Professional Documents

Culture Documents

A Critical Review On Different Types of Wear of Materials

Uploaded by

IAEME PublicationOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Critical Review On Different Types of Wear of Materials

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 6, Issue 11, Nov 2015, pp. 77-83, Article ID: IJMET_06_11_009

Available online at

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=6&IType=11

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

IAEME Publication

A CRITICAL REVIEW ON DIFFERENT

TYPES OF WEAR OF MATERIALS

Dr. A. Devaraju

Principal and Professor,

Department of Mechanical Engineering,

Adhi College of Engineering and Technology,

Affiliated to Anna University,

Kanchipuram-631 605, Tamilnadu, India

ABSTRACT

Many mechanical equipments are subjected to sliding contact in real time

applications. Pumps, valves, belt drives, bearings, machinery guide ways,

piston- cylinder arrangements etc. are the few important sliding components

which are continuously subjected to sliding wear. Much mechanical

equipments failure occurred due to wear related problems. Therefore,

understanding of different wear mechanism is important to design the

mechanical components. In this paper, various wear mechanisms have been

discussed with the help previous published research works and text books.

Key words: Wear Mechanism, Wear Rate, Mechanical Components,

Lubrication

Cite this Article: Dr. A. Devaraju. A Critical Review on Different Types of

Wear of Materials, International Journal of Mechanical Engineering and

Technology, 6(11), 2015, pp. 77-83

http://www.iaeme.com/currentissue.asp?JType=IJMET&VType=6&IType=11

1. INTRODUCTION

When two solid surfaces are in contact, there is damage to the surface and/or

subsurface. Wear is the removal of solid metal from the one or both surface of which

are in solid state contact. Wear is quantified by the term 'wear rate' which is defined as

"the mass or volume or height loss of material removed per unit time or sliding

distance". The wear is characterized by mild and severe wear. The outcome of mild

wear, the worn surfaces is smooth and smaller in wear debris (typically 0.01m to

1m in particle size).

In contrast, the severe wear results in larger wear debris size (20 m to 200 m)

which can be seen in naked eye and roughened worn surface. The important wear

mechanisms are adhesive wear, abrasive wear, delamination wear, erosive wear,

fretting wear, fatigue wear and corrosive wear [1]. The wear behavior of materials is

important in tribology like frictional force [2]. The wear surfaces can be protected

http://www.iaeme.com/IJMET/index.asp

77

editor@iaeme.com

Dr. A. Devaraju

mainly in two ways: (1) separation of surfaces by applying a lubricant, and (2) surface

modification.

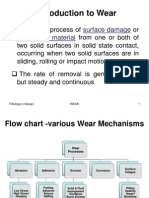

2. WEAR AND ITS MECHANISMS

As per available literature and current researchers knowledge concerned, seven

important types of wear mechanisms exhibit for different metal pairs. These seven

mechanisms are discussed as follows;

2.1. Adhesion

Adhesive wear is due to transfer of material from one surface to another surface by

shearing of solid welded junctions of asperities. It leaves pits, voids, cavities or valley

on the surface [3]. This wear occurs because of the adhesive bond. At the contact

points, the adhesive bond is stronger than the cohesive bond of the weaker material of

the Pair. Normally, adhesion occurs when two similar chemical composition metals

are in contact or contact surface are free from oxide layer (vacuum or an inert

atmosphere).Fig. 1.illustrates the adhesive wear mechanism of steel vs. indium Pair.

Figure 1 A schematic diagram illustrating adhesive wear mechanism [4].

When a clean steel or brass rounded end rod is pressed on the block of soft and

ductile metals such as lead and indium, strong adhesion will occur. When the rod is

removed, a fragment of soft metal (indium) adheres to the rod. It shows that the

adhesive strength of the contact junctions are stronger than the cohesive strength of

indium. The small addition of alloying element in the bulk material can alter the

adhesion between the solid surfaces. For example, the addition of sulfur in steel

enhances its machinability. Further, during sliding process, the iron sulfide comes out

of the surface and reduces friction as well as wear.

