Professional Documents

Culture Documents

30 Years' History of Roller-Compacted Concrete Dams in Japan

Uploaded by

BartoFreitasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30 Years' History of Roller-Compacted Concrete Dams in Japan

Uploaded by

BartoFreitasCopyright:

Available Formats

30 Years History of Roller-compacted Concrete Dams in Japan.

Isao Nagayama

Public Works Research Institute, Japan

Shigeharu Jikan

Water Resource Development Public Corporation, Japan

ABSTRACT: Japan is the country where the worlds first roller-compacted concrete dam was constructed in

1980. Since then, about 40 roller-compacted concrete dams have been constructed in Japan. Japanese

roller-compacted concrete dams are called RCD dams and are distinguished from the other roller-compacted

concrete dams because there are some differences in their design and construction philosophies. This paper

describes the history of RCD dam construction in Japan. The paper also describes a new type of dams called

the trapezoidal CSG dams that are being comprehensively studied and field-tested in Japan.

Sand and Gravel) dams. The technology will first be

applied at the Okukubi dam with height of 39 m and

volume of 339,000 m3. Trapezoidal CSG dams are

classified as a new type of dams (not a new type of

construction method) because their structural features

differ from those of conventional triangular concrete

gravity dams (described in detail in Chapter 6).

Because they are such a new type of dams, they can

use extremely low quality material such as riverbed

materials or rock muck without washing, screening and

grading processes.

This paper presents the history of RCD dams and an

outline of trapezoidal CSG dams in Japan.

1. INTRODUCTION

Japan is the country where the worlds first

roller-compacted concrete dam was constructed. The

89 m high Shimajigawa dam with volume of 317,000

m3 was completed in 1980. Since then, about 40

roller-compacted concrete dams have been constructed

in Japan.

Japanese roller-compacted concrete dams are called

RCD (RCD is the abbreviation of Roller-Compacted

Dam concrete) dams in order to distinguish them from

the other types of RCC (RCC is the abbreviation of

Roller-Compacted Concrete) dams. The reason is that

RCD dams are not considered to be a new type of

dams (i.e., they are classified into concrete gravity

dams.), but are considered to be dams constructed with

a new construction method. The required performance

of the RCD dams should be completely the same as

that of conventional concrete gravity dams. For

example, transverse contraction joints are installed

every 15 m in order to prevent temperature cracks in

the dams, conventional concrete with high quality is

placed at the upstream and the downstream surfaces of

the dams in order to obtain water-tightness and high

resistance to freeze-and-thaw action caused by climate

change, and lift joints (lift surfaces) are treated in the

same way as in the case of conventional concrete dams

in order to assure good bond and water-tightness

between the lifts, and so on.

On the other hand, Japan is now developing

trapezoidal CSG (CSG is the abbreviation of Cemented

2. DEVELOPMENT OF RCD CONSTRUCTION

METHOD

CONSTRUCTION OF THE SHIMAJIGAWA

DAM

2.1. Development of the RCD Construction Method

Construction of safe and economical dams is the

objective of dam engineers.

In ancient times, earth dams were constructed by

trial-and-error or empirical methods. The first earth

dam referred to in Japanese historical sources was the

Sayamaike Dam with height of 15 m built in the 6th

century. This dam was modified and raised and is still

in use.

The first dam constructed using modern technology

was the 33 m high Nunobiki Gohonmatsu Masonry

Dam built in 1900. And the 79 m high Komaki Dam

1

conditions had further increased the volumes of

concrete gravity dams and raised their construction

costs.

constructed in 1929 was the first concrete gravity dam

built using modern machinery construction technology.

Concrete gravity dams were considered to be a safe

and economical type of dams and many concrete

gravity dams followed. Of course, earth dams were

constructed at the same time, but they were limited to

small pond construction.

The second stage of dam construction was the age of

concrete arch dams. The concrete volume of dams

could be drastically reduced utilizing the arch action.

The first large arch dam in Japan was the 110 m high

Kamishiiba Dam constructed in 1955. Many arch dams

were constructed in the 1950s and 1960s. However,

concrete gravity dams were still constructed at many

sites because the sites with good foundation rock which

were required for concrete arch dams were limited.

However, high economic growth in the 1960s and

1970s increased labor costs. Then, complicated

construction techniques using a lot of labor, which

were typical of concrete arch dam construction,

obstructed economical dam construction. And dam

construction using many machines was encouraged

and rock fill dam construction was started. An example

of rock fill dams in the early stage was the 131 m high

Miboro dam. Rock fill dams were economical in wide

valleys where spillways were easily constructed, but in

Japan, valleys were generally so steep that rock fill

dams could not be economically constructed in many

places. So, efforts to find economical concrete dams

construction methods began.

The Committee for the Economical Construction of

Concrete Dams was established in 1974 by the

Ministry of Construction (now reorganized as the

Ministry of Land, Infrastructure and Transport.), and

made a comprehensive study on the economical

construction of concrete dams (Hirose, 1985, Kokubu

et al., 1985). The basic philosophy of the committee

was as follows:

The construction method used at Alpe Gera dam in

Italy where dump truck were used for concrete

transportation on the dam, and the roller-compacted

concrete construction that was studied at the Lost

Creek Dam in the USA were referred to in order to

accomplish rapid and economical construction.

After comprehensive research and discussions the

following conclusions were reached.

(1) Concrete should be transported by simple

machinery from a mixing plant to the construction

area.

(2) The construction surface of dams should be so flat

that dump trucks can transfer concrete from a

ground hopper on the dam to concrete pouring areas.

(3) Concrete should be compacted by vibrating rollers

in order to speed up its consolidation.

(4) Concrete should be stiff enough to be compacted by

vibrating rollers.

(5) Concrete should be workable enough to be

consolidated by vibrating rollers.

(6) Concrete lift should be thin enough to be

compacted by vibrating rollers.

(7) Concrete should be spread uniformly (without

segregation) by bulldozers.

(8) The upstream and downstream surfaces should be

covered by high quality concrete to maintain

water-tightness and to protect the concrete from

freeze-and-thaw attack.

(9) The surface concrete and internal concrete should

be cut by vibrating blades at 15 m intervals to

prevent temperature cracks.

(10) Lift surfaces should be treated by green cutting

and mortar spreading to obtain good bond for shear

stress and water-tightness.

(1) Reduction of the unit cost of concrete should be

studied because of recent high labor costs. Reducing

the concrete volume as in the case of concrete arch

dams and concrete hollow gravity dams provided no

benefit. Efforts should be made to reduce the unit

cost of concrete.

