Professional Documents

Culture Documents

Us 5078779

Uploaded by

Javier Alejandro Rodriguez MelgozaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 5078779

Uploaded by

Javier Alejandro Rodriguez MelgozaCopyright:

Available Formats

lllllilllllllllllllilllllllil

US005078779A

United States Patent [19]

[11] Patent Number:

Van de Walle et a1.

[45]

[54] BINDER FOR THE GRANULATION OF

FERTILIZERS

SUCH AS AMMONIUM

SULFATE

Date of Patent:

[56]

Inventors:

Richard

Md; Duid

H. Van

Smith,

de Kcameysviuc,

Walle, Columbia,

w

Va.

_

[73] Asslgneer

Jan. 7, 1992

References Cited

U.S. PATENT DOCUMENTS

3,476,544 11/1969

[75]

5,078,779

Vasan ........................... .. 71/64.06 X.

331mm!

....................................

' ' '

' ..' '

FOREIGN PATENT DOCUMENTS

.

0065785

Martin Mme! Mlsnem

specumes Inc" Hum valley Md

4/1985

Japan ................................ .. 7l/64.06

0145932 8/1985 Japan ................................ .. 7l/64.06

Primary Examiner-Ferris H. Lander

Attorney, Agent, or Finn-Herbert W. Mylius; Alan G.

[21] Appl. No.: 278,631

[22]v Filed:

Dec. 1,1988

Town"; Gay Chin

[571

ABSTRACT

A binder composition is taught for the granulation of

[51] Int. Cl.5 ....................... .. 0156 1/00; 0056 3/00;

(305C 3/00

?ne particulate fertilizer, which binder comprises an

admixture of reactive carbonate, sulfate, silicate

[52]

strengthener, and water dispersant, said binder being

reactive in the presence of an acid activator.

[58]

us. C1. ......................................... .. 71/63; 71/60;

71/61; 71/64.06; 106/600; 106/627

Field of Search .................. .. 71/36, 64.06, 74, 60,

71/61, 63; 106/106, 600, 627; 423/525

10 Claims, No Drawings

5,078,779

while the ?nes are returned to the drum granulator.

BINDER FOR THE GRANULATION OF

FERTILIZERS SUCH AS AMMONIUM SULFATE

BACKGROUND OF THE INVENTION

This invention relates to a binder for the granulation

This process produces spherical granules, but its use is

dependent upon the availability of cheap ammonia. In

addition, the ammonium sulfate produced in this man~

5 ner is usually not competitive with by~product ammo

nium sulfate from coke ovens.

In U.S. Pat. No. 4,277,253, a method is taught for the

of a dry, stable particulate fertilizer, such as ammonium

preparation of dry, stable granular material from water

sulfate, utilizing conventional commercially available

blend of granules of a speci?c desired sizing for use as a

soluble potassium and ammonium salts, or a mixture

thereof, by subjecting a dispersion of crystals of the salt

fertilizing material.

in an aqueous liquid to the action of a granulating de

granulating devices, to prepare a relatively uniform

vice in the presence of calcium sulfate hemi-hydrate and

a hydrophilic surface-active agent to effect agglomera

tion of said crystals, and thereafter subjecting the ag

glomerated crystals to a drying operation. Thus, gyp

A commonly utilized fertilizer material is dry ammo

nium sulfate, which for convenience is usually granu

lated to a speci?ed size range for application. The grain

size of ammonium sulfate varies considerably according

to the method of manufacture. Usually, the crystal size

sum and a hydrophilic surface-active agent are used in a

can vary between 0.1 mm and 2 mm. The use of such

small grain sizes in fertilizers presents a problem of

dispersion of a salt, such as ammonium sulfate which is

sprayed onto dry crystals in a drum or pan granulator or

blending with other granulated primary nutrients, with

pug mill. This technique necessitates the addition of

respect to segregation. Also, such small crystal sizes are

not ideal for direct application to the ?eld through

extra equipment to mill ammonium sulfate to a ?ner

particle size, then dissolve the same to make a granula

fertilizer applicators.

The fertility of varying soils often requires the appli

tals. Also, high levels of calcium sulfate are required to

tion fluid to spray onto other ammonium sulfate crys

cation of more than one nutrient for the correction of

give agglomerates of good quality, at the expense of

nutritional de?ciencies in the soil. While it is common 25 greatly reduced nitrogen value.

practice to produce granular, multiple-nutrient fertiliz

What has been needed for some time has been a gran

ers, in which each granule contains the primary nutri

ents nitrogen, phosphorous, and/or potassium in a de?

nite predetermined ratio, a speci?c ratio will not always

meet the requirements of a speci?c soil. Thus, a pro

ducer of fertilizers has either to produce a great number

ulation technique which utilizes commonly operated

granulating equipment, and is capable of recovering

?nes or reduced size ammonium sulfate, and agglomer

" ating the same into a carefully controlled size range.

Most fertilizer granulators operating in the United

of nitrogen-phosphorous-potassium type fertilizers in

granular form, or to physically mix together the pri

vStates are of the continuous ammoniation-granulation

type. In such a plant, potassium sulfate and other dry

nutrient-containing materials are measured continu

mary nutrients as individual granules. Granular ammo

nium sulfate would, if suitably available, he an appropri

ously by gravimetn'c belt feeders. Liquid raw materials,

such as anhydrous ammonia, nitrogen solutions, sulfuric

acid, or phosphoric acid, are measured continuously by

ate primary nutrient source of nitrogen and sulfur for

such blending.

These mechanically mixed fertilizers, or bulk blended

metering. Both liquid or dry materials are fed into a

fertilizers, allow the production of an in?nite number of

ratios in regard to their content of primary nutrients. 40 rotating drum or granulator, where products are inti

mately mixed and agglomeration takes place. After the

initial granulation phase, the product passes through a

rotary dryer and cooler. The cooled product is screened

to separate the on-size product from over-size and ?nes.

Bulk blending is, however, only a practical proposition

as long as the fertilizer materials used in the preparation

of the bulk blended fertilizer are well granulated and

have not only a close, but also a very similar, spectrum

of sizings. Accordingly, it has become increasingly 45 Over-size material is crushed and rescreened, and ?nes

are recycled back into the ammoniator-granulator. The

important to closely control the granule size of various

TVA and the United States Department of Agriculture

nutrient materials. It has previously been difficult to

have contributed a wealth of additional information to

achieve the formation of granules of ammonium sulfate

the granular process over the last three decades. Circu

within very narrow size ranges in a practical manner in

conventional granulating devices, such as a rotating 50 lar Z-l8, published in November 1970 by the TVA and

the National Fertilizer Development Center, entitled

drum or pan, or a blunger. Attempts to granulate such

"Producing Granular Fertilizers, describes in detail

salts in these devices have produced a wet crystalline

pulp during the wetting of the cascading bed, which

could not be coalesced and agglomerated into spheres.

One process, which was developed by the National

Fertilizer Development Center of the Tennessee Valley

typical granulation techniques for fertilizers.

Raw materials used in such granulation processes

55 usually vary in size from as small as, for example, -325

mesh to as large as the minimum size speci?cation of the

?nished product. Great care must be exercised in deter

mining the proportions of various sized raw materials to

be included in granulating product so as to produce a

acid and ammonia are pre-neutralized in a reactor to an

?nal mix which granulates at an ef?cient rate. Maxi

60

Mimi-12804 molar ratio of 1:1. The pre-neutralized ?uid

Authority (TVA), may be used for the production of a

granular ammonium sulfate. In this process, sulfuric

which usually contains less than 10 percent free water,

and has a temperature of about 150' C., is then fully

ammoniated and granulated in a TVA drum granulator

operating at a recycle ratio of about 1:1. The heat

evolved during the ammoniation makes the drying of 65

the granules superfluous. The granules discharged from

the drum are cooled and screened. The over-size is

disintegrated and recycled to the double-deck screen,

mum level of on-size ?nished product, particularly

when no binder is used, is produced when a variety of

sizes of raw material is included in the raw material

feed. This, however, tends to signi?cantly increase the

cost of the ?nal product. At the same time, the speci?c

nutrient material levels must be maintained at the re

quired speci?cation in order to meet the desired formu

lation.

5,078,779

Many raw material products available to the fertilizer

granulator are more economically priced if the granula

granules and assists in formation of uniform granule

sizing.

tor can use reduced size or frnes" of the raw material.

The reactive carbonate salt may be selected from

Raw materials such as ammonium sulfate, and others,

are frequently available to the fertilizer granulator in a

reduced sizing at a reduced cost. Maximum economy in

such cases depends upon maximum use levels. In addi

tion, there is often raw material available which is con

sidered distressed goods," as it is no longer in condi

calcium carbonate, dolomite, magnesium carbonate,

tion to be used for bulk blended product.

If a proper balance of fertilizer chemistry, binder, and

raw material size balance is not met, granules which are

formed during granulation are often weak and readily

disintegrate to powder during handling and use. Dusti

ness in the product can become excessive, causing ex

potassium carbonate, ammonium carbonate, other car

bonates, and mixtures thereof. The preferred carbonate

for the present invention is calcium carbonate. The

reactive carbonate may comprise from 60 percent to 85

percent of the binder composition, preferably from

10 about 65 percent to about 75 percent, and most prefera

bly about 70 percent of the binder composition.

