Professional Documents

Culture Documents

Ojcv027i02p405 415

Uploaded by

anand singhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ojcv027i02p405 415

Uploaded by

anand singhCopyright:

Available Formats

ISSN: 0970-020 X; CODEN: OJCHEG

Oriental Journal of Chemistry

2011, Vol. 27, No. (2): Pg. 405-415

http://www.orientjchem.org

Linear Regression Analysis for Kinetics and Isotherm

Studies of Sorption of Manganese (II) Ions Onto

Activated Palm ash from Waste Water

ZAIRA ZAMAN CHOWDHURY*, SHARIFUDDIN MOHD. ZAIN,

RASHID ATTA KHAN and KHALISANNI KHALID

Department of Chemistry, Faculty of Science, University Malaya, Kuala Lumpur (Malaysia).

E-mail: Zaira_chowdhury@live.com

(Received: May 03, 2011; Accepted: June 16, 2011)

ABSTRACT

The potential of low cost adsorbent, palm oil ash was investigated as a replacement of current

expensive methods for treating wastewater contaminated by Mn (II) cation. To enhance the uptake

capacity, natural oil palm ash (OPA) was refluxed sodium hydroxide solution for certain period of time

and temperature. Reaction rate constants were calculated by linear regression analysis of Pseudo first

order, Pseudo second order, and Intra-particle diffusion kinetic equations. The linear plots of intra

particle diffusion suggested that the adsorption process was mainly carried out by pore diffusion.

Experimental data showed that equilibrium uptake was increased with the increase of initial Mn (II) ion

concentration and contact time. The values of Langmuir dimensionless constant, RL and Freundlich

constant, 1/n were less than 1, which revealed that the adsorption process is favourable.

Key words: Kinetics, Isotherm, Thermodynamics, Oil palm ash.

INTRODUCTION

The Aqueous effluents emanating from

various natural and industrial sources contain heavy

metals dissolved in it. The hazardous impact of

heavy metals in waste stream has generated

considerable concern in recent years. Primarily,

some manmade factors such as unplanned

urbanization, deforestation, industrialization along

with anthropogenic activities, such as weathering

of rocks and volcanic activities are the major

cause for enriching the water reservoirs with heavy

metals1-5. Different metals such as manganese

(Mn), lead (Pb), chromium (Cr), mercury

(Hg),cadmium (Cd), arsenic (As), copper (Cu) etc.

are known to be highly toxic due to their nonbiodegradability . Among these heavy metals,

manganese is considered as one of the most toxic

one. If manganese, Mn (II) is present in water than

the tolerance limit, then it may cause severe damage

to the nervous system6.

406

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

In order to reach environmental standards,

many conventional methods including oxidation,

membrane filtration, coagulation, reverse osmosis,

adsorption onto activated carbon, ion exchange,

precipitation, etc. have been reported in the literature

to remove manganese along with other heavy

metals from waste water 7-12. These methods are

extremely expensive especially when it is relatively

dissolved in low concentration of about (1-100ppm)

in large volume of waste stream. However,

adsorption onto low cost adsorbent can be

considered as one of the most popular method for

the removal of heavy metals from the wastewater

due to its cheap cost, easy availability,

biodegradability and simplicity of design with high

removal efficiency. Moreover, it does not generate

toxic substances. Therefore, removal of heavy

metals including manganese by adsor ption

technique from aqueous streams by using

agricultural and industrial waste products which are

abundant in nature and requires little processing has

received much attention in recent years 13. Several

adsorbent derived from low cost material such as:

zea mays Tassel 14, sunflower stalk15, spent grain16,

onion skin17, rice husk 18-19, almond husk20, sea

mussel and white clay21, Spirogyra neglecta22, dried

activated sludge23, etc. for treating metal bearing

waste water at the solid-solution interface have been

reported.

Above perusal of the literature clearly

depicts the importance of using several types of low

cost adsorbents for removal of heavy metals from

waste water. Oil palm ash after activation with

sodium hydroxide possesses some unique features

of extended surface area, porosities and oxide

content in it which significantly can contribute for its

enhanced uptake capacity of Mn (II) in liquid phase

adsorption.

Malaysia produces a large amount of agrobased waste biomass-generated from oil palm

industries which consists of empty fruit bunch (EFB),

palm shell (PS) and mesocarp fiber. The statistical

report showed that, about 110 million tones of

renewable non oil biomass (trunks, fronds, shell,

press palm fiber and empty fruit bunch) are

produced each year 24. Oil palm ash (OPA) is a kind

of particulate material produced from combustion

of this waste biomass in boiler to obtain steam for

electricity generation. Present research aims to

remove Mn (II) from waste water by using chemically

treated palm oil ash and to investigate the influence

of all the physicochemical parameters involved

during the removal process. The research focuses

on adsorption kinetics and isotherm studies of Mn

(II) onto the prepared adsorbent. The efforts have

been made to develop an improved activation

strategy for natural oil palm ash by using sodium

hydroxide which can enhance its surface area

significantly and consequently increase its

adsorption capability for Mn (II) ions from waste

water.

EXPERIMENTAL

Preparation of stock solution

Manganese (II) chloride, MnCl 2.2H 2O,

sodium hydroxide (NaOH) and hydrochloric acid

(HCl) were obtained from Merck, Germany. Stock

solution of manganese salt having concentration of

about 1000 mg/l was prepared with double distilled

water. Various concentrations of test solution of Mn

(II) ranging from 50mg/l to 100 mg/l were prepared

by subsequent dilution of the stock solution. The

initial pH was adjusted to 5.5 using a pH meter

(Mettles Toledo, Model: Ross FE 20, USA) so as to

avoid any precipitation at higher concentration. Fresh

dilution of the stock solution was done for each

adsorption study to minimize the error. All reagents

used for the research purpose were of AR grade

chemicals.

