Professional Documents

Culture Documents

Conbextra GP2

Uploaded by

Sikander GirgoukarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conbextra GP2

Uploaded by

Sikander GirgoukarCopyright:

Available Formats

Conbextra GP2

constructive solutions

Free ow, high strength, non-shrink,

cementitious precision grout

Uses

Conbextra GP2 is used for precision grouting where it is essential

to withstand static and dynamic loads. Typical applications would

be the grouting of base plates of turbines, compressors, boiler

feed pumps etc., It can also be used for anchoring a wide range

of xings. These include masts, anchor bolts and fence posts.

Advantages

Gaseous expansion system compensates for shrinkage

and settlement in the plastic state

Properties

Compressive strength : (BS 1881 - Part 116: 1983)

Compressive strength (N/mm2)

Age (days)

Consistency

Flowable (W/P 0.18)

24

27

45

54

55

66

28

65

78

Compressive strength with addition of aggregates

Compressive strength (N/mm2) W/P 0.18

Age

(days)

No metallic iron content to cause staining

% of aggregates ( IS 516 - 1959)

50%

75%

28

30

32

50

52

55

60

63

68

High ultimate strength ensure the durability of the hardened

grout

28

70

75

78

Free ow ensures high level of contact with load bearing

area

Age

Pre-packed material overcomes onsite batching variations

Develops high early strength without the use of chlorides

100%

Flexural strength ( BS 4551, 1998)

(days)

Flexural strength (N/mm2)

W/P 0.18

2.5

Description

7.0

Conbextra GP2 is supplied as a ready to use dry powder. The

addition of a controlled amount of clean water produces a free

owing, non-shrink grout for gap thicknesses up to 100mm.

9.0

28

10.0

Conbextra GP2 is a blend of Portland cement, graded llers

and chemical additives which impart controlled expansion in the

plastic state whilst minimising water demand. The low water

demand ensures high early strength. The graded llers are

designed to assist uniform mixing and produce a consistent

grout.

Tensile strength

(W/P - 0.18)

3.5N/mm 2 @ 28 days

Pullout bond strength

(W/P - 0.18)

17 N/mm 2 @ 7 days

20 N/mm2 @ 28 days

Time for expansion

(after mixing )

Start : 20 minutes

Finish : 120 minutes

Freshwet density

Approximately 2220kg/m3

depending on actual

consistency used

Technical support

An experienced technical advisory team is available to give

technical service on request.

Youngs modulus

(ASTM D469 - 94)

Dynamic load resistance

Conbextra GP2

Pourable (W/P 0.165)

page 1 of 4

28 kN/mm 2

Specimens of Conbextra GP2

remained undamaged even

after subjecting them to

alternate loads of 5N/mm 2 &

25N/mm2 at the rate of 500

cycles / minute for two million

cycles.

Conbextra GP2

Coefcient of thermal expansion 11 x 10 -6/ 0 C

Unrestrained expansion

2 - 4 % in the plastic

state enables to

overcome shrinkage.

Pressure to restrain

0.004 N/mm 2 approx.

Flow characteristics : The maximum distance of ow is

governed by the gap width and the head of the grout. Typical

data for ow design assuming grout is poured immediately

after mixing is given in the table below :

Grout

consistency

Flowable

Max. ow distance in mm

Gap width 50mm 100mm 250mm

(mm)

head

head

head

30

40

50

350

500

900

1000

1500

2000

The exural strength of grout must exceed 9N/mm2 @ 28 days.

The fresh wet density of the mixed grout must exceed 2150 kg/m3.

The storage, handling and placement of the grout must be in

strict accordance with the manufacturers instructions.

Application instructions

Preparation

Foundation surface

1500

2000

3000+

Note : This table is based on the following factors temperature

- 300C ; Water saturated substrate; Minimum unrestricted ow

width is 300mm.

The substrate surface must be free from oil, grease or any

loosely adherent material. If the concrete surface is defective

or has laitence, it must be cut back to a sound base. Bolt holes

and xing pockets must be blown clean of any dirt or debris.