The reactive sulfate may be selected from langbeinite,

kieserite, magnesium sulfate salts, potassium sulfate

salts, other sulfate salts, and mixtures thereof. The pre

ferred sulfate salt for use in the present invention com

prises langbeinite. The sulfate salt may comprise from

about

15 percent to about 40 percent by weight of the

in fertilizer application equipment. Certain other raw

binder

formulation, preferably from about 20 percent to

materials and raw material combinations, when used at

about

35

percent by weight, and most preferably from

the most economically desirable levels, draw excessive

about

28

percent

to about 30 percent of the binder for

20

moisture to the furished granules, thus limiting storage

mulation.

and shelf life and causing excessive caking in storage

The silicate strengthening agent may preferably be

bins, ?nished product piles, and fertilizer application

potassium

silicate, but may also be any other suitable

equipment. One class of such ingredient which may be

commercially available material which will enhance

used in combination with ammonium sulfate, and which

25 granular green strength. The potassium silicate may

frequently exhibits this characteristic, is urea and urea

comprise from about 0.5 to 5.0 percent by weight of the

combinations. A granular ureacontaining composition

binder formulation, preferably from about 0.5 to 2.0

encompassing calcium sulfate and calcium phosphate is

percent, and most preferably about 1 percent of the

taught in US. Pat. No. 4,283,423. Various possibilities

binder formulation.

have been proposed to avoid such caking when utilizing

The dispersant composition may be any water dis

urea in fertilizer manufacture. They include dusting" a

persing agent, such as polymethacrylate, bentonite,

conditioning agent on the manufactured granule. Such

sodium phosphate, lignin sulfonate, organic dispersing

dusting agents include starch, clays, and calcium

agents, etc. The preferred dispersant for use in the pres

treme handling and flow problems during transfer and

sources, as described in US. Pat. No. 3,332,827. This

method is less than satisfactory, as it requires additional

equipment and, at best, only coats particles of the gran

ent binder formulation is polymethacrylate. The water

dispersing agent may be present in a concentration of

ule, thus providing only partial relief from the caking.

from about 0.10 percent to about 3.0 percent by weight

of the binder formulation, preferably from 0.10 to about

SUMMARY OF THE INVENTION

2.0 percent, and most preferably from about 0.10 to

about 0.50 percent by weight of the binder formulation.

It is therefore the object and advantage of this inven 40 The binder composition of the present invention is

tion to provide a binding medium for granulated fertil

intended to be provided to the fertilizer manufacturer

izer, such as ammonium sulfate, which increases the

or mill operator in powder form, in bags, barrels, or in

level of raw material ?nes which may be used, and

bulk. To activate the binder mix, it is necessary to pro

enables one to maximize the yield of on-size" granules.

vide a liquid acid so as to cause the carbonate to evolve

Another object of the invention is to provide a binder 45 carbon dioxide and provide free ions to react with the

which promotes a free flowing granular fertilizer mate

water soluble sulfate salt to thereby form a complex salt

rial of a vary narrow granule sizing. Another object of

binder. Suitable acid activators include sulfuric acid,

the invention is to provide a product with binding abil

nitric acid, hydrochloric acid, phosphoric acid, other

ity which is useful in agglomerating high concentrations

of raw material ?nEs into a granular consistency as a

inorganic acids, and such organic acids as acetic acid.

Sulfuric, nitric, and phosphoric acids are preferred, as

complete mixed fertilizer or for ultimate use in fertilizer

they are additional sources of fertilizer values.

bulk blending applications.

Depending upon the particle size of the crystals to be

Another object of the invention is to provide a bind

agglomerated, the amount of granulation binder may

ing medium which increases the rate of agglomeration,

vary from a minimum of about 1 percent by weight of

and produces a higher level of on-size product in ammo 55 final product to about 10 percent. The preferred range

nium sulfate granulation.