Activation of Oil palm ash (OPA)

The palm oil ash used here was taken from

the middle section of the flue tower. The sample

was collected from East oil Mill, Golden Hope

Plantation Sdn. Bhd, Pulau Carey, Selangor. The

raw OPA thus obtained was sieved through sieve

no 200m. It was washed with deionized water for

several times to remove foreign particles which might

interfere during the sorption process. It was oven

dried at 110 C over night to remove moisture. The

ratio of oil palm ash with caustic soda was

predetermined and was kept constant at 5:1 that is

50 grams of oil palm ash were mixed with 10 gm of

NaOH in 250 ml distilled water. Then the mixture

transferred into a round bottom flask with a magnetic

stirrer placed inside it and was refluxed at 160C

for 8 hours. After the heating was stopped, the slurry

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

was allowed to cool at room temperature and

filtered. The filter cake was repeatedly washed with

deionized water until neutral pH of the filtrate was

observed to ensure complete removal of unreacted

caustic soda from the adsorbent surface. Then it

was dried in an oven at 110 C for 12 hours before

use for adsorption study and stored in desiccators

over fresh silica gel for further application.

Surface Characterization

The surface functional groups of activated

OPA were detected by Fourier transform infrared

(FTIR) spectroscope FTIR-2000, PerkinElmer and

the spectra were recorded from 4000 to 400 cm1.

Textural characterization of the activated OPA was

carried out by N2 adsorption at 77 K using Autosorb

I (Quantachrome Corporation, USA). Before

performing the nitrogen gas adsorption, the natural

and activated OPA was out gassed under vacuum

at temperature 300C for 4 hours to ensure

complete removal of moisture content from the

surface of both types of OPA. Surface area and

pore volume were calculated by using Brunaure

Emmett Teller (BET).

Equilibrium Studies

Each of the batch experiment was carried

out by adding 0.2 gm of OPA with 50 ml of different

concentration of Mn (II) solution at agitation speed

of about 150 rpm. The residual concentration of Mn

(II) was analyzed after predetermined interval of

time until the system reached equilibrium by using

atomic absorption spectrophotometer (Perkin

Elmer Model 3100).

Isotherm Studies

For isotherm studies, each experiment was

conducted at 30 C in a thermoregulated water

bath (Haake Wia Model, Japan) with shaker cover

in order to prevent heat loss to the surroundings.

The equilibrium adsorption amount (qe) is calculated

according to equation (1)

...(1)

Where,

q e = adsorption amount of metal ion (mg/g) at

equilibrium contact time

407

W= weight of adsorbent (g)

V = volume of solution (ml)

The removal efficiency of the metal ion was

calculated by using equation (2)

...(2)

RESULTS AND DISCUSSION

The FTIR spectroscopy is a well known

method for identification of groups and quantitative

analysis of the sample. The FTIR spectrum of

natural and activated samples of oil palm ash is

shown by following Figure1. It is quite clear from

the spectra that some peaks shifted due to activation

and some peaks disappeared even after the

treatment with sodium hydroxide. The peaks of

468.16 cm -1 and 474.02 cm -1 for natural and

activated samples of oil palm ash represented

bending of Si-O group. The peaks of 797.79 cm-1

and 793.99 cm-1 on both the sample were detected

meaning CH out of plane deformation. The band of

1050.70 cm -1 in natural and 1030.20 cm -1 in

activated OPA were assigned for Si-O-Si stretching

vibration. The peak of 1651.42 cm-1 shifted to

1638.68 cm-1 in activated sample represented C=C

stretching vibration. The peaks of 3394.21 cm-1 and

3449.52 cm -1 corresponded to OH stretching

vibration of hydroxyl functional group in natural and

activated samples of activated OPA. However, the

two peaks of 2901.88 cm-1 and 2976.41 cm-1 for

aliphatic CH2 vibration disappeared in activated

sample. Another peak at 880.78 cm -1 for Si-H

deformation also disappeared in activated sample.

The presence of peaks at 2366.31 cm-1 in natural

sample and 2346.23 cm-1 and 2375.43 cm-1 in

activated sample was due to the presence of CaC

stretching vibration in alkyne groups.

Adsorption is mainly dependent on surface

area, pore structure and surface functional groups.

The BET surface area for the natural sample was

3.774 m2/g, but it increased to 467.1 m2/g after

activation with NaOH. The micro pore volume and

micro pore surface area of natural sample of OPA

calculated was 0.0014cm 3 /g and 4.057 m 2 /g

408

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

Table 1: Comparison of pseudo-first order and pseudo-second order adsorption

rate constant for different initial concentration Mn (II) ion

Pseudo-first order kinetics

qe (cal)

K1

(mg/g)

(mg/g)

C0

qe (exp)

(mg/l)

50

60

70

80

90

100

8.3125

9.8050

10.550

11.505

12.3025

13.3050

7.6559

13.964

11.246

10.069

6.6374

7.2778

0.0392

0.0369

0.0322

0.0392

0.0276

0.0345

R2

(min-1)

Pseudo-second order Kinetics

qe (cal)

K2

R2

(mg/g)

(min-1)

0.945

0.947

0.979

0.969

0.980

0.972

9.8039

12.346

12.500

12.500

12.987

14.085

0.0044

0.0022

0.0030

0.0070

0.0084

0.0092

0.983

0.983

0.993

0.998

0.998

0.999

Table 2: Intra particle rate constant for different initial concentration

Initial Concentration

(mg/L)

50

60

70

80

90

100

1.975

1.049

2.044

5.400

7.027

8.080

Table 3: Essential Characteristics

of Langmuir Isotherm

Value of RL

Type of Isotherm

RL > 1

RL= 1

0 < RL < 1

RL= 1

Unfavourable

Linear

Favourable

Irreversible

Kdif(mg/gh0.5)

Correlation

coefficient,R2

4.502

5.899

5.797

4.214

3.507

3.562

0.765

0.898

0.882

0.850

0.919

0.884

respectively which were increased to 0.199 cm3/g

and 561.9 m2/g after activation.

