) =

wt./ft. =

Ix = Iy =

Sx = Sy =

rx = ry =

Zx = Zy =

J=

C=

7.85

8.63

7.98

0.322

0.3

in.^2

28.6

68.1

15.8

2.95

20.8

136

---

plf.

in.

in.

in.

in.

in.^4

in.^3

in.

in.^3

in.^4

in.^3

"AISC 14.1 Properties Viewer.xls" Program

Version 1.0

NOMENCLATURE FOR AISC VERSION 14.1 MEMBER PROPERTIES AND DIMENSIONS:

A=

d=

h=

tw =

bf =

b=

tf =

k=

k1 =

T=

gage =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

rts =

xp =

yp =

ho =

J=

Cw =

C=

a=

E=

G=

W no =

Sw =

Qf =

Qw =

x(bar) =

y(bar) =

eo =

xo =

yo =

ro(bar) =

H=

LLBB =

SLBB =

h(flat) =

b(flat) =

A(surf) =

STD =

XS =

XXS =

Cross-sectional area of member (in.^2)

Depth of member, parallel to Y-axis (in.)

Reference:

The shapes contained in this database are taken from the "AISC Shapes Database"

Depth of member, parallel to Y-axis (in.)

Version 14.1 (Oct. 2013) from the www.AISC.org website as well as those listed in

Thickness of web of member (in.)

the AISC 14th Edition Manual of Steel Construction (2011).

Width of flange of member, parallel to X-axis (in.)

Width of member, parallel to X-axis (in.)

Thickness of flange of member (in.)

Distance from outer face of flange to web toe of fillet (in.)

Distance from web centerline to flange toe of fillet (in.)

Distance between fillets for wide-flange or channel shape = d(nom)-2*k(det) (in.)

Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Moment of inertia of member taken about X-axis (in.^4)

Elastic section modulus of member taken about X-axis (in.^3)

Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A)

Moment of inertia of member taken about Y-axis (in.^4)

Elastic section modulus of member taken about Y-axis (in.^3)

Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Plastic section modulus of member taken about X-axis (in.^3)

Plastic section modulus of member taken about Y-axis (in.^3)

SQRT(SQRT(Iy*Cw)/Sx) (in.)

horizontal distance from designated member edge to plastic neutral axis (in.)

vertical distance from designated member edge to plastic neutral axis (in.)

Distance between centroid of flanges, d-tf (in.)

Torsional moment of inertia of member (in.^4)

Warping constant (in.^6)

Torsional constant for HSS shapes (in.^3)

Torsional property, a = SQRT(E*Cw/G*J) (in.)

Modulus of elasticity of steel = 29,000 ksi

Shear modulus of elasticity of steel = 11,200 ksi

Normalized warping function at a point at the flange edge (in.^2)

Warping statical moment at a point on the cross section (in.^4)

Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Statical moment at the mid-depth of the section (in.^3)

Distance from outside face of web of channel shape or outside face of angle leg to Y-axis (in.)

Distance from outside face of outside face of flange of WT or angle leg to Y-axis (in.)

Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

x-coordinate of shear center with respect to the centroid of the section (in.)

y-coordinate of shear center with respect to the centroid of the section (in.)

Polar radius of gyration about the shear center = SQRT(xo^2+yo^2+(Ix+Iy)/A) (in.)

Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

Long legs back-to-back for double angles

Short legs back-to-back for double angles

The workable flat (straight) dimension along the height, h (in.)

The workable flat (straight) dimension along the width, b (in.)

The total surface area of a rectangular or square HSS section (ft.^2/ft.)

Standard weight (Schedule 40) pipe section

Extra strong (Schedule 80) pipe section

Double-extra strong pipe section

You might also like

- ValueEngineering Practical PDFDocument416 pagesValueEngineering Practical PDFjhoward2012npNo ratings yet

- Stair Shop Drawing ExampleDocument1 pageStair Shop Drawing ExampleRoberto CatalaniNo ratings yet

- Slab On Ground (ACI360R)Document2 pagesSlab On Ground (ACI360R)Roberto Catalani100% (2)

- Solid State WeldingDocument14 pagesSolid State WeldingRaju_pancal100% (1)

- All DesignDocument45 pagesAll Designchandan kumar c gNo ratings yet

- Detail Dimensi Material GRPDocument5 pagesDetail Dimensi Material GRPdwi noviana nugrohoNo ratings yet

- Jindal SectionsDocument2 pagesJindal SectionsVivek GosaviNo ratings yet

- Beam design and analysisDocument5 pagesBeam design and analysisjanethNo ratings yet