Pre-soaking

Several hours prior to placing, the concrete substrates should

be saturated with fresh water.

Immediately before grouting takes place any free water should

be removed with particular care being taken to blow out all bolt

holes and pockets.

Specication Clauses

Performance specication

All grouting shown on the drawing must be carried out with a

pre packed cement based product which is chloride free.

It shall be mixed with clean water to the required consistency.

The grout must not bleed or segregate.

A positive volumetric expansion shall occur while the grout is

plastic by means of gaseous system.

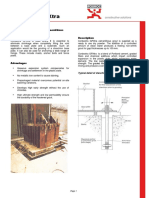

Typical detail of stanchion base plate

The compressive strength of the grout must exceed 50 N/mm2

at 7 days and 60 N/mm2 at 28 days.

Base plate

It is essential that this is clean and free from oil, grease or scale.

Air pressure relief holes should be provided to allow venting

of any isolated high spots.

Levelling shims

If these are to be removed after the grout has hardened, they

should be treated with a thin layer of grease.

Formwork

The formwork should be constructed to be leakproof. This

can be achieved by using foam rubber strip or mastic sealant

beneath the constructed formwork and between joints.

In some cases it is practical to use a sacricial semi-dry sand

and cement formwork. The formwork should include outlets

for pre-soaking.

constructive solutions

page 2 of 4

Conbextra GP2

Unrestrained surface area

This must be kept to a minimum. Generally the gap width

between the perimeter formwork and the plate edge should

not exceed 150mm on the pouring side and 50mm on the opposite side. It is advisable, where practical, to have no gap

at the ank sides.

Mixing and placing

Any bolt pockets must be grouted prior to grouting between the

substrate and the base plate.

Continuous grout ow is essential. Sufcient grout must be

prepared before starting. The time taken to pour a batch must

be regulated to the time to prepare the next one.

Typical hopper system

Mixing

For best results a mechanically powered grout mixer should

be used. When quantities up to 50kg are used, a heavy duty

slow speed drill (400-500 rpm) tted with a paddle is suitable..

Larger quantities will require a heavy duty mixer.

Removable hopper : For large pours the grout may be hand

placed or pumped into a removable hopper ( trough)

To enable the grouting operation to be carried out continuously, it is essential that sufcient mixing capacity and labour

are available. The use of a grout holding tank with provision

to gently agitate the grout may be required.

Consistency of grout mix

The quantity of clean water required to be added to a 25kg bag

to achieve the desired consistency is given below :

Pourable

: 4.125 litres

Flowable

: 4.5 litres

The selected water content should be accurately measured

into the mixer. The total content of the Conbextra GP2 bag

should be slowly added and continuous mixing should take

place for 5 minutes. This will ensure that the grout has a

smooth even consistency.

Placing

At 300C place the grout within 20 minutes of mixing to gain

full benet of the expansion process.

Conbextra GP2 can be placed in thicknesses up to 100mm in

a single pour when used as an underplate grout.

Pouring should be from one side of the void to eliminate any air

or presoaked water becoming trapped under the base plate. It

is advisable to pour the grout across the shortest distance of

travel. The grout head must be maintained at all times so that

a continuous grout front is achieved.

Where large volumes have to be placed Conbextra GP2 may

be pumped. A heavy duty diaphragm pump is recommended

for this purpose. Screw feed and piston pumps may also be

suitable.

Curing

For thicker sections it is necessary to ll out Conbextra GP2

with well graded silt free aggregate to minimise heat build up.

Typically a 10mm aggregate is suitable. 50 - 100% aggregate

by weight of Conbextra GP2 can be added.

constructive solutions

On completion of the grouting operation, exposed areas should

be thoroughly cured. This should be done by the use of Concure WB curing membrane, continuous application of water

and/or wet hessian.

page 3 of 4

Conbextra GP2

Limitations

Storage

Low temperature working

Shelf life

When the air or contact surface temperatures are 100C or below

on a falling thermometer, warm water ( 30 - 400C) is recommended to accelerate strength development.