Fig. 2 describes the effect of initial Mn (II)

ion concentration and uptake by activated OPA with

equilibrium contact time. It is clearly visible from the

graph, that amount of uptake, qt (mg/gm) increased

with increased agitation time and after certain period

Table 4: Isotherm model parameters and

correlation coefficient at 30 C Temperature

Isotherm Model

Parameters

values

R2

Langmuir

qm ,maximum monolayer

adsorption capacities(mg/g)

RL, separation factor

KL, Langmuir constant

KF,Affinity

Factor(mg/gm(L/mg)1/n)

1/n, Freundlich exponent

A, (l/mg)

B

19.2307

0.1801

0.0455

0.993

2.604

0.978

0.422

0.3924

4.492

0.981

Freundlich

Temkin

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

Fig. 1: The FTIR spectra of activated and natural oil palm ash

Fig. 2: Effect of initial Mn (II) ion concentration with equilibrium contact time

Fig. 3: Effect of pH on removal % of Mn (II) ion having concentration of 100 mg/l

409

410

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

of contact time with the activated OPA; it reached

to a static value beyond which no further change of

uptake was observed reflecting the equilibrium state

of the system. The experimental data showed that,

the adsorption process was taking place rapidly at

initial stage of contact period and after that near

the equilibrium point it became slower. The rate of

Mn (II) uptake was initially high due to the availability

of larger surface area of activated oil palm ash for

adsorption. With the lapse of time, the surface

adsorption sites were occupied. The remaining

vacant sites were difficult to be captured by Mn (II)

ions due to repulsive forces between adsorbate that

is Mn (II) present in solid and bulk phases. As the

concentration of the Mn (II) ion is increasing, the

sorption capacity by the prepared adsorbent is also

increasing. Similar trend was observed for Cu (II)

and Pb (II) adsorption on sawdust of meranti wood25.

The plot reveals that within 80 min the system

reached equilibrium and after that no more

adsorption was taking place. However, here

experimental data were measured for 180 min. to

ensure that full equilibrium was achieved.

In order to study the effect of pH, the

solution pH was changed from 2-8 while keeping

the other variable constant. Following fig. 3 describes

the effect of pH on removal% of Mn(II) onto activated

OPA. It was observed that adsorption of Mn (II) ion

from the solution was strongly pH dependent. At

lower pH of 2-3 range the adsorption was very low

and it rapidly increased between pH 4-7. After that

with increase of pH, there was no increase of

removal % of Mn (II) from the solution. At lower pH,

the presence of H+ and H3O+ ions in the solution

compete with Mn (II) ions for active binding sites on

the surface of palm oil ash, which leads to fewer

binding sites being available for binding Mn (II) ions.

As the pH increases from 3-7, the adsorption surface

became less positive and therefore electrostatic

attraction between Mn(II) ions and the surface of

palm oil ash was increased resulting greater removal

efficiency between pH 4-7. The result depicts that

removal% was increased steadily up to pH 6, after

pH 7 , more or less it was same. Cumulative effect

of adsorption and precipitation has enhanced the

removal efficiency at higher pH values. Therefore,

to ensure true adsorption, all kinetics experiments

were carried out at pH 5.5.

Calculation of chemical kinetics is very

important to understand the rate of reaction 26-28.

The pseudo first order equation based on equilibrium

adsorption is expressed as:

...(3)

Where, q e and q t are the amount of

adsorbed (mg/g) at equilibrium and at any time t, k1

is the first order rate constant (min-1).

The plot of log (qe-qt) versus gave the slope

k 1 and intercept of log qe and is shown by the

following Fig 4.

Pseudo second order equation can be

given by:

...(4)

11

kq2eorder

q 2e

Here, k2 is the rate constant of second

adsorption. The linear plot of

as slope and

t

qt

versus t gave

as intercept. This model is more

likely to predict the behaviour for the range of

concentration studied here for adsorption and

represents chemisorptions. The linear plots of

pseudo second order model is shown in Fig. 5 and

the model parameters for both pseudo first and

second order kinetics are listed in Table 1.

Table 1 summarizes the results obtained

for both types of kinetics studies. In the same table,

the correlation coefficients, R2 was determined and

experimental equilibrium uptake, qe were compared

with those calculated theoretically from pseudo first

and second order kinetics. From Table 1, it clearly

reflects that the experimental values of q e

determined in this work were very close to the

theoretical ones in case of second order kinetics.

With no exception, the accuracy is better for second

order kinetics in all concentration range studied here

as R2 values are near to unity and this indicated

the chemisorption nature of adsorption here.

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

411

Fig. 4: Plots for Pseudo First Order Kinetics of Mn (II) ion solution onto activated OPA at pH 5.5

Fig. 5: Plots for Pseudo Second Order Kinetics of Mn (II) ion solution onto activated OPA at pH 5.5

Fig. 6: Plots for Intra- Particle Diffusion of Mn (II) ion solution onto activated OPA at pH 5.5

412

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

The rate-limiting step is the key factor to

be determined in the adsorption process to

understand the overall mechanism for sorption. The

most commonly used technique for identifying the

mechanism involved in the adsorption process is

by fitting an intraparticle diffusion plot. According to

Weber and Morris 29, an intraparticle diffusion

coefficient Kid is given by the equation:

...(5)

The linear plots of qt versus t0.5 is shown

by Fig. 6. The slope of the plot has been defined to

give the intraparticle diffusion parameter kid (mgg-1

min-0.5). On the other hand, the intercept of the plot

yields C, the boundary layer effect. The larger the

intercept observed, the greater will be the

contribution of the surface sorption in the ratecontrolling step.

From the plot it is observed that the lines

did not pass through the origin. This indicated that

the rate limiting process is not only governed by

intra particle diffusion. Some other mechanism

along with intraparticle diffusion was involved 30.

The Langmuir isotherm predicts monolayer

adsorption for the adsorbate assuming constant

heat of adsorption for all sites on the active sites of

the adsorbent and it is expressed by following

equation31:

qmax =

KL =

(mg/l),

The maximum monolayer adsorption

capacity of the adsorbent (mg/g),

The Langmuir adsorption constant (l/mg).

When Ce/qe is plotted against Ce, a straight

line having slope 1/qmax and intercept of 1/qmaxKL is

obtained.

The essential characteristics of the

Langmuir equation can be represented by a

dimensionless factor, RL which is given below-

RL =

1

1 + K L Co

...(8)

Co is the highest initial cation concentration

(mg/l). The value of separation factor RL, can be

represented by following Table 3The linear plot of Langmuir Isotherm at

30C temperature is shown by Fig. 7 and the model

parameters at 30C are listed in Table 4.

Freundlich isotherm gives the relationship

between equilibrium liquid and solid phase capacity

based on the multilayer adsorption representing

heterogeneous surface properties 32. This isotherm

is based on the assumption that the adsorption sites

are distributed exponentially with respect to the heat

of adsorption and is given by:

...(9)

...(6)

And can be linearized as:

The linear form of the Langmuir isotherm

is given by:

Ce

1

1

Ce

=

+

qe qmax K L qmax

ln

= ln

+ ln

...(10)

...(7)

Where Kf (mg g-1 ) = Multilayer adsorption

capacity and

Where,

qe =

Equilibrium cation concentration on the

adsorbent (mg/g),

Ce =

Equilibrium cation concentration in solution

1/n

= Intensity of adsorption. The linear

plot of Freundlich Isotherm at 30C temperature is

given on Fig. 8 and the model parameters at 30C

are listed in Table 4.

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

Fig. 7: Langmuir Isotherm at onto activated palm ash at 30 C Temperature at pH 5.5

Fig: 8 Freundlich Isotherm at onto activated palm ash at 30 C Temperature at pH 5.5

Fig. 9: Temkin Isotherm at onto activated palm ash at 30 C Temperature at pH 5.5

413

414

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

Temkin isotherm assumes that the effects

of the heat of adsorption of all molecules in the layer

would decrease linearly with coverage due to the

adsorbate and adsorbent interactions and is given

by33:

...(11)

Equation 11 can be linearized as:

...(12)

Here,

RT/b

A (L/g)

R (8.314 J/mol k)

T (K)

B (j/mol), which is Temkin

constant related to heat

of sorption

Equilibrium binding

constant corresponding

to the maximum binding

energy,

Universal; gas constant

and

Absolute

solution

temperature.

The R2 values of the Langmuir model here

suggested that the adsorption process was

monolayer and adsorption of each molecule had

equal activation energy. The RL value obtained is

below 1 indicating that the adsorption of Mn (II) onto

activated oil palm ash is favourable. The Langmuir

model was found to fit the data significantly better

than Freundlich model, which demonstrated more

homogeneous nature of activated palm ash.

Freundlich exponent, 1/n ranging between 0 and 1

is a measure of adsorption intensity or surface

heterogeneity which is below one indicating

favourable adsorption of Mn (II) onto activated oil

palm ash. Linear regression analysis of Temkin

isotherm showed a higher regression coefficient,

which may be due to the linear dependence of heat

of adsorption at low or medium coverage. The

regression coefficient of these models showed a

strong affinity for the adsorption of Mn (II) onto

activated palm ash.

CONCLUSIONS

From the findings of this research, it can

be concluded that sodium hydroxide activated oil

palm ash is a versatile, novel and environmentally

friendly adsorbent which can be used successfully

for separation of Mn (II) from waste water.

ACKNOWLEDGEMENTS

Fig. 9 depicts Temkin model under the

concentration range studied here.

The authors are grateful for the financial

support of this project by Research Grant (UMRG

056-09SUS) of University Malaya, Malaysia.

REFERENCES

1.

2.

3.

4.

5.

6.

Bailey S. E., Olin T J, Bricka R M and Adrian

D D., Water Res., 33(11): 2469,(1999).

Cay S., Uyanik A. and Ozajik A., Sep. Purif.

Technol., 38: 273 (2004).

Tee T. W. and Khan A. R. M., Environ. Technol.

Lett., 9: 1223 (1988).

Jonathan Y. Am. J. Applied Sci., 7(2): 153

(2010).

Ong M.C., and Kamruzzaman, B.Y., Am. J.

Applied Sci., 6(7): 1418 (2009).

Savova D., Petrov N., Yardin M.F., Ekinci E.,

Budinova T., Razvigorova M. and Minkova V.,

7.

8.

9.

10.

11.

12.

Carbon, 41: 1897 (2003).

Pandey A., Shukla A. and Ray L., Am. J.

Biochem. & Biotech. 3(2): 55 (2009).

Toles C.A., Marshal W.E., and Johns M.M.,

Carbon, 35: 1407 (1997).

Dastgheib S.A. and Rockstraw A.D. Carbon,

31: 1849 (2001).

Hashim M. A. and Chu K. H., Chem. Eng. J.,

97: 249 (2004)

Horsfall M., Abia A. A. and Spiff A. I., Afr. J.

