Professional Documents

Culture Documents

Design of Column

Uploaded by

D SRINIVASCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Column

Uploaded by

D SRINIVASCopyright:

Available Formats

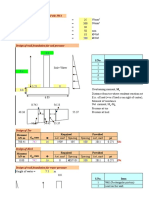

DESIGN OF COLUMN

Height of the Column (H)

5 m

Properties of ISMB 500 @0.75 KN/M

Gross area of the section (Ag)

11074 mm2

Depth of the Section (D)

500 mm

Width of flange (B)

180 mm

Thickness of flange tf =

17.2 mm

Thickness of web tw =

10.2 mm

Centre to centre distance between flanges (h f)

482.8 mm

Depth of web (dw)

431.6 mm

Radius at Fillet or Root (R1)

17 mm

Radius of gyration (rzz)

202.1 mm

Effective length of the Column (leff)

5 m

Section Classification as per Table 2 of IS 800-2007

= SQRT (250/fy) 1

b/tf =

5.233

(Plastic)

<9.4

Flange is fully effective

d/tw =

42.314

(Slender)

>42

Web is not fully effective and hence exclude web width morethan 42. The section is classified as Slender

Net area of the section (Anet)

11041.36

Slenderness Ratio (LT)= leff/ry

24.74

mm2

Section Properties:

Moment of Inertia about z axis (Izz)

429323166.28 mm4

Moment of Inertia about z axis (Iyy)

16756568.114 mm4

Elastic Section Modulus (Ze) = Izz/y

1717292.6651 mm3

Plastic Section Modulus (Zp) = 2*bf*tf(D-tf)/2+tw*d2/4

1969759.128 mm3

Shear Modulus (G)

76900 Mpa

Youngs Modulus (E)

200000 Mpa

Yield Stress of steel (fy)

250 Mpa

hy = (D-tf)

f (for symmetrical sections, the value is 0.5)

Wraping Constant (Iw) = (1-f)*f*Iy*hy2

482.8 mm

=If/If+Iw

0.5

471580036 mm6

Torsion Constant (It) = bt3/3

763286.2176 mm4

Elastic Critical Moment =Mcr

424135485.85 N.mm

424.14 KN.M

p (for plastic & compact sections, 1)

For semi compact sections Ze/ZP

0.8718287636

Slenderness Ratio (LT) = SQRT (p*Zp*fy/Mcr)

1.0775173214

Imperfection factor LT for welded section

0.490

LT

1.296

Strength reduction factor to account for lateral

torsional buckling of beams (XLT)

0.496

Design bending compressive stress (fbd) as per Eqn.

under Cl. 8.2.1 of IS 800, p.54

112.80 Mpa

Design bending compressive strength (M d) = bZp*fbd

193717510.717734 N.mm

193.72 KNM

>230.63 KN.M

Loads per m length

Live Load

0.750 kN/m

Self Weight of Section (Unit weight - 78.5 kN/m3)

0.832 kN/m

1.582 kN/m

Say

Concentrated Load on beam ( W )

1.800 kN/m

120.000 KN

Totl UDL Including load factor

= (1.5 x 1.8) =

2.70 Kn

Total Concen. load Including load factor

= (1.5 x 120) =

180.00 Kn

BM due to UDL

5.625 kN-m

BM due to Concentrated Load

225.00 KN-M

Max.Bending Moment

230.63 KN.M

Shear Force ( Vudl ) due to UDL

= 2.7 x 5 / 2

1.01 kN

Shear Force ( Vpoint ) due to Concentrated load

90.00 KN

Total SF at Support (V)

91.01 KN

Check for Shear Capacity:

Partial Safety Factor for material (mo)

1.1

Design Shear strength of the section (Vd)

577.65 KN

> 91.01

Also, 0.6 x Vd

346.59 KN

Therefore, the design Shear Force (V) is less than 0.6Vd

Check for Deflection:

The deflection (which is a serviceable limit state) must be calculated on the basis of the unfactored imposed

loads

Deflection Due to Dead and live load (udl)

0.17

Deflection due to concentrated load (point)

3.64

Total Deflection ()

3.81 mm

Allowable Maximum Deflection (max)

As per Table 6 of IS 800-2007, For gantry crane load

(electric operation upto 50 t)

=Span/750

6.67 mm

Hence OK

Radius of gyration (ryy)

Moment of Inertia about y axis (Iyy)