Conbextra GP2 has a shelf life of 6 months if kept in a dry store

in sealed bags. If stored in high temperature and high humidity

locations, the shelf life may be reduced.

Precautions

For ambient temperature below 100C the formwork should be

kept in place for at least 36 hours.

Health and Safety instructions

Normal precautions for winter working with cementitious materials should then be adopted.

Conbextra GP2 is alkaline and should not come into contact

with skin and eyes. Inhalation of dust during mixing should

be avoided.

High temperature working

Gloves, goggles and dust mask should be worn.

At ambient temperatures above 400 C, cool water ( below 200C)

should be used for mixing the grout prior to placement.

Estimating

Packaging

If contact with skin occurs, it shall be washed with water.

Splashes to eyes should be washed immediately with plenty

of clean water and medical advice sought.

Fire

Conbextra GP2 is supplied in 25 kg moisture resistant bags.

Conbextra GP2 is non ammable.

Yield

Additional information

Allowance should be made for wastage when estimating quantities required. The approximate yield per 25 kg bag for different

consistency is :

Consistency

Pourable

Yield ( litres)

12.5

Fosroc Chemicals

(India) Pvt. Ltd.

Head Ofce

Sapthagiri Palace, No.38,

II & III Floor, 12th Cross,

CBI Road, Ganganagar North,

Bangalore 560 024

For further details about the use and selection of grouts refer

to the Fosroc Information module entitled Precision grouting

in the Construction industry.

Flowable

13.3

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold

subject to its standard terms and conditions of sale, copies of which may be obtained on

request. Whilst Fosroc endeavours to ensure that any advice, recommendation specication

or information it may give is accurate and correct, it cannot, because it has no direct or

continuous control over where or how its products are applied, accept any liability either

directly or indirectly arising from the use of its products whether or not in accordance with

any advice, specication, recommendation or information given by it.

telephone

fax

++91 80-42521900

++91 80-23551510

enquiryindia@fosroc.com

Regional Ofces

Chennai

Mumbai

Noida

Kolkata

No. 26(old no.33), 1st Floor,

1st Street Postal Colony,

West Mambalam,

Chennai 600 033.

Ph: 044-24899949-94

Fax: 044-24896641

1401/1402, 14th Floor,

A-WingThe Great Eastern Summit

Sector-15, CBD, Belapur

Navi Mumbai 400 614

Ph: 022-43406800-04

Fax: 022-27562423

D-166 Sector 10

Dist. Gautam Budha Nagar,

Noida,

UP 201 301

Ph:0120-4270620-21

Fax: 0120-4270622

304, Jodhpur Park

Kolkata 700 068

Ph:033-65343188

Fax: 033-2499-0280

www.fosroc.com

page 4 of 4

INDIA/2014/0306/A

You might also like

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Vikas Singh ChandelNo ratings yet

- Fosroc Conbextra GP2Document4 pagesFosroc Conbextra GP2awsdhnjkklmNo ratings yet

- Conbextra GP TDSDocument4 pagesConbextra GP TDSMoataz MedhatNo ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- Non-shrink precision grout for heavy machineryDocument4 pagesNon-shrink precision grout for heavy machineryTori SmallNo ratings yet

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- Conbextra GP 1011Document4 pagesConbextra GP 1011Srinivasan ReddyNo ratings yet

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Gautam PaulNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFUbaid Mazhar Abidi SyedNo ratings yet

- Conbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutDocument3 pagesConbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutTori Small100% (1)

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- SikaGrout212 PdsDocument4 pagesSikaGrout212 PdsdidbeauNo ratings yet

- Fast-setting emergency patching mortar for concreteDocument4 pagesFast-setting emergency patching mortar for concreteBalasubramanian AnanthNo ratings yet

- Conbextra Cable GroutDocument4 pagesConbextra Cable GroutVenkata RaoNo ratings yet