Biotechnol., 2(10): 360 (2003).

Okieimen F. E. and Onyenkpa V. U., Biol.

CHOWDHURY et al., Orient. J. Chem., Vol. 27(2), 405-415 (2011)

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

Wastes, 29: 11 (1989).

Zuorro, A. and Lavecchia R., Am .J. Applied

Sci., 7: 153 (2010).

Caliph M. Z., Okonkwo O.J. and Agyei N.M.,

Am. J. Biochem. & Biotech. 6(1): 10 (2010).

Sun G. and Shi W., Ind. Eng. Chem. Res.,

37(4): 1324 (1998).

Low K. S., Lee C. K. and Liew S. C., Process

Biochem., 36(1-2): 59, (2000).

Kumar P. and Dara S. S., J. Polym. Sci. Polym.

Chem. Ed., 19: 397, (1981).

Khalid N., Ahmad S., Kiani S. N. and Ahmed

J., J Sep Sci Technol., 34(16): 3139 (1999).

Munaf E., and Zein R., Environ. Technol.,

18(3): 359 (1997).

Hasar H., J. Hazard. Mater. B97: 49 (2003).

Sakulkhaemaruethai, S., Duangduen C.,

Pivsa-Artand W. and Pivsa-Art S. Energy

Research Journal, 1(2): 78 (2010).

Modher, A.H., Salleh A. and Milow P., Am. J.

Biochem. & Biotech, 6(1): 1 (2009).

Solatani, R. D.C., Jafari A.J. and

Khorramabadi G.S., Am. J. Environ. Sci. 5(1):

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

415

41 (2009).

Saifuddin, N. and Fazlili S.A., Am. J. Eng. &

Applied Sci., 2(1): 139 (2009).

Ahmad A., Rafatullah M., Sulaiman O.,

Ibrahim M.H., Chee Y.Y. and Siddique B.M.,

Desalination, 247: 636, (2009).

Ho Y.S. and McKay G., Process Biochemistry,

34(5): 451 (1999a).

Ho Y.S. and McKay G., Water Research,

33(2): 578, (199b).

Wong K.K., Lee C.K., Low K. S. and Haron

M.J., Chemosphere, 50: 23 (2003)

Weber W.J. and Morris J.C., In: Proc. Int.

Conf. Water pollution symposium, 2:

Pergamon, Oxford, (1962), 231 (1962).

Weber W.J. and Morris J.C., J. Sanit. Eng.

Div. Am. Soc. Civ. Eng. 89: 31 (1963).

Langmuir I., J. Am. Chem. Soc. 38: 2221

(1916).

Freundlich H.M.F., J. Phys. Chem. 57A: 385

(1906).

Temkin M.I., and Pyzhev V., Jour. Phys.

Chem. (U.S.S.R.), 13: 851 (1939).

You might also like

- Interactive Textbook 1 PDF 4 1Document8 pagesInteractive Textbook 1 PDF 4 1api-240094705100% (2)

- Chapter 5 - Plug and Abandonment of Subsea WellsDocument23 pagesChapter 5 - Plug and Abandonment of Subsea WellsSalvador Morales LeónNo ratings yet

- Nursing Pharmacology HandoutsDocument9 pagesNursing Pharmacology HandoutsVince LeonidaNo ratings yet

- BS 1881-5 Testing ConcDocument15 pagesBS 1881-5 Testing Conchz135874No ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- Experiment 10 - Quantitative Determination of The Purity and Dissociation of Potassium Hydrogen Phthalate by Potentiometric Titration AtqDocument3 pagesExperiment 10 - Quantitative Determination of The Purity and Dissociation of Potassium Hydrogen Phthalate by Potentiometric Titration AtqDoom RefugeNo ratings yet

- Sandler ThermodynamicsDocument5 pagesSandler Thermodynamicsanand singh0% (12)

- Rare Earth Elements in CoalDocument4 pagesRare Earth Elements in CoalPepitoNo ratings yet

- Dose The Right Amount of ChemicalsDocument3 pagesDose The Right Amount of ChemicalsrajachemNo ratings yet

- Thermodynamics (Prausnitz) Manual SolutionDocument195 pagesThermodynamics (Prausnitz) Manual SolutionColin Zhang78% (9)

- Adsorption of ZN (II) On Activated Red Mud: Neutralized by CODocument17 pagesAdsorption of ZN (II) On Activated Red Mud: Neutralized by COisukuruNo ratings yet

- Equilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionDocument11 pagesEquilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionĐỗ Quang TháiNo ratings yet

- Batch Method For The Removal of Toxic Metal From Water Using Sugar Palm Fruit (Arenga Pinnata Merr) Shell.Document11 pagesBatch Method For The Removal of Toxic Metal From Water Using Sugar Palm Fruit (Arenga Pinnata Merr) Shell.Supawinee KointhaNo ratings yet

- Removal of Copper (II) Ion From Aqueous Solution by High-Porosity Activated CarbonDocument8 pagesRemoval of Copper (II) Ion From Aqueous Solution by High-Porosity Activated Carbonjuan perezNo ratings yet

- Journal of Chemical & Engineering Data ShamsDocument13 pagesJournal of Chemical & Engineering Data ShamsShamsMohdNo ratings yet

- Fabrication of PolyacrylonitrileDocument21 pagesFabrication of PolyacrylonitrileFadhilatul AdhaNo ratings yet

- Metal Removal From Acid Waters by An Endemic MicroDocument14 pagesMetal Removal From Acid Waters by An Endemic MicroErika M. Sánchez MaquiNo ratings yet