35.2 mm

13700000 mm4

Elastic Section Modulus (Zec) =

1808700 mm3

Plastic section modulus (Zp)

2074670 mm3

Length of Span

Effective Length of Span l

5 m

5.00 m

Depth of web ( d)

431.60 mm

Slenderness Ration (KL/r)

142.05

Ration of height to thickness (hf/tf ) =

28.07

Yield Stress (fy)

250.00 N/mm2

Critical stress fcr,b (As per table 14 of IS 800:2007)

157.04 N/mm2

Imperfection factor LT =

for rolled steel section

From Table 13(a) in IS 800:2007

Critical stress fcr,b (As per formula)

162.49 N/mm2

fcr,b=

Yield stress (fy = )

N/mm2

Lateral Torsional Buckling (Mcr)

325.81 KN.M

Design bending compressive stress (fbd) as per Eqn. under Cl. 8.2.1 of IS 800,

p.54

110.64 N/mm2

Design Bending Compressive stress as per Cl. 8.2.2 of IS 800-2007, P.54

Slenderness Ratio (LT)

#VALUE!

Imperfection factor LT =

0.21

LT

#VALUE!

for rolled steel section

Strength reduction factor to account for lateral

torsional buckling of beams (XLT)

#VALUE!

Design bending compressive stress (fbd)

#VALUE! N/mm2

Section Classification

= (250/fy)1/2

#VALUE!

From Table 2 in IS 800:2007; Limiting width to Thickness ratio

For rolled section b/tf =

d/tw =

So, The section is of Class 1

<

9.4

<

84

Plastic

b=

For Plastic & Compact sections

where mo =

Shear capaciy of the section

1.1

577.65 kN

0.6Vd = >

#REF!

0.6Vd > V

Design Bending Capacity of the section (Md)

=

#VALUE!

Md

kNm

>

#REF!

>

#VALUE!

Check for Deflection :

Permissible Deflection

Actual Deflection

33.3 mm

#VALUE! mm

DESIGN OF CANTILEVER BEAM

Span of Beam ( L )

5 m

Loads per m length

Live Load

0.750 kN/m

Self Weight of Purlin (ISMB @ 350)

0.524 kN/m

1.274 kN/m

Say

1.300 kN/m

120.000 KN

Concentrated Load on beam ( W )

w =

Including load factor

Including load factor

BM due to UDL

120.00

= (1.5 x 1.3) =

= (1.5 x 120) =

= 1.95 x 5^2 / 8

BM due to Concentrated Load

Max.Bending Moment

Shear Force ( Vudl ) due to UDL

1.95 Kn

180.00 Kn

6.09 kN-m

225.00 KN-M

231.09 KN.M

= 1.95 x 5 / 2

4.88 kN

Shear Force ( Vpoint ) due to Concentrated load

90.00 KN

Total SF at Support (V)

94.88 KN

Assume ISMB 200:

Overall depth h

Width of flange b

Thickness of flange tf =

350 mm

140 mm

14.2 mm

Thickness of web tw =

8.1 mm

Radius at Fillet or Root (R1)

14 mm

ryy

28.4 mm

Ixx

13600000 mm4

Zec =

779000 mm3

Plastic section modulus

889570 mm3

Length of Span

Effective Length of Span l

R1

5 m

4.25 m

1.3 mm

Depth of web ( d)

KL/r

h/ tf =

0..

mm

149.65

24.65

Critical stress fcr, b=

163.46

Imperfection factor LT =

for rolled steel section

From Table 13(a) in IS 800:2007

fcr,b=

163.46

145.41

KN.M

fy =

Lateral Torsional Buckling (Mcr)

fbd = design bending compressive stress =

N/mm2

114.15 N/mm2

Slenderness Ratio (LT)

#VALUE!

Imperfection factor LT =

0.21

LT

#VALUE!

for rolled steel section

Strength reduction factor to account for lateral

#VALUE!

torsional buckling of beams (XLT)

Design bending compressive stress (fbd)

#VALUE!

N/mm2

Section Classification

= (250/fy)1/2

#VALUE!

LT =

1.2 Ze fy / Mcr

=

From Table 2 in IS 800:2007; Limiting width to Thickness ratio

For rolled section b/tf =

d/tw =

So, The section is of Class 1

Plastic

<

<

9.4

84

2

b= 0.88

For self compact section

=

b=

For Plastic & Compact sections

where mo = 1.1

Shear capaciy of the section

372.00 kN

0.6Vd = >

94.88

0.6Vd > V

Design Bending Capacity of the section (M d)

=

#VALUE!