- Sika PDS - E - SikaGrout - 214-11 HF2 PDFDocument4 pagesSika PDS - E - SikaGrout - 214-11 HF2 PDFlwin_oo2435No ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Constructive solutions for non-shrink cement groutDocument69 pagesConstructive solutions for non-shrink cement groutGavriel NgNo ratings yet

- TDS - Emaco S88 PlusDocument2 pagesTDS - Emaco S88 PlusVenkata RaoNo ratings yet

- Conbextra GP PDFDocument4 pagesConbextra GP PDFPrabowo SandiNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutilhamNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutJoshua EkoNo ratings yet

- Foslok Data SheetDocument4 pagesFoslok Data Sheetemma boatNo ratings yet

- High Strength Grout for 400°CDocument3 pagesHigh Strength Grout for 400°CTori SmallNo ratings yet

- Tds - Emaco s88c TDocument2 pagesTds - Emaco s88c TVenkata RaoNo ratings yet

- Fosroc non-shrink cement grout for bridgesDocument3 pagesFosroc non-shrink cement grout for bridgesGigih M. PrayogoNo ratings yet

- High Performance Epoxy GroutDocument2 pagesHigh Performance Epoxy Groutpravi3434No ratings yet

- Masterflow 928T PDFDocument5 pagesMasterflow 928T PDFChristian D. OrbeNo ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Non-shrink cement grout for foundation platesDocument4 pagesNon-shrink cement grout for foundation platesLftea AdiNo ratings yet

- Masterflow 928 TDocument5 pagesMasterflow 928 THaresh BhavnaniNo ratings yet

- Sikagrout 215 (New)Document3 pagesSikagrout 215 (New)ArbiNo ratings yet

- Method Statement Cementitious GroutingDocument3 pagesMethod Statement Cementitious Groutingmahmoud husseinNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- en-GB - Flo-Grout 2.03012016065544 PDFDocument2 pagesen-GB - Flo-Grout 2.03012016065544 PDFHassan SleemNo ratings yet

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Fosroc Conbextra GP Non-Shrink Cementitious GroutDocument4 pagesFosroc Conbextra GP Non-Shrink Cementitious GroutShahanis NabilaNo ratings yet

- Sikagrout 214-11 PdsDocument2 pagesSikagrout 214-11 PdscharlessimoNo ratings yet

- Cmci Cmci: High Flow Epoxy Grout SystemDocument2 pagesCmci Cmci: High Flow Epoxy Grout Systempravi3434No ratings yet

- TDS DC High Grout 210Document4 pagesTDS DC High Grout 2104919404No ratings yet

- Sikagrout®-114 Ae: Product Data SheetDocument3 pagesSikagrout®-114 Ae: Product Data SheetAlexander Jonas Zach ValdrizNo ratings yet

- Conbextra GP4Document4 pagesConbextra GP4Chukwuma OgbonnaNo ratings yet

- Non-shrink precision groutDocument4 pagesNon-shrink precision groutEngr.Mohammed KhaledNo ratings yet

- TDS - Masterflow 928 TDocument4 pagesTDS - Masterflow 928 TVenkata RaoNo ratings yet

- 15 Epoxy Injection GroutDocument2 pages15 Epoxy Injection GroutPriyank MotivarasNo ratings yet

- Cebex Cable Grout - FosrocDocument4 pagesCebex Cable Grout - FosrocIrshadYasinNo ratings yet

- Flo-Grout PC100 - TDSDocument2 pagesFlo-Grout PC100 - TDSAhmed AbuoelnagaNo ratings yet

- Nitocote cm210Document4 pagesNitocote cm210pravi3434No ratings yet

- Masterflow 980 TdsDocument4 pagesMasterflow 980 Tdszhangjinlin132No ratings yet

- Ultra High Strength Non-Shrink Cementitious GroutDocument2 pagesUltra High Strength Non-Shrink Cementitious Groutmail2meanwar7865No ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Brosur Deltagrout CG - REV - 20100725MTDocument2 pagesBrosur Deltagrout CG - REV - 20100725MTjimdabrondNo ratings yet

