Professional Documents

Culture Documents

Smart Com 450 Manual English V5 - 14

Uploaded by

Anonymous kcSG2vtv3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smart Com 450 Manual English V5 - 14

Uploaded by

Anonymous kcSG2vtv3Copyright:

Available Formats

Becker Smart Com 450 Leaky Feeder

Training Manual

V5.14

0.1 150 MHz or 450 MHz?

Smart Com 150 is well suited for hard-rock mines where

lateral coverage from the LF cable is not critical.

Smart Com 450 is better suited to room and pillar or

longwall mines as the signal propagates up to 4x better.

UHF cable costs approximately 300% more than VHF,

however the increased coverage may result in a more

attractive solution.

Table of Contents

1.0 Two-Way Radio Basics

2.0 Leaky Feeder Concept

3.0 RF Power Measurement

4.0 System Layout

5.0 Splitter Installation

6.0 Amplifier Spacing

7.0 Base Station Installation

8.0 LF Cable Installation

9.0 Passive Component Installation

10.0 Amplifier Installation

11.0 DC Supply Installation

12.0 Troubleshooting

13.0 Maintenance

Contact Information

1.0 Two-Way Radio Basics

1.1

1.2

1.3

1.4

1.5

Two-Way Radio

Simplex Radio System

Half-Duplex Radio

Leaky Feeder is.?

Real Time Communications

1.1 Two-Way Radio

VHF/UHF Radios are available as stationary (base),

hand-held (portable), vehicle-mounted (mobile),

integrated with cap lamp batteries or radio-modem (data

applications).

Radios support multiple channels and can be configured

to interface with telephone systems.

Trunked voice radio is cost-competitive when 200 or

more radios are used on-site. Trunked systems also

provide private voice conversations.

1.2 Simplex Radio System

VHF

150 MHz TX

150 MHz RX

UHF

455 MHz TX

455 MHz RX

VHF

150 MHz TX

150 MHz RX

UHF

455 MHz TX

455 MHz RX

Transmit (TX) and Receive (RX)

frequencies are the same.

UHF is a good choice for room &

pillar type mines.

Line of sight communication (LOS):

1.3 Half-Duplex Radio

Obstructions or extreme distances between the radios will

prevent simplex radio from working. To remedy this a

Repeater is added to create a half duplex communication

network.

Repeater

170 MHz RX

150 MHz TX

Radio #2

Radio #1

PTT

150 MHz RX

150 MHz RX

170 MHz TX

170 MHz TX

Mountain

1.4 Leaky Feeder is?

Leaky Feeder cable runs along tunnels and emits and

receives radio signals. The cable is leaky since it has

gaps or slots in its outer shielding to allow signal to leak

into or out of the cable along it's entire length.

Radio Receive

150 MHz VHF

475 MHz UHF

Radio Transmit

170 MHz VHF

455 MHz UHF

1.5 Real Time Communications

Leaky Feeder acts like a long antenna, connecting Radios

to Repeaters.

2.0 Leaky Feeder Concept

2.1 Leaky Feeder Highway

2.2 Leaky Feeder RF Spectrum

2.2.1 Smart Com 150 Band pass

2.2.2 Becker Smart Com 150 Band pass

2.2.3 Smart Com 450 Band pass

2.3 Data - Smart Com + Ethernet

2.4 Data - Low Speed, Mine-Wide Data

2.1 Leaky Feeder Highway

Leaky Feeder is analogous to a

divided, multi-lane highway.

A single highway (cable) carries

several lanes of traffic

(channels) in opposite directions

(band-pass) with a median

(guard band) between them to

prevent collisions.

2.2 Leaky Feeder RF Spectrum

Base Station & Repeaters

Downstream

Downstream channels

are connected directly to

Repeater transmitter,

thus all channels are at

same strong RF power.

Upstream

Guard Band

Downstream channels

drive Local Diagnostic

LEDs.

Frequency

Upstream signals are

at different RF power

depending (mainly)

on distance between

U/G radio and LF

cable

2.2.3 Smart Com 450 Band pass

8 Channels Voice/Data

All Downstream radio

signals are at same RF

power

8 Channels Voice/Data

RF Power

Upstream signals are at

different RF power

depending (mainly) on

distance from cable.

Upstream

Ethernet

20-42 MHz

Downstream

Ethernet

140-185 MHz

Upstream

Voice

450-455

Guard Band

Base Station & Repeaters

Downstream

Voice

475-480

Frequency

Note: Opposite to Smart Com 150, Smart Com 450 Upstream is the lower frequency.

Smart Com 450 Band pass

Downstream Signals

475-480 MHz

Upstream Signals

450-455 MHz

2.3 Data Smart Com + Ethernet

Connect industry standard cable modems to

Smart Com to provide 54 Mbps Ethernet

hotspots.

Connect standard Ethernet equipment including

wireless networking equipment.

VOIP Handset

SP2

CMI

Cable

Modem

WLAN

IP Camera

Non-Intrinsically Safe

equipment

PC

2.4 Data Low Speed, Mine-Wide Data

1.

Low-speed (9600 bps) wireless networks can run over Leaky Feeder.

2.

Master Radio Modem in Base Station is connected to main PC/PLC.

3.

Slave units are connected to PLCs or RTUs.

3.0 RF Power Measurement

3.1

3.2

3.3

3.4

Relative Measurements

Decibels: dB and dBm

Gain and Loss using dBs

dBs and Power

3.1 Relative Measurements

+25C

0C

-25C

Temperature units are C.

Reference level is 0 C.

All temperatures are relative,

the numbers just indicate

higher/lower than reference

level of 0 C.