(2) Reduction of the unit cost of concrete should be

studied, because worsening foundation rock

2.2. Mixture of RCD

The success of RCD construction depends on the

mixture design of RCD. So the concepts of the

coefficients and were introduced. The coefficient

is the volume ratio of cement slurry to the voids

between sand particles (fine aggregate) and it must be

designed as larger than 1. The coefficient is the

2

volume ratio of mortar to voids between gravel

particles (coarse aggregate) and it must also be

designed as larger than 1.

Compaction energy is also an important factor in

determining the strength of RCD. So the consistency of

RCD mixture was measured with the VC meter shown

in Figure 1 and Table 1. Concrete specimens were

made using the large specimen compaction device

shown in Figure 2 and Table 2.

The RCD mixture is designed by the following

process.

of the RCD mixture.

(3) Determination of sand aggregate ratio that gives

RCD the lowest VC value. Usually a ratio around

30 % to 35 % is adopted.

(4) Determination of water content. Water content that

gives RCD 20 second of VC value is optimum.

Usually 80 to 100 kg/m3 of water is adopted.

(5) Strength and surface appearance of RCD (without

honeycomb voids) were evaluated with the large

specimen compaction device.

Typical features of RCD mixture from these tests are

shown in Figure 3 to Figure 5.

(1) Determination of the maximum size of aggregate.

Usually 80 mm is adopted.

(2) Determination of cement content. Usually 120

kg/m3 is adopted in consideration of the high quality

Figure 2. Large Specimen Compaction Device

Figure 1. VC Meter

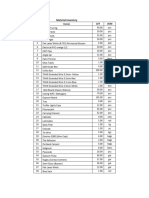

Table 2. Specification of Large Specimen

Compaction Device

(1) Vibrating Mass

Table 1. Specification of VC Meter

(1) Vibrating Table

Item

value

Item

Value

Full Amplitude

2.4 mm

Full Amplitude

1 mm

Frequency

1900 cpm

Frequency

3000 cpm

Mass

648 kg

Loading Mass

20 kg

(2) Specimen

(2) Specimen

Item

Value

Item

Value

Diameter

24 cm

Diameter

48 cm

Height

20 cm

Height

40 cm

1000

Table 3 RCD Mixture at Shimajigawa Dam

VC Value (s)

C=120 kg/m3 s/a=32%

100

10

1

70

80

90

100

110

120

Item

Value

Maximum Size of Aggregate

80 mm

Water

105 kg/m3

Cement

84 kg/m3

Fly-ash

36 kg/m3

Sand Aggregate Ratio

34 %

Fine Aggregate

752 kg/m3

Coarse Aggregate

1482 kg/m3

Air

1.5 %

130

Unit Water Content (kg/m )

2.3. Construction of the Shimajigawa Dam

Figure 3. Unit Water Content vs. VC Value

The Shimajigawa Dam (height = 89 m, completed in

1980 by the Ministry of Construction) was selected as

the first RCD dam, because its height was moderate

and the installed structures in the dam body were very

simple. The dam is located on the Saba River in the

Chugoku Region. At the test yard, test filling was

performed to study the lift thickness, the number of

passes of a vibrating roller, and so on (Figure 6).

At the Shimajigawa Dam, a 75 cm lift (25 cm x 3

layer spreading) was planned at first. But, because it

was noted that the upper layer was weaker than the

lower layer after vibration, the lift thickness was

lowered to 50 cm (17 cm x 3 layer spreading).

However, good quality was revealed by the later test

fill, and a 75 cm lift was adopted (25 cm x 3 layer

spreading) in the upper part of the dam. The standard

mixture proportion is shown in Table 3.

A typical feature of Japanese roller-compacted

concrete dam construction is adoption of high lifts that

can reduce the number of weak planes between

100

VC Value (s)

W=100 kg/m3 C=120 kg/m3

10

1

26

28

30

32

34

36

Sand Aggregate Ratio (%)

38

Figure 4 Sand Aggregate Ratio vs. VC Value

Compressive Strength (MPa)

25

20

15

10

C=120 kg/m3 s/a=32%

0

70

80

90

100 110 120

Unit Water Content (kg/m3)

130

Figure 5 Unit Water Content vs. Compressive Strength

Figure 6. RCD Construction Method

the cutting plane to prevent closing (Figure 8). And at

the upstream and downstream edges of the dam,

galvanized steel plates were installed in advance. Then,

water-stop plates and drainage holes were set in the

upstream galvanized steel plate (Figure 9).

Lift joints were cleaned (green-cut) 24 to 48 hours

after concrete placement (depending on the season). A

motor sweeper or water jet was used for green cutting.

Mortar with thickness of 1.5 mm was then spread

before the above lift was placed.

Figure 10 is a perspective view of the completed

Shimajigawa dam. Its features were the completely the

same as those of conventional concrete gravity dams.

successive lifts. Roller-compacted concrete is spread

into thin layers by bulldozers, and then they are

compacted by vibrating rollers. Thin layer spreading of

roller-compacted concrete was the key factor that

makes thick lift placement possible.

Roller-compacted concrete was consolidated by

vibrating rollers. Vibrating rollers were passed over

roller-compacted concrete twice without vibration and

9 times with vibration at the Shimajigawa Dam

(nowadays, 5 to 6 passes are the norm).

Concrete was transported from the concrete batching

and mixing plant to the dam by a fixed 13.5 t

cableway-type crane. Concrete was received by a

ground hopper and was transferred by dump trucks

from the ground hopper to the placement area (Figure

7). Contraction joints were cut by a vibrating blade

machine and galvanized steel plates were installed in

Figure 7 Concrete Transportation

Figure 9. Installation of Water-stop and Drainage

Figure 8. Installation of Transverse Joint

Figure 10. Shimajigawa Dam

3. ESTABLISHMENT OF RCD CONSTRUCTION

METHOD

CONSTRUCTION OF THE TAMAGAWA

DAM

3.1. General

The Tamagawa Dam is a 100 m high concrete

gravity dam with volume of 1.15 x 106 m3. The dam

was constructed on the Omono River in the Tohoku

Region in 1987 by the Ministry of Construction. Figure

11 shows a view during construction, and Figure 12 is

a perspective view of the completed dam. The RCD

construction method developed at the Shimajigawa

Dam was really established through the experience of

the Tamagawa Dam.

The Tamagawa Dam was located in a cold region

where snowfall accumulates to 2 m and the air

temperature falls as low as 15C. Construction work

of the dam had to be suspended for five months in the

winter. To economically construct a high dam under

such climate conditions, the RCD construction method

was adopted.