- Amer Et AlDocument8 pagesAmer Et AlNadarlis Binti DarmawiNo ratings yet

- Fabrication of Sugar Palm Fiber/Andisol Soil Composites For Iron (III) Ion, Removal From Aqueous SolutionDocument6 pagesFabrication of Sugar Palm Fiber/Andisol Soil Composites For Iron (III) Ion, Removal From Aqueous SolutionYessy Dwi RNo ratings yet

- 12.study On The Removal of PB (II) Ions From Aqueous Solution Using Chemically Modified Corn Cob. (Siti Raihan Zakaria) PP 74-81Document8 pages12.study On The Removal of PB (II) Ions From Aqueous Solution Using Chemically Modified Corn Cob. (Siti Raihan Zakaria) PP 74-81upenapahangNo ratings yet

- Polimer 2013Document12 pagesPolimer 2013Regina PramuditaNo ratings yet

- Zandevakili 2014Document11 pagesZandevakili 2014Cyrene MBolañosNo ratings yet

- Adsorption of CD (II) Ions From Aqueous Solution Using Activated Carbon Prepared From Vitellaria Paradoxa ShellDocument4 pagesAdsorption of CD (II) Ions From Aqueous Solution Using Activated Carbon Prepared From Vitellaria Paradoxa ShellHernan ChavezNo ratings yet

- PMMADocument9 pagesPMMArehanNo ratings yet

- Potential of Nano Crystalline Calcium Hydroxyapatite For T - 2017 - Arabian JourDocument11 pagesPotential of Nano Crystalline Calcium Hydroxyapatite For T - 2017 - Arabian Jourlucian_lovNo ratings yet

- Adsorption of Chromium From Wastewater By: Platanus Orientalis LeavesDocument6 pagesAdsorption of Chromium From Wastewater By: Platanus Orientalis LeavesLaura Triviño ClavijoNo ratings yet

- Removal of Lead (II) and Copper (II) From Aqueous Solution Using Pomegranate Peel As A New AdsorbentDocument3 pagesRemoval of Lead (II) and Copper (II) From Aqueous Solution Using Pomegranate Peel As A New AdsorbentDea AlvichaNo ratings yet

- A Feasibility Study On Production, Characterisation and Application of Empty Fruit Bunch Oil Palm Biochar For Mn2+ Removal From Aqueous SolutionDocument11 pagesA Feasibility Study On Production, Characterisation and Application of Empty Fruit Bunch Oil Palm Biochar For Mn2+ Removal From Aqueous SolutionZackkNo ratings yet

- A Comparative Isothermal and Kinetic Study of The Removal of Lead (II) From Aqueous Solution Using Different SorbentsDocument21 pagesA Comparative Isothermal and Kinetic Study of The Removal of Lead (II) From Aqueous Solution Using Different Sorbentssagar dasguptaNo ratings yet

- Adsorption of PB (II) On Mentha Piperita Carbon (MTC) in Single and Quaternary SystemsDocument10 pagesAdsorption of PB (II) On Mentha Piperita Carbon (MTC) in Single and Quaternary Systemslucian_lovNo ratings yet

- Electrochemical Degradation of Petroleum Hydrocarbons (PAHS) From Synthetic Aqueous SolutionsDocument9 pagesElectrochemical Degradation of Petroleum Hydrocarbons (PAHS) From Synthetic Aqueous SolutionsEhab DheyaaNo ratings yet

- Effectiveness of Sunflower Seed Husk Biochar For Removing Cu 2+ in Waste WaterDocument11 pagesEffectiveness of Sunflower Seed Husk Biochar For Removing Cu 2+ in Waste WaterMuhamad SuharNo ratings yet

- Reprint in JASR 233-239 2013-Libre PDFDocument7 pagesReprint in JASR 233-239 2013-Libre PDFWali YudinNo ratings yet

- Chemical Engineering Journal: M. ArshadiDocument13 pagesChemical Engineering Journal: M. ArshadiLalo BernalesNo ratings yet

- Zinc BagasseDocument6 pagesZinc BagassePRATYUSH TRIPATHYNo ratings yet

- Jur UtamaDocument11 pagesJur UtamaEtrinaldi Lawan CariNo ratings yet

- Study of The Adsorption of Heavy Metal (PB) at Batch Conditions in Aqueous Solution Onto Apricot Stone As Low Cost AdsorbentDocument11 pagesStudy of The Adsorption of Heavy Metal (PB) at Batch Conditions in Aqueous Solution Onto Apricot Stone As Low Cost AdsorbentAlgerian Journal of Materials ChemistryNo ratings yet

- Adsorption of Nickel (Ii) Ions From Aqueous Solution Using Banana Peel and Coconut ShellDocument12 pagesAdsorption of Nickel (Ii) Ions From Aqueous Solution Using Banana Peel and Coconut ShellDevita AmeliaNo ratings yet

- 2-Mercaptobenzothiazole in BentoniteForMercureAdsorption2005Document15 pages2-Mercaptobenzothiazole in BentoniteForMercureAdsorption2005TouatiNo ratings yet

- Biosorption of Mno in Aqueous Solutions Using Pinus InsularisDocument9 pagesBiosorption of Mno in Aqueous Solutions Using Pinus InsularisAYAUWU LOVEDAYNo ratings yet

- Abdelwahab - 2007 - Kinetic and Isotherm Studies of Copper (II) Removal From Wastewater Using Various AdsorbentsDocument18 pagesAbdelwahab - 2007 - Kinetic and Isotherm Studies of Copper (II) Removal From Wastewater Using Various Adsorbentscukaasam123456No ratings yet

- Cyanide Phytoremediation by Water Hyacinths (Eichhornia Crassipes)Document8 pagesCyanide Phytoremediation by Water Hyacinths (Eichhornia Crassipes)Arka SenNo ratings yet