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziNo ratings yet

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDocument7 pagesMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- ArmGrout M 65 Ver 7Document3 pagesArmGrout M 65 Ver 7beemasundarNo ratings yet

- Masterflow 928 TdsDocument5 pagesMasterflow 928 Tdsrobin rezkNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Accessibility ProcessDocument1 pageAccessibility ProcessSikander GirgoukarNo ratings yet

- Le FDocument7 pagesLe FSikander GirgoukarNo ratings yet

- Curriculum VitaeDocument5 pagesCurriculum VitaeSikander GirgoukarNo ratings yet

- Oil and Gas Companies ListDocument2 pagesOil and Gas Companies ListSikander GirgoukarNo ratings yet

- Computer Timeday Mon TUE WED THU FRI SATDocument13 pagesComputer Timeday Mon TUE WED THU FRI SATSikander GirgoukarNo ratings yet

- Bio-Data: 9766268779 (Sikander) 9975272442 (Azharuddin)Document1 pageBio-Data: 9766268779 (Sikander) 9975272442 (Azharuddin)Sikander GirgoukarNo ratings yet

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Document7 pagesShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarNo ratings yet

- Project ReportDocument16 pagesProject ReportSikander GirgoukarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentSikander GirgoukarNo ratings yet

- ANSIHI Pump Standards LibraryDocument4 pagesANSIHI Pump Standards LibraryRommy RomanzaNo ratings yet

- Aspiring Mechanical Engineer Seeks Challenging OpportunityDocument3 pagesAspiring Mechanical Engineer Seeks Challenging OpportunitySikander GirgoukarNo ratings yet

- Lokesh Sapre: Uid NoDocument3 pagesLokesh Sapre: Uid NoSikander GirgoukarNo ratings yet

- SampleDocument5 pagesSampleSikander GirgoukarNo ratings yet

- Sample Mech CVDocument2 pagesSample Mech CVSikander GirgoukarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentSikander GirgoukarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentSikander GirgoukarNo ratings yet

- Computer Timeday Mon TUE WED THU FRI SATDocument13 pagesComputer Timeday Mon TUE WED THU FRI SATSikander GirgoukarNo ratings yet

- CVDocument3 pagesCVSikander GirgoukarNo ratings yet

- Recuitment Advertisement NagpurDocument1 pageRecuitment Advertisement NagpurSikander GirgoukarNo ratings yet

- Lokesh Sapre: Uid NoDocument3 pagesLokesh Sapre: Uid NoSikander GirgoukarNo ratings yet

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Document7 pagesShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentSikander GirgoukarNo ratings yet

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Document7 pagesShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarNo ratings yet

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Document7 pagesShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentSikander GirgoukarNo ratings yet

- MP-LP Piping CCCW System Pressure Test Package DetailsDocument309 pagesMP-LP Piping CCCW System Pressure Test Package DetailsSikander GirgoukarNo ratings yet

- Aspiring Mechanical Engineer Seeks Design RoleDocument3 pagesAspiring Mechanical Engineer Seeks Design RoleSikander GirgoukarNo ratings yet

- Arya Bhatt JobDocument2 pagesArya Bhatt JobSikander GirgoukarNo ratings yet

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument11 pagesCondition Monitoring of Steam Turbines by Performance AnalysisSikander Girgoukar100% (1)

- Oil and Gas Companies ListDocument2 pagesOil and Gas Companies ListSikander GirgoukarNo ratings yet

- PBI Warranty Building Technical BidDocument39 pagesPBI Warranty Building Technical BidDonalyn NatorillaNo ratings yet

- Compact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BaseDocument4 pagesCompact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BasekicsnerNo ratings yet

- Lead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsDocument1 pageLead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsMyint Myat NaingNo ratings yet

- Material Canvass FormDocument3 pagesMaterial Canvass FormMarie AriadneNo ratings yet