- No. Momen (M11) B D Ø Fy Tipe Plat Kode TabelDocument4 pagesNo. Momen (M11) B D Ø Fy Tipe Plat Kode TabelazizahNo ratings yet

- BoltDocument39 pagesBoltHarmeet SinghNo ratings yet

- EQL and DesignDocument6 pagesEQL and Designsabareesan09No ratings yet

- Alya Haura Melani - Tugas 2 Beton 2 - 3 TKG 2Document6 pagesAlya Haura Melani - Tugas 2 Beton 2 - 3 TKG 2fahira khairaniNo ratings yet

- Watertank 1Document16 pagesWatertank 1Anand.5No ratings yet

- Calculating reinforcement for concrete beam with stirrupsDocument10 pagesCalculating reinforcement for concrete beam with stirrupsOdie Ongkek MufrodiNo ratings yet

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- American SteelBook 2Document472 pagesAmerican SteelBook 2MiguelRagasNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Bridge Geometry SpecsDocument8 pagesBridge Geometry SpecsSharyn PolleyNo ratings yet

- Slab Design - Roof: Ca CBDocument26 pagesSlab Design - Roof: Ca CBAnissah ManialaNo ratings yet

- HDTRHDocument1 pageHDTRHjudeNo ratings yet

- Jindal SectionsDocument2 pagesJindal Sectionsanon_107812982No ratings yet

- Indian Steel Weight Calculator FreeDocument1 pageIndian Steel Weight Calculator Freeparth shahNo ratings yet

- Pipe Weight Formulas & TablesDocument12 pagesPipe Weight Formulas & TablesuzairmetallurgistNo ratings yet

- Link BeamDocument8 pagesLink BeamNeil SonNo ratings yet

- Columnsteel 1Document1 pageColumnsteel 1Gelbert SilotNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)engyana engyyyNo ratings yet

- Wind Load Calculation for 6.5m High BuildingDocument98 pagesWind Load Calculation for 6.5m High BuildingAnonymous HJ7hmihhNo ratings yet

- Pipe Stiffness CalculationDocument1 pagePipe Stiffness Calculationข้าวเม่า ทอดNo ratings yet

- Rect Plates: Enter Pipe Size in Decimals Enter Schedule From The FollowingDocument15 pagesRect Plates: Enter Pipe Size in Decimals Enter Schedule From The FollowingosbertodiazNo ratings yet

- Calculate Product Weight from DimensionsDocument2 pagesCalculate Product Weight from Dimensionssanghvi_mukeshNo ratings yet

- UAS BETON 2 NewDocument8 pagesUAS BETON 2 NewFakhri AbdilaNo ratings yet

- Design of Plate Elements - v1.7Document49 pagesDesign of Plate Elements - v1.7faridullah100% (1)

- Design of Rectangular Beam: The Values Are Displayed in Blue Color Are The Input ValuesDocument6 pagesDesign of Rectangular Beam: The Values Are Displayed in Blue Color Are The Input ValuesDeepikaVaishnavNo ratings yet

- Basic Etabs or SAP2000Document29 pagesBasic Etabs or SAP2000rizkyNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- Thrust 2 eDocument6 pagesThrust 2 eWaheed AhmadNo ratings yet

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaNo ratings yet

- Steel TableDocument41 pagesSteel Tablechirag0102No ratings yet

- Calculating Pressure Loss Using Equivalent Pipe LengthDocument1 pageCalculating Pressure Loss Using Equivalent Pipe LengthmanikantanNo ratings yet

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- StaadDocument10 pagesStaadAgrawalAnuragNo ratings yet

- Schematic Beam Dimensions and Properties ValuesDocument4 pagesSchematic Beam Dimensions and Properties ValuesFredy Campos FloresNo ratings yet

- Asd VS LRFDDocument107 pagesAsd VS LRFDRicardo Jorge Vieira Pinto67% (3)

- Beam-Spread SheetDocument25 pagesBeam-Spread SheetUmesh ChamaraNo ratings yet

- Check Shear and Bending Capacity of Reinforced Concrete BeamDocument1 pageCheck Shear and Bending Capacity of Reinforced Concrete BeamAthar YogaNo ratings yet

- Design of Unsymmetrical I-Section (Approx Method)Document118 pagesDesign of Unsymmetrical I-Section (Approx Method)LC LeeNo ratings yet

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengNo ratings yet

- Capacity Charts For The Hydraulic Design of Highway CulvertsDocument95 pagesCapacity Charts For The Hydraulic Design of Highway CulvertsphisitlaiNo ratings yet

- Rcc13 Punching Shear Ver2.6Document10 pagesRcc13 Punching Shear Ver2.6Hoo Yen HowNo ratings yet