- Facile Fabrication of Novel Analcimesodium AluminuDocument15 pagesFacile Fabrication of Novel Analcimesodium Aluminulee huyNo ratings yet

- 00 Adsorption of Copper (II) by Sulfur MicroparticlesDocument29 pages00 Adsorption of Copper (II) by Sulfur MicroparticlesYousef SailiniNo ratings yet

- 2892 PDFDocument11 pages2892 PDFkenatejoyNo ratings yet

- 10 1016@j Jwpe 2017 08 007Document10 pages10 1016@j Jwpe 2017 08 007saeedsshNo ratings yet

- Optimization of Roasted Sphalerite Concentrate Leaching Conditions To Dissolve Maximum Amount of IndiumDocument5 pagesOptimization of Roasted Sphalerite Concentrate Leaching Conditions To Dissolve Maximum Amount of IndiumminingnovaNo ratings yet

- 1051-Article Text-3401-1-10-20200311Document17 pages1051-Article Text-3401-1-10-20200311Kulet GuazonNo ratings yet

- 2, Amino-4,6-Dihydroxylpyrimidine Modified Corn Starches For Uptake of Cu (II) Ions From Aqueous MediaDocument7 pages2, Amino-4,6-Dihydroxylpyrimidine Modified Corn Starches For Uptake of Cu (II) Ions From Aqueous MediaresearchinventyNo ratings yet

- OJC Vol34 No5 P 2548-2553Document6 pagesOJC Vol34 No5 P 2548-2553Nórida Pájaro GómezNo ratings yet

- Archives of Environmental Protection: Vol. 39 No. 2 Pp. 129 - 140 2013Document12 pagesArchives of Environmental Protection: Vol. 39 No. 2 Pp. 129 - 140 2013nagavigneshNo ratings yet

- Removal of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiDocument2 pagesRemoval of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiMargabrielNo ratings yet

- Removal of Phosphate From Aqueous Solutions Using Calcined Metal Hydroxides Sludge Waste Generated From ElectrocoagulationDocument8 pagesRemoval of Phosphate From Aqueous Solutions Using Calcined Metal Hydroxides Sludge Waste Generated From ElectrocoagulationLamine tech & scienceNo ratings yet

- Kinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellDocument7 pagesKinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellsureshbabuchallariNo ratings yet

- Banana Peel Removes Heavy Metals2Document6 pagesBanana Peel Removes Heavy Metals2Ogunranti RasaqNo ratings yet

- Dried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsDocument7 pagesDried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsNataliakusumaDewiNo ratings yet

- Tesis Referencia 1Document6 pagesTesis Referencia 1Marilu Bueno RamosNo ratings yet

- Vo Cam Loai NikenDocument9 pagesVo Cam Loai NikenAnonymous g348UottZqNo ratings yet

- 584 PDFDocument7 pages584 PDFAdi Wahyu ArzantoNo ratings yet

- Baybars Ali Fil, and Mustafa Korkmaz, Cengiz ÖzmetinDocument6 pagesBaybars Ali Fil, and Mustafa Korkmaz, Cengiz ÖzmetinAmmr MahmoodNo ratings yet

- Paper9 PDFDocument7 pagesPaper9 PDFbarlosNo ratings yet

- International Journal of Chemical StudiesDocument7 pagesInternational Journal of Chemical StudiessalwaNo ratings yet

- Clay, Ctab, PB, Jurnal 6Document9 pagesClay, Ctab, PB, Jurnal 6SyarifahNo ratings yet

- 131739-Article Text-355354-1-10-20160310Document12 pages131739-Article Text-355354-1-10-20160310Leanne RedfearnNo ratings yet

- Research ArticleDocument10 pagesResearch ArticleSoussou PerlaNo ratings yet

- IJEDR1802018Document5 pagesIJEDR1802018BRAHIMNo ratings yet

- Validity of Egyptian Na-Montmorillonite For Adsorption of Pb2+, Cd2+ and Ni2+ Under Acidic Conditions: Characterization, Isotherm, Kinetics, Thermodynamics and Application StudyDocument15 pagesValidity of Egyptian Na-Montmorillonite For Adsorption of Pb2+, Cd2+ and Ni2+ Under Acidic Conditions: Characterization, Isotherm, Kinetics, Thermodynamics and Application StudyAnonymous RjOCIo1ucNo ratings yet

- Environmental Engineering and Management Journal, Vol. 6 Nr. 6Document109 pagesEnvironmental Engineering and Management Journal, Vol. 6 Nr. 6Andrei BerteaNo ratings yet

- Wang 2005Document10 pagesWang 2005hellna284No ratings yet

- Schedule M Tech 201512 MarchDocument3 pagesSchedule M Tech 201512 Marchanand singhNo ratings yet

- Thesis GuidelinesDocument1 pageThesis Guidelinesanand singhNo ratings yet

- Vectors Tensors 14 Tensor CalculusDocument9 pagesVectors Tensors 14 Tensor Calculusanand singhNo ratings yet

- Specimen Copy For M.Tech Admission Interview Call Letter (For TA/TAP/RA/RAP/SW/IS/PS/IIT B.Tech. Categories)Document1 pageSpecimen Copy For M.Tech Admission Interview Call Letter (For TA/TAP/RA/RAP/SW/IS/PS/IIT B.Tech. Categories)anand singhNo ratings yet

- Schedule PRDocument33 pagesSchedule PRanand singhNo ratings yet

- Rashant Umar Hattacharya: Date of Birth and Place Residence Address Academic QualificationsDocument42 pagesRashant Umar Hattacharya: Date of Birth and Place Residence Address Academic Qualificationsanand singhNo ratings yet

- Supercritical Fluids Supercritical Fluid Extraction : SCF SFEDocument11 pagesSupercritical Fluids Supercritical Fluid Extraction : SCF SFEanand singhNo ratings yet