3.2. Characteristics of RCD Construction Method at

the Tamagawa Dam

The principal features of the RCD construction

method at the Tamagawa Dam were the challenge to

high construction speed and thick lift of concrete

(Yamauchi,et al., 1985, Yamaguchi, et al., 1988).

At the Tamagawa Dam, the concrete batching and

mixing plant was built at the crest level of the dam.

Mixed concrete was loaded on the transfer-car. Then it

was loaded on the bucket-cars that ran on the inclined

railways. Then, concrete was dumped into the hopper

station at the construction level and was transported to

the pouring area by 20 t dump trucks.

The incline system consisted of two bucket-cars and

two rows of railways. The maximum height difference

of the railway was 94.5 m and maximum speed of the

bucket-cars was 150 m/min (Figure 13). This incline

system recorded 270 m3/h of concrete transportation at

the peak time. It revealed that the incline system was

superior to the conventional cableway-type crane

system in terms of its transport capacity, easiness of

operation, safety of operation and so on. For these

reasons, the incline system has been adopted at many

Figure 11. RCD Construction Method

Figure 12. Tamagawa Dam

Figure 13. Incline System

dams since the Tamagawa Dam.

In order to speed up construction and to reduce the

number of lift surface treatments, lift thickness had to

be increased. But it was accompanied by a risk of

inadequate compaction of RCD. At the Tamagawa

Dam, 1 m of lift thickness was made possible by thin

layer placement. A 1 m thick lift was divided into four

thin layers that were spread by bulldozers. After

spreading, the entire lift was compacted by vibrating

rollers. Furthermore, in order to control the quality of

RCD after compaction, density control was executed

with an insert-type radioisotope density meter. These

measures permitted thick lift placement without

inadequate compaction.

The thin layer spreading method used in the RCD

construction completely differs from compaction in

RCC construction which adopted compacting concrete

in a single layer. Thick lift placement, as used in

conventional concrete dam construction, prevents the

formation of a possible weak plane on the lift surface.

After experience of constructing 1 m thick lifts at the

Tamagawa Dam, new vibrating rollers with high

vibrating force have been developed and used for all

RCD construction.

Because the Tamagawa Dam was the first high dam

built by the RCD construction method, a wide-ranging

surveys and research on temperature control were

carried out. In order to reduce the cement content, 150

mm of maximum size of aggregate was used and the

cementitious material content was limited to 130 kg/m3.

Moderate heat Portland cement was used and 30 % of

it was replaced by fly-ash. Table 4 shows the design

mixture of RCD at the Tamagawa Dam.

Thanks to the use of the RCD construction method

in this way, 1.15 x 106 m3 of concrete were placed in

26 months excluding a break period during the winter,

and a calculation has showed that using RCD

construction method at the Tamagawa Dam shortened

the concrete placing period 5 to 7 months compared

with the conventional block construction method.

4.

POPULARIZATION OF THE RCD

CONSTRUCTION METHOD

4.1. General

The completion of the Tamagawa Dam confirmed

that the RCD construction method is a rapid and

economical concrete dam construction method. Since

then, it has been widely applied to many concrete

gravity dams throughout Japan, not only those

constructed by the Ministry of Construction and the

Water Resource Development Public Corporation, but

also those constructed by local governments (Toyoda,

et al., 1991). With about 40 completed RCD dams and

about 20 RCD dams at the design stage, this

technology has now matured.

Technology development of the RCD construction

method started with the introduction of vibrating roller

compaction, and it extended to the improvement of

concrete transportation systems. Other related studies

such as temperature control, quality control, and

peripheral technologies such as installed structures and

contraction joint cutting have also been improved. In

these improvements, the improvement of RCD mixture

and improvement of transportation machinery are

described below.

4.2. Improvement of RCD Mixture

The mixture design of RCD has been improved

throughout the history of RCD dam construction. In

particular, the filling properties of concrete, i.e., the

appropriate values of the parameter (the volume ratio

of cement slurry to the voids between sand particles)

and the parameter (the volume ratio of mortar to

voids between gravel particles) have been studied in

detail. The results have shown that compared with the

= 1.5 to 1.8, = 1.2 to 1.5 of conventional dam

concrete, and = 2.1 to 2.4, = 2.0 to 2.3 of structural

concrete, = 1.1 to 1.3, = 1.2 to 1.5 are suitable

values for RCD. It is noted in particular that the

volume of cement slurry is close to the volume of

Table 4 RCD Mixture at Tamagawa Dam

Item

Value

Maximum Size of Aggregate

150 mm

Water

95 kg/m3

Cement

91 kg/m3

Fly-ash

39 kg/m3

Sand Aggregate Ratio

30 %

Fine Aggregate

657kg/m3

Coarse Aggregate

1444 kg/m3

Air

1.5 %

transport RCD to every pouring area on the dam. It

provides greater freedom of choice of the

transportation system from concrete batching and

mixing plant to the dam. These transportation systems

include direct transportation by dump trucks, belt

conveyors, inclines, tower cranes, cableway-type

cranes and so on.

The Pirika Dam (height = 40 m, completed in 1991,

by the Hokkaido Development Bureau) is a combined

dam consisting of a concrete gravity dam and a rock

fill dam with crest length of 1,480 m and with height of

40 m. Because of it topographical feature of the site,

the RCD construction method using the direct

transportation system by dump trucks was adopted for

the concrete gravity sections (the crest length is 755 m

of the left side). The road to the dam body was

designed as an embankment-type road. The direct

transportation system by dump trucks was applied at

the Shiramizugawa Dam (height = 54.5 m, completed

in 1991, by Yamagata Prefecture). The road to the dam

body was connected by a temporary bridge that was 30

m long and 4 m wide. The bridge raised itself every 50

cm. The use of the direct transportation system by

dump trucks is often applied to lower dams or the

lower part of the dams (Figure 14).

At the Tsugawa Dam (height = 76 m, completed in

1996 by Okayama Prefecture), a belt conveyor system

was used to transport concrete. Concrete transported

from the concrete batching and mixing plant by belt

conveyers was temporarily stocked in a ground hopper

installed on the dam, then was transported by dump

trucks to the pouring area (Figure 15). Transportation

of RCD by a belt conveyer system was performed at

the high dams such as the Gassan Dam (height = 123m,

completed in 2001 by the Ministry of Construction).

