Professional Documents

Culture Documents

QAP

Uploaded by

Ravi BhadaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAP

Uploaded by

Ravi BhadaniCopyright:

Available Formats

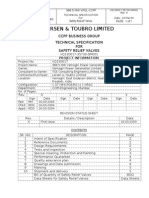

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN

Manufacturer: OMEEL Coils

Sr.

No

1

1

Component

s&

Operation

2

Design

Review

Legends

P: Perform

W: Witness

V: Verification

Characteristics and

Checks

3

Design Input Review

Review of Design

Calculation

1. Area

calculation

2. Shell Thickness

Calculation

3. Dished Head

Thickness

4. Flange

Standards

5. General

Layout of Oil

Cooler

6. Review of the

Drawing and

BOM

Categ

ory

4

CR

Type/Met

hod of

Check

5

Review

design

calculatio

n and

drawings

Extent

of

Check

6

100%

Reference

Documents

Acceptance

Norms

7

Clients

drawing

8

Clients

drawing

3: Vendor/Manufacturer

2: Customer/Customer Nominated Agency

1: Customer Nominated Agency

Equipment: Oil Cooler

Format of

Record

9

Calculation

sheets and

drawings

MA: Major

CR: Critical

Agency

P

Remarks

10

2

11

Drawing given

by client so

manufacturing

will be done

as per the

drawing, there

is no

interference

of

manufacturer.

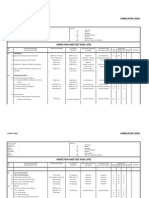

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN

Manufacturer: OMEEL Coils

Sr.

No

Components

& Operation

Characteristics and

Checks

1

2

2

Raw Material

Inspection

3

1. Shell

2. Dished End

3. Oil Cooler

Tubes

4. Tube Sheet

5. Baffle Plates

6. Heat

Exchanger

Supporting

leg

7. Nozzles

8. Pipes &

Flanges

9. Tie Rods

10. Hard Wares

Dimensional

Inspection

M/C

Component

Tubesheet and

End Flange

Legends

P: Perform

W: Witness

V: Verification

Categ

ory

4

MA

MA

MA

MA

MA

MA

Type/Met

hod of

Check

5

Visual,

Mechanic

al &

Chemical

Extent

of

Check

6

1 on

Each

Lot

Reference

Documents

7

Acceptance

Norms

Equipment: Oil Cooler

Format of

Record

8

Material

TC/Lab

record

9

TC

As per

Approved

drawing

IR

Visual &

Chemical

MA

MA

MA

MA

MA

Visual &

100%

Measuring

As per

Approved

drawing

3: Vendor/Manufacturer

2: Customer/Customer Nominated Agency

1: Customer Nominated Agency

MA: Major

CR: Critical

Agency

P

W

10

Remarks

V

11

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN

Manufacturer: OMEEL Coils

Sr.

No

Components

& Operation

Characteristics and

Checks

Categ

ory

1

4

2

Layout of

Arrangement

4

MA

In Process

Inspection

3

Fit up of Tube

Dimensional

Inspections

Mock up For Tube

Expansion

1. Fit up of total

system

Dimensional

Inspection

2. Dimensional

Inspection of

After

Completed

Welding

Layout & Total

Assembly

Dimensional

Inspection

Hydro Testing

Surface

Preparation &

Painting

Legends

P: Perform

W: Witness

V: Verification

Type/Met

Extent

Reference

hod of

of Check Documents

Check

5

6

7

Visual &

100%

As per

Measuring

Approved

drawing

Equipment: Oil Cooler

Acceptance

Norms

8

As per

Approved

drawing

Format

of

Record

9

IR

MA

Visual &

100%

Measuring

As per

Approved

drawing

As per

Approved

drawing

IR

MA

Visual &

100%

Measuring

As per

Approved

drawing

As per

Approved

drawing

IR

MA

Visual &

100%

Measuring

CR

Shade & DFT

MA

Visual &

Testing

Visual &

100% at

Measuring Random

As per

Approved

drawing

PQR

IR

Hydro Testing

As per

Approved

drawing

Hydro Test @

PSI

Approved

Paint

Specification

Approved

Paint

Specification

IR

3: Vendor/Manufacturer

2: Customer/Customer Nominated Agency

1: Customer Nominated Agency

IR

MA: Major

CR: Critical

Agency

P

W

10

Remarks

V

11

You might also like

- Bhel-Quality Plan PipingDocument7 pagesBhel-Quality Plan PipingMl Jain100% (1)

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- The Authorized Inspector's Responsibility For Dimensional InspectionDocument6 pagesThe Authorized Inspector's Responsibility For Dimensional InspectionsuparnaNo ratings yet

- Samples ITPDocument4 pagesSamples ITPHassan SajidNo ratings yet

- Inspection and Test Plan (Itp) For Control ValvesDocument15 pagesInspection and Test Plan (Itp) For Control ValveszakariaNo ratings yet

- Ub Engineering LimitedDocument1 pageUb Engineering LimitedproxywarNo ratings yet

- E - Lightning Protection System INSPECTION CHECKLISTDocument1 pageE - Lightning Protection System INSPECTION CHECKLISTmandelaria01100% (7)

- Inspection & Test PlanDocument19 pagesInspection & Test Planaszliza100% (1)

- Quality Assurance PlanDocument6 pagesQuality Assurance Planvkrishnamoorthy100% (2)

- Works Instruction For Piping Welding InspectionDocument5 pagesWorks Instruction For Piping Welding InspectionAbg SepulNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- QA-F-VN-PCM - T & C Check List For ChillerDocument2 pagesQA-F-VN-PCM - T & C Check List For ChillerKevin TranNo ratings yet

- Quality Assurance Plan Product Name: Stone Ware PipesDocument3 pagesQuality Assurance Plan Product Name: Stone Ware PipesAnonymous ciKyr0tNo ratings yet

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- Itp HeDocument15 pagesItp HeAldeline SungahidNo ratings yet

- Indicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalDocument3 pagesIndicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalmsuidNo ratings yet

- SM 001 SRV SpecDocument5 pagesSM 001 SRV Specvardan_vardanNo ratings yet

- 1.5 Assurance ProcessDocument9 pages1.5 Assurance Processaswar100% (1)

- Eme745 Csi 3 Part Guide Specification RTF 2577Document8 pagesEme745 Csi 3 Part Guide Specification RTF 2577Eldhose VargheseNo ratings yet

- PE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesDocument8 pagesPE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesCoquin AntNo ratings yet

- Check Fixture Standards Rev 4 Dated 9-10-2019Document11 pagesCheck Fixture Standards Rev 4 Dated 9-10-2019SasiNo ratings yet

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- D 100 Mda WHP Bem 004 Tbe PipeDocument30 pagesD 100 Mda WHP Bem 004 Tbe PipeAdvisNo ratings yet

- VT Report PipingDocument1 pageVT Report PipingAhmed Men3emNo ratings yet

- A096 2441 2118 MR 0 PDFDocument119 pagesA096 2441 2118 MR 0 PDFMohsen Halweni100% (1)

- Inspection and Test Procedure and Plan Rev 0 Commented by HDECDocument16 pagesInspection and Test Procedure and Plan Rev 0 Commented by HDECarchalys4u100% (4)

- Mechanical Design Engineer-ZainDocument5 pagesMechanical Design Engineer-ZainSyedZainAliNo ratings yet

- 5-ITP-Concrete Works PDFDocument4 pages5-ITP-Concrete Works PDFShivarajJadhavNo ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Inspection and Testing RequirementsDocument10 pagesInspection and Testing Requirementsnaoufel1706No ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Inspection Report For Grouting: No. Accept Remarks Check Items Reject Inspection ResultDocument4 pagesInspection Report For Grouting: No. Accept Remarks Check Items Reject Inspection ResultChozha RajanNo ratings yet

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiNo ratings yet

- 030-Itp For Ug GRP Piping PDFDocument22 pages030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- Technical Specification - LPG HeaterDocument94 pagesTechnical Specification - LPG Heaterhbsheen100% (1)

- Inspection and Test Plan (KDBK)Document5 pagesInspection and Test Plan (KDBK)Abdul Wadood Gharsheen100% (1)

- Division 1 General Requirements Section 01000 - Field EngineeringDocument10 pagesDivision 1 General Requirements Section 01000 - Field EngineeringLuis Gabriel BautistaNo ratings yet

- Albany Profile (GT) RevDocument48 pagesAlbany Profile (GT) RevHeri SetyantoNo ratings yet

- Inspection Record For Grouting: Items To InspectDocument1 pageInspection Record For Grouting: Items To InspectJoseph PeterNo ratings yet

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- KP-00+++-CQ712-B7510-Rev A-INSPECTION TEST PLAN FOR I C INSTRUMENT CONNECTION PART OF PIPING EQUIPMENTDocument17 pagesKP-00+++-CQ712-B7510-Rev A-INSPECTION TEST PLAN FOR I C INSTRUMENT CONNECTION PART OF PIPING EQUIPMENTUtku Can Kılıç100% (1)

- TBE Pumps CP 16Document21 pagesTBE Pumps CP 16ivomNo ratings yet

- Inlet of Foam Box Dwg.Document1 pageInlet of Foam Box Dwg.solquihaNo ratings yet

- Inspection Test PlanDocument3 pagesInspection Test Planfabin100% (3)

- Injection Mold Dept. Dimensional Inspection Report: Unit of Measurment: MillimeterDocument2 pagesInjection Mold Dept. Dimensional Inspection Report: Unit of Measurment: MillimeteralliceyewNo ratings yet

- 2004 A Piping DesignDocument76 pages2004 A Piping DesignRudy SuryaNo ratings yet

- 11-Quality Assurance - HariharanDocument29 pages11-Quality Assurance - Hariharanabhinay soniNo ratings yet

- CSQSDocument108 pagesCSQSBenNo ratings yet

- ISO FORMATS PaperDocument42 pagesISO FORMATS Papermilkbikis1114100% (1)

- 1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkDocument5 pages1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkLi LiuNo ratings yet

- Line Pipes Factory Acceptance Test ChecklistDocument1 pageLine Pipes Factory Acceptance Test ChecklistIdaba100% (3)

- FMEA ChartDocument1 pageFMEA Chartwawawa1No ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- Effective Project Management: Guidance and Checklists for Engineering and ConstructionFrom EverandEffective Project Management: Guidance and Checklists for Engineering and ConstructionNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Technical DetailsDocument2 pagesTechnical DetailsRavi BhadaniNo ratings yet

- Condenser Body New-ModelDocument1 pageCondenser Body New-ModelRavi BhadaniNo ratings yet

- New Doc 2018-02-20 - 2Document1 pageNew Doc 2018-02-20 - 2Ravi BhadaniNo ratings yet

- Industrial Refrigeration CompressorDocument8 pagesIndustrial Refrigeration Compressorr_sridhar20064780100% (2)

- Qap PDFDocument3 pagesQap PDFRavi BhadaniNo ratings yet

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Indian Boiler Regulations Form Iii-A Certificate of Manufacture and Test (Regulation 4 (E) )Document1 pageIndian Boiler Regulations Form Iii-A Certificate of Manufacture and Test (Regulation 4 (E) )Ravi BhadaniNo ratings yet

- RCDocument20 pagesRCRavi BhadaniNo ratings yet

- Catpdf en 26Document6 pagesCatpdf en 26Nooruddin SheikNo ratings yet

- Schedule September 2013Document1 pageSchedule September 2013Ravi BhadaniNo ratings yet

- Camless Engine PresentationDocument20 pagesCamless Engine PresentationRavi Bhadani80% (10)

- Expanding Access To Modern Energy in Rural India: Dr. P. BalachandraDocument51 pagesExpanding Access To Modern Energy in Rural India: Dr. P. BalachandraRavi BhadaniNo ratings yet

- Adults Guide To Special Interest Areas 07Document13 pagesAdults Guide To Special Interest Areas 07Warwick AudetNo ratings yet

- Ec3491 CT Iat 1Document2 pagesEc3491 CT Iat 1Dr.M.SubbulakshmiNo ratings yet

- VFP9 All Versions On One ComputerDocument25 pagesVFP9 All Versions On One ComputerJorge PorteNo ratings yet

- TR-069 Configuration Guide: Thomson GatewayDocument110 pagesTR-069 Configuration Guide: Thomson Gatewayfarlocco23No ratings yet

- Beam Me Up Star Trek Traveller - L3 - STDocument2 pagesBeam Me Up Star Trek Traveller - L3 - STBrahim BelitNo ratings yet

- De VILBISSDocument64 pagesDe VILBISSAlejandro NietoNo ratings yet

- Acknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffDocument16 pagesAcknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffShubham PhadtareNo ratings yet

- ACOS 4.1.4-GR1-P10 Release Notes: For A10 Thunder Series 19 June 2022Document258 pagesACOS 4.1.4-GR1-P10 Release Notes: For A10 Thunder Series 19 June 2022Nguyen AnhNo ratings yet

- 03 2 Seyi SD SDG2 Sde2 eDocument16 pages03 2 Seyi SD SDG2 Sde2 eCông Quang Trường PhanNo ratings yet

- Automated Solar Thermal Power PlantDocument6 pagesAutomated Solar Thermal Power PlantDa VuNo ratings yet

- Study Guide ML Math PDFDocument4 pagesStudy Guide ML Math PDFjerryNo ratings yet

- NFS-320 ProgrammingDocument120 pagesNFS-320 ProgrammingDel Heffron50% (2)

- Ceragon FibeAir IP-20S DatasheetDocument6 pagesCeragon FibeAir IP-20S DatasheetManuel ICNo ratings yet

- Chapter 12 - Fluid MachineriesDocument98 pagesChapter 12 - Fluid MachineriesWaw0% (1)

- Philips TV Software Upgrade With USB Portable MemoryDocument4 pagesPhilips TV Software Upgrade With USB Portable MemoryAmin AsawabNo ratings yet

- jBASE Command LanguageDocument137 pagesjBASE Command LanguageVictor WoodrowNo ratings yet

- Ethernetwebserver For Wt32 - Eth01 (Esp32 + Lan8720) : FeaturesDocument6 pagesEthernetwebserver For Wt32 - Eth01 (Esp32 + Lan8720) : FeaturestraiandNo ratings yet

- Mr. Michael Johnston (Orica)Document16 pagesMr. Michael Johnston (Orica)Don CorleoneNo ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoGuillermo Cabrera ContreraNo ratings yet

- Curriculum Vitae - Ruben Puli: Personal DetailDocument6 pagesCurriculum Vitae - Ruben Puli: Personal DetailRuben PuliNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- ENM232-6VIA - With Encore Electronics 5.1 Channel PCI Sound CardDocument2 pagesENM232-6VIA - With Encore Electronics 5.1 Channel PCI Sound CardmarcojaoNo ratings yet

- Huawei Hilens: Issue 01 Date 2020-03-26Document67 pagesHuawei Hilens: Issue 01 Date 2020-03-26Riyanto riyantoNo ratings yet

- Manitou 6400seriesDocument19 pagesManitou 6400seriesДенис ЧерныйNo ratings yet

- Word ProcessorsDocument38 pagesWord ProcessorsCaryll BaylonNo ratings yet

- DCNM - Wliion - Dicentis Battery PackDocument3 pagesDCNM - Wliion - Dicentis Battery PackAndrew Halim RamadanNo ratings yet

- L3H CAS - PresoDocument140 pagesL3H CAS - PresoPablo RestrepoNo ratings yet

- Repair KeretaDocument17 pagesRepair KeretaIefa Shafie100% (3)

- GCSE SolvingQuadratics 2Document42 pagesGCSE SolvingQuadratics 2Oghomwen OsundeNo ratings yet

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDocument8 pagesCambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationMaro Sofy100% (1)