Similarly, the cast iron produces better tribological property than iron based

alloys. The reason is that the graphite becomes smeared out over the contact zone and

provides a lubricating film [3]. In the case of dissimilar metals, when the mutually

insoluble metals come in contact with each other, they would generally exhibit poor

adhesion [2,5,6]. However, if the surfaces are atomically clean, the adhesion would be

strong for this case also. Irrespective of solubility, the degree of softness also plays an

important role in adhesion. The soft metals exhibit a large real area of contact which

is responsible for high adhesion [7]. Although the use of lubricants at the contact

surfaces reduces the surface energy, the condensate of liquid film or pre-existing film

can significantly increase the adhesion [8,9].

2.2. Abrasion

Wear occurs due to hard particles or protuberances sliding along a soft solid surface.

It results in ploughing, wedging and cutting phenomena. In ploughing (also called

ridge formation) process, material is displaced at both the sides and forms a groove

with or without removal of material. The fundamental abrasive wear mechanism is

shown in Fig.2. There are two modes of abrasive wear: (1) Single body abrasive wear

http://www.iaeme.com/IJMET/index.asp

78

editor@iaeme.com

A Critical Review on Different Types of Wear of Materials

(Fig. 2(a)) in which abrasive marks will occur on one surface. The practical example

for single body abrasive wear is grinding, cutting and machining. (2) Two body

abrasive wear (Fig. 2(b)) in which abrasive marks will occur on both surfaces. In

tribological systems, the debris becomes entrapped between the contact surfaces and

makes grooves on one or both the contact surfaces.

In some practical applications like polishing process, the abrasive particles are

beneficial or desirable since it produces polished surfaces. The ridges formed during

abrasion or ploughing process become flattened after some sliding distance and

fractured due to repeated cyclic system [10, 11]. It also causes subsurface deformation

and surface as well as subsurface crack nucleation. The hardness is an important

property to control the abrasive wear. The experimental evidence reported that the

wear rate of two body abrasions is inversely proportional to the hardness [12] and

proportional to the normal load and abrasive particle size for many pure metals [13].

However, the complex behavior has been observed for alloys [14-16]. Wear

resistance of annealed pure metals are also directly proportional to their hardness but

more complex for alloys [12, 17, 18]. The reason for decrease of wear rate for longer

sliding distance experiments has been reported as (a) result of blunting of abrasive

surfaces and (b) clogging of the abrasive surface by wear debris [2].

Figure 2 A schematic diagram of abrasive wear mechanism (a) Single body abrasive

(b) Two body abrasive [3]

2.3. Erosive wear

Wear due to mechanical interaction between solid surface and fluid, or impinging

liquid or solid particles is called erosive wear. When particles with some velocity are

impacted on the surface of metal, the pits and large scale subsurface deformation

occur on the metal surface. The best example is when the rain droplets with different

velocities hit normal earth surface; it removes the surface and causes erosive wear. In

http://www.iaeme.com/IJMET/index.asp

79

editor@iaeme.com

Dr. A. Devaraju

plasma nitriding process, the sputtering is done to clean the specimens. In sputtering,

the argon ion which is in the gaseous form strikes the specimen surface and removes

the oxide layer.

From the practical point of view, the erosive wear is important. However, in some

experiments conducted with ceramic surfaces, the impingement of silicon carbide

particles with high velocity causes localized surface melting [19]. There is a

fundamental relationship between material loss and cohesive binding energy of the

metal. It has been proved that the cohesively stronger metals exhibit lower erosive

wear than cohesively weaker metals [20].

2.4. Fretting wear

Wear due to small amplitude of oscillatory or reciprocating movement between two

surfaces is known as fretting wear. It is a two step mechanism. Initially, the adhesive

wear occurs due to rubbing of two surfaces and then they become oxidized due to

large quantity of energy stored in wear particles.

2.5. Fatigue/ Delamination wear

Wear caused by fracture arising from surface fatigue due to cyclic loading is called

Fatigue/ Delamination wear. It results in a series of pits or voids. It usually occurs in

rolling or sliding contact bodies such as bearings, roads, etc. After repeated cyclic

loading, a crack is observed on the subsurface or the surface. The subsurface cracks

propagate, connect with other cracks, reach the surface and generate wear particles.

Similarly, the surface cracks move downward into bulk, connect with other cracks and

liberate a wear particle. The crack propagation is influenced by a number of factors.

