Professional Documents

Culture Documents

4-Wheel Steering System Mechanism Using DPDT Switch

Uploaded by

IAEME PublicationOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4-Wheel Steering System Mechanism Using DPDT Switch

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 6, Issue 11, Nov 2015, pp. 176-182, Article ID: IJMET_06_11_020

Available online at

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=6&IType=11

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

IAEME Publication

4-WHEEL STEERING SYSTEM

MECHANISM USING DPDT SWITCH

Aman Doraya, Mohit Singh Panesir, Bhavya Bhardwaj and Aditya Bochare

Medicaps Institute of Science and Technology, Automobile Engineering Department

Indore

ABSTRACT

In standard 2 Wheel Steering System, the rear set of wheels are always

directed forward and do not play an active role in controlling the steering,

thus it results in increased turning radius. While in 4 Wheel Steering System,

the rear wheels do play an active role for steering and helps to decrease the

turning radius. Vehicle parking and driving in city conditions with heavy

traffic in tight spaces, driving would be very difficult due to larger wheelbase

and track width. Hence there is a need of a mechanism that can decrease the

vehicles turning radius. We have developed an innovative 4 wheel steering

design to implement a mechanism that can be used for high speed lane

changing, crab steer, parallel parking depending upon the conditions of

turning and lane changing with respect to front wheels, by using servo motors

and direct current motor which are controlled by DPDT switch, thus

enhancing the maneuverability of a sedan.

Key words: 4-Wheel steering, DPDT Switch, Turning radius, Lane changing,

Crab steer, Parallel parking, Servo motors, DC motors

Cite this Article: Aman Doraya, Mohit Singh Panesir, Bhavya Bhardwaj and

Aditya Bochare. 4-Wheel Steering System Mechanism Using DPDT Switch.

International Journal of Mechanical Engineering and Technology, 6(11),

2015, pp. 176-182.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=6&IType=11

1. INTRODUCTION

With the increase in demands for an automobile, parking problems are increasing

proportionally. Now-a-days people are willing to buy bigger vehicles, which are more

powerful, which requires more parking space, causes severe parking problems at

home, office, multiplexes etc.

Four wheel steering vehicle can be employed to increase the maneuverability,

easy parking and smooth lane changing. Mostly available four wheel steering vehicle

uses guiding computers and electronics for steering control, our concept uses

mechanical in combination with electronics to steer the vehicle in different direction.

http://www.iaeme.com/IJMET/index.asp

176

editor@iaeme.com

Aman Doraya, Mohit Singh Panesir, Bhavya Bhardwaj and Aditya Bochare

This paper focuses on feasibility and innovative approach which uses 4 rack, 2

pinon arrangement enclosed in a casing. There will be 4 direct current motors for

propulsion and minimum turning radius and 2 servo motors for other operating

modes. Driving modes can be change by a press of a button. We have used DPDT

(dual pole dual throw switch) to change the polarity of the motor which tends to

change the direction of the rotation. Since there are independent motors for each

pinion, there is no need of motion transmission from front to rear which in turn

reduces the total weight.

2. LITERATURE REVIEW

2.1. Perfect steering condition

While negotiating a turn, the condition is said to be true rolling or perfect steering

when the axes of the all 4 wheels should meet at a point known as instantaneous

centre and when the following equation is satisfied.

Cot cot = c/b

2.2. Parallel parking

Zero steer can significantly reduce the parking problems that driver has to deal with in

metro cities. In foreign countries parallel parking is preferred which includes drivers

skills as well as more space for parking. In parallel parking the car has to be parked

between 2 vehicles, such maneuver requires 3 way motion of the vehicle, hence

increases steering inputs. Additionally vehicle requires 1.75 times length of the car to

successfully park the vehicle without damage.

As it can be seen, with the zero steer car requires about the same length, as its own

for the parking. Moreover in the 3600 rotation the driver does not need to steer the

vehicle, all he has to do is braking and throttling to park the vehicle.

http://www.iaeme.com/IJMET/index.asp

177

editor@iaeme.com

4-Wheel Steering System Mechanism Using Dpdt Switch

2.3. The DPDT (Double Pole Double Throw) switch

A Double Pole Double Throw (DPDT) switch is a switch that has 2 inputs and 4

outputs; each input has 2 corresponding outputs that it can connect to. Each of the

terminals of a double pole double switch can either be in 1 of 2 positions. This makes

the double pole double switch a very versatile switch. With 2 inputs, it can connect to

4 different outputs or reroute a circuit into 4 different modes of operation.

3. THE CONCEPT

This concept has 4 rack and 2 pinions, one pinion at the front and other at the rear.

Pinion is connected by a geared servo motor which is operated through the 12V

battery and the direction of rotation can be change by changing the polarity of the

motor, which is done by the DPDT switch. There are 4 bell crank lever for parallel

parking, which helps to rotate the wheels through 900. In this concept there are 4

modes of operations which are as follows.