- Bihar Gramin Bank Bihar Gramin Bank: Challan Form-01 (Cash Voucher) Challan Form - 01 (Cash Voucher)Document1 pageBihar Gramin Bank Bihar Gramin Bank: Challan Form-01 (Cash Voucher) Challan Form - 01 (Cash Voucher)anand singhNo ratings yet

- Pol.J.environ - stud.Vol.22.No.1.205 211Document8 pagesPol.J.environ - stud.Vol.22.No.1.205 211anand singhNo ratings yet

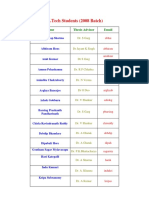

- M.Tech Students (2008 Batch) : Name Thesis Advisor EmailDocument2 pagesM.Tech Students (2008 Batch) : Name Thesis Advisor Emailanand singhNo ratings yet

- No NPH FinalDocument13 pagesNo NPH Finalanand singhNo ratings yet

- Scaling-Up Effects On Supercritical CO Extraction Kinetics of Pelletized TomatoDocument6 pagesScaling-Up Effects On Supercritical CO Extraction Kinetics of Pelletized Tomatoanand singhNo ratings yet

- Extracting Lycopene From Tomato Powders by Supercritical Propane and Carbon Dioxide With Industrial Scale PilotDocument6 pagesExtracting Lycopene From Tomato Powders by Supercritical Propane and Carbon Dioxide With Industrial Scale Pilotanand singhNo ratings yet

- Problems AnswersDocument15 pagesProblems Answersanand singhNo ratings yet

- Polyvalent / Eco - Friendly / High Performance Solvent Extraction Lab System SFE 100 MLDocument2 pagesPolyvalent / Eco - Friendly / High Performance Solvent Extraction Lab System SFE 100 MLanand singhNo ratings yet

- M.Tech. Students (2006 December Batch) : Name Thesis Topic Thesis Advisor Email Contact AddressDocument1 pageM.Tech. Students (2006 December Batch) : Name Thesis Topic Thesis Advisor Email Contact Addressanand singhNo ratings yet

- M.Tech. Students (2007 July Batch) : Name Thesis Topic Thesis Advisor Email Contact AddressDocument2 pagesM.Tech. Students (2007 July Batch) : Name Thesis Topic Thesis Advisor Email Contact Addressanand singhNo ratings yet

- M.Tech. Students (2006 July Batch) : Name Thesis Topic Thesis Advisor Email Contact AddressDocument3 pagesM.Tech. Students (2006 July Batch) : Name Thesis Topic Thesis Advisor Email Contact Addressanand singhNo ratings yet

- Theory of Stick-Slip Effect in Friction: KeywordsDocument8 pagesTheory of Stick-Slip Effect in Friction: KeywordsAndré Victor CastilhoNo ratings yet

- Carbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Document5 pagesCarbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Matias Riera LópezNo ratings yet

- Foster PDS 32 19 R0415Document2 pagesFoster PDS 32 19 R0415Simoncarter LawNo ratings yet

- Gas Cylider Technical Regulation PDFDocument37 pagesGas Cylider Technical Regulation PDFVinod Varadan SNo ratings yet

- Growing and Feeding Lucerne: Key MessagesDocument20 pagesGrowing and Feeding Lucerne: Key MessagesMike MurefuNo ratings yet

- ULO TempDocument7 pagesULO TempcnacevedoNo ratings yet

- January - February 2013 - International Aquafeed Magazine - Full EditionDocument68 pagesJanuary - February 2013 - International Aquafeed Magazine - Full EditionInternational Aquafeed magazineNo ratings yet

- ID Senyawa Antibakteri Yang Diproduksi OlehDocument8 pagesID Senyawa Antibakteri Yang Diproduksi OlehNurawaliah RezkyNo ratings yet

- Landfill-Gas-Engine-Oil AnalysisDocument2 pagesLandfill-Gas-Engine-Oil AnalysisKeith ChengNo ratings yet

- ASTM C1240-15Microsilica Specification 硅灰Document7 pagesASTM C1240-15Microsilica Specification 硅灰杨过No ratings yet

- Watercut Monitors-Delta CDocument8 pagesWatercut Monitors-Delta CShakeel AhmedNo ratings yet

- PHYSIO ReviewerDocument3 pagesPHYSIO ReviewerPHILYP EPHRAIM PARANGALANNo ratings yet

- Designing Concrete For Exposure To Seawater - tcm45-342265Document3 pagesDesigning Concrete For Exposure To Seawater - tcm45-342265Ignatius Samraj100% (2)

- ECOSIADocument8 pagesECOSIAaliosk8799No ratings yet

- M05 SpecificationsDocument97 pagesM05 SpecificationsLê Văn TrườngNo ratings yet

- HamzaDocument20 pagesHamzaHamza KhakwaniNo ratings yet

- Energy and Power Ib2Document24 pagesEnergy and Power Ib2Gkid GkidNo ratings yet

- Inorganic Chemistry Book2Document272 pagesInorganic Chemistry Book2bhaks1976No ratings yet

- Ex 3 - Reacting Masses, Solutions & ConcentrationsDocument4 pagesEx 3 - Reacting Masses, Solutions & ConcentrationsLeon Lim Teck ShernNo ratings yet

- Ansul: Extinguishing Agent Data SheetDocument2 pagesAnsul: Extinguishing Agent Data SheetjuandagarciamNo ratings yet

- Basic Food Chemistry Guided NotesDocument3 pagesBasic Food Chemistry Guided NotesJBE legendsNo ratings yet

- Analysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesDocument33 pagesAnalysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesaviantaraNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Processraulpalma93No ratings yet