The relative humidity in the air is one of the important factors. It has been

experimentally reported that the crack growth occurs rapidly in high moisture

environment rather than in dry air [21].

2.6. Corrosive/ Oxidative wear

Corrosive wear occurs when sliding takes place in corrosive or oxidative

environment. During dry sliding also, the oxygen from the normal environment or

other gases present in the environment can react with the solid surface. The excessive

presence of antiwear additives or other chemical agents also can bring corrosive wear.

At elevated temperature, oxygen can interact with sliding surface and form oxides

called oxidative wear. For example, oxidation of Inconel (nickel chromium alloys

containing some iron) occurs at 100C resulting in the formation of nickel oxide

(NiO) and chromium oxide (Cr2O3). However, when the temperature is increased to

280C, the surface contains spinel of NiFe 2O4 near the surface and Cr2O3 near the

metal interface [22]. It results in the formation of weak, mechanically incompatible

corrosive/oxide layer.

2.7. Deformation and Ploughing

When hard rough surface slides over a soft metal surface, the frictional resistance is

mainly developed by the asperities of hard surface ploughing through soft material

[23]. The force required for plastic flow of softer material represents the friction

coefficient. The ploughing of the surfaces by hard asperities and wear particles is

found to be the most important mechanism in most sliding situations [24].

http://www.iaeme.com/IJMET/index.asp

80

editor@iaeme.com

A Critical Review on Different Types of Wear of Materials

3. LUBRICATION

Lubrication is the process of introducing lubricants between contact surfaces to

reduce the frictional force. The main property of the lubricant is that it should produce

very lower shear strength and form a layer between the sliding surfaces [25]. In some

lubricating systems, although the lubricant film may not completely separate the

asperity contacts, it reduces the strength of the junctions formed. In other cases, the

lubricant film completely separates the surfaces and no asperity junctions are formed

at all. Regimes of lubrication are normally associated with dominant lubrication

mechanism involved in the mechanical system. The three main methods of lubrication

are: (1) hydrodynamic (or full film) lubrication, (2) boundary lubrication, and (3)

mixed lubrication [26].

Figure3 Methods of lubrication (a) Hydrodynamic lubrication (b) Boundary

lubrication and (c) Mixed lubrication

In hydrodynamic lubrication (Fig. 3(a)), the adequate pressure of fluid is supplied

between two contact surfaces which are in relative motion. The layers of fluid

completely separate the contact surfaces and support the load. In boundary lubrication

regime (Fig.3(b)), thin mono-layer of fluid film is formed between the frequent

asperity contact that leads to high values of coefficient of friction and wear compared

to hydrodynamic lubrication. Mixed film lubrication (Fig.3(c)) is the combination of

http://www.iaeme.com/IJMET/index.asp

81

editor@iaeme.com

Dr. A. Devaraju

full film lubrication and boundary lubrication. Boundary lubrication can be defined as

the regime in which average film thickness is less than the composite roughness.

4. CONCLUSION

The various types of wear mechanism and different lubrication process have been

discussed in detail. This review concludes that wear cannot be completely eliminated

between the sliding surfaces. However, it can be reduced (1) by applying lubricants

between sliding surfaces, (2) hardening the contact surfaces by mechanical and

chemical process and (3) designing the component material according to sliding

contact conditions. Wear is occurred by combination of two or more wear

mechanisms. Hence, understanding of wear mechanisms exhibited between sliding

surfaces are important while designing the any mechanical component.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

Halling, J. Principles of tribology, Macmillan Education Ltd., London, 1978.

Rabinowicz, E. Friction and Wear of Materials, Second edition, Wiley, New

York, 1995.

Buckley, D. H. Surface effects in Adhesion, Friction, Wear and Lubrication,

Elsevier Scientific Publishing Company, New York, USA, 1981.

Hucthings, I. M. Tribology: Friction and Wear of Engineering Materials, Edward

Arnold, London, 1992.

Keller, D. V. Adhesion between solid metals, Wear, Vol.6, pp. 353-365, 1963.

Keller, D. V. Recent results in particle adhesion: UHV measurements, light

modulated adhesion and the effect of adsorbates, J. Adhesion, pp. 83-86, 1972.