3.1. Crab steer

In crab steer all of the wheels will rotate in same direction, with the same angle.

http://www.iaeme.com/IJMET/index.asp

178

editor@iaeme.com

Aman Doraya, Mohit Singh Panesir, Bhavya Bhardwaj and Aditya Bochare

3.2. Co-ordinated steer

In coordinated steer, wheels at the front will rotate in opposite direction, to the wheels

at the rear.

3.3. Minimum turning radius

For minimum turning radius, wheels of one side of the vehicle will rotate in opposite

direction, to the wheels of another side of the vehicle.

3.4. Parallel parking

In this condition axis of wheels will be perpendicular to the axis of the tie rod.

4. CONSTRUCTION OF THE MECHANISM

1. Pinion is connected to the servo motor with the help of gear which is mounted on

the servo motor.

2. The gear of rack is connected to the pinion gear for converting the rotational

motion of the servo motor in to the translation motion.

3. There are 3 pivot at the bell crank lever, first is connected with the rack, second is

connected to the chassis, while the third one is connected to the hub.

4. There are 2 DPDT switches for the front and rear respectively.

5. Each DPDT switch is connected to one motor, total two.

http://www.iaeme.com/IJMET/index.asp

179

editor@iaeme.com

4-Wheel Steering System Mechanism Using Dpdt Switch

6. For the propulsion and for minimum turning radius of the vehicle DC motors are

employed at each wheel.

7. There will be another set of DPDT switches for changing the polarity of the DC

motor.

8. Two DPDT switches are connected to 4 DC motor for minimum turning radius.

9. Two of the DC motors will be in series with each other, while other two will be in

series connection with each other, hence with one switch, two motors can be operated

simultaneously.

5. DPDT SWITCH FOR CHANGING THE POLARITY OF

MOTOR

5.1. When switch is not shorted

In an initial condition when the switch is in off state, than the terminal C and terminal

D are not connected to any of the terminal, which doesnt allow any current to flow in

to the circuit, since the circuit is not completed. This will stop the motor from

rotating.

5.2. For clockwise rotation of the motor

Working for clockwise rotation of the vehicle is shown in the figure. When the

terminal C is connected to the terminal A, and also, terminal D is connected to the

terminal B then the motor will rotate in clockwise direction. The direction of current

flow is, positive terminal of battery -D-B-E- positive terminal of motor-negative

terminal of motor -F-A-C- negative terminal of battery. In this way the motor will

rotate in the clockwise direction.

http://www.iaeme.com/IJMET/index.asp

180

editor@iaeme.com

Aman Doraya, Mohit Singh Panesir, Bhavya Bhardwaj and Aditya Bochare

5.3. Condition 3. For anticlockwise rotation of the motor

Working for the anticlockwise rotation of the motor is shown in Figure. When the

terminal C is shorted with terminal E and terminal D is shorted with terminal F than

the direction of current is from positive terminal of the battery- terminal D- terminal

F- positive of the motor- negative of the motor- terminal E- terminal C- negative of

the battery. As can be seen that the polarity of the motor has changed due to change in

the direction of current.

6. WORKING FOR DIFFERENT MODES

6.1. Crab steer

For crab steer, the motor at the front wheels will rotate in the same direction as motor

at the rear wheels. This will turn the wheels at the front of the vehicle in same

direction as of the wheels at the rear of the vehicle.

6.2. Coordinated steer

For coordinated steer, the motor at the front wheels will rotate in the opposite

direction to the motor at the rear of the vehicle. This will turn the wheels at the front

in opposite direction, to the wheels at the rear of the vehicle.

6.3. Parallel parking

With the help of the bell crank lever, all the wheels can be turned through 900.

http://www.iaeme.com/IJMET/index.asp

181

editor@iaeme.com

4-Wheel Steering System Mechanism Using Dpdt Switch

6.4. Minimum turning radius

Minimum turning radius can be obtain through the opposite rotation of the wheels of

right side of the vehicle to the wheels of left side of the vehicle or vice versa,

depending upon the side of rotation of the vehicle.

7. ADVANTAGES

1 The vehicles cornering behavior becomes more stable and controllable at high

speeds as well as on wet or slippery road surfaces

2 There are no mechanical linkages for the connection between front wheels and the

rear wheels, hence weight reduction.

3 Decrease in turning radius of the vehicle.

4 DPDT is a cost efficient device, hence decrease in overall cost of the system.

8. CONCLUSION

As per the focus of the project we have created an innovative 4 wheel active steering

mechanism using DPDT switch which is feasible to manufacture, easy to install and

highly efficient in crab steer and coordinated steering. This system assists in high

speed lane changing and better cornering. It combats the problems faced in sharp

turning. It reduces the turning circle radius of the car and gives better maneuverability

and control while driving at high speeds, thus attaining neutral steering.