of granulation binder is from about 3 percent to about 6

percent by weight of the ?nal agglomerated product,

DESCRIPTION OF PREFERRED

with about 3 to 5 percent by weight being the most

EMBODIMENTS

preferred concentration of granulation binder in the

The novel combination binder for use in the granula 60 granular product. For use as a granulation binder, the

tion of fertilizer materials such as ammonium sulfate

component mixture may be added to the crystals and

comprises a mixture of reactive carbonates and sulfates

batch blended before being processed in a granulation

in combination with a silicate strengthening agent and a

apparatus, i.e., drum granulator, pan granulator, pug

water-dispersing agent. A reactive acid, such as sulfuric

mill, or any other device designed to upgrade particle

acid, is utilized to initiate reaction between the sulfate 65 size; or the binder may be fed directly into the system

salt and the metal ion of the carbonate, to form a com

plex salt to bind the fertilizer material together. The

silicate material further provides a quick initial set to the

via a rate control device so that the desired rate of

binder addition may be obtained in a continuous process

operation. After the binder and fertilizer material are

5,078,779

introduced into the granulation device, an acid activa

tor, i.e., 92 percent to 93 percent sulfuric acid, is intro

duced into the granulator at a controlled rate of one

half to three-fourths of the weight of the binder, the

preferred means of introduction of the acid being via

spray system, so that good dispersion in the granulator

bed material is obtained. However, sparger systems or

the TVA "pipe reactor may be used. Water may also

be introduced into the granulator at a metered rate

which is appropriate to obtain the desired granule size.

The rate of water usage will vary, depending upon the

granulation device used, drying load, etc., and may be

determined experimentally for each batch operation or

for each individual fertilizer material source.

pelletizer, and the water and acid are then mixed with

the dry components. The components of the binder, i.e.,

the carbonate and sulfate materials, are activated during

this phase, to form the complex sulfate binder salt. After

granules have been formed in the pelletizing or granu

lating phase, they are next fed to a dryer system. As

indicated, the typical dryer system is a rotary type in

which product is fed continuously into one end of the

rotary drum with heat supplied at the end to which the

product is fed. Heated air is forced through the drum as

it rotates and granules are dried at from about 100' F. to

about 220' F. or higher. Other drying systems adequate

for this purpose could also be used. An additional

unique aspect of this invention is the effect that the

The binder of the preferred embodiment composed 15 binder has on the energy utilized to dry the product. A

signi?cant reduction in total drying requirement is often

primarily of a calcium carbonate salt, which reacts to

evolve carbon dioxide in the presence of acid. The free

calcium ions are then available to react with the water

noted, as seen by exit temperature, as a result of the

reactive mechanism of the binder.

soluble langbeinite to form complex salt combinations

There appears to be no upper limit to the level of

thereof. Thus, the acid is present to initiate reaction of 20 ?nes, or the speci?c range of ?ne ammonium sulfate

the carbonate and sulfate. Also present is the water

soluble silicate, which adds to the initial strength of the

green granules to aid in their transfer from the granula

which may be treated with the binders of the present

invention, as long as adequate binder material and liquid

phase is maintained, in the presence of suf?cient silicate

tor to the drying apparatus. This silicate strengthening

and acid activator to both assist initial agglomeration

agent also allows a quick initial set to the granules in the 25 and initiate or activate the novel binder of this inven

dryer, until the free water that is usually added to facili

tion. While the present description of the invention

tate granulation begins evaporation, and the crystals of

emphasizes the granulation of ammonium sulfate ?nes,

the complex salt combinations begin formation to ce

ment the granules together. A small amount of the

water dispersing chemical is bene?cial to reduce the

amount of water needed to facilitate granulation, and to

reduce the heat requirement load on the dryer system.

In the preferred embodiment of the invention, ammo

nium sulfate ?nes and carbonate/sulfate/acid/water

binder are allowed to granulate, with the wet granules 35

it should be noted that the invention is broadly applica

ble to nitrogen, phosphate, and potassium fertilizers in

general, and to full analysis or complete mix fertil

being collected from the discharge end of the granula

tor and transferred by any convenient conveying/tran

sport equipment into the drying apparatus, normally of

izers speci?cally.

The following illustrative examples are not intended

to limit the scope of this invention, but only to show

practical application of its use.

EXAMPLE 1

Under plant conditions, three tests were conducted

using ?ve percent binder as set forth in the present

invention. The binder formulation utilized comprises 70

the rotary type, wherein the free water may be evapo

rated and main constituents of the binder begin cement 40 percent calcium carbonate, 28.9 percent potassium

ing the agglomerates together. The dried granules are

then transferred to a screening operation, where the

desired size granules are collected for packaging.

The normally desired size range of fertilizer granules

magnesium sulfate (langbeinite), 1 percent potassium

silicate, and 0.10 percent sodium polymethacrylate. In

Test 1, the agglomerated material was sampled at the

pug mill discharge point. In Test 2, the composition

is from to 6 to 16 mesh. That is, the particles will pass 45 consisted of binder, ammonium sulfate, and enough urea

to maintain a 20 percent nitrogen level in the ?nal prod

uct. Test 2 sampling was after the pug mill discharge to

(minus 16 mesh) may be recycled to the granulator, and

the pan granulator for one minute. In Test 3 utilizing 5

through a standard 6 mesh screen, and remain on the

surface of a 16 mesh screen. The undersized granules

the oversized (plus 6 mesh) granules may be run

through a cnishing operation and reintroduced to the

screening system.

A factor in providing the reactive carbonate and

sulfate components of the binder composition of the

present invention is the particle size of such compo

nents. Appropriate particle sizes may range from not 55

greater than -l6 mesh U.S. sieve to 325 mesh U.S.

sieve scale or smaller. The most desirable sizing is from

60 mesh to 325 mesh.

The acid activator component of the present inven

percent binder, sampling wu after the pug mill dis

charge to the pan granulator for one minute. The sam

ples were dried in an oven overnight and the following

screen tests obtained.

'

Screen Size, Tyler

Test 1

% Retained

Test 2

% Retained

Test 3

k Retained

6

6 X 16

-l6

12.7

68.6

18.7

26.7

67.8

5.4

16.9

76.9

6.7

tion may be present as concentrated acid or as water

diluted acid. In either event, the amount of water pres

ent in the total mixture may be determined and adjusted

by the operator at the time of granulation, so as to ob

tain the most favorable results.

It is noted that the percentage of on-size (6X16)

product was excellent in each case, with the pan granu

lated product somewhat higher than straight pug mill

agglomerated material (Test 1). In this plant test, the

As previously indicated, the ammonium sulfate ?nes 65 activating sulfuric acid was present in the amount of

one-half to three-forths of the weight of the binder

and the novel binding agent of this invention are prefer

composition. Thus, for each 100 pounds of binder per

ably intimately mixed and physically blended in the dry

ton of product, sulfuric acid was present in the amount

form. The dry mix is then fed into the granulator or

5,078,779

85 percent by weight of a reactive carbonate, selected

from the group consisting of calcium carbonate, dolo

of 50 to 75 pounds per ton. The pH of the wet granules

from the granulator is about 2.0.

mite, magnesium carbonate, potassium carbonate, am

EXAMPLE 2

monium carbonate, and mixtures thereof from about 15

A comparative plant trial was conducted to demon- 5 to about 40 percent by weight of a reactive sulfate,

strate the superiority of granules produced using ?ve

selected from the group consisting of langbeinite, kie

percent binder of the present invention over granules

serite, magnesium sulfate salts, potassium sulfate salts,

produced using ligninsulfonate as a binder at 0.5%

and mixtures thereof from about 0.5 to about 5 percent

addition.

by weight silicate strengthener, and from about 0.1 to

about 3.0 percent by weight of a water dispersant se

lected from the group consisting of polymethacrylate,

bentonite, sodium phosphate, lignin sulfonate, and or

More durable granules were produced using the

binder of the present invention, as re?ected by granule

crushing strength and percent attrition. In addition, the

present binder composition displayed more ability to

ganic dispersing agents.

keep material non-caking and free ?owing than the

2. A binder as set forth in claim 1, wherein said sili

15 cate is potassium silicate.

lignin sulfonate binder.

The ammonium sulfate granules produced using

3. A binder as set forth in claim 1, consisting essen

0.5% lignin sulfonate displayed a reduced critical rela

tially of from about 65 to about 75 percent by weight

reactive carbonate, from about 20 to about 35 percent

by weight reactive sulfate, from about 0.5 to about 2

tive humidity compared to ammonium sulfate granu

lated using the binder of this invention. Moisture pick

up was observed at 70% relative humidity for the 0.5% 20 percent by weight silicate strengthener and from about

lignin product while the product manufactured with

0.1 to about 2 percent by weight water dispersant.

this invention recorded no moisture pick-up at this rela

tive humidity level.

4. A binder as set forth in claim 3, wherein said reac

tive carbonate is calcium carbonate, said reactive sulfate

Free ?ow tests on granules manufactured with 0.5%

is langbeinite, said silicate is potassium silicate, and said

lignin tended to cake more quickly than those granules 25 water dispersant is polymethacrylate.

manufactured with binder of this invention, as evi

5. A binder as set forth in claim 3, consisting essen

denced by results below.

tially

of about 70 percent by weight calcium carbonate,

The granules prepared in accordance with the pres

from about 28 to about 30 percent by weight langbein

ent invention also had an advantage in on-size 6X 16

mesh material with 89.6 percent on-size compared with 30 ite, about 1 percent by weight potassium silicate, and

from about 0.1 to about 0.5 percent by weight poly

85.2 on-size for the lignin sulfonate binder added prod

methacrylate.

uct.

6. A binder composition for the granulation of partic

ulate fertilizer, said composition being reactive in the

Lignin Sulfonale (0.5%)

Invention (2%) H2SO4

presence of an acid activator and water and consisting

Crushing

Strength

3.7

4.4

(lbs)

Attrition (%)

0.45

0.03

essentially of an admixture of from about 60 to about 85

percent by weight of a reactive carbonate, selected

from the group consisting of calcium carbonate, dolo

mite, magnesium carbonate, potassium carbonate, am

Noncaking

monium carbonate, and mixtures thereof from about 15

Test, 70%

RH

70 F.

Zero Tap

0.9

39.0

39.1

0.1

Note: 1.0 gm Wt. Gain

0.7

to about 40 percent by weight of a reactive sulfate,

selected from the group consisting of langbeinite, kie

(Km)

1 Tap (grns)

2 Tap (grns)

Starting Wt. 39.1 grns

Note: 0.7 gms Wt. Loss

Starting Wt. 40.4 gms

88.5

8.4

3.3

98.3

23.2

8.7

serite, magnesium sulfate salts, potassium sulfate salts,

and mixtures thereof from about 0.5 to about 5 percent

45 by weight silicate strengthener, and from about 0.1 to

Screen Test

#6

#14

#16

about 3.0 percent by weight of a water dispersant.

7. A binder as set forth in claim 6 wherein said silicate

% Passing

The above examples demonstrate the superiority and

utility of the present invention, which is capable of

providing granular ammonium sulfate of a desired-size

is potassium silicate.

8. A binder as set forth in claim 6 consisting essen

tially of from about 65 to about 75 percent by weight

reactive carbonate, from about 20, to about 35 percent

by weight reactive sulfate, from about 0.5 to about 2

percent by weight silicate strengthener, and from about

0.1 to about 2 percent by weight water dispersant.

range. It is to be understood that the above description 55 9. A binder as set forth in claim 8 wherein said reac

tive carbonate is calcium carbonate, said reactive sulfate

of the present invention is susceptible to various modifi

cations, changes, and adaptations by those skilled in the

art, and that the same are to be considered to be within

the scope of the present invention, which is set forth by

the claims which follow.

We claim

1. A reactive binder composition for the granulation

of ammonium sulfate, said composition being reactive in

the presence of an acid activator and water and consist

ing essentially of an admixture of from about 60 to about 65

is langbeinite, said silicate is potassium silicate, and said

water dispersant is polymethacrylate.

10. A binder as set forth in claim 8 consisting essen

tially of about 70 percent by weight calcium carbonate,

from about 28 to about 30 percent by weight langbein

ite, about 1 percent by weight potassium silicate, and

from about 0.1 to about 0.5 percent by weight poly

methacrylate.

.

'

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENT NO.

5,073,779

DATED

January 7, 1992

'NVENTOR(5) 1

Richard H. Van de HaIIe et aI

It is certified that error appears in the above-identified patent and that said Letters Patent

is hereby corrected as shown below:

CoIumn 3, I ine 50, finEs shouId read -fines-- .

CoIumn 6, I ine 66, three-forths shouId read --three-fourths-- .

CoIumn 8, I ine 1, after carbonate deIete the comma ,; Iine 4, after

thereof insert a comma -- , --; Iine 5, after suIfate deIete the

comma ,; I ine 8, after thereof insert a comma -- , --; Iine 37,

after carbonate deIete the comma ,; I ine 40, after thereof

insert a comma -- , --; I ine 41, after suI fate deI ete the comma -- , --;

I ine 44, after thereof insert a comma -- , --; I ine 46, after

di spersant and before the period insert --seIected from the group

consisting of poIymethacryI ate, bentonite, sodium phosphate, I ignin

suIfonate, and organic dispersing agents-- .

Signed and Sealed this

Twenty-?rst Day of December, 1993

Ami-

@444 W '

BRUCE LEI-{MAN

Arresting Officer

Commissioner of Pater: and Trademarks

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Efficient Strength Training by Matt BrzyckiDocument5 pagesEfficient Strength Training by Matt Brzyckigregorio919100% (2)

- Production of Pure Platinum and Palladium From DoreDocument4 pagesProduction of Pure Platinum and Palladium From DoreLựuLiềuLìNo ratings yet

- Rexnord® High Performance Bucket Elevators PDFDocument12 pagesRexnord® High Performance Bucket Elevators PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Final - Phosphate Fertilizer PlantsDocument20 pagesFinal - Phosphate Fertilizer PlantsJavier Alejandro Rodriguez MelgozaNo ratings yet

- AOne Per Bus How To Sta ASma BusDocument43 pagesAOne Per Bus How To Sta ASma BusJavier Alejandro Rodriguez MelgozaNo ratings yet