Bhushan, B. Principles and Applications of Tribology, A Wiley- Interscience

Publication, John wiley& sons, Inc., New York, 1999.

Adamson, A.W. Physical chemistry of surfaces, 5th edition, Wiley, New York,

1990.

Israelachvili, J. N. Intermolecular and Surface Forces, 2nd edition, Acadamic,

San Diego, 1992.

Stout, K. J., King, T. G. and Whitehouse, D. J. Analytical techniques in surface

topography and their application to a running in experiment, Wear, Vol. 43, pp.

99-115, 1977.

Suh, N. P. Tribophysics, Prentice-Hall, Inc., Englewood Cliffs, New Jersey,

1986.

Kruschov, M. M. Resistance of metals to wear by abrasion as related to

hardness, in Proc. Conf. Lubrication and wear, Instn.Mech. Engrs.Lond., UK,

pp. 655-659, 1957.

Misra, A. and Finnie, I. Some observations on two body abrasive wear, Wear,

Vol. 68, pp. 41-56, 1981.

Mulhearn, T. O. and Samuels, L. E. In abrasion of metals: A model of the

process, Wear, Vol. 5, pp. 478-498, 1962.

Goddard, J. and Wilman, M. A theory friction and wear during the abrasion of

metals, Wear, Vol. 5, pp. 114-135, 1962.

Moore, M. A. and King, F. S. Abrasive wear of brittle solids, Wear, Vol. 60,

pp. 123-140, 1980.

Kruschov, M. M. Principles of abrasive wear, Wear, Vol. 28, pp. 69-88, 1974.

http://www.iaeme.com/IJMET/index.asp

82

editor@iaeme.com

A Critical Review on Different Types of Wear of Materials

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

Kruschov, M. M. and Babichev, M. A. Resistance to abrasive wear of

structurally inhomogeneous materials, Friction and wear in machinery, ASME,

New York, Vol. 12, pp. 5-23, 1958.

Yust, C. S. and Crouse, R. S. Melting at particle impact sites during erosion of

ceramics, Wear, Vol. 51, pp. 335-343, 1978.

Vijh, A. K. Resistance of metals to erosion by solid particles in relation to the

solid state cohesion of metals, Wear, Vol. 39, pp. 173-175, 1976.

Endo, K. and Goto, H. Effects of environment on fretting fatigue, Wear, Vol.

48, pp. 347-367, 1978.

McIntyre, N. S., Zetaruk, D. G. and Owen, D. XPS study of initial growth of

oxide film on Inconel 600 alloy, Appl. Surf. Sci., Vol. 2, pp. 55-73, 1978.

Bowden, F. P. and Tabor, D. The Friction and Lubrication of Solids, Part-I,

Clarendon Press, Oxford, 1950.

Kim, D. E. and Suh, N. P. On microscopic mechanisms of friction and wear,

Wear, Vol. 149, pp. 199-208, 1991.

Ludema, K. C. Friction, wear, lubrication A text book in Tribology, CRC press,

New York, 1996.

Stachowiak, G. W. and Batchelor, A. W. Engineering tribology, Butterworth

Heinemann, 2001.

Santhosh Sivan. K, Chandrasekar Sundaram, Hari Krishnan. R and Anirudh

Srinivasan. Fairing Flap Drag Reduction Mechanism (FFDRM), International

Journal of Mechanical Engineering and Technology, 5(9), 2014, pp. 435 439.

Qayssar Saeed Masikh, Dr. Mohammad Tariq and Er. Prabhat Kumar Sinha.

Analysis of A Thin and Thick Walled Pressure Vessel for Different Materials,

International Journal of Mechanical Engineering and Technology, 5(10), 2014,

pp. 9 - 19.

http://www.iaeme.com/IJMET/index.asp

83

editor@iaeme.com

You might also like

- Adhesion Wear and AbrasiveDocument28 pagesAdhesion Wear and AbrasiveSanjay Shelar100% (1)

- Naval Reactor Handbook Vol 3Document523 pagesNaval Reactor Handbook Vol 3Peter AngeloNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Basic Wear ModesDocument6 pagesBasic Wear ModesolguinrfNo ratings yet