Moreover components used in this system are easy to manufacture, material used

is feasible, reliable and easily available in market. The system assembly is easy to

install and light in weight and can be implemented in all sections of cars efficiently.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

http://images.mocpages.com/user_images/174/13022756038_SPLASH.jpg

http://www.learningaboutelectronics.com/Articles/Double-pole-double-throwswitch-DPDT

https://www.quora.com/What-are-the-disadvantages-of-using-a-mechanicallinkage-steering-systemsteering

http://victorylibrary.com/graphics/235/Linkage/foz-products-bell-crank-2.jpg

http://www.ijeit.com/Vol%203/Issue%2012/IJEIT1412201406_65.pdf

http://www.parkingenforcer.com/blog/wpcontent/uploads/2014/07/parkingproble

sm.jpg

Gajanan S. Rao and Prof. R. R. Deshmukh. Art of Fatigue Analysis of Helical

Compression Spring Used in Two-Wheeler Horn. International Journal of

Mechanical Engineering and Technology, 4(2), 2013, pp. 196-208.

http://www.iaeme.com/IJMET/index.asp

182

editor@iaeme.com

You might also like

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNo ratings yet

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MSC Ingi Niels Karlsson 2018Document228 pagesMSC Ingi Niels Karlsson 2018Anshul BhardwajNo ratings yet

- Eclate Iseki Tm3160Document486 pagesEclate Iseki Tm3160loiclerouxNo ratings yet

- r2 DA40 NG AMM Complete PDFDocument1,635 pagesr2 DA40 NG AMM Complete PDFKaisNo ratings yet

- The Genuine Definition of Winning!Document5 pagesThe Genuine Definition of Winning!Fernando CentenoNo ratings yet

- Monroe Quick Strut Installation Instructions en PDFDocument2 pagesMonroe Quick Strut Installation Instructions en PDFDaniel BriggsNo ratings yet

- Brake Pads PDFDocument2 pagesBrake Pads PDFMohammad TahaNo ratings yet

- Truck & Bus: Spare Parts Catalogue 2017Document49 pagesTruck & Bus: Spare Parts Catalogue 2017كـروري كـشخةةNo ratings yet

- Farymann Technical Data Engines After 1981Document1 pageFarymann Technical Data Engines After 1981emreorakNo ratings yet

- Manual de Taller Honda CBR 250: Read/DownloadDocument3 pagesManual de Taller Honda CBR 250: Read/Downloadjorge dazaNo ratings yet

- Crown FC 4500 PDFDocument697 pagesCrown FC 4500 PDFDaniel Popescu100% (1)

- Robinson HelicopterDocument1 pageRobinson HelicopterTony GarrisonNo ratings yet

- Fdocuments - in - Massey Ferguson MF 158 Mkiii 158 V Tractors Parts Catalogue ManualDocument23 pagesFdocuments - in - Massey Ferguson MF 158 Mkiii 158 V Tractors Parts Catalogue ManualPawełOsadaNo ratings yet

- Rotary Drilling Rig KR-125: Delivering Innovation, Results & Reliability, While Saving You MoneyDocument3 pagesRotary Drilling Rig KR-125: Delivering Innovation, Results & Reliability, While Saving You MoneymliugongNo ratings yet

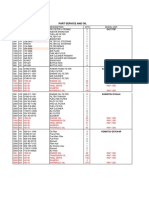

- Part Service and Oil: CAT 775FDocument5 pagesPart Service and Oil: CAT 775FWildan Zainun NasiqinNo ratings yet

- A9EA - Rev20 VT-ELX PDFDocument20 pagesA9EA - Rev20 VT-ELX PDFsaradeepsNo ratings yet

- Affidavit of AccidentDocument3 pagesAffidavit of AccidentBel RosaNo ratings yet

- McqsDocument9 pagesMcqsFaraz NawazNo ratings yet

- CVT-Transmission G1 TR690Document52 pagesCVT-Transmission G1 TR690Rogério Freitas100% (2)

- Chapter 1 MotoresDocument23 pagesChapter 1 MotoresWalter GonzalezNo ratings yet

- Sunseeker 95yacht 400x225 WebDocument23 pagesSunseeker 95yacht 400x225 WebBoris MartinezNo ratings yet

- Automobile Car Industry OverviewDocument8 pagesAutomobile Car Industry OverviewsavaliyamaheshNo ratings yet

- Blow by Breather SystemsDocument19 pagesBlow by Breather SystemsekumaranNo ratings yet

- Excavadora SY365HDocument12 pagesExcavadora SY365HAydeé Aguilar JulianNo ratings yet

- Mercury Mercruiser #24 - Marine Engines GM V-8 305 CID (5.0L) - 1Document189 pagesMercury Mercruiser #24 - Marine Engines GM V-8 305 CID (5.0L) - 1薛泽绵No ratings yet

- Understanding How Airplanes FlyDocument4 pagesUnderstanding How Airplanes FlyLaura Marcela Poveda OrtegonNo ratings yet

- El AlmeraDocument600 pagesEl AlmeraEdgar RiosNo ratings yet

- Build A 2 Wheel Cargo Bike PDFDocument7 pagesBuild A 2 Wheel Cargo Bike PDFmichal_slawinskiNo ratings yet

- Cme380 Ae QBDocument15 pagesCme380 Ae QBTM TamilselvanNo ratings yet

- Prado Model OutlineDocument9 pagesPrado Model OutlineLuis Fernando Vasquez RamosNo ratings yet