- Dimpled Jacket 2Document4 pagesDimpled Jacket 2grincheu7050% (2)

- Electrical NotesDocument1 pageElectrical NotesKenneth MarcosNo ratings yet

- C2!6!455 Grout and Adhesive Rev.BDocument50 pagesC2!6!455 Grout and Adhesive Rev.BAreaya mahetemNo ratings yet

- Abbreviations and Symbols For Hvac&R Drawings: Iranian Petroleum StandardsDocument12 pagesAbbreviations and Symbols For Hvac&R Drawings: Iranian Petroleum StandardsRoel FranciscoNo ratings yet

- List Updated 14 Augustus 2019Document1,032 pagesList Updated 14 Augustus 2019muhammad fuad hasanNo ratings yet

- Opening ChecklistDocument75 pagesOpening Checklistsujay13780100% (1)

- Engineering Materials by RK RajputDocument528 pagesEngineering Materials by RK Rajputmv599766No ratings yet

- Matlab Code ABBD MatrixDocument4 pagesMatlab Code ABBD MatrixmehdiNo ratings yet

- Effectiveness F Pervious Concrete Blocks in Reducing The Depth of Stagnant WaterDocument43 pagesEffectiveness F Pervious Concrete Blocks in Reducing The Depth of Stagnant WaterJay SalesNo ratings yet

- 09a-Moteur-Ewj-3.1L TDDocument68 pages09a-Moteur-Ewj-3.1L TDfizou123No ratings yet

- Full of Example Guys!!!!! Heheheheh: Chapter 4: Flow in Pipes Example #1Document6 pagesFull of Example Guys!!!!! Heheheheh: Chapter 4: Flow in Pipes Example #1ilya danisyahNo ratings yet

- Towards Understanding Client Quality Requirements On Public Building Construction ProjectsDocument11 pagesTowards Understanding Client Quality Requirements On Public Building Construction ProjectsJohn Muhumuza KakitahiNo ratings yet

- Trocal Stone Floor Sheet 1.2Document3 pagesTrocal Stone Floor Sheet 1.2the pilotNo ratings yet

- SteelMaster 1200WF BrochureDocument4 pagesSteelMaster 1200WF BrochureSatish VishnubhotlaNo ratings yet

- IMG - 0140 PSME Code 2012 139Document1 pageIMG - 0140 PSME Code 2012 139Bugoy2023No ratings yet

- ProjectSchedulingHandbook 1Document391 pagesProjectSchedulingHandbook 1Lucio Loyloy SanchezNo ratings yet

- Sanitary FixturesDocument11 pagesSanitary Fixturesyash goyalNo ratings yet

- 211-02. Steering System Power Steering Removal and Installation (Power Steering Pump - 6.4L Dies 6Document3 pages211-02. Steering System Power Steering Removal and Installation (Power Steering Pump - 6.4L Dies 6KawikaNo ratings yet

- MORTH BT, CC, Causeway, BridgeDocument247 pagesMORTH BT, CC, Causeway, BridgesrinivasparasaNo ratings yet

- WRAP-A120 Stansted To Braintree Bypass Case HistoryDocument7 pagesWRAP-A120 Stansted To Braintree Bypass Case HistorysandycastleNo ratings yet

- Planning and Scheduling of High Rise BuildingsDocument14 pagesPlanning and Scheduling of High Rise BuildingsvivedaaNo ratings yet

- Procedure For PilingDocument21 pagesProcedure For PilingBhargav Bbvs100% (2)

- Domestic building regulations contents guideDocument618 pagesDomestic building regulations contents guidedncservices100% (1)

- Pump Selection GuideDocument12 pagesPump Selection GuideLeok Tang100% (2)

- Champion r30d BreakdownDocument32 pagesChampion r30d Breakdowncav4444No ratings yet

- 200 3PS E00x 00001 000Document30 pages200 3PS E00x 00001 000Henry MontenegroNo ratings yet