- IP15 Area Classification Code For Installations Handling Flammable FluidsDocument15 pagesIP15 Area Classification Code For Installations Handling Flammable FluidsAl Faruq ShinagaNo ratings yet

- Wear Debris AnalysisDocument28 pagesWear Debris AnalysisAman Kumar SaranNo ratings yet

- Science: Quarter 4 - Module 2 - Week 2 Behavior of Gases Part 2Document20 pagesScience: Quarter 4 - Module 2 - Week 2 Behavior of Gases Part 2Mary Ann100% (1)

- How Do I Layer The Ordinary Skincare ProductsDocument3 pagesHow Do I Layer The Ordinary Skincare Productsdiana fenichiuNo ratings yet

- Introduction To Wear: Surface Damage Removal of MaterialDocument33 pagesIntroduction To Wear: Surface Damage Removal of MaterialSelvamuthu KumaranNo ratings yet

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- 15 - Chapter 7 PDFDocument24 pages15 - Chapter 7 PDFpavan_1988No ratings yet

- Dickson and Benson 560 Assignment TwoDocument7 pagesDickson and Benson 560 Assignment TwoDICKSON SIMUTAMINo ratings yet

- For Other Uses, See .: Wear (Disambiguation)Document7 pagesFor Other Uses, See .: Wear (Disambiguation)Vishal SinghNo ratings yet

- Rear (Driven) Bicycle Sprockets. New, Left, Shows No Wear. Right, Used, Shows Obvious Wear From Being Driven ClockwiseDocument7 pagesRear (Driven) Bicycle Sprockets. New, Left, Shows No Wear. Right, Used, Shows Obvious Wear From Being Driven Clockwiseumar_hazrad8219No ratings yet

- Wear of Impact Socket - A ReviewDocument4 pagesWear of Impact Socket - A Reviewlaukik_rautNo ratings yet

- Hardfacing To Increase Wear ResistanceDocument6 pagesHardfacing To Increase Wear ResistanceanruloNo ratings yet

- Engineering Tribology: Prof. Dr. Tamer S. MahmoudDocument44 pagesEngineering Tribology: Prof. Dr. Tamer S. MahmoudbassemNo ratings yet

- Wear Mitigation by The Use of Surface CoatingsDocument10 pagesWear Mitigation by The Use of Surface CoatingsRodrigo Jechéla BarriosNo ratings yet

- Wear Introduction of WearDocument22 pagesWear Introduction of WearVinit ShrivastavaNo ratings yet

- Wear in Hydrodynamic Journal Bearings ADocument13 pagesWear in Hydrodynamic Journal Bearings ADjamel DjamNo ratings yet

- Module 3: Wear: Fig. 3.1 (A) : Zero Wear of Helical GearDocument30 pagesModule 3: Wear: Fig. 3.1 (A) : Zero Wear of Helical GearMohammad Ishfaq BhatNo ratings yet

- Study of Abrasion Wear and Affecting Wear RateDocument8 pagesStudy of Abrasion Wear and Affecting Wear RateNABIL HUSSAINNo ratings yet

- Chapter 8Document7 pagesChapter 8Tamirat NemomsaNo ratings yet

- A Wear and Surface DamageDocument3 pagesA Wear and Surface Damageemad sabriNo ratings yet

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocument15 pagesWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuNo ratings yet

- What Is Wear? 1.1 DefinitionDocument18 pagesWhat Is Wear? 1.1 DefinitionSHYAM SUNDARNo ratings yet

- Interactive Mechanism and Friction Modelling of Transient Tribological Phenomena in Metal Forming Processes: A ReviewDocument21 pagesInteractive Mechanism and Friction Modelling of Transient Tribological Phenomena in Metal Forming Processes: A ReviewvinothkumarNo ratings yet

- Brief Discussion On Tribology: Department of Orthopaedics Kasturba Medical CollegeDocument7 pagesBrief Discussion On Tribology: Department of Orthopaedics Kasturba Medical CollegechinmayghaisasNo ratings yet

- Tribology Wear PDFDocument30 pagesTribology Wear PDFkarthikNo ratings yet

- Module 3Document27 pagesModule 3Aditya ranjan BubunNo ratings yet

- 2 ND Proposal With RamiDocument9 pages2 ND Proposal With Ramiyunus_mohammed1641No ratings yet