An incline system is a transportation method that is

often used at relatively large scale RCD dams because

it has large transportation capacity and is not dependent

on the dam site topography. Dams constructed by the

incline transportation system include the Tamagawa

Dam (height = 100 m, completed in 1987 by the

Ministry of Construction), the Sakaigawa Dam (height

= 115m, completed in 1993 by Toyama Prefecture),

and the Miyagase Dam (height = 156 m, completed in

1998 by the Ministry of Construction).

Concrete transportation by buckets such as the tower

crane and cableway-type crane methods are also used,

voids between fine aggregates. This result shows that

unit cementitious material (cement and fly-ash) content

is in the range of 110 to 130 kg/m3 and unit water

content is in the range of 80 to 100 kg/m3 for RCD.

However, reducing the cement paste content or

mortar content may cause the segregation of the

aggregates. It is improved by adding finer particles

(50 % grain size of about 50 m) to the fine aggregate.

At the Hiyoshi Dam (height = 67 m, completed in 1997

by the Water Resource Development Public

Corporation), a dry-process-type sand production

facility was adopted in order to increase the content of

finer particles. Then, workability was improved and the

unit cementitious material content was reduced to 110

kg/m3. And at the Urayama Dam (height = 156 m,

completed in 1999, by the Water Resource

Development Public Corporation), a dry-process-type

coarse aggregate production facility was adopted. The

finer particles produced during production of coarse

aggregates that were formerly discarded as industrial

waste material, were effectively used to improve the

workability of the RCD mixture.

Technological progress has been achieved in the

areas of admixture mineral, chemical admixture, and

cement. Fly-ash is generally used as admixture mineral

and 20 % to 40 % of cement is replaced by fly-ash. The

use of fly-ash contributes to lowering the heat of

hydration, improving consistency, and increasing long

term strength. At the Tomisato Dam (height = 111 m,

completed in 2000 by the Water Resource

Development Public Corporation), cement and fly-ash

were mixed at the dam site according to the season and

concrete mixture. Namely, 40 % of the cement in RCD

was replaced by fly-ash in the summer season and

30 % in the other seasons, and 35 % of the cement in

conventional concrete (external concrete) was replaced

by fly-ash in the summer season.

Special chemical admixtures for RCD and low

hydration heat type cements were also developed.

4.3. Improvement of Transportation Machinery

Noteworthy achievements in the RCD construction

method were the improvement of transportation

machinery and the diversification of transportation

system.

Because the construction surface of a dam built by

the RCD construction method is flat, dump trucks can

8

right banks. Two 9 m3 ground hoppers were installed

on the construction surface of the dam and concrete

was transported from the ground hoppers to the

pouring area by dump trucks (Yamamoto et al., 1994).

At the Tomisato Dam, 20 ton both-side-running

cableway-type cranes were installed as RCD

transportation system (Figure 16). This cableway-type

crane permitted transportation not only in the dam axis

direction but also in the river flow direction by 22 m.

This crane was fully used for installation of water

discharge facilities and pouring of the concrete around

the conduit pipe, and for pouring concrete of the upper

parts of the dam where working area was so narrow.

In addition, the automated transportation system and

automated concrete batching and mixing plant were

introduced.

because they permit three-dimensional transportation.

At the Sabigawa Dam (height = 104 m, completed in

1994 by Tokyo Electric Power Corporation), change of

the environment at the dam site was minimized by

installing two 13.7 ton tower cranes on the left and

5.

APPLICATION OF RCD CONSTRUCTION

METHOD TO EXTREMELY HIGH DAMS

5.1. The Miyagase Dam

The Miyagase Dam (completed in 1998 by the

Ministry of construction) is an extremely high RCD

dam with height of 156 m and with volume of 2.06 x

106 m3. The dam was located on the Sagami River in

the Kanto Region. Figure 17 shows a perspective view

of the completed Miyagase Dam.

At the Miyagase Dam, the major challenge to be

overcome was the problem of thermal stress in the

large RCD dams. To resolve this problem, thermal

stress analysis based on the restraint matrix method

was performed and a comprehensive study of the

starting time of concrete placement and the placement

schedule was performed (Hirose et al., 1988). When a

dam is raised uniformly as it is using the RCD

construction method, the concrete temperature at each

elevation of the dam is governed not only by the heat

of hydration but also by the seasonal temperature

fluctuation. At the Miyagase Dam, various studies of

the placement starting time and concrete placement

schedule were performed by restraint matrix analysis,

obtaining the conclusion that beginning concrete

placement in October would be most beneficial for

temperature control. In practice, inclined contraction

joints were installed in order to make concrete

placement efficient at the lower part of dam and in

order to reliably protect RCD from temperature cracks

(Figure 18).

Figure 14. Temporary Bridge

Figure 15. Belt Conveyor

Figure 16. Both-side-running Cableway type Crane

At the Miyagase Dam, the concrete was transported

by inclines where dump trucks were directly loaded

(Figure 19). Concrete mixed at the batching and

mixing plant was dumped into 20 t dump trucks, then

dump trucks with 9 m3 of concrete were transported to

the construction surface through two rows of inclines.

Dump trucks were carried on the incline at a speed of

180 m/min. Since this transportation method eliminates

the transfer of concrete from bucket to bucket, it

effectively shortened the transportation cycle time,

reduced the segregation of materials that occurs during

reloading, and restricted quality fluctuations such as the

temperature or consistency of concrete.

In addition, pre-cast products were efficiently used at

the Miyagase Dam. Pre-cast products were used for the

inspection galleries and the elevator shaft.

5.2. The Urayama Dam

The Urayama Dam is an extremely high RCD dam

with the height of 156 m and volume of 175 x 106 m3

constructed on the Ara River in the Kanto Region by

the Water Resource Development Public Corporation.

It was completed in 1999. Figure 20 is a view of the

completed the Urayama Dam.

From the results of a detailed study of the thermal

stress problem that was carried out based on experience

at the Miyagase Dam, it was concluded that the

thermal stress was under the regulated value even at the

maximum layer length of 170 m at the bottom of the

dam, as long as the concrete was raised rapidly and

constantly (Yamazumi. et al., 1994).

To increase the amount of concrete product per hour,

an integrated belt conveyor system was installed from

the quarry to the dam. This belt conveyer system

Figure 17. Miyagase Dam

Normal Water Level

EL.286.000m

EL.290.000m

1 :0

1:0.2

EL274.500m

.5

EL.210.000m

Inclined

Contraction Joint

EL.176.250m

Unit:m

1:0

.

38.195

1:0.3

1:1

.5

EL.134.000m

118.350

59.200

100.000

177.550

Figure 18. Inclined Contraction Joint

Figure 19 Dump Truck Mounted Incline

Figure 20. Urayama Dam

10

attached to the dam body. The access conveyors were

4-level conveyors with a trough angle of 18 and a lift

head of 40 m so that it could cover a dam height of 156

m . The RCD was transported at approximately 140

m/min. During these processes, hoods were placed on

the belt conveyors to prevent infrared rays and the belt

surface was moistened before material was loaded.

consisted of three kinds of conveyors, one for crushed

rock, one for aggregate, and one for concrete. The

quarry was located 4.5 km upstream from the dam site,

the aggregate production plant 2.5 km upstream from

the dam site, and the concrete batching and mixing

plant directly upstream from the dam site. The belt

conveyor for crushed rock was 1,050 mm wide, 1,500

mm long, and operated at a speed of 120 m/min. It

transported crushed rock with maximum size of 300

mm from the quarry to the aggregate production plant.

The belt conveyer for aggregate was 1,050 mm wide,

2,300 m long, and operated at a speed of 110 m/min. It

transported four grades of coarse aggregate and one

grade of fine aggregate produced at the aggregate

production plant to the concrete batching and mixing

plant (Figure 21, Figure 22). The belt conveyor for

concrete consisted of two parts: the main conveyor that

was 900 mm wide, moved at 120 m/min, and had a

trough angle of 30, and the access conveyor that was

6. DEVELOPMENT OF CSG AND

TRAPEZOIDAL CSG DAMS

6.1. Development of CSG at the Nagashima Dam

Site.

The 113m high Nagashima dam was a conventional

concrete gravity dam, because the many conduit gates

installed in the dam body prevented flat layer

construction such as the RCD construction method.

However, because the riverbed deposit was very thick

at the site, the RCD construction method was used to

replace the original riverbed and a conventional

concrete dam was constructed on it.

At first, the upstream cofferdam was to be made of

earth and rock because it was constructed on

deformable riverbed deposits. However, after a large

flood washed away the cofferdam, the dam constructor

decided to construct a new cofferdam with

Water-stop sheet &

Shot-concrete

River Bed Material

Facing Concrete

CSG

Figure 21. Belt Conveyor from Aggregate

River Deposit

Production Plant to Dam Site

Cut-off Wall

Rock

Figure 23. Cross Section of Nagashima Coffer Dam

Figure 22. Belt Conveyor and Ground Hopper

Figure 24 Nagashima Coffer Dam

11

soil-cement-like material. First riverbed material was

dumped at the site then cement was dusted on it. Then

a skeleton-type backhoe mixed the materials and a

vibrating roller compacted the materials. When the

water content was judged to be low, additional water

was sprinkled on it. This material is called CSG that is

the abbreviation of Cemented Sand and Gravel. The

cross section of the CSG cofferdam at the Nagashima

Dam is shown in Figure 23 and a perspective view in

Figure 24. The CSG cofferdam had properties similar

to soil-cement. It was confirmed that the structure

could resist overflow by flood water during the flood

season. CSG cofferdams have been constructed at

many dam sites since then.

CSG had the optimum water content from 6 to 8 %,

as the soil had. The water content was kept on the wet

side in the consolidating CSG to prevent honeycomb

voids and to keep the strength deviation relatively low.

Cement content was about 60 kg per unit volume (1

m3) of CSG.

This CSG was designed to allow for a wide range of

deviation of mechanical properties (unit weight,

strength, modulus of elasticity) and the existence of

entrapped voids, because it was used as the material for

temporary structures. For example, the strength range

of CSG was sometimes 2 to 10 N/mm2 on the 28th day.

constructed in the reservoir of the Nagashima Dam, its

safety requirements were relatively low. Economical

construction methods were, therefore, studied in

advance of construction (Yokotsuka et al., 2000).

As a result of the study, CSG was used to make the

dam body. Using skeleton backhoes to mix the CSG

was not effective because of the large volume of the

dam. Then, the continuously mixing drum-type mixer

was adopted. CSG materials were provided from the

river bed. Originally no grading process was planned,

but the variation of the grading of the materials proved

very high. So, a 20 mm sieve feeder was adopted and

CSG materials were classified into materials larger

then 20 mm (larger aggregate) and materials not larger

than 20 mm (smaller aggregate). They were stocked

separately. Furthermore, it was found that grain size

under 5 mm is very small, so fine sand was excavated

from a pool in the river and mixed into the smaller

aggregate (Figure 26).

In the design, the unit mass of CSG was assumed to

be 2,200 kg/m3, and 100 kg of cement and 100 kg of

6.2. the Nagashima Sand-Trap Dam

The Nagashima dam was constructed on the Oi

River by the Ministry of Construction. Because the

river flow of the Oi River includes much silt and sand

during flooding, a 34 m high sand-trap dam with

volume 50,000 m3 was constructed in the upper part of

the reservoir (Figure 25).

Because the Nagashima Sand-trap Dam was

Figure 25. Nagashima Sand-trap Dam

Turn Head Shoot

Rotary Drum Mixer

Capacity6080m3/h

Cement Supplier

20-0 mm

150-20 mm

Fine Sand

Apron

Feeder

Belt Conveyor with

Belt Scale

Belt Feeder

Belt Conveyor with

Belt Scale

Dump Truck

Concrete Hopper

4m34

Figure 26 Bathing and Mixing Plant (Continuously Mixing Type)

12

sand were added. These materials were weighed on the

belt scale. Also, the water contents of sand and smaller

aggregate were measured on a belt scale and adequate

water was added to obtain VC value of 20 seconds.

The result of the test fill was excellent and cement

content was reduced to 90 kg/m3.

CSG manufactured by the continuously mixing

drum type mixer was stocked in the hopper and a

dump truck transported it from the hopper station to the

dam. The compaction method and other processes

were almost the same as those of RCD except that

surface concrete (conventional concrete with 220

kg/m3 of cement) and bedding mortar were

manufactured at a local private concrete plant. Delay of

concrete supply was not observed.

with other concrete structures. This means that a

trapezoidal concrete dam can utilize even CSG as its

dam body material (Hirose et al., 2001).

On the other hand CSG does have low resistance to

freeze-and-thaw attack and high permeability. Then

conventional concrete should be placed in order to

prevent water leakage at the upstream surface, and in

order to prevent freeze-and-thaw attack at the

downstream surface.

Furthermore, leakage of water from the foundation

rock to the CSG should be prevented. Therefore, the

bottom of the dam along the foundation rock from the

heel of the dam to the drainage holes is covered with

conventional concrete and foundation grouting is

executed.