Md

kNm

>

231.09

>

#VALUE!

Check for Deflection :

Permissible Deflection

Actual Deflection

33.3 mm

4.0 mm

You might also like

- Base Plate DesignMS601aDocument3 pagesBase Plate DesignMS601aduazo2009No ratings yet

- Deep Beam Flexural and Shear DesignDocument6 pagesDeep Beam Flexural and Shear DesignManal ElkasabyNo ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Water TankDocument4 pagesWater Tankraghu kiranNo ratings yet

- Cantilever RCC WallDocument15 pagesCantilever RCC WallPraveen Kumar0% (1)

- TCC11 Element DesignDocument8 pagesTCC11 Element DesignMelinda GordonNo ratings yet

- Strip Beam Design 24 07 19Document37 pagesStrip Beam Design 24 07 19Ahammad KabeerNo ratings yet

- JSW Severfield Structure Ltd. composite column design EC4Document3 pagesJSW Severfield Structure Ltd. composite column design EC4RonakShahNo ratings yet

- Corbel Design ExcelDocument6 pagesCorbel Design ExcelVIJAY PARMARNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Crack WidthDocument4 pagesCrack Widthnavneet3bawaNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- 60 KL KOTHRI OHT DesignDocument39 pages60 KL KOTHRI OHT Designsanju middyaNo ratings yet

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Timber DesignDocument1 pageTimber DesignJohn SmithNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaNo ratings yet

- Water Tank Design CalcDocument5 pagesWater Tank Design CalcUttam Kumar Ghosh100% (1)

- Summary of IS 3370 Detailing RequirementsDocument2 pagesSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Design of haunch and splice connectionsDocument3 pagesDesign of haunch and splice connectionsMukarramuddinNo ratings yet

- Pipe CulvertDocument14 pagesPipe CulvertPraveen M balaramNo ratings yet

- Water Tank - Is 3370-Sludge TankDocument4 pagesWater Tank - Is 3370-Sludge TankDhayalan PalanisamyNo ratings yet

- Rafter & Rafter connection designDocument3 pagesRafter & Rafter connection designnikmmmecNo ratings yet

- Water Tank Wall FootingDocument4 pagesWater Tank Wall FootingAbhishekKumarNo ratings yet

- Retaining Wall DesignDocument120 pagesRetaining Wall DesignMohammed HanafiNo ratings yet

- Consultant Engineering Design of ROUNDED HSS SecDocument2 pagesConsultant Engineering Design of ROUNDED HSS SectamerragaaNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- RaftDocument5 pagesRaftvidyaNo ratings yet

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1No ratings yet

- Beam LSMDocument6 pagesBeam LSMARVIND SINGH RAWATNo ratings yet

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Purlin DesignDocument10 pagesPurlin Designitissa INGENIERIANo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Rectangular Ground Water TankDocument26 pagesRectangular Ground Water TankJhon DonNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document5 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Circular Water Tank Design: Capacity of Tank Free Board Total HeightDocument2 pagesCircular Water Tank Design: Capacity of Tank Free Board Total HeightyasirjurabaNo ratings yet

- Pier Cap DesignDocument2 pagesPier Cap DesignAnand SoniNo ratings yet

- Name of Work:-Design of Circular Beam: DegreeDocument25 pagesName of Work:-Design of Circular Beam: DegreeAnirban DeyNo ratings yet

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangaloreNo ratings yet

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- Project Grid BearingDocument30 pagesProject Grid BearingSujan SinghNo ratings yet

- Design of Circular Water TankDocument27 pagesDesign of Circular Water TankAbhay Thakur100% (1)

- Eccentricity Footing - 01022020Document7 pagesEccentricity Footing - 01022020naveenpnaidu1No ratings yet

- Check Crack Width in Beam As Per IS 456Document4 pagesCheck Crack Width in Beam As Per IS 456Rupali ChadhaNo ratings yet

- Anchor Bolt Design Example As Per Indian Code - Google SearchDocument2 pagesAnchor Bolt Design Example As Per Indian Code - Google Searchjebin_87No ratings yet

- Shear Check for 530UB82.0 Beam ProjectDocument1 pageShear Check for 530UB82.0 Beam ProjectArjun RajaNo ratings yet

- Design of Water TankDocument30 pagesDesign of Water TankDeepthi ReddyNo ratings yet