- Fundamental Theory of DamagesDocument30 pagesFundamental Theory of DamagesMisge ChekoleNo ratings yet

- A Review Paper On Abrasive Wear CharacteristicsDocument6 pagesA Review Paper On Abrasive Wear CharacteristicsSalem GarrabNo ratings yet

- Module 5 WearDocument23 pagesModule 5 WearrohanNo ratings yet

- Basic Wear Modes in Lubricated SystemDocument8 pagesBasic Wear Modes in Lubricated SystemTino_No ratings yet

- 01 Dujv UE Presentation 2018 PDFDocument69 pages01 Dujv UE Presentation 2018 PDFelias attalahNo ratings yet

- Tribology of The Wheel Rail Contact Aspects of Wear Particle Emission and AdhesionDocument31 pagesTribology of The Wheel Rail Contact Aspects of Wear Particle Emission and AdhesionShaat KumarNo ratings yet

- Chapter#2 Assignment#3Document5 pagesChapter#2 Assignment#3Tilahun WorkuNo ratings yet

- (Wear Mechanism) IJIRSTV2I9092 PDFDocument7 pages(Wear Mechanism) IJIRSTV2I9092 PDFRizal AbdillahNo ratings yet

- Ques - AnsDocument9 pagesQues - Ansahmed titoNo ratings yet

- Presentation 1Document43 pagesPresentation 1TgemunuNo ratings yet

- Basics of Wear IiwDocument7 pagesBasics of Wear IiwSomnath ChakravartyNo ratings yet

- Chapter Two Fundamentals of The Theory of DamagesDocument33 pagesChapter Two Fundamentals of The Theory of DamagesMuket Agmas0% (1)

- Tribological Study of AISI 1040 Steel On A Pin-On-Disc SetupDocument32 pagesTribological Study of AISI 1040 Steel On A Pin-On-Disc SetupSAGUN MURMUNo ratings yet

- FrettingDocument2 pagesFrettingsolidwormNo ratings yet

- Coconut Ash FinalDocument47 pagesCoconut Ash FinalMusic LoverNo ratings yet

- Artigo Dos ItalianosDocument17 pagesArtigo Dos ItalianosFernando RockerNo ratings yet

- System Study of Wear Mechanism of Railway Wheel Tread SurfaceDocument6 pagesSystem Study of Wear Mechanism of Railway Wheel Tread SurfaceAndika Pandu VidiantoNo ratings yet

- Wear Debris AnalysisDocument28 pagesWear Debris AnalysisAjmal EsNo ratings yet

- Current and Future Applications of Surface EngineeringDocument14 pagesCurrent and Future Applications of Surface EngineeringAbdul jabbarNo ratings yet

- Metallurgical Aspects of Steels Designed To Resist Abrasion, and Impact-Abrasion WearDocument17 pagesMetallurgical Aspects of Steels Designed To Resist Abrasion, and Impact-Abrasion WearAlexis Guzmán MéndezNo ratings yet

- Cracks in A Powder VibratingDocument12 pagesCracks in A Powder Vibratinglrodriguez_892566No ratings yet

- GallingDocument6 pagesGallinghrh_pogcNo ratings yet

- Holmberg2007 FrictionWearCoatedSurfacesDocument16 pagesHolmberg2007 FrictionWearCoatedSurfacesEng-Mohammed Abu NuktaNo ratings yet

- 10 1016@j Triboint 2019 05 038Document21 pages10 1016@j Triboint 2019 05 038Danti DantiNo ratings yet

- Characterizations of Cutting Tool Flank Wear-Land ContactDocument5 pagesCharacterizations of Cutting Tool Flank Wear-Land ContactEsmeralda MuñozNo ratings yet

- 8.. - Study of Tin .FullDocument8 pages8.. - Study of Tin .FullTJPRC PublicationsNo ratings yet

- 2-1 Unit 1 Part 1 TribologyDocument77 pages2-1 Unit 1 Part 1 Tribologyshivamchakravarti27No ratings yet

- Chap 2Document49 pagesChap 2goitomNo ratings yet

- Modes of FractureDocument10 pagesModes of FractureAHMED DIABNo ratings yet

- Mir Azhar Fayaz Pre ThesisDocument22 pagesMir Azhar Fayaz Pre Thesismirazhar7006No ratings yet