At the crest level of a CSG dam, 8 to 10m width is

adopted because the transportation of CSG by dump

trucks and the compaction of CSG by vibrating rollers

can be easily done.

Therefore, the typical cross section of a trapezoidal

CSG dam is as shown in Figure 27. Trapezoidal CSG

dams are now at the design stage of the Okukubi Dam

(height = 39 m), Sanru Dam (height = 50 m) and

Hommyogawa Dam (height = 64 m).

6.3. Concept of a trapezoidal CSG dam

A trapezoidal CSG dam is a new type of a dam that

combines a trapezoidal dam and CSG materials.

Conventional concrete gravity dams were usually

designed to satisfy three requirements: resistance

against overturning, resistance against sliding and

allowable compressive strength. In the seismic

coefficient method, middle third condition guarantees

the no tensile stress in the concrete gravity dam. But

under real earthquake conditions, the large tensile

stress is induced in the dam body. So, the compressive

strength of concrete should have much larger than the

allowable stress. However, if the shape of the dam is

trapezoidal with a slope of 0.8 : 1.0, no tensile stress is

induced even by the design earthquake. This means a

large safety factor is unnecessary.

At the same time, the maximum compressive stress

in a concrete gravity dam is relatively low compared

Reference

- T. Hirose. 1982. Research and practice concerning RCD method,

Proceeding of ICOLD C,

- T. Yamaguchi, J, Harada, et al. 1985. Construction of Tamagawa

Dam by the RCD method, Proceeding of ICOLD, Q57-R6

- M. Kokubu, S. Shimizu, S. Jojima. 1985. Present stage and

problems of rationalized construction of concrete dams in Japan,

Proceeding of ICOLD, C7

- T. Hirose, I. Nagayama, et al. 1988. A study on control of

Temperature cracks in large roller compacted concrete dams,

Proceeding of ICOLD, Q62-R7

Protection Concrete

- J. Yamaguchi, K. Ohyabu, et al. 1988. Construction Work and

CSG

Quality and temperature concrete for Tamagawa RCD Dam,

Proceeding of ICOLD, Q62-R8

- M. Imamura , K. Torii, et al. 1988. Embedded facilities within the

Water Stop Concrete

RCD dam bodies, Proceeding of ICOLD, Q62-R9

Structure Concrete

Rich CSG

- T. Toyoda, S. Nagataki, et al. 1991. The latest situation of

Rationalized construction methods for concrete dams in Japan,

Grouting

Proceeding of ICOLD, C9

- A. Yamazumi, K. Harita, et al. 1994. Long layer performance by

Figure 27. Trapezoidal CSG dam

the plane construction method No-joint 170 m layer by the

13

RCD method. Proceeding of ICOLD, C6

- Y. Yamamoto, A Hirai, et al. 1994. Quality control and

temperature regulation of Sabigawa RCD dam, Proceeding of

ICOLD, C9

- K. Takemura, Y. Kobayashi, et al. 1994. Development of concrete

dam construction methods and their applications in Japan,

Proceeding of ICOLD, C3

- T. Fujisawa, I, Nagayama, et al. 1997. A study on mixture design

of RCD concrete using standard specimen compaction device.

Proceeding of ICOLD, C5

- T. Tonegawa, Y. Sekine, et al. 1997. Experimental field study for

increasing the lift thickness of the RCD construction Method,

Proceeding of ICOLD, C6

- T. Yokotsuka, Y. Otaka, et al. 2000. Application of CSG method

to construction of gravity dam, Proceeding of ICOLD, C6

- T. Hirose, T. Fujisawa, et al.2001. Design criteria for

trapezoid-shaped CSG dams, Proceedings workshop on Modern

Technique for Dams - Financing, Construction, Operation, Risk

Assessment

14

You might also like

- 3tq3f Basic Knowledge in Civil Engineering Book of 59 Topics Including History of Civil Engineering NR 1Document148 pages3tq3f Basic Knowledge in Civil Engineering Book of 59 Topics Including History of Civil Engineering NR 1La0% (1)

- Geotechnical and Foundation Engineering by Robert W DayDocument848 pagesGeotechnical and Foundation Engineering by Robert W DayJesus Gonzalez100% (1)

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- Sustainable Construction Materials and TechnologiesDocument821 pagesSustainable Construction Materials and TechnologiesAhmed Zidan100% (6)

- Design and Construction of Concrete Gravity DamsDocument69 pagesDesign and Construction of Concrete Gravity Damshenybam83% (6)

- Guide To The Design of Retaining WallsDocument149 pagesGuide To The Design of Retaining Wallspierre_oosthuizen100% (1)

- RollerDocument4 pagesRollerkapola100% (1)

- Ste05121 Spreadsheet Anchor Bolt DesignDocument10 pagesSte05121 Spreadsheet Anchor Bolt Designsivaguruswamy thangarajNo ratings yet

- Work Schedule Ajay.Document4 pagesWork Schedule Ajay.kasturi YogenderNo ratings yet

- GodaDocument22 pagesGodaLazaros NtoanidisNo ratings yet

- Bridge - Concrete StructuresDocument71 pagesBridge - Concrete Structuresကိုနေဝင်းNo ratings yet

- Carport DesignDocument6 pagesCarport DesignTuroyNo ratings yet

- Estimate Gadawara Power Plant, NTPCDocument420 pagesEstimate Gadawara Power Plant, NTPCGopal SudhirNo ratings yet

- Pressure Testing of DI, PVC & HDPE Pipe Uploaded On 22-10-2020Document8 pagesPressure Testing of DI, PVC & HDPE Pipe Uploaded On 22-10-2020CrazyBookWormNo ratings yet

- Why Steel Reinforcement Is Needed in Concrete SlabsDocument2 pagesWhy Steel Reinforcement Is Needed in Concrete SlabsAuYongTheanSengNo ratings yet

- Interview QueDocument9 pagesInterview QueDhanashri MusaleNo ratings yet

- Sewer TunnelDocument10 pagesSewer TunnelshahqazwsxNo ratings yet

- WVA Consulting Engineers PVT LTD: Analsyis and Design of Steel Watch TowerDocument23 pagesWVA Consulting Engineers PVT LTD: Analsyis and Design of Steel Watch TowerRomyMohanNo ratings yet

- Heater Draft DesignDocument3 pagesHeater Draft DesignHell SinNo ratings yet

- HT Khanh RCC DamsDocument70 pagesHT Khanh RCC DamsManzar Mumtaz100% (1)

- Floating Concrete StructuresDocument10 pagesFloating Concrete StructuresCyril LongtonNo ratings yet

- Construction of MRT Chaloem Ratchamongkhon Line Underground Structures North and Japanese Shield Tunnel TechnologyDocument10 pagesConstruction of MRT Chaloem Ratchamongkhon Line Underground Structures North and Japanese Shield Tunnel TechnologyTeera AthirahNo ratings yet

- Design of Water Based Fire Fighting SystemDocument47 pagesDesign of Water Based Fire Fighting SystemDonald's KitchenNo ratings yet

- Self Compacting Concrete: J.Vani J.Supriya III/IV B.Tech Students, Koneru Lakshmaiah College of EngineeringDocument10 pagesSelf Compacting Concrete: J.Vani J.Supriya III/IV B.Tech Students, Koneru Lakshmaiah College of Engineeringpremkumar_senguntharNo ratings yet

- Civil Engineering for Underground Rail TransportFrom EverandCivil Engineering for Underground Rail TransportJ. T. EdwardsRating: 5 out of 5 stars5/5 (2)

- 1.1 General: Chabahil Road in Kathmandu District, BagmatiDocument25 pages1.1 General: Chabahil Road in Kathmandu District, Bagmatienlacer009No ratings yet

- 30 Years' History of Roller CompactedDocument14 pages30 Years' History of Roller CompactedElena O.No ratings yet

- Technical Paper (FINAL)Document10 pagesTechnical Paper (FINAL)jarabos8609No ratings yet

- 1.1 Background To The StudyDocument6 pages1.1 Background To The StudyEduga PraiseNo ratings yet

- Chapter 1Document19 pagesChapter 1JOSEFINA MOENNENo ratings yet

- Paper13 Warren RDocument9 pagesPaper13 Warren RHemin EssaNo ratings yet

- Q Shaw CONCRETE DAM TYPES AND THE CIRCUMSTANCES ANDDocument10 pagesQ Shaw CONCRETE DAM TYPES AND THE CIRCUMSTANCES ANDTansel YılmazNo ratings yet

- Development, Applications and Investigations of Self-Compacting ConcreteDocument3 pagesDevelopment, Applications and Investigations of Self-Compacting ConcreteAnonymous 9iK0i8h0dPNo ratings yet

- Civil Engineering Construction Technology CV4251 TUTORIAL #3, #4 and #5Document3 pagesCivil Engineering Construction Technology CV4251 TUTORIAL #3, #4 and #5zzz_monsterNo ratings yet

- Rock Filled ConcreteDocument8 pagesRock Filled ConcreteKay Hyang CheeNo ratings yet

- Earthquake Aspects of Roller Compacted Concrete and Concrete-Face Rockfill DamsDocument12 pagesEarthquake Aspects of Roller Compacted Concrete and Concrete-Face Rockfill DamsHaryadi StNo ratings yet

- Bridge Design Engineering May 2010Document4 pagesBridge Design Engineering May 2010Gonzalo NavarroNo ratings yet

- Roller Compacted Concrete: A Litrature Review: S.D. Bauchkar, Dr.H.S. ChoreDocument5 pagesRoller Compacted Concrete: A Litrature Review: S.D. Bauchkar, Dr.H.S. ChoreoussamaNo ratings yet

- Dam EngineeringDocument25 pagesDam EngineeringAbdii AbdallaaNo ratings yet

- Introduction To ConcreteDocument29 pagesIntroduction To ConcreteLuqman Alee KhanNo ratings yet

- Section A 30 MarksDocument2 pagesSection A 30 MarksKailash ChaudharyNo ratings yet

- 21Document20 pages21štatebolidupeNo ratings yet

- 130-Study On Cemented-Rockfill DamDocument9 pages130-Study On Cemented-Rockfill DamManzar MumtazNo ratings yet

- Concrete Durability Presented by Acceptable Chloride Level and Chloride Diffusion Coefficient in Concrete: 10-Year Results in Marine SiteDocument11 pagesConcrete Durability Presented by Acceptable Chloride Level and Chloride Diffusion Coefficient in Concrete: 10-Year Results in Marine SiteTarek ChikerNo ratings yet

- Comparison of RCC and Prestressed Concrete Ciircular Water TanksDocument4 pagesComparison of RCC and Prestressed Concrete Ciircular Water TanksShivakumar PatilNo ratings yet

- ProjectDocument20 pagesProjectRakesh Rosan SahooNo ratings yet

- Economics of RCC Water Tank Resting Over Firm Ground Vis-A-Vis Pre-Stressed Concrete Water Tank Resti PDFDocument15 pagesEconomics of RCC Water Tank Resting Over Firm Ground Vis-A-Vis Pre-Stressed Concrete Water Tank Resti PDFRahul KarnaNo ratings yet

- Qingdao Gulf BridgeDocument3 pagesQingdao Gulf BridgeRafiath SiraNo ratings yet

- Usefulness Roller Compected ConcreteDocument2 pagesUsefulness Roller Compected ConcreteRistu RihatmajiNo ratings yet

- Reaching For The Sky FDDocument17 pagesReaching For The Sky FDHARSHITA JAINNo ratings yet

- Present Status and Technology of Shield Tunneling Method in JapanDocument15 pagesPresent Status and Technology of Shield Tunneling Method in JapanKhuê - 64XE1 Nguyễn TuấnNo ratings yet

- The Asphalt Core Embankment Dam: A Very Competitive AlternativeDocument11 pagesThe Asphalt Core Embankment Dam: A Very Competitive AlternativeTrí Hồ Minh LêNo ratings yet

- Introduction To Self Compacting ConcreteDocument39 pagesIntroduction To Self Compacting ConcreteAyesha ShaikhNo ratings yet

- Curve Jacking - Paper Bangkok T-1ThorenDocument10 pagesCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaNo ratings yet

- Self Compacting Concrete: Presented By, Ahsan Rabbani Civil Engineering DepartmentDocument15 pagesSelf Compacting Concrete: Presented By, Ahsan Rabbani Civil Engineering DepartmentAbhishek SinghNo ratings yet

- Ahsan Rabbani Civil DepartmentDocument15 pagesAhsan Rabbani Civil DepartmentAhsan RabbaniNo ratings yet

- XX Copinaval-Concrete OffshoreDocument9 pagesXX Copinaval-Concrete OffshoreacabreraNo ratings yet

- GT2 Criteria For Dams and Ancillary Works DesignsDocument39 pagesGT2 Criteria For Dams and Ancillary Works Designsjorgepercy1177No ratings yet