- 6 Vol. 4, Issue 1, January 2013, IJPSR, RE 806, Paper 6Document13 pages6 Vol. 4, Issue 1, January 2013, IJPSR, RE 806, Paper 6Isma Yanti100% (1)

- RCE Brochure 05 - 15Document10 pagesRCE Brochure 05 - 15Javier Alejandro Rodriguez MelgozaNo ratings yet

- A Rheological Study of Ammonium Phosphate SlurriesDocument23 pagesA Rheological Study of Ammonium Phosphate SlurriesJavier Alejandro Rodriguez MelgozaNo ratings yet

- Material SpecificationsDocument5 pagesMaterial SpecificationsJavier Alejandro Rodriguez MelgozaNo ratings yet

- Outcome Effects of Single-Set Versus Multiple-Set TrainingDocument20 pagesOutcome Effects of Single-Set Versus Multiple-Set Trainingdavesta100% (1)

- Spiral Nozzle Pigtail BETE - TF-imperialDocument2 pagesSpiral Nozzle Pigtail BETE - TF-imperialBasil OguakaNo ratings yet

- Material Chemistry and Microstructure Stainless Steel PDFDocument3 pagesMaterial Chemistry and Microstructure Stainless Steel PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Centrifugal Pumps: Aiche Equipment Testing ProcedureDocument6 pagesCentrifugal Pumps: Aiche Equipment Testing ProcedureJavier Alejandro Rodriguez MelgozaNo ratings yet

- Material Chemistry and Microstructure Stainless Steel PDFDocument3 pagesMaterial Chemistry and Microstructure Stainless Steel PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Us 4619684Document10 pagesUs 4619684Javier Alejandro Rodriguez MelgozaNo ratings yet

- Datasheet How To Weld 2205 Hpsa Imperial Outokumpu en AmericasDocument7 pagesDatasheet How To Weld 2205 Hpsa Imperial Outokumpu en AmericasJavier Alejandro Rodriguez MelgozaNo ratings yet

- Ashland Derakane Chemical Resistance Compatibility ChartDocument24 pagesAshland Derakane Chemical Resistance Compatibility ChartJavier Alejandro Rodriguez MelgozaNo ratings yet

- CEP Article - Litzen and BravoDocument8 pagesCEP Article - Litzen and BravoA MNo ratings yet

- 086EAHPPPGM Listado de PartesDocument1 page086EAHPPPGM Listado de PartesJavier Alejandro Rodriguez Melgoza100% (1)

- Bodyweight Circuits Sheet1Document22 pagesBodyweight Circuits Sheet1Javier Alejandro Rodriguez MelgozaNo ratings yet

- Heat Exchanger FoulingDocument9 pagesHeat Exchanger FoulingJavier Alejandro Rodriguez MelgozaNo ratings yet

- Past Present and Future of The Duplex Stainless SteelsDocument10 pagesPast Present and Future of The Duplex Stainless SteelsbayumahardikaNo ratings yet

- Portable Heavy Duty Horiz Screening Plant FeedDocument8 pagesPortable Heavy Duty Horiz Screening Plant FeedJavier Alejandro Rodriguez MelgozaNo ratings yet

- NMDTM PhosphoricAcidDocument10 pagesNMDTM PhosphoricAcidacas35No ratings yet

- Reliability DistributionDocument16 pagesReliability DistributionJavier Alejandro Rodriguez MelgozaNo ratings yet

- Phillips Dietary Protein AthletesDocument8 pagesPhillips Dietary Protein AthletesJavier Alejandro Rodriguez MelgozaNo ratings yet

- Prac Rel Tools Refn ChemPltDocument9 pagesPrac Rel Tools Refn ChemPltJavier Alejandro Rodriguez MelgozaNo ratings yet

- Rouge: The Intrinsic Phenomenon in 316L Stainless Steel - A Key Material For Biopharmaceutical FacilitiesDocument8 pagesRouge: The Intrinsic Phenomenon in 316L Stainless Steel - A Key Material For Biopharmaceutical FacilitiesJavier Alejandro Rodriguez MelgozaNo ratings yet

- Rep BrochureDocument4 pagesRep BrochureqbangkaNo ratings yet

- Brain Sciences: Exercise Strengthens Central Nervous System Modulation of Pain in FibromyalgiaDocument13 pagesBrain Sciences: Exercise Strengthens Central Nervous System Modulation of Pain in FibromyalgiaJavier Alejandro Rodriguez MelgozaNo ratings yet

- Q2 Science 9 Module 2 1editedDocument20 pagesQ2 Science 9 Module 2 1editedSamantha BecieraNo ratings yet

- Applied Sciences: Gold Nanoparticles For Drug Delivery and Cancer TherapyDocument21 pagesApplied Sciences: Gold Nanoparticles For Drug Delivery and Cancer TherapyGénesis OsorioNo ratings yet

- Biological Recovery of Metals From Electronic Waste Polluted Environment Using MicroorganismsDocument33 pagesBiological Recovery of Metals From Electronic Waste Polluted Environment Using MicroorganismsRohan BachhavNo ratings yet

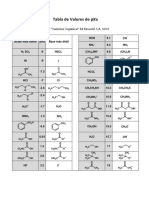

- Tabla de Valores de Pka: S. Ege "Química Orgánica" Ed Reverté S.A. 1997Document7 pagesTabla de Valores de Pka: S. Ege "Química Orgánica" Ed Reverté S.A. 1997loaca95No ratings yet

- Review On Calcium-And Magnesium-Based Silicates For Bone Tissue Engineering ApplicationsDocument17 pagesReview On Calcium-And Magnesium-Based Silicates For Bone Tissue Engineering ApplicationsWeihao CaiNo ratings yet

- Sustainability 14 08783 v2Document27 pagesSustainability 14 08783 v2Shaker QaidiNo ratings yet

- Biochem Pre-Lab 3bDocument2 pagesBiochem Pre-Lab 3bOla Anna GamutinNo ratings yet

- D BlockDocument17 pagesD Block145556No ratings yet

- 4 - CHAPTER With NumericalsDocument356 pages4 - CHAPTER With NumericalsSindhuja PachikaNo ratings yet

- TRANSISIDocument61 pagesTRANSISIAlanNo ratings yet

- Stoichiometry WorksheetDocument4 pagesStoichiometry WorksheetLily PanNo ratings yet

- Actividades PlantasDocument3 pagesActividades PlantasMARIA ISABEL SANCHEZ PIEDRAS100% (2)

- Stainless Steel PlateDocument19 pagesStainless Steel PlateHarsh AdvaniNo ratings yet

- CBSE NCERT Solutions For Class 9 Science Chapter 3: Back of Chapter QuestionsDocument9 pagesCBSE NCERT Solutions For Class 9 Science Chapter 3: Back of Chapter QuestionsNarayanamurthy AmirapuNo ratings yet

- Technology of Making Tablets: Murat KizaibekDocument79 pagesTechnology of Making Tablets: Murat KizaibekSangram KendreNo ratings yet

- RXN of Sulphuric Acid With SaltsDocument16 pagesRXN of Sulphuric Acid With SaltsSteve ClowesNo ratings yet

- Read These Instructions FirstDocument7 pagesRead These Instructions FirstSalman Ul MoazzamNo ratings yet

- PLATINGDocument1 pagePLATINGdineshNo ratings yet

- Project FileDocument18 pagesProject FileAdarsh SrivastavaNo ratings yet

- GlycolysisDocument21 pagesGlycolysisAli AlqumaNo ratings yet

- Incineration of Fluoropolymers PDFDocument65 pagesIncineration of Fluoropolymers PDFsubbarao1967No ratings yet

- Section 8.5 Enzymes Can Be Inhibited by Specific MoleculesDocument8 pagesSection 8.5 Enzymes Can Be Inhibited by Specific MoleculesMohamed FaizalNo ratings yet

- Glenhill School Manduadih, Varanasi: Chemistry Project FileDocument15 pagesGlenhill School Manduadih, Varanasi: Chemistry Project FileashishNo ratings yet

- Tissue Engineered Scaffold Fabrication Methods For Medical ApplicationsDocument26 pagesTissue Engineered Scaffold Fabrication Methods For Medical ApplicationsSarah FathiNo ratings yet

- PD Ca (ClO) 2Document3 pagesPD Ca (ClO) 2Michelle MendozaNo ratings yet

- Fermentation and Distillation of Corn StarchDocument9 pagesFermentation and Distillation of Corn StarchI. Murali Krishna100% (1)

- Nanofiltration and Ultrafiltration Ceramic Membranes For Food Processing A Mini Review 2155 9589 1000140 PDFDocument13 pagesNanofiltration and Ultrafiltration Ceramic Membranes For Food Processing A Mini Review 2155 9589 1000140 PDFGaneshNo ratings yet

- Formula Writing and Naming of CompoundsDocument24 pagesFormula Writing and Naming of CompoundsKentCastro100% (2)

- Geology of Titanium-Mineral Deposit Force1991Document113 pagesGeology of Titanium-Mineral Deposit Force1991Nicouux MagnetiteNo ratings yet