3.2 Decibels: dB and dBm

dBs are ratios of RF power levels that simplify

calculations of RF loss and gain.

Calculating power level differences in dB works

just like calculating temperature differences in

C.

dBm is a measurement of the absolute power,

not a power ratio. Power can be expressed as

Watts, dBm and volts, but dBm and dBs work

together to make things easy. No kidding.

3.3 Gain and Loss using dBs

Gain or loss is the difference between output and input in

dBm and the result is expressed in decibels (dB).

What is RF loss through 100 m LF cable?

-4 dBm -0 dBm = -4 dB

100 meters of Smart Com

150/150IS Leaky Feeder

cable has 4 dB loss.

Output RF power -4 dBm

Input RF power 0 dBm

What is the gain of the LF amplifier?

+4 dBm (-20 dBm) = +24 dB

Input RF power -20 dBm

Output RF power +4 dBm

Leaky Feeder amplifier provides

24 dB gain.

3.4 dBs and Power

Decibels are logarithmic. Increasing a signal by 3 dB

doubles the power, decreasing a signal by 3 dB cuts the

power in half. An increase of 10 dB is 10x the power.

Gain/

Loss

+3 dB

+ 6 dB

+10 dB

-10 dBm -6 dBm -3 dBm 0 dBm

3 dBm

6 dBm

10 dBm

2x

4x

10x

-10 dB

1/10

-6 dB

1/4

-3 dB

1/2

Power

4.0 System Layout

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

Base Station Location

LF Cable Layout

System Layout Example

Smart Com 150 Gains/Losses

Smart Com 150IS Gains/Losses

Smart Com 450 Gains/Losses

Smart Com 150IS System Layout

Smart Com 150IS System Notes

4.1 Base Station Location

IS Systems:

Must be installed on surface (Safe Area).

Non-IS Systems:

Non-IS Systems can benefit from the Base Station

installed underground as all four Head End branches

may be used. This reduces the requirement for U/G

DC supplies and also provides a form of redundancy.

Another benefit of U/G Base Stations is that it

reduces the number of amplifiers in cascade and

thus the noise floor.

4.2 LF Cable Layout

LF cable must be installed wherever communications is

required.

Allow for 10% extra cable when laying system out to

accommodate for drip loops and cable slack.

Each cable run must be terminated by either a

Termination Unit or Stope Antenna.

Stope Antennas increase coverage by up to 200-300%

to provide coverage into stopes and other areas where

cable damage is likely.

4.3 System Layout Example

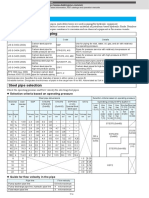

4.6 Smart Com 450 Gains/Losses

5.0 Splitter Installation

5.1

5.2

5.3

5.4

Smart Com 150/150IS SP2 Splitters

Smart Com 150/150IS SP3 Splitters

Smart Com 450 SP2 Splitters

Smart Com 450 SP3 Splitters

5.3 Smart Com 450 SP2 Splitters

Smart Com 450 SP2 splitters split the power

into two equal branches.

>OUT:

Input

100%

1 50%

IN>

SP2

2 50%

>OUT:

280m

3m

-70m

210m

-70m

+350m

-4 dB

-70m/-230ft

-70m

-70m

210m

-4 dB

-70m/-230ft

5.4 Smart Com 450 SP3 Splitters

Smart Com 450 SP3 splitters have all higher

loss branches.

>OUT:

Input

100%

1 33%

>OUT:

IN>

SP3

33% 3

>OUT:

2 33%

230m

3m

-120m

-120m

+350m

-120m

-7 dB

-120m/-395ft

230m

230m

-7 dB

-120m/-395ft

-7 dB

-120m/-395ft

6.0 Amplifier Spacing

6.1 Amplifier Spacing

6.2 500m vs 350m Spacing

6.3 150/150IS Amplifier Spacing, Example 1

6.4 150/150IS Amplifier Spacing, Example 2

6.5 150/150IS Amplifier Spacing, Example 3

6.6 150/150IS Amplifier Spacing, Example 4

6.7 150/150IS Amplifier Spacing, Example 5

6.8 450 Amplifier Spacing, Example 1

6.9 450 Amplifier Spacing, Example 2

6.10 450 Amplifier Spacing, Example 3

6.11 450 Amplifier Spacing, Example 4

6.12 450 Amplifier Spacing, Example 5

6.13 Smart Com 150/150IS Amplifier Spacing Quiz

6.1 Amplifier Spacing

Line Amplifiers are installed to compensate for cable and

splitting losses.

Maximum

Amplifier

Gain (dB)

Amplifier

Spacing

Cable Loss at

highest

frequency

Reserve

Gain (dB)

Smart Com

150/150IS

(RNG-AMP,

RIS-AMP, BSCAMP)

28

500 m

1650 feet

23 dB/500 m

Smart Com 450

(450-AMP)

25

350 m

1150 feet

21 dB/350 m

RNG-AMP and RIS-AMP line amplifiers require first amplifier on

each Head End branch be spaced 350 m from Head End! BSCAMP amplifiers can be spaced 500m from head end.

6.2 500m vs 350m Spacing

500 meter spacing

Smart Com 150/150IS.

All other LF systems have 350 meter

350 meter spacing

Smart Com 450.

amplifier

spacing.

All other LF

competitors.

6.8 450 Amplifier Spacing, Example 1

280 meters

+350 Meters

3m

210 meters

450-AMP

3m

210 meters

230 meters

+350 Meters

3m

230 meters

450-AMP

230 meters

450-AMP

6.9 450 Amplifier Spacing, Example 2

280 meters

+350 Meters

3m

450-AMP

160 meters

3m

160 meters

160 meters

450-AMP

6.10 450 Amplifier Spacing, Example 3

180 meters

+350 Meters

100m

60 meters

450-AMP

3m

60 meters

60 meters

450-AMP

6.11 450 Amplifier Spacing, Example 4

280 meters

+350 Meters

3m

450-AMP

60 meters

100m

60 meters

60 meters

450-AMP

6.12 450 Amplifier Spacing, Example 5

180 meters

+350 Meters

100m

450-AMP

-40 meters

100m

-40 meters

-40 meters

450-AMP

7.0 Base Station Installation

7.1

7.2

7.3

7.4

7.5

7.6

What is a Base Station?

Typical Smart Com 150 Base Station Schematic

Base Station Location

Smart Com 150 Base Station RF Flow

Leaky Feeder Head End

Smart Com 150 Head Ends

7.6.1 RNG-Hxx Head End

7.6.2 BSC-HE Head End

7.6.3 RNG-Hxx Head End Indications and Controls

7.6.4 BSC-HE Head End Indications and Controls

7.6.5 RNG-Hxx RF Distribution

7.6.6 BSC-HE RF Distribution

7.6.7 RNG-Hxx Remote Diagnostic Connections

7.6.8 BSC-HE Remote Diagnostic Connections

7.6.9 Smart Com 150 Downstream RNG-Hxx

7.6.10 Smart Com 150 Downstream BSC-HE

7.6.11 Smart Com 150 Channel Plan

7.7 Smart Com 450 Head End

7.7.1 Smart Com 450 Head End Indications

7.7.2 Smart Com 450 RF Distribution

7.7.3 Smart Com 450 Remote Diagnostics

7.7.4 Smart Com 450 Channel Plan

7.8 Base Station Power Supplies

7.9 Voice Repeaters

7.10 Telephone Interconnects

7.1 What is a Base Station?

Its the brains of the Leaky Feeder

network, housed in a 19 rack-mount

cabinet.

Inside the Base Station are the

interfaces to the Leaky Feeder network:

Leaky Feeder Head End

RF Distribution

Power Supplies

Radio Repeaters, surface coverage

antennas

CMTS

CMTSI (RNG-Hxx head end only if needed)

Server PC

Mine Pager Phone Interconnect

Telephone Interconnect

7.3 Base Station Location

Base Stations for Intrinsically Safe systems need

to be on surface (Safe Area).

Dry, heated area with reliable, clean AC power.

If located outdoors a climate controlled NEMA

4/4X enclosure is required.

Base Station should be placed so that access to

both front and rear doors is possible.

LF cables can enter Base Station cabinet

through top of cabinet or through access panel

on bottom of cabinet. Cable glands required to

maintain NEMA rating of cabinet.

7.5 Leaky Feeder Head End

The Head End is the interface between Base

Station equipment such as Repeaters and the

Leaky Feeder cables.

The Head End unit also injects DC power onto

the Leaky Feeder cable to power the LF Line

Amplifiers.

7.7 Smart Com 450 Head End

The Smart Com 450 system head end provides connection to

8 Tx/Rx channels. The head end does not pass DC voltage

onto the Leaky Feeder network or provide pre-amplification.

Front View, 3U high

Insertion Loss

CMTS Upstream (20-42 MHz)

14 dB

CMTS Downstream (140-185 MHz)

14 dB

Voice Upstream (450-455 MHz)

22 dB

Voice Downstream (475-480 MHz)

35 dB

7.7.1 Smart Com 450 Head End Indications

Front panel LEDs

show the remote

diagnostics state.

Downstream

LED should

always be ON.

Downstream LED

ON = Pilot ON,

Upstream LED ON

= Amplifier data

being received.

These LEDs can be

used to calibrate a

single Tx channel at a

time, all other Tx ports

must be properly

terminated during the

test.

Enclosure Front LEDs

Once the Tx channel

is connected, adjust

the signal level so

the green OK LED is

lit.

High LED: > 31 dBm

Enclosure Back LEDs

OK LED: <=31 dBm,

>= 28 dBm

LO LED: < 28 dBm

7.7.2 Smart Com 450 RF Distribution

Voice Repeater Transmitter

CMTS

Rack Mount Server

Down: -9 dBm

Up: -39 dBm

Voice: -5 dBm

CMTS Downstream: -21 dBm

Voice: 30 dBm

Pilot: -25 dBm

CMTS Upstream: -23 dBm

RS232

7.7.3 Smart Com 450 Remote Diagnostics

Remote Diagnostics

Connection

Ensure Downstream Pilot is

active (front panel LEDs).

Connect serial crossover cable

between the Head End and the

server PC running the Remote

Diagnostic software.

Server polls each amplifier in the

system.

7.7.4 Smart Com 450 Channel Plan

7.8 Base Station Power Supplies

PS-110, PS-220

13.8 VDC, 40 Amp redundant

system (2 x 20A supplies).

Battery terminals to create

UPS. In-line fuse required

between battery and P/S

(supplied with RNG-BAT).

Voltage & Current Meter.

CSA certified.

Not CE certified.

CSA Certified.

CE certified.

Requires UPS.

PS-UNIV-CE

7.9 Voice Repeaters

One voice repeater is required for each voice channel.

Typically supplied by Varis Distributor.

RNG-RPT1

(one channel)

RNG-RPT5

(two channel)

7.10 Telephone Interconnects

INT-TEL

Telephone Interconnects connect a PABX telephone

line to a LF radio channel.

Enables one non-private telephone connection per

connected channel.

Radios must be equipped with DTMF keypads to

access the Telephone Interconnect.

Typically

supplied by Varis

Distributor

INT-TEL-CE

8.0 LF Cable Installation

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

LF Cable Installation Drift

LF Cable Installation Shaft

IS Leaky Feeder Installation

VHF LF Cable & Tools

UHF LF Cable & Tools

RNG-500 LF Cable Preparation

RCF12-50 LF Cable Preparation

Smart Com 150 Component Connection

Smart Com 450 Component Connection

8.5 UHF LF Cable & Tools

Smart Com 450 uses RCF12-50

LF cable.

50 ohm impedance.

Copper coated aluminum

center conductor, corrugated

copper jacket.

Cable reel sizes tbd,

depending on reel length.

Installation requires:

Hacksaw

RFS12-L cable preparation

tool (pictured)

8.7 RCF12-50 LF Cable Preparation

Cut the cable with a

hacksaw.

Follow RFS TRIM-12-L cable

preparation tool instructions.

Optionally, slide on heat

shrink tubing.

Install screw-on N-Type

connector.

Optionally, apply heat to

shrink tubing to seal

connector.

8.9 Smart Com 450 Component Connection

Amplifier and Splitter

connectors marked

HEADEND must be

connected to LF

cable coming from

Head End.

Torque nut to 1 Nm (8 inchlbs). Specific SMA-Type

torque wrenches available

from Tessco for connections.

Optionally, waterproof

connector with Heat Shrink.

9.0 Passive Component Installation

9.1

9.2

9.3

9.4

9.5

9.6

9.7

System Impedance

Two-way Splitter Installation

Three-way Splitter Installation

Termination Unit Installation

Stope Antenna Installation

Splice Unit Installation

Smart Com 150IS Barrier Unit Installation

9.1 System Impedance

Smart Com 150/150IS systems

characteristic impedance is 75 ohms.

Smart Com 450 systems characteristic

impedance is 50 ohms.

This impedance difference means you

cannot mix Smart Com 150/150IS and

Smart Com 450 components or cable in a

single network!

9.2 Two-Way Splitter Installation

RNG-SP2

H/E

RIS-SP2

H/E

UHF-SP2

H/E

Equivalent

LF cable

lengths

(loss) of

splitter

branches

Smart

Com

150/

150IS

Smart

Com

450

Branch 1, 2

100 m

(325)

70 m

(230)

Smart Com 150/150IS Splitters have jumpers that

can:

Terminate an unused/damaged branch.

Inject RF Only for runs of LF with no

amplifiers so that short circuits in the LF cable

will not bring down the system.

9.3 Three Way Splitter Installation

RIS-SP3

RNG-SP3

H/E

3

1

2

UHF-SP3

H/E

H/E

Equivalent LF cable lengths

(loss) of splitter branches

Branch 1

Smart Com Smart Com

150/150IS

450

100 m (325) 120 m (395)

Branches 2 & 3

200 m (650) 120 m (395)

9.4 Termination Unit Installation

RNG-TER

RIS-TER

Termination Units are

required at the end of

each LF cable to absorb

RF signals, preventing

reflections and dead

zones.

UHF-TER

9.6 Splice Unit Installation

RNG-SPL

RIS-SPL

UHF-SPL

Splice Unit is used for cable

repairs.

Smart Com 150/

150IS

RNG-SPL

RIS-SPL

Smart Com 450

UHF-SPL

RF Loss

0.1 dB, 0 m

0.1 dB, 0 m

10.0 Amplifier Installation

10.1 Smart Com 150 Amplifier Installation

10.2 Smart Com 150IS Amplifier Installation

10.3 Smart Com 450 Amplifier Installation

10.4 The 3 Meter Rule

10.5 Amplifier Gain Control

10.6 Smart Com 150 Amplifier Local Diagnostics

10.7 Smart Com 450 Amplifier Local Diagnostics

10.8 Smart Com 150 Amplifier AGC

10.9 Smart Com 450 Amplifier AGC

10.10 Smart Com 150 Amplifier Manual Gain Control

10.11 Smart Com 450 Amplifier Manual Gain Control

10.12 Smart Com 150 Amplifier Remote Diagnostics

10.13 Smart Com 450 Amplifier Remote Diagnostics

10.3 Smart Com 450 Amplifier Installation

450-AMP

HEADEND

terminals connect

to the LF cable

coming from the

Base Station.

RF Level

Rotary switch

adjusts Gain if in

manual mode

Used to calibrate in

Manual gain mode.

Amplifier ID

Jumper is to select the

amplifiers mode, Automatic

or Manual. Automatic is

recommended.

10.5 Amplifier Gain Control

Amplifiers compensate for the RF (Radio Frequency) cable

and splitting losses in the cable run preceding it in the

Downstream direction.

RF High

RF Low

Amplifier Gain

RF OK

10.7 Smart Com 450 Amplifier Local Diagnostics

If there is no Pilot active then the Red (Low) LED

will be on.

Any LED lit means DC voltage

OK.

Amber LED indicates pilot level is

too high.

Green LED indicates pilot level is

OK. Green OK LED thresholds

are AGC or MGC-Calibrated: -4 to

-6 dBm, MGC with Calibrate PB

not pressed: -3 to -7 dBm.

Red LED indicates pilot level is

too low.

10.9 Smart Com 450 Amplifier AGC

Automatic gain control (AGC) is the recommended

setting. Set jumper JU16 to AUTO.

Set to Auto mode

Verify green LED is on.

Amplifier continues to

monitor Downstream

signals and adjust gain as

required to maintain OK.

10.11 Smart Com 450 Amplifier Manual Gain Control

Ensure Pilot is ON.

Depress CALIBRATE p/b.

Turn SW1 until green OK

LED is on.

The dial indicator on SW1

shows the dBs of extra

gain available.

10.13 Smart Com 450 Amplifier Remote Diagnostics

All RF Leds light when a

Remote Diagnostics

packet is sent

Amplifier is polled by

the RD webserver

Poll rate is

determined by the

number of amplifiers

in the system.

The remote

diagnostic web server

also provides

functionality to

reprogram the

amplifier firmware

remotely.

11.0 DC Supply Installation

11.1 Smart Com 150 DC Supply

11.1.1 Smart Com 150 DC Supply Installation

11.1.2 Smart Com 150 DC Supply Upgrade

11.1.3 Smart Com 150 DC Supply Spacing

11.2 Smart Com 150IS DC Supply

11.2.1 150IS DC Supply Installation

11.2.2 150IS DC Supply Spacing

11.2.3 150IS DC Supply Layout

11.2.4 150IS DC Voltage Calculation

11.3 Smart Com 450 DC Supply

11.3.1 450 DC Supply Spacing

11.3 Smart Com 450 DC Supply

UHF-DC16

UHF-DPC

Power supply has an output voltage of 16 VDC.

A Power Coupler UHF-DPC is supplied with

each DC Power Supply to tie it into the LF

network. Use LF cable between coupler and DC

Supply.

The RF loss for the coupler is < 0.5 dB and

therefore does not affect amplifier spacing.

Amplifiers must be no further than four amplifiers

away from the DC supply.

Local Diagnostic LEDs

11.3.1 450 DC Supply Spacing

Maximum of 8 amplifiers (4 in each direction) per

booster

12.0 Troubleshooting

12.1 Troubleshooting Strategy

12.2 Smart Com 150 Quick Reference Guide

12.3 Becker Smart Com 150 Quick Reference Guide

12.4 Smart Com 150/150IS Remote Diagnostics

12.5 Smart Com 150/150IS Amplifier Local Diagnostics

12.6 Smart Com 450 Remote Diagnostics

12.7 Smart Com 450 Amplifier Local Diagnostics

12.8 Mine-Wide Failure

12.9 Area Failure

12.10 Short Circuit Repair

12.11 Base Station Testing

12.12 Upstream Band

12.13 Noisy Upstream Band

12.14 Downstream Band

12.15 Noisy Downstream Band

12.1 Troubleshooting Strategy

Remote Diagnostics is key in detecting faults and seeing

what is going on in the system.

Comments from users are very useful in determining

what type of problem is occurring.

70% of all failures are due to cable and water damage.

Upstream noise and failed DC power supplies account for

the remaining 30% of problems.

Always start troubleshooting at the Head End. Start on

the branch with the reported fault, and work your way

towards the end of that branch.

Show DRX Help

12.6 Smart Com 450 Remote Diagnostics

Verify DRX

web server

communication

-3 to -7

OK

There

should be

no alarms.

Reserve

Gain

Depends on

the number of

amplifiers in

the system

12.7 Smart Com 450 Amplifier Local Diagnostics

RF LED

Indication

DC

Status/LED

RF Status

Action

No LEDs

Failed, below

minimum

voltage

Unknown

Determine why DC voltage is low:

No incoming voltage check for cable short/open or DC Power Supply failure.

Red LED

Too Low

(Previous

Amplifier OK)

OK (any LED

lit indicated

DC voltage

OK)

Downstream Pilot:

Ensure that downstream pilot is on at the head end.

Otherwise, increased cable loss (addition of splitter, cable damage) may require more gain from

amplifier.

Manual Gain Control (MGC)

Decrease Attenuation Setting switch SW1 until Green OK LED On. For more accuracy, press and

hold Calibrate button while adjusting SW1.

Otherwise, if adjusting MGC does not achieve Green LED, then cable damage or new splitter

prevents Green LED On even with 0 (zero) attenuation.

Find and repair cable damage.

If new splitter installed, amplifier will show Red LED, but otherwise system performance will be

unchanged.

Green LED

OK

OK

None

Amber LED

OK (any LED

lit indicated

DC voltage

OK)

Too High

Manual Gain Control (MGC)

Increase SW1 until Green OK LED on. For more accuracy, press and hold Calibrate button while

adjusting SW1.

If problem persists:

Ensure that amplifiers are not spaced too closely

Ensure that an amplifier is not oscillating due to cable being bundled too closely.

(Previous

Amplifier OK)

12.8 Mine-Wide Failure

Possible Cause

Remedy

Base Station un-powered.

Verify Base Station power.

Failure of main LF cable

feed.

Verify using Remote or Local Diagnostics.

If amplifiers cannot call in within 15

minutes it would indicate a problem.

Upstream noise floor too

high.

Verify using Remote Diagnostics. If

amplifiers cannot call in within 15 minutes

it would indicate a problem. Measure

Upstream Noise Floor.

Failure of DC Power Supply. Verify using Remote or Local Diagnostics.

If amplifiers cannot call in within 15

minutes it would indicate a problem.

Failure of Voice Repeater.

Confirm operation of other voice channels.

12.9 Area Failure

Possible Cause

Remedy

Failure of LF cable feed.

Verify using Remote or Local Diagnostics.

If amplifiers cannot call in within 15 minutes

it would indicate a problem.

Failure of DC Power

Supply.

Verify using Remote or Local Diagnostics.

If amplifiers cannot call in within 15 minutes

it would indicate a problem.

Amplifier or cable fault.

If amplifier cannot achieve Green LED then

either the amplifier is faulty or cable

between it and previous amplifier has too

high a loss. Verify amplifier spacing and

replace amplifier.

12.10 Short Circuit Repair

Short Circuits cause the DC voltage to drop while the DC current increases.

How to detect Short Circuits

Low voltage alarms on Remote Diagnostics.

Fault LEDs on DC Supplies.

Higher than normal current draw from DC Supplies. DC Supply output current hiccupping.

No LEDs on amplifiers (DC voltage below minimum voltage).

Too Low Red LEDs on amplifiers (RF level too low due to cable damage, cable open but not

shorted).

How to locate Short Circuits

Use information from Remote Diagnostics. Which sections of amplifiers are not calling in?

Start from DC Supply, and temporarily isolate cable sections using jumpers on splitters and

amplifiers. Using a voltmeter, watch for increase in voltage (to normal) when branch isolated.

Once the faulty cable section has been identified, perform a visual check of the cable looking for

obvious physical damage. If possible feel cable for damage.

How to repair Short Circuits

Repair broken cable with splice units.

Replace damaged cable sections with new cable.

12.11 Base Station Testing

Smart Com 150/150IS

Connect a Spectrum Analyzer to a spare Rx port on RNGRF16 or the BSC-HE. Monitor the Upstream band 170-185

MHz.

Spectrum Analyzer

Smart Com 450

Connect a Spectrum Analyzer to a spare Rx port on UHFH00. Monitor the Upstream band 450-455 MHz.

12.12 Upstream Band

The Upstream band should look as shown below.

Upstream Band

Its possible that you can hear

someone talking but not be able to

talk back. This indicates a problem

with the upstream communications.

12.13 Noisy Upstream Band

If noise is coming back to the Base Station from any or all

of the LF branches it might look similar to below.

12.14 Downstream Band

Its possible that someone can hear

you but you cannot talk back. This

indicates a problem with the

Downstream communications.

12.15 Noisy Downstream Band

Connect spectrum analyzer to the LF terminals at the Head

End.

13.0 Maintenance

13.1 Daily Maintenance

13.2 Monthly Maintenance

13.3 Annual Maintenance

13.1 Daily Maintenance

Use Remote Diagnostics (RD) each day.

Check for warnings and alarms.

The RD web server can be configured to send e-mail

when alarms are detected.

RD gives confidence in the system.

RD is easy to use, does not require a dedicated

computer and can support up to 50 simultaneous users.

13.2 Monthly Maintenance

1. Confirm Base Station operation:

1.

2.

3.

4.

5.

Repeater transmitter levels

Clarity of voice communications

Noise in Upstream direction below -90 dBm

Head End circuit board Local Diagnostic LEDs OK

Verify backup batteries in place and on float charge

2. Test line components:

1. Amplifier and DC Supply Local Diagnostics LEDs OK

2. Verify backup batteries in place and on float charge

3. Verify minimum 30 meters communication range from

cable throughout mine.

13.3 Annual Maintenance

It is advised to perform a system audit on an

annual basis. The audit verifies:

1. Remote Diagnostics configuration up to date with

installed system.

2. Repeater sensitivity.

3. Repeater transmit power and stability.

4. Head End splitter/combiner operation.

5. Downstream and Upstream noise floor.

6. Amplifier DC voltage and output levels.

7. Communication coverage and clarity, including

surface.

Contact Information

Varis Mine Technology Ltd.

22 Brady Street, Unit 4

Sudbury, Canada P3E 6E1

www.varismine.com

info@varismine.com

Toll Free USA/Canada:

Phone:

Fax:

877-658-2747

705-674-8111

705-674-7834

You might also like

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterFrom EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterRating: 5 out of 5 stars5/5 (4)

- Leutert DPI-2 UM eDocument46 pagesLeutert DPI-2 UM eSidNo ratings yet

- Aalborg OL Modular Boiler Plant Capacities and DimensionsDocument2 pagesAalborg OL Modular Boiler Plant Capacities and Dimensionsthlim19078656No ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04No ratings yet

- 106H5300E1Document45 pages106H5300E1mnbvqwertNo ratings yet

- L60MC-C Project Guide Two-stroke EnginesDocument304 pagesL60MC-C Project Guide Two-stroke EnginesАлександр ЗамахинNo ratings yet

- CatalogZP Yamaha 9.9FMH-15FMHDocument40 pagesCatalogZP Yamaha 9.9FMH-15FMHAndrey IVanNo ratings yet

- LX 310Document2 pagesLX 310imamNo ratings yet

- EVK Seal ManualDocument18 pagesEVK Seal Manualgelo_17100% (1)

- MEP 002A Unit Direct Support General Support and Depot Level Maintenance Repair Parts and Special Tools List TM 9 6115 584 24PDocument254 pagesMEP 002A Unit Direct Support General Support and Depot Level Maintenance Repair Parts and Special Tools List TM 9 6115 584 24PGreenMountainGeneratorsNo ratings yet

- Samsung HT-D350 PDFDocument58 pagesSamsung HT-D350 PDFboroda2410100% (2)

- Flexible Sensor Handling On Board - With HOSET 2.0Document2 pagesFlexible Sensor Handling On Board - With HOSET 2.0DestaNo ratings yet

- Safetec Prince ListDocument3 pagesSafetec Prince ListGaurav MaithilNo ratings yet

- Opel Corsa Aircon InstallationDocument18 pagesOpel Corsa Aircon InstallationMOLL1234100% (1)

- Manual TerrameterDocument148 pagesManual TerrameterAlexandra Gerea50% (2)

- Material and supplier part numbers for electronic componentsDocument344 pagesMaterial and supplier part numbers for electronic componentschompink69000% (1)

- Spicer 10 Series Driveshafts Ij900 03 PDFDocument86 pagesSpicer 10 Series Driveshafts Ij900 03 PDFJoao Silva100% (1)

- ICOMDocument47 pagesICOMal nakheel electronicsNo ratings yet

- Instruction Manual For Epcon: Electro-Pneumatic Controller (2.9 Ver.)Document9 pagesInstruction Manual For Epcon: Electro-Pneumatic Controller (2.9 Ver.)rpmNo ratings yet

- GSM Fixed Wireless Terminal FCT-400 User ManualDocument13 pagesGSM Fixed Wireless Terminal FCT-400 User ManualAnibal Aparicio אניבאל אפאריסיעNo ratings yet

- HJ Mechtronic SystemDocument4 pagesHJ Mechtronic SystemSteve BoteNo ratings yet

- Inv 2nd FLR CabinetDocument2 pagesInv 2nd FLR CabinetJack HarrisonNo ratings yet

- Manual - WAS100 (R1) AnemometerDocument33 pagesManual - WAS100 (R1) Anemometerrohithunni.pNo ratings yet

- Magnetic Compass ManualDocument21 pagesMagnetic Compass ManualvlcktorNo ratings yet

- Process Safety and Environmental Protection 2009 Volume 87, Number 1Document2 pagesProcess Safety and Environmental Protection 2009 Volume 87, Number 1jenanboyzNo ratings yet

- Service Bulletin No. 10-08 - Aker SolutionsDocument6 pagesService Bulletin No. 10-08 - Aker SolutionsReda HmrNo ratings yet

- D3 LCCDocument36 pagesD3 LCCstankovukanovicNo ratings yet

- Technical Description: Type: 810.001.210Document6 pagesTechnical Description: Type: 810.001.210Radu VasilacheNo ratings yet

- FAR2137S BB 2837S Installation Manual L 4-12-11 PDFDocument123 pagesFAR2137S BB 2837S Installation Manual L 4-12-11 PDFtariktunadNo ratings yet

- Quinti Prop ManualDocument47 pagesQuinti Prop ManualfasilpereiraNo ratings yet

- UG Governor Limit Switches: Operation ManualDocument12 pagesUG Governor Limit Switches: Operation Manualnguyenhieucun100% (1)

- Quint DC Ups 24dc 20Document9 pagesQuint DC Ups 24dc 20danielliram993No ratings yet

- Biffi Flow ControlDocument100 pagesBiffi Flow ControlGiovanni Andrade ReinoNo ratings yet

- Parts Reference List: MODELS:DCP-T310/T510W/T710W MFC-T810W/T910DWDocument31 pagesParts Reference List: MODELS:DCP-T310/T510W/T710W MFC-T810W/T910DWJesus Arellanes OrtizNo ratings yet

- 4.12 - LC Avm 01 (1007)Document24 pages4.12 - LC Avm 01 (1007)jarekNo ratings yet

- Man Lgip - Factsheet - 7 PDFDocument2 pagesMan Lgip - Factsheet - 7 PDFblehNo ratings yet

- Parker SSD 650 Series User ManualDocument70 pagesParker SSD 650 Series User ManuallivanelNo ratings yet

- ANFOMATIC INSTRUCTION MANUAL Rev 8.1Document25 pagesANFOMATIC INSTRUCTION MANUAL Rev 8.1Rachit SharmaNo ratings yet

- H12 VXCVXCVDocument538 pagesH12 VXCVXCVVinay Kumar NeelamNo ratings yet

- Monthly SFF filter procedure for hydraulic system cleaningDocument2 pagesMonthly SFF filter procedure for hydraulic system cleaningCharalampos BarNo ratings yet

- Bridge Center Console Cable Code GuideDocument3 pagesBridge Center Console Cable Code Guidevuhoan84No ratings yet

- T4800 Load Sharer Automatic Generator ControlDocument4 pagesT4800 Load Sharer Automatic Generator Controlmujo_11No ratings yet

- 3BSE020923R4101 A en S800 I O - General Information and Installation - User S GuideDocument256 pages3BSE020923R4101 A en S800 I O - General Information and Installation - User S GuideRavenShieldXNo ratings yet

- Smart OdmeDocument2 pagesSmart Odmeေအာင္ ေက်ာ္ မုိးNo ratings yet

- TMH Catalogue 2016Document460 pagesTMH Catalogue 2016IvanNo ratings yet

- BZFMV7e (Intructions)Document21 pagesBZFMV7e (Intructions)Jose MariaNo ratings yet

- Aderco 2055G PDFDocument7 pagesAderco 2055G PDFpyaesoneNo ratings yet

- Installation Instructions Vcds Vag ComDocument2 pagesInstallation Instructions Vcds Vag ComLive PrixNo ratings yet

- 80 900 PDFDocument751 pages80 900 PDFgordon tennantNo ratings yet

- SRX 75 ManualDocument24 pagesSRX 75 ManualLucasNo ratings yet

- Technical Sheet: Generating Set QLS13TDocument1 pageTechnical Sheet: Generating Set QLS13Tdjef djefNo ratings yet

- XSH - 0 - 2 Iss3 Type 1801 External Seahorse' Pantograph WiperDocument12 pagesXSH - 0 - 2 Iss3 Type 1801 External Seahorse' Pantograph WipertylerdurdaneNo ratings yet

- Rod Drop Monitroing TheoryDocument10 pagesRod Drop Monitroing TheoryAvik BhaiNo ratings yet

- Engine Indicator Type 50 z1Document2 pagesEngine Indicator Type 50 z1CalandrasReyCalandrasreyNo ratings yet

- Model: T1400 Diesel GensetDocument5 pagesModel: T1400 Diesel Gensetengnajeeb75No ratings yet

- Smart Com 150 Manual English V5 - 14Document121 pagesSmart Com 150 Manual English V5 - 14Zeljko M BoskovicNo ratings yet

- Enabling Low Cost Femtocell Deployment with a Multi-Standard Transceiver ICDocument7 pagesEnabling Low Cost Femtocell Deployment with a Multi-Standard Transceiver ICThevesteNo ratings yet

- Beckercom: Welcome To The Becker ElectronicsDocument68 pagesBeckercom: Welcome To The Becker ElectronicsMichael Erdis50% (2)

- RF Fundementals TAC Fred NiehausDocument86 pagesRF Fundementals TAC Fred NiehausbaratscribedNo ratings yet

- Cor para MotorolaDocument5 pagesCor para MotorolaJose Luis Pardo FigueroaNo ratings yet

- Cor para MotorolaDocument5 pagesCor para MotorolaJose Luis Pardo FigueroaNo ratings yet

- Offset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffDocument1 pageOffset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffAnonymous kcSG2vtv3No ratings yet

- Offset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffDocument1 pageOffset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffAnonymous kcSG2vtv3No ratings yet

- Offset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffDocument1 pageOffset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffAnonymous kcSG2vtv3No ratings yet

- Offset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffDocument1 pageOffset 1232B1 - 7509 A 9090 Password Off Offset 20287B - 7505 A 9090 Region Off Offset 23DD75 - 7505 A 9090 Region OffAnonymous kcSG2vtv3No ratings yet

- WC Unit 1 & 2 - Numerical AnswersDocument6 pagesWC Unit 1 & 2 - Numerical AnswersHills JiiNo ratings yet

- Digimini: Product Specification SheetDocument2 pagesDigimini: Product Specification Sheetbasil sharyNo ratings yet

- Opti BWS 1600G Optical Power CalculationDocument33 pagesOpti BWS 1600G Optical Power CalculationM Tanvir AnwarNo ratings yet

- Anetnnas & TMAsDocument136 pagesAnetnnas & TMAsWael Alkodami0% (1)

- SBL-1 PDFDocument2 pagesSBL-1 PDFfox7878No ratings yet

- Optical and Digital Communication Homework SolutionsDocument3 pagesOptical and Digital Communication Homework SolutionsBắc NguyễnNo ratings yet

- GNS430W InstallationManual 190-00356-02Document222 pagesGNS430W InstallationManual 190-00356-02robbertmdNo ratings yet

- Comm. 1 Lecture Assignment 3Document3 pagesComm. 1 Lecture Assignment 3John CastroNo ratings yet

- Link BudgetDocument3 pagesLink Budgetshahid2346No ratings yet

- Definition RSCP, RSSI and Ec IoDocument1 pageDefinition RSCP, RSSI and Ec Iovujo1987No ratings yet

- Dtma-Ata181100 & Ata182000 DatasheetDocument3 pagesDtma-Ata181100 & Ata182000 Datasheetcrash5v5No ratings yet

- Dual Polarised Antenna AlignmentDocument9 pagesDual Polarised Antenna AlignmentmohamedNo ratings yet

- RF Design MCQ-1Document16 pagesRF Design MCQ-1JeyavelNo ratings yet

- 8-Optical Power Calculation TrainingDocument47 pages8-Optical Power Calculation TrainingDerrick Senyo100% (2)

- Base Station Antennas for Mobile Communications 790-2500 MHzDocument229 pagesBase Station Antennas for Mobile Communications 790-2500 MHzGaby Linda JacomeNo ratings yet

- New em 1000 He Plus Main Features: Rev.: 1v0 May 2011Document2 pagesNew em 1000 He Plus Main Features: Rev.: 1v0 May 2011awan_ajheNo ratings yet

- Amplifier Frequecny ResponseDocument63 pagesAmplifier Frequecny ResponseNuman khanNo ratings yet

- Introduction To Communication: Dr. Haider Tarish HaiderDocument14 pagesIntroduction To Communication: Dr. Haider Tarish HaiderakhalifeNo ratings yet

- Training - 2G BSS Network ParameterDocument59 pagesTraining - 2G BSS Network ParameterHilda Elizabeth100% (3)

- Site Classification and Test Case DataDocument36 pagesSite Classification and Test Case DataAlapanChakraborty86No ratings yet

- BTS Fiber Transport For DAS 4.6Document2 pagesBTS Fiber Transport For DAS 4.6jspn01No ratings yet

- 1KHW002568AE System Test Report ETL600R4Document17 pages1KHW002568AE System Test Report ETL600R4fayssal salvadorNo ratings yet

- gns430w IM PDFDocument198 pagesgns430w IM PDFsuganthsuthaNo ratings yet

- 2100L Power AmplifierDocument2 pages2100L Power AmplifierTeck ChuanNo ratings yet

- RF CalculatorDocument4 pagesRF CalculatorSalman ShahNo ratings yet

- DB Operations and NoiseDocument79 pagesDB Operations and NoisePatrick BelenNo ratings yet

- T04 Propagation v11 1Document12 pagesT04 Propagation v11 1nacho1963No ratings yet

- AAMCS S-Band AmplifierDocument14 pagesAAMCS S-Band AmplifierMazlum ÜnalNo ratings yet

- Rumus Cell Reselection Lte To WcdmwaDocument11 pagesRumus Cell Reselection Lte To WcdmwaDonny Aryobowo0% (1)