- Cement and Concrete Are The Most Widely Used Construction Materials From Many Decades Due To Its Many AdvantagesDocument5 pagesCement and Concrete Are The Most Widely Used Construction Materials From Many Decades Due To Its Many AdvantagesPraveen RajNo ratings yet

- Test Done in Akashi Kaikyo Bridge PDFDocument10 pagesTest Done in Akashi Kaikyo Bridge PDFCris BandaNo ratings yet

- IJCRT2107046Document5 pagesIJCRT2107046المهندس: محمد محمود السوائيNo ratings yet

- IS Panel Road Maintenance System Applied To "Hyogo Viaduct": IIDA Masao: NISHIOKA MasaharuDocument7 pagesIS Panel Road Maintenance System Applied To "Hyogo Viaduct": IIDA Masao: NISHIOKA MasaharuOga MeoNo ratings yet

- Industrial Visit ..... Final ReportDocument21 pagesIndustrial Visit ..... Final ReportÃjâY Sîñgh ÇhãûhâñNo ratings yet

- Self-Compactig Concrete Development, Applications and Investigations OUCHIDocument5 pagesSelf-Compactig Concrete Development, Applications and Investigations OUCHIlauravoineagNo ratings yet

- Part 4 2 RMCdamDocument38 pagesPart 4 2 RMCdamKremen Mitov100% (1)

- 25 Iunie 09 Sakata FootbridgeDocument8 pages25 Iunie 09 Sakata FootbridgeGyorgy Adrienne100% (1)

- Paper On Design Voded SlabDocument9 pagesPaper On Design Voded SlabAnonymous b9fkTYfEoRNo ratings yet

- Several Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationDocument15 pagesSeveral Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationMuhammad Mubashir QureshiNo ratings yet

- Design of Water TanksDocument15 pagesDesign of Water TankscherogonyaNo ratings yet

- Q2 - 2009 (Hazardous Liquid Storage Building)Document12 pagesQ2 - 2009 (Hazardous Liquid Storage Building)manishNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Air Entrainment in Fly Ash Concrete: Effect of Sequence of AEA-SP AdditionDocument66 pagesAir Entrainment in Fly Ash Concrete: Effect of Sequence of AEA-SP AdditionBartoFreitasNo ratings yet

- Fdot bd545 67 RPT PDFDocument224 pagesFdot bd545 67 RPT PDFBartoFreitasNo ratings yet

- Mix Designs: Appendix 2Document33 pagesMix Designs: Appendix 2BartoFreitasNo ratings yet

- Materials Testing Manual Part 9: ConcreteDocument62 pagesMaterials Testing Manual Part 9: ConcreteBartoFreitasNo ratings yet

- Rebelo Jonathan 201406 MASc Thesis PDFDocument149 pagesRebelo Jonathan 201406 MASc Thesis PDFBartoFreitasNo ratings yet

- Practical Method For Mix Design of Cement-Based Grout: SciencedirectDocument10 pagesPractical Method For Mix Design of Cement-Based Grout: SciencedirectBartoFreitasNo ratings yet

- 552 Structural Concrete Mix Design Submittal: Metric English Specified Concrete Compressive Strength (@ 28 Days)Document5 pages552 Structural Concrete Mix Design Submittal: Metric English Specified Concrete Compressive Strength (@ 28 Days)BartoFreitasNo ratings yet

- Bu Mat Chapt4ap PDFDocument18 pagesBu Mat Chapt4ap PDFBartoFreitasNo ratings yet

- 2008 Rakshya ShresthaDocument91 pages2008 Rakshya ShresthaBartoFreitasNo ratings yet

- Schindler ACI Vol 101 2004Document10 pagesSchindler ACI Vol 101 2004BartoFreitasNo ratings yet

- SBland - Carolinas RCCDocument91 pagesSBland - Carolinas RCCBartoFreitasNo ratings yet

- ICAR 108-1 (Proportioning)Document24 pagesICAR 108-1 (Proportioning)BartoFreitasNo ratings yet

- BrownSchindler GeoDenver 2007Document11 pagesBrownSchindler GeoDenver 2007BartoFreitasNo ratings yet

- Aci 8Document89 pagesAci 8BartoFreitasNo ratings yet

- Material InventoryDocument1 pageMaterial InventorylegallyhungryblueNo ratings yet

- Resistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IDocument12 pagesResistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IJoel BrasilBorgesNo ratings yet

- Ohab Ali - MergedDocument17 pagesOhab Ali - MergedMD SAMANNo ratings yet

- Terremotos Devastadores: Fecha Region Magnitud RichterDocument16 pagesTerremotos Devastadores: Fecha Region Magnitud RichterEdu OC RamNo ratings yet

- Daftar Pustaka: Standard Naming Convention For Aircraft Landing Gear Configurations - United State of AmericaDocument4 pagesDaftar Pustaka: Standard Naming Convention For Aircraft Landing Gear Configurations - United State of AmericaNaldo LumbantoruanNo ratings yet

- Surveying DictionaryDocument6 pagesSurveying DictionaryMarijanaJNo ratings yet

- ULO2 BDocument4 pagesULO2 BKaris DemetriaNo ratings yet

- Composite Deck EurocodeDocument99 pagesComposite Deck EurocodeĐoàn Đức PhongNo ratings yet

- Thumb RuleDocument4 pagesThumb RulenishadNo ratings yet

- Investigation of Failure Modes and Mechanisms of Alibey Earth Dam by Solid-Fluid Coupled Nonlinea PDFDocument87 pagesInvestigation of Failure Modes and Mechanisms of Alibey Earth Dam by Solid-Fluid Coupled Nonlinea PDFMad WonderNo ratings yet

- Fluid MechanicsDocument182 pagesFluid Mechanicsreddy331No ratings yet

- East Ring Road (STC)Document3 pagesEast Ring Road (STC)mohamed ayadNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsChidi OkoloNo ratings yet

- SWRD Concrete-Lined Trapezoidal CanalDocument1 pageSWRD Concrete-Lined Trapezoidal CanalscrNo ratings yet

- Ppr2013 263alrDocument11 pagesPpr2013 263alrAbrar MughalNo ratings yet

- Alignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)Document1 pageAlignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)sivaNo ratings yet

- Experiment 4 (Re No.)Document21 pagesExperiment 4 (Re No.)Mervin PerezNo ratings yet

- Common Causes of Failures of Dam StructuresDocument6 pagesCommon Causes of Failures of Dam Structuresvenkateswara rao pothinaNo ratings yet