- Design of Cast in Situ Box Culvert (1.5x1.5) Without Earth CushionDocument2 pagesDesign of Cast in Situ Box Culvert (1.5x1.5) Without Earth CushionshashiNo ratings yet

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- RCC Drain DesignDocument39 pagesRCC Drain DesignShubham AgrawalNo ratings yet

- Truss DRGDocument1 pageTruss DRGkvamshi_1971No ratings yet

- Nagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)Document21 pagesNagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)rammohanNo ratings yet

- Assume A Plate Girder of The Following Properties: Span of Beam (L)Document10 pagesAssume A Plate Girder of The Following Properties: Span of Beam (L)D SRINIVASNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Pinned and fixed base plate design calculations for I-section and tube columnsDocument7 pagesPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Is.4880.1.1987 0 PDFDocument10 pagesIs.4880.1.1987 0 PDFD SRINIVASNo ratings yet

- Fluid Mechanics and Hydraulic Machines Textbook Scanned PDFDocument287 pagesFluid Mechanics and Hydraulic Machines Textbook Scanned PDFPullavartisrikanthChowdaryNo ratings yet

- Pile Foundations in Engineering Practice by S PDFDocument784 pagesPile Foundations in Engineering Practice by S PDFD SRINIVASNo ratings yet

- 101 Math Short Cuts-Mental Ability PDFDocument20 pages101 Math Short Cuts-Mental Ability PDFsanits591100% (1)

- Shotcrete GuideDocument4 pagesShotcrete GuideVpln Sarma100% (1)

- Brinch Hansen - An Extended Formula For Bearing Capacity PDFDocument21 pagesBrinch Hansen - An Extended Formula For Bearing Capacity PDFJuan Carlos Torres Hernández100% (4)

- 53 1f CTR PDFDocument70 pages53 1f CTR PDFJohneey DeepNo ratings yet

- Linings FOR: Irrigation CanalsDocument160 pagesLinings FOR: Irrigation CanalsmrmerajNo ratings yet

- Cable TrenchDocument22 pagesCable TrenchD SRINIVASNo ratings yet

- Staad Pro and Circular SlabDocument10 pagesStaad Pro and Circular SlabP&D CIRCLE PWD0% (1)

- vb6.0 Guide Made EasyDocument258 pagesvb6.0 Guide Made Easysb_rameshbabuNo ratings yet

- Terzaghi and Meyerhof Bearing Capacity TheoriesDocument23 pagesTerzaghi and Meyerhof Bearing Capacity Theorieskiddho100% (2)

- Bridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleDocument16 pagesBridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleRohit Gupta33% (3)

- Efficient 3D and 2D Modelling of Pile Foundations in FEMDocument21 pagesEfficient 3D and 2D Modelling of Pile Foundations in FEMOmar Elio67% (3)

- Connection FigDocument1 pageConnection FigD SRINIVASNo ratings yet

- Bridge Hand BookDocument50 pagesBridge Hand BookSunny Godugu100% (1)

- Eccentric FootingDocument15 pagesEccentric FootingD SRINIVASNo ratings yet

- Block Shear Capacity For Staggered BoltsDocument1 pageBlock Shear Capacity For Staggered BoltsD SRINIVASNo ratings yet

- Hollow Sections Book WardenierDocument199 pagesHollow Sections Book WardenierANUSSBAUMER100% (3)

- Advancement of Is CodeDocument8 pagesAdvancement of Is CodeD SRINIVASNo ratings yet

- Eccentric FootingDocument15 pagesEccentric FootingD SRINIVASNo ratings yet

- Crack WidthDocument1 pageCrack WidthD SRINIVASNo ratings yet

- Open Newel Stair Design with Quarter LandingDocument4 pagesOpen Newel Stair Design with Quarter LandingD SRINIVASNo ratings yet

- En Micro Hydro Design Aids GIZ 2005Document27 pagesEn Micro Hydro Design Aids GIZ 2005D SRINIVASNo ratings yet

- Two Way SlabDocument80 pagesTwo Way SlabD SRINIVAS100% (1)

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- Design of Slab Bs-2 Calculation of Crack WidthDocument2 pagesDesign of Slab Bs-2 Calculation of Crack WidthD SRINIVASNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- Classical Electrodynamics Part IIDocument331 pagesClassical Electrodynamics Part IIPankaj SolankiNo ratings yet

- Chem 114Document12 pagesChem 114lesliemarie272No ratings yet

- 02 Statics of Rigid Bodies 01 ConceptsDocument3 pages02 Statics of Rigid Bodies 01 Conceptsxaaabbb_550464353No ratings yet