- Erosion-Corrosion Interactions and Their Affect On Marine and Offshore ComponentsDocument10 pagesErosion-Corrosion Interactions and Their Affect On Marine and Offshore ComponentsAnonymous uCYIu1No ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- ISC 2013 Chemistry Theory Paper 1 Solved PaperDocument20 pagesISC 2013 Chemistry Theory Paper 1 Solved PaperAakash Singh100% (1)

- Aqueous Ammonia Process For CO2 Capture: IOP Conference Series: Earth and Environmental ScienceDocument2 pagesAqueous Ammonia Process For CO2 Capture: IOP Conference Series: Earth and Environmental Sciencetariq fareedNo ratings yet

- Major Plant of NirmaDocument3 pagesMajor Plant of NirmaAnndy TrivediNo ratings yet

- Understanding Oscillatory Behaviour of Gibbsite Precipitation CircuitsDocument12 pagesUnderstanding Oscillatory Behaviour of Gibbsite Precipitation CircuitsPRACHIPRAVA PRADHANNo ratings yet

- Algoritmos para BioreactoresDocument4 pagesAlgoritmos para BioreactoresMarlon Arista VasquezNo ratings yet

- 3.05 Ionic Bonding and Ionic CompoundsDocument3 pages3.05 Ionic Bonding and Ionic CompoundsIBRAHIM ABOU EL NAAJNo ratings yet

- Lesson 3 - Respiratory SystemDocument6 pagesLesson 3 - Respiratory SystemlarraNo ratings yet

- Basic Molecules of LifeDocument78 pagesBasic Molecules of LifeRavi ParkheNo ratings yet

- Materials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraDocument80 pagesMaterials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraAisyah Addia AzizanNo ratings yet

- XII PT-1 Phy KeyDocument9 pagesXII PT-1 Phy KeyRoshini SNo ratings yet

- Roadmark India: Manufacturing Unit: Plot No. 8, Kadipur Industrial Area, Gurugram, Haryana - 122001Document1 pageRoadmark India: Manufacturing Unit: Plot No. 8, Kadipur Industrial Area, Gurugram, Haryana - 122001ptk94287No ratings yet

- 2 - Potentiometry 2013Document52 pages2 - Potentiometry 2013AtikDwiOktavianiNo ratings yet

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- PTFE Cap1Document6 pagesPTFE Cap1RajanSharmaNo ratings yet

- RayterDocument4 pagesRayterLTE002No ratings yet

- The Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishDocument3 pagesThe Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishYuvraj SinghNo ratings yet

- Export Promotion Council (EPC) For LeatherDocument25 pagesExport Promotion Council (EPC) For Leathersiddharthjain9149No ratings yet

- Manufacture of RadiopharmaceuticalsDocument9 pagesManufacture of RadiopharmaceuticalsRainMan75No ratings yet

- Mobil Chassis Grease LBZDocument1 pageMobil Chassis Grease LBZtribolasNo ratings yet

- Revision Notes - Basic Nuclear PropertiesDocument10 pagesRevision Notes - Basic Nuclear PropertiesPankaj BiswasNo ratings yet

- Pneumatic Bench Vice Project-Report PDFDocument30 pagesPneumatic Bench Vice Project-Report PDFrahul bhatt100% (4)

- Gas SweeteningDocument3 pagesGas SweeteningAleem AhmedNo ratings yet

- Molecular Microbiology - 2013 - Leitsch - Trichomonas Vaginalis Flavin Reductase 1 and Its Role in Metronidazole ResistanceDocument11 pagesMolecular Microbiology - 2013 - Leitsch - Trichomonas Vaginalis Flavin Reductase 1 and Its Role in Metronidazole ResistanceJulieta SeifertNo ratings yet

- Brenntag Tofa Data Sheet: BFA 101 - Tall Oil Fatty AcidDocument1 pageBrenntag Tofa Data Sheet: BFA 101 - Tall Oil Fatty AcidniteshacharyaNo ratings yet

- Specifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonDocument3 pagesSpecifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonnicholasyudhistiraNo ratings yet