Professional Documents

Culture Documents

Automobile Rotisserie - Google Patents

Uploaded by

Alonso IbarraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automobile Rotisserie - Google Patents

Uploaded by

Alonso IbarraCopyright:

Available Formats

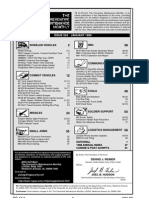

Patent US20110101586 - Automobile rotisserie - Google Patents

Sign in

Patents

Automobile rotisserie

An automobile rotisserie may include a pair of support columns, a neck clamp

Publication number

Publication type

Application number

Publication date

Filing date

Priority date

US20110101586 A1

Application

US 12/917,939

May 5, 2011

Nov 2, 2010

Nov 2, 2009

clamped to each support column, a rotation assembly attached to each neck

Also published as

US8596627

clamp, a swing arm clamp attached to each rotation assembly, a swing arm

Inventors

Donald Scott Lands, Samuel O. Dean

received in and clamped by each swing arm clamp, a balancing assembly

Original Assignee

Donald Scott Lands, Dean Samuel O

Export Citation

BiBTeX, EndNote, RefMan

US 20110101586 A1

ABSTRACT

effective for controlling the movement and positioning of said swing arm within

said swing arm clamp, and a mounting arm extending from each swing arm. Each

neck clamp and/or swing arm clamp may include an L-shaped outer clamp plate

and a W-shaped inner clamp plate. Each rotation assembly may include an outer

sleeve attached to a neck clamp, an inner insert sleeve attached to a swing arm

Patent Citations (10), Referenced by (3), Classifications (4),

Legal Events (2)

External Links:USPTO, USPTO Assignment, Espacenet

clamp, a plurality of ball bearings between the outer sleeve and the inner sleeve

to facilitate rotational movement of said inner sleeve within said outer sleeve, and a retainer bearing to retain said inner sleeve within said outer sleeve. The balancing

assembly may include a threaded balancer block attached to a swing arm clamp, an unthreaded balancer block attached to a swing arm, a threaded rod extending

through the threaded balancer block and through the unthreaded balancer block, a gripping head at one end of the threaded rod, a thrust bearing assembly

sandwiching said unthreaded balancer block, and a locking collar fixed to said threaded rod adjacent said thrust bearing assembly and said unthreaded balancer block.

IMAGES (17)

DESCRIPTION

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

CLAIMS (18)

Patent US20110101586 - Automobile rotisserie - Google Patents

REFERENCE TO RELATED APPLICATIONS

This application claims priority from U.S. Provisional Patent Application Ser. No.

1. An automobile rotisserie, comprising:

a) a pair of rectangular, vertical support columns;

61/280,368, the entire contents of which are hereby incorporated herein by

b) a neck clamp clamped to each vertical support column;

reference.

FIELD OF THE INVENTION

The present invention relates generally to automobile rotisseries, and more

particularly to an automobile rotisserie having improved stability and

c) a rotation assembly fixedly attached to each neck clamp;

d) a swing arm clamp fixedly attached to each rotation assembly;

e) a swing arm slidably received in and clamped by each swing arm clamp;

performance.

f) a balancing assembly effective for controlling the movement and

BACKGROUND TO THE INVENTION

positioning of said swing arm relative to said swing arm clamp; and

Automobile rotisseries are used to hold an automobile or other large object above

g) a mounting assembly extending from each swing arm;

the ground in a manner in which the object can be rotated about its longitudinal

axis. This allows a worker to access all areas of the object without having to go

wherein at least one of said neck clamp and said swing arm clamp comprises

under it, and provides improved worker safety and comfort.

an L-shaped outer clamp plate and a W-shaped inner clamp plate.

Prior art rotisseries have several known defects. For example, the various

2. An automobile rotisserie according to claim 1 wherein each of said

components are often not held in a rigid, perfectly aligned condition when loaded

pair of support columns comprises a base.

with heavy object such as an automobile. This is due to the tolerances or

clearances between components in prior art rotisseries, which introduces some

level of tilt when weight is applied to the rotisserie, and often leads to binding

3. An automobile rotisserie according to claim 1 wherein the two

members of said pair of support columns are connected by a connector.

during rotation or when the object is being lowered. Poor connections and

4. An automobile rotisserie according to claim 1 wherein said swing arm

alignment also introduce more stress on the device, causing components to wear

clamp comprises an L-shaped outer clamp plate and a W-shaped inner

faster and become even more misaligned.

clamp plate.

A need therefore exists for an improved rotisserie that holds heavy objects such

5. An automobile rotisserie according to claim 1 wherein said neck

as automobiles in a rigid, well aligned position. The present invention addresses

clamp comprises an L-shaped outer clamp plate, a W-shaped inner

that need.

clamp plate, and an anti-binding bearing effective for maintaining said

SUMMARY OF THE INVENTION

Briefly describing one aspect of the present invention, there is provided an

automobile rotisserie comprising:

a) a pair of vertical support columns;

b) a rotation assembly attached to each support column;

d) a swing arm clamp attached to each rotation assembly;

e) a swing arm slidably received in and clamped by each swing arm

neck clamp in a spaced apart relationship with respect to said vertical

support column when the neck clamp is released from it's fully-clamped

condition.

6. An automobile rotisserie according to claim 1 wherein said rotation

assembly comprises:

a) an outer neck sleeve fixedly attached to said neck clamp;

b) an inner insert sleeve fixedly attached to said swing arm clamp;

clamp;

f) a balancing assembly effective for controlling the movement and

c) a plurality of ball bearings between said outer sleeve and said

positioning of said swing arm within said swing arm clamp; and

inner sleeve to facilitate rotational movement of said inner sleeve

g) a mounting connection extending from each swing arm to

within said outer sleeve; and

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

facilitate connection to an object to be held by the rotisserie.

The rotation assembly may be attached to the vertical support columns by a neck

clamp that allows the rotation assembly to be moved vertically with respect to the

support column.

The neck clamp and/or the swing arm clamp may comprise an L-shaped outer

clamp plate and a W-shaped inner clamp plate.

The support columns may include a base.

d) a retainer bearing to retain said inner sleeve within said outer

sleeve.

7. An automobile rotisserie according to claim 6 wherein said rotation

assembly additionally comprises a locking bolt to selectively prevent

rotation of said inner sleeve within said outer sleeve.

8. An automobile rotisserie according to claim 6 wherein said inner

sleeve includes at least two grooves for retaining bearings, and wherein

said plurality of bearings are retained in said inner sleeve groove.

The two members of the pair of support columns may be connected by a

9. An automobile rotisserie according to claim 6 wherein said retained

connector.

bearing is retained by a concave end of a set screw.

The neck clamp may include an anti-binding bearing effective for maintaining the

neck clamp in a slightly spaced apart relationship with respect to the vertical

10. An automobile rotisserie according to claim 1 wherein said balancing

support column when the neck clamp is released from it's fully-clamped condition.

assembly comprises:

This prevents binding of the neck clamp when the object is being lowered.

The rotation assembly may comprise:

a) a outer neck sleeve fixedly attached to said neck clamp;

b) an inner insert sleeve fixedly attached to said swing arm clamp,

wherein said inner insert sleeve includes a groove effective for

a) a threaded balancer block fixedly attached to said swing arm

clamp;

b) an unthreaded balancer block fixedly attached to said swing arm;

c) a threaded rod extending through said threaded balancer block

and through said unthreaded balancer block;

retaining bearings;

c) a plurality of bearings in said inner sleeve groove to facilitate

rotational movement of said inner sleeve within said outer sleeve;

and

d) a retaining bearing to retain said inner sleeve within said outer

sleeve.

The rotation assembly may additionally comprises a locking bolt to selectively

prevent rotation of said inner sleeve within said outer sleeve.

The balancing assembly may comprise:

d) a gripping portion effective for turning said threaded rod;

e) a thrust bearing assembly sandwiching said unthreaded balancer

block; and

f) a locking collar fixed to said threaded rod adjacent said thrust

bearing assembly and said unthreaded balancer block.

11. An automobile rotisserie according to claim 10 wherein said

unthreaded balancer block is attached to the face of the swing arm

nearest the object being supported by the rotisserie, and wherein said

a) a threaded balancer block fixedly attached to said swing arm

threaded balancing block is attached to the face of the swing arm clamp

clamp;

nearest the object being supported by the rotisserie, and wherein said

b) an unthreaded balancer block fixedly attached to said swing arm;

threaded balancing block is vertically aligned with said unthreaded

c) a threaded rod extending through said threaded balancer block

balancer block.

and through said unthreaded balancer block;

d) a gripping head at one end of said threaded rod;

e) a thrust bearing assembly sandwiching said unthreaded balancer

12. An automobile rotisserie according to claim 1 wherein each of said

mounting arms is clamped to said swing arm by a mounting arm clamp.

block; and

13. An automobile rotisserie according to claim 1 wherein said mounting

f) a locking collar fixed to said threaded rod adjacent said thrust

arm clamp comprises an L-shaped outer clamp plate and a W-shaped

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

bearing assembly and said unthreaded balancer block.

Each of the mounting arms may be clamped to said swing arm by a mounting arm

inner clamp plate.

14. An automobile rotisserie, comprising:

clamp.

a) a pair of vertical support columns;

The mounting arm clamp may comprise an L-shaped outer clamp plate and a Wshaped inner clamp plate.

b) a rotation assembly connected to each vertical support column;

Additional features and advantages of the present invention are described in the

c) a swing arm clamp fixedly attached to each rotation assembly;

description of preferred embodiments below.

d) a swing arm slidably received in and clamped by each swing arm clamp;

DESCRIPTION OF THE DRAWINGS

and

FIG. 1 is a perspective view of one preferred embodiment of the assembled

e) a balancing assembly effective for controlling the movement and

rotisserie of the present invention.

positioning of said swing arm within said swing arm clamp;

FIG. 2 is a perspective view of one end of the rotisserie of the present invention,

wherein said balancing assembly comprises:

according to one preferred embodiment.

FIG. 3 is a side view, in partial section, of the rotation assembly of the rotisserie of

the present invention, according to one preferred embodiment.

FIG. 4 is a perspective view of the balancing assembly of the rotisserie of the

present invention, according to one preferred embodiment.

FIG. 5 is a perspective view of a mounting arm assembly of the rotisserie of the

present invention, according to one preferred embodiment.

FIGS. 6A and 6B show an automobile held and rotated by one preferred

embodiment of the assembled rotisserie of the present invention.

FIG. 7 is a perspective view of a vertical support column and associated base,

according to one preferred embodiment of the present invention.

FIGS. 8A and 8B are perspective views of W-L clamping members, according to

preferred embodiments of the present invention.

i) a threaded balancer block fixedly attached to said swing arm clamp;

ii) an unthreaded balancer block fixedly attached to said swing arm;

iii) a threaded rod extending through said threaded balancer block and

through said unthreaded balancer block;

iv) a gripping portion effective for turning said threaded rod;

v) a thrust bearing assembly sandwiching said unthreaded balancer

block; and

vi) a locking collar fixed to said threaded rod adjacent said thrust bearing

assembly and said unthreaded balancer block.

15. An automobile rotisserie according to claim 14 wherein said

unthreaded balancer block is attached to the face of the swing arm

nearest the object being supported by the rotisserie, and wherein said

threaded balancing block is attached to the face of the swing arm clamp

FIG. 9 is a perspective view of a neck clamp and the outer sleeve of a rotation

nearest the object being supported by the rotisserie, and wherein said

assembly, according to one preferred embodiment of the present invention.

threaded balancing block is vertically aligned with said unthreaded

balancer block.

FIG. 10 is a perspective view of a swing arm clamp and the inner sleeve of a

rotation assembly, according to one preferred embodiment of the present

invention.

FIG. 11 is a perspective view of an inner sleeve and associated bearings of a

rotation assembly, according to one preferred embodiment of the present

invention.

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

16. An automobile rotisserie, comprising:

a) a pair of vertical support columns;

b) a rotation assembly connected to each vertical support column;

c) a swing arm clamp fixedly attached to each rotation assembly;

Patent US20110101586 - Automobile rotisserie - Google Patents

FIG. 12 is a perspective view of a set screw for holding a retaining bearing,

d) a swing arm slidably received in and clamped by each swing arm clamp;

according to one preferred embodiment of the present invention.

and

FIG. 13 is a perspective view of a threaded balancing block, according to one

e) a balancing assembly effective for controlling the movement and

preferred embodiment of the present invention.

positioning of said swing arm within said swing arm clamp;

FIG. 14 is a perspective view of an unthreaded balancing block, according to one

wherein said rotation assembly comprises:

preferred embodiment of the present invention.

i) an outer neck sleeve fixedly attached to said neck clamp;

FIG. 15 is a perspective view of a thrust bearing from a thrust bearing assembly,

according to one preferred embodiment of the present invention.

FIG. 16 is a perspective view of a swing arm, according to one preferred

embodiment of the present invention.

ii) an inner insert sleeve fixedly attached to said swing arm clamp;

iii) a plurality of ball bearings between said outer sleeve and said inner

sleeve to facilitate rotational movement of said inner sleeve within said

outer sleeve; and

FIG. 17 is a perspective view of a mounting arm, according to one preferred

embodiment of the present invention.

FIG. 18 is a perspective view of a swing arm and associated mounting arm,

iv) a retainer bearing to retain said inner sleeve within said outer sleeve.

17. An automobile rotisserie, comprising:

according to one preferred embodiment of the present invention.

a) a pair of rectangular, vertical support columns;

DESCRIPTION OF THE PREFERRED EMBODIMENTS

b) a neck clamp clamped to each vertical support column;

For the purpose of promoting an understanding of the principles of the present

c) a rotation assembly fixedly attached to each neck clamp;

invention, reference will now be made to certain preferred embodiments, and

specific language will be used to describe the same. It will nevertheless be

understood that no limitation of the scope of the invention is thereby intended.

Any alterations and further modifications in the described embodiments and any

d) a swing arm clamp fixedly attached to each rotation assembly;

e) a swing arm slidably received in and clamped by each swing arm clamp;

further applications of the principles of the present invention as described herein

f) a balancing assembly effective for controlling the movement and

are contemplated as would normally occur to one skilled in the art to which the

positioning of said swing arm relative to said swing arm clamp; and

invention relates.

g) a mounting assembly extending from each swing arm;

As briefly described above, one aspect of the invention provides a rotisserie for

holding a heavy object, such as an automobile, in a position up off the ground,

wherein at least one of said neck clamp and said swing arm clamp comprises

such that the object may be rotated about its longitudinal axis. The preferred

an L-shaped outer clamp plate and a W-shaped inner clamp plate; and

rotisserie comprises a pair of vertical support columns. Each vertical support

wherein said balancing assembly comprises:

column has a rotation assembly attached to it. Each rotation assembly is

connected to a swing arms and associated hardware for holding an object and

i) a threaded balancer block fixedly attached to said swing arm clamp;

allowing it to rotate on the stand. Each swing arm is associated with a balancing

assembly for balancing the object with respect to the axis of rotation of the

rotisserie.

The vertical support columns are typically free-standing metal columns that may

include a base for stability. The columns may be made of steel tubes, preferably

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

ii) an unthreaded balancer block fixedly attached to said swing arm;

iii) a threaded rod extending through said threaded balancer block and

through said unthreaded balancer block;

iv) a gripping portion effective for turning said threaded rod;

Patent US20110101586 - Automobile rotisserie - Google Patents

with a rectangular cross-section. The columns are designed to support heavy

loads in excess of 500 pounds each, and more commonly in excess of 1000

v) a thrust bearing assembly sandwiching said unthreaded balancer

pounds each. In particular, each support column is designed to hold one end of

block; and

an object such as an automobile or a truck as the object is raised from the

ground.

In the more preferred embodiments each vertical support column includes a

mechanism, such as a clamp, for holding the associated rotation assembly in a

selected location on the support column. In the preferred embodiments this

vi) a locking collar fixed to said threaded rod adjacent said thrust bearing

assembly and said unthreaded balancer block; and

wherein said rotation assembly comprises:

i) an outer neck sleeve fixedly attached to said neck clamp;

mechanism is a neck clamp that comprises an L-shaped outer plate and a Wshaped inner plate that is bolted to the outer plate in two directions. The L-shaped

plate/W-shaped plate clamp combination provides superior contact with the

vertical support column by ensuring that the inner surfaces of the L-shaped plate

and the W-shaped plate maintain full contact with the support column even under

ii) an inner insert sleeve fixedly attached to said swing arm clamp;

iii) a plurality of ball bearings between said outer sleeve and said inner

sleeve to facilitate rotational movement of said inner sleeve within said

outer sleeve; and

heavy loads. This prevents the clamp, and more importantly the rotation

assembly, from moving out of vertical alignment with the column.

iv) a retainer bearing to retain said inner sleeve within said outer sleeve.

In the most preferred embodiments the neck clamp also includes an anti-binding

18. An automobile rotisserie according to claim 17 wherein said

bearing effective for maintaining the neck clamp in a spaced apart relationship

unthreaded balancer block is attached to the face of the swing arm

with respect to the vertical support column when the neck clamp is released from

nearest the object being supported by the rotisserie, and wherein said

it's fully-clamped condition. This prevents the leading, lower edge of the clamp

threaded balancing block is attached to the face of the swing arm clamp

plate from digging the support column as the clamp is lowered.

nearest the object being supported by the rotisserie, and wherein said

threaded balancing block is vertically aligned with said unthreaded

As indicated above, a rotation assembly is attached to each support column. The

balancer block.

rotation assemblies comprise an inner tube and an outer tube, with the inner tube

rotating inside the outer tube to allow rotation of the object being held by the

rotisserie. Accordingly, one end of the rotation assembly is attached to the

support column and the other end of the rotation assembly is attached to a swing arm that rotates (or swings) as the

rotation assembly rotates.

In the most preferred embodiments the outer sleeve of the rotation assembly is fixedly attached to the neck clamp that is

connected to the support column. The inner insert sleeve of the rotation assembly is fixedly attached to a swing arm clamp

that holds the swing arm. A plurality of ball bearings between the outer sleeve and the inner sleeve to facilitate rotational

movement of the inner sleeve within the outer sleeve.

The plurality of bearings is preferably provided in two grooves in the inner sleeve to keep the inner and outer sleeves

completely aligned with respect to each other under load. A retainer bearing is provided in another groove to retain the inner

sleeve within the outer sleeve. A set screw or a locking bolt to selectively prevent rotation of said inner sleeve within said

outer sleeve may also be included.

The swing arm assembly preferably includes a swing arm clamp fixedly attached to the rotation assembly as described

above. A swing arm is slidably received in and clamped by the swing arm clamp. In the preferred embodiments the swing

arm clamp comprises an L-shaped outer plate and a W-shaped inner plate that is bolted to the outer plate in two directions.

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

The L-shaped plate/W-shaped plate clamp combination provides superior contact with the swing arm by ensuring that the

inner surfaces of the L-shaped plate and the W-shaped plate maintain full contact with the swing arm under heavy loads.

This prevents the clamp, and more importantly the swing arm, from moving out of proper vertical alignment.

A T-shaped swing arm is preferably used. The T-shaped swing arm includes a vertical member that moves up and down with

respect to the rotation assembly to allow proper vertical balancing of the object being held by the rotisserie, and a horizontal

member that allows horizontal adjustment of the object being held by the rotisserie.

One or more mounting arms may be provided on the swing arm to facilitate attachment of an object to the rotisserie. The

mounting arms may be attached with a clamp such as the W-L clamp preferably used for other connections.

The swing arm is balanced with respect to the rotation assembly so that the center of gravity of the object being held is on or

very near the axis of rotation of the rotation assembly. Accordingly, the balancing assembly raises or lowers the object being

held so that the longitudinal axis of the object is along the axis of rotation of the rotisserie.

The balancing assembly preferably includes a threaded balancer block fixedly attached to the swing arm clamp, an

unthreaded balancer block fixedly attached to the swing arm, a threaded rod extending through the threaded balancer block

and through the unthreaded balancer block, a gripping portion effective for turning said threaded rod, a thrust bearing

assembly sandwiching said unthreaded balancer block, and a locking collar fixed to said threaded rod adjacent said thrust

bearing assembly and said unthreaded balancer block. The unthreaded balancer block is preferably attached to the face of

the swing arm nearest the object being supported by the rotisserie, and the threaded balancing block is preferably attached

to the face of the swing arm clamp nearest the object being supported by the rotisserie. With this construction the threaded

balancing block is vertically aligned with the unthreaded balancer block.

More particularly describing the balancing assembly, the upper end of the swing arm may be provided with an unthreaded

balancer block sized to receive a threaded rod. A threaded rod passes though the balancer block, and is free to rotate with in

the block. Immediately above and below the balancer block are a pair of bearings, referred to herein as thrust bearings.

Immediately adjacent the thrust bearings are two locking collars that grip and lock to the threaded rod. Most preferably, one

of the locking collars is also a gripping member that allows the user to grip and rotate the rod when the rotisserie is loaded

with a heavy load. The two locking collars hold the threaded rod securely in the unthreaded balancer block, and additionally

hold the thrust bearings tightly above and below the balancer block. When held in this compact assembly, the thrust bearings

allow the locking collars to rotate with respect to the balancer block.

The threaded balancer block is provided in the swing arm clamp below and vertically aligned with the unthreaded balancer

block. The threaded rod passes through the threaded balancer block such that the rod moves up or down as the rod is

turned. This moves the end of the threaded rod held by the unthreaded balancer block up or down relative to the swing arm

clamp. Accordingly, by turning the threaded rod the user may move the swing arm up or down relative to the rotation

assembly. This enables the user to move vertically the object being held by the rotisserie, and thus to balance the object with

respect to the axis of rotation of the rotisserie.

In one preferred embodiment the automobile rotisserie, comprises:

a) a pair of rectangular, vertical support columns;

b) a neck clamp clamped to each vertical support column;

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

c) a rotation assembly fixedly attached to each neck clamp;

d) a swing arm clamp fixedly attached to each rotation assembly;

e) a swing arm slidably received in and clamped by each swing arm clamp;

f) a balancing assembly effective for controlling the movement and positioning of said swing arm relative to said

swing arm clamp; and

g) a mounting assembly extending from each swing arm;

wherein at least one of said neck clamp and said swing arm clamp comprises an L-shaped outer clamp plate

and a W-shaped inner clamp plate; and

wherein said balancing assembly comprises:

i) a threaded balancer block fixedly attached to said swing arm clamp;

ii) an unthreaded balancer block fixedly attached to said swing arm;

iii) a threaded rod extending through said threaded balancer block and through said unthreaded balancer

block;

iv) a gripping portion effective for turning said threaded rod;

v) a thrust bearing assembly sandwiching said unthreaded balancer block; and

vi) a locking collar fixed to said threaded rod adjacent said thrust bearing assembly and said unthreaded

balancer block; and

wherein said rotation assembly comprises:

i) an outer neck sleeve fixedly attached to said neck clamp;

ii) an inner insert sleeve fixedly attached to said swing arm clamp;

iii) a plurality of ball bearings between said outer sleeve and said inner sleeve to facilitate rotational

movement of said inner sleeve within said outer sleeve; and

iv) a retainer bearing to retain said inner sleeve within said outer sleeve.

As with other embodiments, the unthreaded balancer block may be attached to the face of the swing arm nearest the object

being supported by the rotisserie, and the threaded balancing block may be attached to the face of the swing arm clamp

nearest the object being supported by the rotisserie, so that the threaded balancing block is vertically aligned with the

unthreaded balancer block.

It is to be appreciated that the rotisserie of the present invention has improved connections and alignment when compared to

the rotisseries of the prior art. The inventive rotisserie construction removes substantially all of the gaps between moving

components and keeps all of the connections tight. Further, the inventive design removes substantially all of the drag at the

pivot and on the outer upright posts by using bearings to reduce the drag.

Referring now to the drawings, FIG. 1 is a perspective view of the assembled rotisserie 8 in a mobile configuration with caster

wheels 16 mounted to each base unit 10 with quick release caster pads 26. The swing arm 20 rotates about an axis via the

rotating assembly 22. The rotating assembly 22 is attached to the upright column 28 of the rotisserie base by an adjustable

clearance clamp system 30 (also referred to as a neck clamp by virtue of its location at the front end of the rotisserie. Swing

arm 20 is adjustable perpendicular to the axis of rotation assembly 22 by means of balancing assembly 32. Mounting arms

18 are attached to swing arm 20 by way of an adjustable clearance clamp system with a redundant locking bolt. Mounting

arms 18 may be positioned at any point necessary along the horizontal member 40 of swing arm 20. This allows adjustment

of the width of the mounting locations, and allows the object to be balanced horizontally with respect to the axis of rotation.

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

Single acting hydraulic cylinders 36 provide height adjustment of rotation assembly 22. A series of telescoping tubes 12, 14

extend between the rotisserie bases 10 to provide adjustment of working room between the rotisserie ends.

FIG. 2 shows one embodiment of the rotisserie end unit in more detail. Hydraulic cylinder 36 is lowered and neck clamp 30 is

positioned in its lowest position in this configuration and secured by a fastener 38 which passes through upright column 28

and the opposite clamping plate. Swing arm 20 is also shown in a lowered position. It may be secured by the balancing

assembly 32 which retains the swing arm in any position along the extent of travel through the swing arm clamp 42. The

fastener 44 which locks the telescoping tubes 12, 14 to the rotisserie base is shown as well.

FIG. 3 is a cutaway view of rotation assembly 22. Outer neck sleeve 46 is secured to neck clamp plate 30 by solidly welding

around the circumference of the junction. Inner insert sleeve 48 is secured to the swing arm clamp plate 42 by solidly welding

around the circumference of the junction. Ball bearings 50 are retained directly within the rotation assembly 22 by means of

mating groves 52 machined circumferentially about insert sleeve 48 which eliminates the need for a separate bearing race. A

number of bearing balls 50 sufficient to wrap the circumference of the insert 48 are placed about mating groves 52 of the

insert with or without a cage assembly. An additional bearing ball 56 or set of balls rides within the mating groove 54 which is

machined circumferentially about the insert 48 and retains the insert and ball assembly within the neck sleeve 46. Retaining

ball 56 is held in place by a fastener with a concave point 58 such as a cup point set screw. A nut 60 is fastened to the neck

sleeve 46 which secures a locking bolt 62. Locking bolt 62 places tension on the insert 48 and thereby preventing the rotating

assembly from rotating. This allows the user to lock the rotisserie at any desired position within the rotation. Hydraulic

cylinder 36, which provides adjustment of working height, is fastened to the neck sleeve 46.

FIG. 4 is a perspective detail of the balancing assembly 32. A solid balancer block 64 with a single smooth hole bored

therethrough is fastened to swing arm 20. Through this smooth bore hole in balancer block 64 passes a threaded rod 66

which screws into a solid block with a single appropriately threaded hole 68. A nut 70 is fastened to one end of the threaded

rod 66. Between the nut 70 and the smooth bore balancer block 64 is a thrust bearing assembly 72. An additional thrust

bearing assembly 74 is placed on the opposite side of the smooth bore balancer block 64. Finally, a threaded clamp on shaft

collar 76 is secured to the threaded rod with the play taken out of the thrust bearing assemblies 72, 74 adjacent to the

smooth bore balancer block 64.

In operation, a device such as a wrench is used to turn threaded rod 66 via the fastened nut 70. In doing so, it causes the

swing arm 20 to move along a plane perpendicular to the rotation of the rotisserie. When the load is at the desired location

the design of the balancing assembly prohibits any further movement without manually turning the threaded rod.

FIG. 5 is a perspective detail of an individual mounting arm 18. A load, such as a vehicle body or other piece of equipment, is

mounted to the rotisserie by securely fastening it to the mounting arms 18. Mounting arm 18 attaches to the horizontal

member 40 of swing arm 20 with adjustable clearance clamping plates 78. The clamping force of the clamping plates is

adjusted by tightening or loosening the series of fasteners 80 along each edge. Mounting arm clamps 78 feature additional

locking bolts 82 which press directly to the horizontal member of the swing arm 40 to provide double securement of the

mounted load.

FIGS. 6A and 6B show an automobile held and rotated by one preferred embodiment of the assembled rotisserie of the

present invention.

FIG. 7 is a perspective view of a vertical support column and associated base, according to one preferred embodiment of the

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

present invention. Vertical support column 28 is kept stable by a base 10, and optionally by a telescoping tube 14 that

extends to connect to another rotisserie end unit.

FIGS. 8A and 8B are perspective views of W-L clamping members, according to preferred embodiments of the present

invention. Outer plate 81 is L-shaped, while inner plate 82 is W-shaped. With this configuration the two plates cooperate to

clamp tightly to the vertical support or swing arm, and hold the surfaces tight against each other. Moreover, the bolts holding

the two plates together are tightened in two directions, which are perpendicular to each other in the illustrated clamp. Note

that FIG. 8B shows an aperture 84 for providing an anti-binding bearing that may be held in place by a set screw. FIG. 8B

also shows a fastener 38 which can pass through the support column and the opposite clamping plate.

FIG. 9 is a perspective view of a neck clamp and the outer sleeve of a rotation assembly, according to one preferred

embodiment of the present invention. Neck clamp 30 includes L-shaped plate 91 and W-shaped plate 92. Rotation assembly

22 extends from neck clamp 30, and includes outer sleeve 46. Locking bolt 62 and fastener 58 with a concave point to hold a

retained bearing (not shown) are also included. Jack mount 93 is provided to facilitate movement of the rotisserie with a

hydraulic jack. Set screw 94 holds an anti-binding bearing effective for maintaining the neck clamp in a spaced apart

relationship with respect to said vertical support column when the neck clamp is released from it's fully-clamped condition.

The anti-binding bearing keeps the clamp (or collar) on the outside post from digging into the post when pressure is released

from the jack to lower the car. The anti-binding bearing ensures and maintains a small gap between the clamp/collar and the

support post to allow for movement of the collar along the post. Since a small gap will naturally exist when the neck clamp is

loosened from its tightened condition, the weight of the automobile (or other heavy object) will cause the neck collar to tilt

forward slightly when the collar is loosened. The anti-binding bearing keeps the clamp away from the post just enough to

keep it from binding up when the object is being lowered.

FIG. 10 is a perspective view of a swing arm clamp and the inner sleeve of a rotation assembly, according to one preferred

embodiment of the present invention. Swing arm clamp 100 includes L-shaped outer plate 101 and W-shaped inner plate

102. Inner sleeve 103 includes a pair of grooves 104 a and 104 b for receiving and retaining bearings that facilitate rotational

movement of the inner sleeve within the outer sleeve. Groove 105 receives and retains a retainer bearing that retains the

inner sleeve within the outer sleeve. Groove 106 receives and retains an O-ring that may be used to seal the interior of the

rotation assembly from fouling.

FIG. 11 is a perspective view of an inner sleeve and associated bearings of a rotation assembly, according to one preferred

embodiment of the present invention. Inner sleeve 103 includes a pair of grooves with bearing sets 108 a and 108 b received

therein to facilitate rotational movement of the inner sleeve within the outer sleeve. Groove 105 is provided to receive and

retain a retainer bearing that retains the inner sleeve within the outer sleeve. In this Figure groove 106 that receives and

retains an O-ring to seal the interior of the rotation assembly from fouling is not illustrated.

FIG. 12 is a perspective view of a set screw for holding a retaining bearing, according to one preferred embodiment of the

present invention. Set screw 120 includes a concave end 121 that may hold a bearing in place.

FIG. 13 is a perspective view of a threaded balancing block, according to one preferred embodiment of the present invention.

Threaded balancing block 131 includes a threaded aperture 132 that is threaded to mate with the threads of the threaded rod

of the balancing assembly.

FIG. 14 is a perspective view of an unthreaded balancing block, according to one preferred embodiment of the present

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

invention. Unthreaded balancing block 141 includes an unthreaded aperture 142 that is sized to allow passage therethrough

of the threaded rod of the balancing assembly.

FIG. 15 is a perspective view of a thrust bearing from a thrust bearing assembly, according to one preferred embodiment of

the present invention. Thrust bearing assembly 151 includes a set of roller bearings that allow surfaces above and below the

thrust bearing to rotate with respect to each other without binding.

FIG. 16 is a perspective view of a swing arm, according to one preferred embodiment of the present invention. Vertical swing

arm member 161 supports horizontal swing arm member 162, which may be used to support mounting assemblies as

described herein.

FIG. 17 is a perspective view of a mounting arm assembly, according to one preferred embodiment of the present invention.

Mounting arm assembly 170 includes mounting arm 171 and mounting arm clamp 172. Mounting clamp 172 is a W-L

clamping member, with an outer plate 173 that is L-shaped, and an inner plate 174 that is W-shaped. Locking bolt 175 is also

illustrated.

FIG. 18 is a perspective view of a swing arm and associated mounting arm, according to one preferred embodiment of the

present invention. Vertical swing arm member 161 supports horizontal swing arm member 162, that supports mounting arm

assemblies 170. As previously illustrated, mounting arm assemblies 170 include mounting arm 171 and mounting arm clamp

172.

The operation of the rotisserie will now be described below using a vehicle body as the object being held. It is to be

understood, however, that the basic operational characteristics of the device are substantially the same regardless of what

type of load or item is attached to the rotisserie.

To properly attach a load to the rotisserie, it is preferable to ensure that the swing arm 20 is at its lowest position, as shown in

FIG. 2. This is recommended because it ensures that a mounted load will always remain in a stable, or bottom heavy,

position and will not rotate unintentionally until properly balanced.

The user may then attach each end of the rotisserie to the vehicle body by securely fastening to the mounting arms 18 at

appropriate locations on the vehicle body, as illustrated in FIGS. 2 and 6A. After securely attaching each end of the rotisserie

to the load at the mounting arm locations 18, the telescoping connector tubes (FIG. 1) 12, 14 are placed between the

rotisserie ends and secured in place. The telescoping center tubes 12, 14 maintain proper position of the rotisserie ends to

prevent possible misalignment and binding of the load. The next step is to remove the locking bolt (FIG. 2) 38 from the neck

clamps 30 of both ends of the rotisserie and raise the rotating assemblies with the hydraulic cylinders 36 to a point where the

locking bolts may be replaced in one of the upper retaining holes of the upright column 28. After the neck clamps 30 are

properly secured the load may be balanced. Adjust the balance by turning the nut (FIG. 4) 70 which will raise the swing arm

20 in relation to the pivot point 22. Raise the swing arm 20 an equal distance on each end of the rotisserie until the weight of

the load is properly distributed and rotates freely about the pivot point 22. See FIG. 6B photographic reference. The locking

bolt may be engaged (FIG. 4) 62 to lock on the insert (FIG. 3) 48 which will fix the mounted object at any angle about the

rotational axis.

In one alternative embodiment the balancing assembly 64, 66, 68, 70, 72, 74, 76 may be housed within the upright post of the

swing arm 20. This prevents possible contamination of the threads and affords a sleeker design.

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

The rotisserie of the present invention is preferably constructed primarily of mild and carbon steel. Other materials with

suitable strength characteristics may also be used. For example, alternative embodiments may be constructed of other

metals, ferrous and non-ferrous, such as aluminum, titanium or stainless steel. Additionally, the rotisserie may be constructed

from non-metals such as reinforced fiberglass or laminated carbon fiber when such materials meet the requirements of a

specific application. Surface treatment options may be commonly availably coatings such as paints, powder coating and zinc

plating.

The cross section of most material used to construct the base and swing arm of this embodiment is square or rectangular

structural steel tubing. In an alternative embodiment the components may be constructed from round or oval section material

with modified mounting clamps to fit the revised sections.

Any number of locking bolts (FIG. 4) 62 may be placed on the pivot point to provide additional load securement. As well,

additional retaining balls (FIG. 3) 56, 58 may be utilized to provide enhanced securement of the pivoting assembly.

The hydraulic cylinders (FIG. 1) 20 are single acting, manually actuated in the preferred embodiment. Additional

embodiments would allow a linear screw type actuator, a double acting hydraulic cylinder or a single or double acting

hydraulic cylinder with a remote reservoir and pump to be utilized.

The rotisserie of the present invention may be used to rotate a work piece or piece of equipment, such an automobile body,

welding fixture, fiberglass mold or the like about an axis to provide ease of access to all areas of said equipment. The

preferred use is to hold and rotate an automobile.

Alternatively, the rotisserie may be used to support assembly fixtures or jigs in a manufacturing environment. Examples would

be for a trailer manufacturer to have full welding access or a cabinet manufacturer to aide in assembly and finishing.

Alternatively, the rotisserie may be used in fiberglass panel and part manufacturing to support, rotate and release panels and

parts from molds to aide in fabrication.

Alternatively, each end of the rotisserie may be used independently as a post type lift, for example to lift a vehicle body off the

chassis.

Among the advantages of the present invention are the secure connections that may be provided by the W-L clamps/collars

that are used. Such collars may be used on the vertical support column (as a neck clamp), on the swing arm (as a swing arm

clamp, and on the mounting assembly (as a mounting arm clamp). In all cases the clamp/collar provides superior connection

by increasing the contact surface area compared to prior art connections. This is particularly important on the swing arm,

where maintaining verticality is especially important.

Among the other advantages of the present invention are the anti-binding performance that may be provided when an antibinding bearing is included in the clamp/collar that connects the rotation assembly to the vertical support. This prevents the

assembly from binding when the collar is being moved downward after the clamp and jack support are released.

Among the other advantages of the present invention is the way that the multiple grooves of bearings in the rotation assembly

keeps the rotation assembly properly aligned and facilitates smoother rotation of the swing arm. Similarly, the optional use of

a retainer bearing in the rotation assembly keeps the inner and outer sleeves from separating when loaded and rotating.

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

Finally, the balancing assembly provides advantages by keeping the load properly aligned and balanced both vertically and

with respect to the axis of rotation of the object being supported by the rotisserie.

While the invention has been illustrated and described in detail in the drawings and foregoing description, the same is to be

considered as illustrative and not restrictive in character, it being understood that only the preferred embodiment has been

shown and described and that all changes and modifications that come within the spirit of the invention are desired to be

protected.

PATENT CITATIONS

Cited Patent

Filing date

Publication date

Applicant

Title

US3044747 *

Jun 29, 1959

Jul 17, 1962

Nolden John L

Fluid-operated jack

US5051056 *

Jan 10, 1990

Sep 24, 1991

G. F. Equipment, Inc.

Portable boat jacking and rotating apparatus

US5632475 *

Mar 2, 1995

May 27, 1997

Mccanse Engineering Incorporated

Work holding apparatus

US6024348 *

Oct 28, 1998

Feb 15, 2000

It's Dents Or Us, Inc.

Adjustable clamping stand for supporting automobile

panels

US6116577 *

Jun 23, 1999

Sep 12, 2000

Mccanse Engineering, L.L.C.

Service lift with curved mast

US7377502 *

Feb 29, 2004

May 27, 2008

Ljubomir Nikolic

Universal vehicle engine, gearbox and like stand

US7448606 *

Nov 4, 2004

Nov 11, 2008

Innovative Tools & Technologies,

Inc.

Large automotive panel paint rack

US8245856 *

Oct 16, 2009

Aug 21, 2012

Pappin Clint G

Remote control car support apparatus

US20030062663 *

Sep 11, 2002

Apr 3, 2003

Norco Industries, Inc.

Convertible engine stand

US20110101586 *

Nov 2, 2010

May 5, 2011

Donald Scott Lands

Automobile rotisserie

* Cited by examiner

REFERENCED BY

Citing Patent

Filing date

Publication date

Applicant

Title

US8596627 *

Nov 2, 2010

Dec 3, 2013

Wurk Metal Products, Inc.

Automobile rotisserie

US20110101586 *

Nov 2, 2010

May 5, 2011

Donald Scott Lands

Automobile rotisserie

WO2013135995A1 *

Mar 5, 2013

Sep 19, 2013

Societe D'applications Electriques Et

Mecaniques - Sapem

Method for turning over a large-sized or

heavy part

* Cited by examiner

CLASSIFICATIONS

U.S. Classification

269/57

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

Patent US20110101586 - Automobile rotisserie - Google Patents

International Classification

B23Q1/64

Cooperative Classification

B25H1/0007

European Classification

B25H1/00B

LEGAL EVENTS

Date

Code

Event

Description

Owner name: DUTRO COMPANY, UTAH

Feb 26, 2014

AS

Assignment

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:WURK METAL PRODUCTS,

INC;REEL/FRAME:032360/0609

Effective date: 20140225

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:LANDS, DONALD SCOTT;DEAN,

SAMUEL O.;REEL/FRAME:026763/0789

Aug 17, 2011

AS

Assignment

Owner name: WURK METAL PRODUCTS, INC., INDIANA

Effective date: 20110721

Rotate

Original Image

GoogleHome - Sitemap - USPTO Bulk Downloads - Privacy Policy - Terms of Service - About Google Patents - Send Feedback

Data provided by IFI CLAIMS Patent Services

2012 Google

http://www.google.com/patents/US20110101586[29/09/2014 09:52:41 p.m.]

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Installation Manual Reverse Gear 5 Speed Revision 7Document6 pagesInstallation Manual Reverse Gear 5 Speed Revision 7arieskittenNo ratings yet

- FordPickup1948 56Document108 pagesFordPickup1948 56Alonso IbarraNo ratings yet

- 09 Fuses and Circuit Brakers SedanDocument25 pages09 Fuses and Circuit Brakers SedanAlonso Ibarra100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AODE-4R75E VacTest PDFDocument2 pagesAODE-4R75E VacTest PDFAlonso IbarraNo ratings yet

- Build A Bicycle FrameDocument42 pagesBuild A Bicycle FrameAlonso IbarraNo ratings yet

- M-900iA600 Mechanical Unit Parts Manual (B-82176EN - 01) PDFDocument95 pagesM-900iA600 Mechanical Unit Parts Manual (B-82176EN - 01) PDFfrederic190pNo ratings yet

- RP23 Rebuild: DisassemblyDocument22 pagesRP23 Rebuild: DisassemblyJohnNo ratings yet

- Powder CoatDocument130 pagesPowder CoatAlonso IbarraNo ratings yet

- Singer 591 Service ManualDocument27 pagesSinger 591 Service ManualjaimeNo ratings yet

- Fusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLDocument54 pagesFusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLAlonso Ibarra100% (1)

- A6VM160 22392757 - en - 20211124Document35 pagesA6VM160 22392757 - en - 20211124David AltarribaNo ratings yet

- 3RD Q Tle10 - Ia - Eim - q3 - Mod1 - Installingwirewaysandcabletrays - v4Document47 pages3RD Q Tle10 - Ia - Eim - q3 - Mod1 - Installingwirewaysandcabletrays - v4Shaina Jean Gil NombradoNo ratings yet

- A0312624 - en - PLM Manual Roller Assembly For Compact Pellet Mill V05Document28 pagesA0312624 - en - PLM Manual Roller Assembly For Compact Pellet Mill V05jose100% (1)

- 2006 Nissan X Trail 38615Document50 pages2006 Nissan X Trail 38615Alonso IbarraNo ratings yet

- 2006 Nissan X Trail 38615Document50 pages2006 Nissan X Trail 38615Alonso IbarraNo ratings yet

- 20150226035204english Manual of SKU192807Document4 pages20150226035204english Manual of SKU192807Alonso IbarraNo ratings yet

- 44re DodgeDocument1 page44re DodgeAlonso IbarraNo ratings yet

- Building An Electronic Fuel Injector Tester HACK A WEEKDocument5 pagesBuilding An Electronic Fuel Injector Tester HACK A WEEKAlonso IbarraNo ratings yet

- Color Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFDocument16 pagesColor Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFAlonso IbarraNo ratings yet

- Industry POWDER COAT Glossary - PDFDocument10 pagesIndustry POWDER COAT Glossary - PDFAlonso IbarraNo ratings yet

- WWW Columbiacoatings Com Basic Instructions Aspx PDFDocument3 pagesWWW Columbiacoatings Com Basic Instructions Aspx PDFAlonso IbarraNo ratings yet

- Autocad LT 2007 & 2008 Setup InstructionsDocument3 pagesAutocad LT 2007 & 2008 Setup InstructionsAlonso IbarraNo ratings yet

- Hobart 210 Ironman PDFDocument56 pagesHobart 210 Ironman PDFAlonso IbarraNo ratings yet

- Service Manual Bell Howell BH1585Document57 pagesService Manual Bell Howell BH1585Luiz GerbaseNo ratings yet

- pr600 2Document43 pagespr600 2Alex Emerson PupialesNo ratings yet

- DSH Say8 12 Sa 12 PartsDocument120 pagesDSH Say8 12 Sa 12 PartsPhilip EgyNo ratings yet

- Operation and Maintenance Manual FOR Pemserter Series Lt4 Pneumatic PressDocument46 pagesOperation and Maintenance Manual FOR Pemserter Series Lt4 Pneumatic PressGuilhermeNo ratings yet

- Parts List Brother Pe700IIDocument25 pagesParts List Brother Pe700IILuis Armando Mendoza Lozoya100% (1)

- Ironridge 3 Sga Per 65 X 39 Per Module Installation Manual 2840153794Document8 pagesIronridge 3 Sga Per 65 X 39 Per Module Installation Manual 2840153794jackcan501No ratings yet

- Parts Reference List: Home Sewing MachineDocument17 pagesParts Reference List: Home Sewing Machinedonnie ashleyNo ratings yet

- CF Series Service & Parts ManualDocument88 pagesCF Series Service & Parts ManualibrahimNo ratings yet

- Mite R Slide Manual 03 08Document8 pagesMite R Slide Manual 03 08kevinrwalker8624No ratings yet

- Tajima Tmfxii C MaquinaDocument63 pagesTajima Tmfxii C Maquinaramon nava100% (1)

- GS Storm CL-1 PRODocument44 pagesGS Storm CL-1 PRORuiNo ratings yet

- The Preventive Maintenance Monthly, Issue 554Document44 pagesThe Preventive Maintenance Monthly, Issue 554"Rufus"No ratings yet

- How To Make ForkliftDocument19 pagesHow To Make ForkliftLambok MarbunNo ratings yet

- MODEL: BL137A2: Published: Mar.,2010 Revised: Jan.,2016Document27 pagesMODEL: BL137A2: Published: Mar.,2010 Revised: Jan.,2016donnie ashleyNo ratings yet

- Senior Project - Final ReportDocument80 pagesSenior Project - Final ReportJennNo ratings yet

- Parts List: Model SR36VP/SR37Document15 pagesParts List: Model SR36VP/SR37AstraluxNo ratings yet

- Pillow BlocksDocument15 pagesPillow BlockszaihasrenNo ratings yet

- 3D Robotics (3DR) Iris - User ManualDocument8 pages3D Robotics (3DR) Iris - User ManualChrisNo ratings yet

- Associated 1:10 Scale GT ManualDocument17 pagesAssociated 1:10 Scale GT ManualmortalityNo ratings yet

- Vol 56 No 03 - Shaft and Hub Keyway and Key SizesDocument4 pagesVol 56 No 03 - Shaft and Hub Keyway and Key SizesramsesluNo ratings yet

- 54 20 Tool Setting Probe: Operating Instructions EnglishDocument34 pages54 20 Tool Setting Probe: Operating Instructions EnglishŁukasz RożejNo ratings yet

- 2G-Motor Technical Manual USADocument58 pages2G-Motor Technical Manual USADiego De La FuenteNo ratings yet