- Load Calculation: Self-Weight of Materials SL No Material Density (KN/M)Document6 pagesLoad Calculation: Self-Weight of Materials SL No Material Density (KN/M)ajith chandranNo ratings yet

- Chap 01 SMDocument20 pagesChap 01 SMMohammed GhisheerNo ratings yet

- 5storey Bldg.Document400 pages5storey Bldg.markeesNo ratings yet

- UB UC Steel SectionsDocument10 pagesUB UC Steel SectionsMuhammad HasanNo ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- AISC 14.1 Steel Member Properties ViewerDocument2 pagesAISC 14.1 Steel Member Properties ViewerJay GalvanNo ratings yet

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerDivina Teja Rebanal-Glino0% (1)

- Aisc 13-0 Properties ViewerDocument4 pagesAisc 13-0 Properties ViewerErnesto RQNo ratings yet

- AISC 13.0 Properties ViewerDocument12 pagesAISC 13.0 Properties ViewerRam ValNo ratings yet

- Propiedades de Perfiles de Acero EstructuralDocument5 pagesPropiedades de Perfiles de Acero EstructuralmandomendoNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument4 pagesAisc Member Dimensions and Properties ViewercoolkaisyNo ratings yet

- AISC 13th Edition Member Properties and Dimensions ViewerDocument25 pagesAISC 13th Edition Member Properties and Dimensions ViewerJosé Carlos TorrezNo ratings yet

- Aisc 13.0 Properties RodrigoDocument21 pagesAisc 13.0 Properties RodrigoJavier Alejandro AñazgoNo ratings yet

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerJorge Luis Borghes CepedaNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Stemwall Reinforcement For PipesDocument1 pageStemwall Reinforcement For PipesRoberto CatalaniNo ratings yet

- Spmats PDFDocument72 pagesSpmats PDFRoberto CatalaniNo ratings yet

- Lightweight Insulating Concrete For Floors and Roof DecksDocument6 pagesLightweight Insulating Concrete For Floors and Roof DecksPeter BussellNo ratings yet

- Analysis and Design of Shipping Container SupportDocument23 pagesAnalysis and Design of Shipping Container SupportRoberto CatalaniNo ratings yet

- Z725 Performance Rated I-JoistsDocument28 pagesZ725 Performance Rated I-JoistsbabshuagNo ratings yet

- Tedds Calculation of ASCE 7-10 Wind Loads For A Pole BarnDocument7 pagesTedds Calculation of ASCE 7-10 Wind Loads For A Pole BarnRoberto CatalaniNo ratings yet

- Pe Rules TexasDocument74 pagesPe Rules TexasRoberto CatalaniNo ratings yet

- Staad Reaction For Overturning Moments in Connex StructureDocument2 pagesStaad Reaction For Overturning Moments in Connex StructureRoberto CatalaniNo ratings yet

- Beam GraphsDocument11 pagesBeam GraphsRoberto CatalaniNo ratings yet

- Failure of Spread FootingsDocument7 pagesFailure of Spread FootingsRoberto CatalaniNo ratings yet

- Structural Deisgn - Elevator SectionDocument1 pageStructural Deisgn - Elevator SectionRoberto CatalaniNo ratings yet

- Design of Steel Canopy NotesDocument1 pageDesign of Steel Canopy NotesRoberto CatalaniNo ratings yet

- BLM Cost Estimating HDBK Dec2002Document158 pagesBLM Cost Estimating HDBK Dec2002osvald97No ratings yet

- Shearwall Overturning Calculation TemplateDocument3 pagesShearwall Overturning Calculation TemplateRoberto CatalaniNo ratings yet

- Typical Jack and King Stud Load Calculation TemplateDocument7 pagesTypical Jack and King Stud Load Calculation TemplateRoberto CatalaniNo ratings yet

- Spmats PDFDocument72 pagesSpmats PDFRoberto CatalaniNo ratings yet

- Seismic Load AnalysisDocument99 pagesSeismic Load AnalysisMANDARAW100% (1)

- Historical Live Loads NFPU NY 2015Document1 pageHistorical Live Loads NFPU NY 2015Roberto CatalaniNo ratings yet

- Joke Elections MexicoDocument1 pageJoke Elections MexicoRoberto CatalaniNo ratings yet

- Diaphragm CalculatorDocument4 pagesDiaphragm CalculatorRoberto CatalaniNo ratings yet

- Seismic Load AnalysisDocument99 pagesSeismic Load AnalysisMANDARAW100% (1)

- National Building Code Recommended NY 1913Document337 pagesNational Building Code Recommended NY 1913Roberto CatalaniNo ratings yet

- Architectural Plan of Pizza JointDocument1 pageArchitectural Plan of Pizza JointRoberto CatalaniNo ratings yet

- Typical Structural Joint DetailDocument1 pageTypical Structural Joint DetailRoberto CatalaniNo ratings yet

- Typical Structural NotesDocument1 pageTypical Structural NotesRoberto CatalaniNo ratings yet

- Typical Structural HatchesDocument1 pageTypical Structural HatchesRoberto CatalaniNo ratings yet

- Typical Base Plate DetailsDocument1 pageTypical Base Plate DetailsRoberto CatalaniNo ratings yet

- Masterrheobuild 1126 v2Document2 pagesMasterrheobuild 1126 v2Shub KotiNo ratings yet

- Install Refnet branches for Daikin heat pumpsDocument4 pagesInstall Refnet branches for Daikin heat pumpsIloaie FlorinNo ratings yet

- Imphal EasaaDocument1 pageImphal EasaaKosygin LeishangthemNo ratings yet

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDocument6 pagesEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљNo ratings yet

- H Beam Sizes Weight ChartDocument8 pagesH Beam Sizes Weight Chartsubodh kumar shahNo ratings yet

- Design of Guyed Mast TowerDocument5 pagesDesign of Guyed Mast TowerShai KoiNo ratings yet

- Laurie Baker Works and IdeasDocument14 pagesLaurie Baker Works and IdeasCebo DharuNo ratings yet

- Assignment 05 Solution (2) - 1Document11 pagesAssignment 05 Solution (2) - 1api-283240283No ratings yet

- Ventilation & Indoor Climate NoteDocument65 pagesVentilation & Indoor Climate NotenervozaurNo ratings yet

- Jacking Method Is More Excellent Than Traditional Method For Field Erected TanksDocument6 pagesJacking Method Is More Excellent Than Traditional Method For Field Erected TanksmannuNo ratings yet

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsDocument6 pagesCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineNo ratings yet

- Structural Drawings: Sl/Adb/St-CsDocument35 pagesStructural Drawings: Sl/Adb/St-Csharold romuald Lele FotsoNo ratings yet

- Vlasov Torsion Theory CT5141 Chap7Document12 pagesVlasov Torsion Theory CT5141 Chap7Anonymous 1rLNlqUNo ratings yet

- Environmental Project ManagementDocument44 pagesEnvironmental Project ManagementCharleneKronstedt0% (1)

- Qdoc - Tips - Flange Asme VIIIDocument41 pagesQdoc - Tips - Flange Asme VIIIHormedo RodriguezNo ratings yet

- HFY3-3125-ELE-SPC-0006 - 0 - Code ADocument11 pagesHFY3-3125-ELE-SPC-0006 - 0 - Code AAshraf AbdulredhaNo ratings yet

- Vertical Pressure Leaf FiltersDocument11 pagesVertical Pressure Leaf Filtersmikomikimilo62No ratings yet

- Module 1 - National Building Code of The Philippines - Part 1Document37 pagesModule 1 - National Building Code of The Philippines - Part 1Rovic VincentNo ratings yet

- h06962 Chemical Injection SystemDocument1 pageh06962 Chemical Injection SystemkirankirkNo ratings yet

- Konteyner PDFDocument36 pagesKonteyner PDFOzgenc Ebil100% (1)

- Mdpe Yellow Gas: ApplicationsDocument2 pagesMdpe Yellow Gas: ApplicationsPrateek GijjannavarNo ratings yet

- Product Catalog PDFDocument979 pagesProduct Catalog PDFa7mos0% (1)

- The Market Scape 01: Goals For "Integrated" Streets For DelhiDocument3 pagesThe Market Scape 01: Goals For "Integrated" Streets For DelhiVamsi Krishna ReddyNo ratings yet

- Development Process of New Bumper Beam For Passenger CarDocument2 pagesDevelopment Process of New Bumper Beam For Passenger CarFemi IbitoyeNo ratings yet

- No Fines Conc SpecsDocument3 pagesNo Fines Conc Specsway2saleemNo ratings yet

- Gravity Retaining Walls: Understanding Rankine's Theory and Stability ConditionsDocument12 pagesGravity Retaining Walls: Understanding Rankine's Theory and Stability ConditionsKshitija100% (2)

- An Applied Approach To Crack AssessmentDocument5 pagesAn Applied Approach To Crack AssessmentCarlos Maldonado SalazarNo ratings yet

- LES Cable Entry SystemsDocument26 pagesLES Cable Entry SystemsVasudev AgrawalNo ratings yet

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocument14 pagesAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALANo ratings yet