- Orthogonal Vs OrthonormalDocument2 pagesOrthogonal Vs OrthonormalShouman BaruaNo ratings yet

- Kinematics DPP 07Document4 pagesKinematics DPP 07ROHANNo ratings yet

- Adiabatic ProcessDocument3 pagesAdiabatic Processshiviitd02No ratings yet

- Mole Concept & Stoichiometry ExplainedDocument58 pagesMole Concept & Stoichiometry ExplainedMuhammad Sahil KhanNo ratings yet

- Mikavukasaragod Physics PDFDocument148 pagesMikavukasaragod Physics PDFRaj SinhaNo ratings yet

- Quest Review 4 Electric Force, Magnetic Fields KEYDocument16 pagesQuest Review 4 Electric Force, Magnetic Fields KEYJ PNo ratings yet

- Biology Exam 4 Study GuideDocument12 pagesBiology Exam 4 Study GuideKhusbu PatelNo ratings yet

- Height & Distance-10Document26 pagesHeight & Distance-10mad_sudrocksNo ratings yet

- Geometry For High Speed RailwaysDocument17 pagesGeometry For High Speed RailwaysRajesh Paralkar100% (1)

- Cummins Generating Set Assembly Torsional Vibration Analysis GuideDocument10 pagesCummins Generating Set Assembly Torsional Vibration Analysis GuideariwibowoNo ratings yet

- Flow of Real FluidDocument52 pagesFlow of Real FluidADIL BAHNo ratings yet

- Calculation of Obstructed View Factors and Adaptative IntegrationDocument23 pagesCalculation of Obstructed View Factors and Adaptative IntegrationErnesto DufrechouNo ratings yet

- Physics Lab 205 Torques and Rotational EquilibriumDocument2 pagesPhysics Lab 205 Torques and Rotational EquilibriumRiah Janiece50% (2)

- Angular momentum of rod about hinged end when vertical = ml√glHence, the correct option is 1Document60 pagesAngular momentum of rod about hinged end when vertical = ml√glHence, the correct option is 1Swaran GhoshalNo ratings yet

- Building Mat 08-09Document39 pagesBuilding Mat 08-09takishiNo ratings yet

- Name: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetDocument9 pagesName: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetKarthikeyan GanesanNo ratings yet

- Math Before Calculus (Find The Tangent Line Without Calculus)Document10 pagesMath Before Calculus (Find The Tangent Line Without Calculus)Michael DyNo ratings yet

- Moment of Force Calculation - Definition, Formula & Examples"TITLE"Principle of Moments - Definition & Equilibrium Examples" TITLE"Calculating Moments: See-Saw, Plank & Weight ProblemsDocument5 pagesMoment of Force Calculation - Definition, Formula & Examples"TITLE"Principle of Moments - Definition & Equilibrium Examples" TITLE"Calculating Moments: See-Saw, Plank & Weight ProblemsPhilip MooreNo ratings yet

- WB-Mech 120 Ch07 BucklingDocument18 pagesWB-Mech 120 Ch07 BucklingMardiSantosoNo ratings yet

- Saudi Aramco UPS Inspection PlanDocument30 pagesSaudi Aramco UPS Inspection PlanVISAKHNo ratings yet

- Alkohol, Eter Dan EpoksidaDocument72 pagesAlkohol, Eter Dan EpoksidaAdi Kurniawan EffendiNo ratings yet

- Unit 1 - Physics - WWW - Rgpvnotes.inDocument15 pagesUnit 1 - Physics - WWW - Rgpvnotes.inMayank SharmaNo ratings yet

- 106 400 1 PBDocument10 pages106 400 1 PBIbtehaj Tasfin RiasatNo ratings yet

- ManometersDocument26 pagesManometersJeninah AbanaNo ratings yet

- Chapter 03 - Flow in PipesDocument83 pagesChapter 03 - Flow in PipesSamnang HangNo ratings yet

- Reviwe of Termal LensDocument32 pagesReviwe of Termal Lensreza vahdaniNo ratings yet

- Chromatographic Techniques WORDDocument56 pagesChromatographic Techniques WORDhelion45No ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Offshore Pipelines: Design, Installation, and MaintenanceFrom EverandOffshore Pipelines: Design, Installation, and MaintenanceRating: 4.5 out of 5 stars4.5/5 (2)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet