Professional Documents

Culture Documents

Double acting pneumatic actuators guide

Uploaded by

Jessicalba LouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Double acting pneumatic actuators guide

Uploaded by

Jessicalba LouCopyright:

Available Formats

Type series booklet

8515.1/8--10

ACTAIR 1.5 to 1600

Double acting

pneumatic actuators

ACTAIR 1.5, 3, 6, 12, 25 and 50 :

rack and pinion kinematics

ACTAIR 100 and 200 :

scotch-- yoke kinematics

ACTAIR 400, 800 and 1600 :

yoke patented kinematics

Output torques up to 17600 Nm

ACTAIR 1.5 to 1600

General features

Designed for the automation of turn valves (butterfly valves, ball valves), the ACTAIR series of double acting pneumatic

actuators and their AMTROBOX/AMTRONIC/SMARTRONIC boxes are involved in all functions of control and supervision

encountered in all modern processes, and more particularly in communication by fieldbus.

3 kinematics are used for the actuators operation:

-- rack and pinion kinematics for ACTAIR 1.5, ACTAIR 3, ACTAIR 6, ACTAIR 12, ACTAIR 25 and ACTAIR 50,

-- scotch--yoke kinematics for ACTAIR 100 and ACTAIR 200,

-- yoke patented kinematics for ACTAIR 400, ACTAIR 800 and 1600.

Mounting plate according to ISO 5211 standard.

Equipped with an interchangeable insert, they can be easily fitted on different valve shaft (square end, flat end, key).

The ACTAIR series actuators are equipped, in standard version, with a visual pointer and adjustable mechanical travel

stops:

-- on the closed or open positions for ACTAIR 1.5 to 200 (see pages 6 and 7),

-- on the closed and open positions for ACTAIR 400, 800 and 1600.

The actuator is mounted directly or by means of an adaptator on turn valve plate.

Protection:

They are hose and fine dust proof and are protected against accidental immersion effects (protection degree: IP 67).

External coating:

ACTAIR 1.5 to 200: Housing with hard anodization 50 m thickness and cylinder head with black cataphoresis coating 30 m.

ACTAIR 400 to 1600: Polyurethane paint (colour dark grey RAL 7016, 80 m thickness).

Working temperature range:

From 20 to +80 C: standard,

Alternative construction for ACTAIR 1.5 to 200:

40 to +80C: dynamic O--rings in special Nitrile,

20 to +120C: dynamic O--rings in Viton (available with corrosive motive medium).

Other working temperature range for ACTAIR 400 to 1600: Please consult us.

This double acting actuator range is completed by the DYNACTAIR series spring return actuator range which is based on

the double acting actuators. Please consult the type series booklet DYNACTAIR 1.5 to 800 no. 8511.1.

Standard variant:

ATEX version in accordance with 94/9/EC directive.

Production range

Maximum allowable dimensions for the shaft

ACTAIR

Type

1.5

3

6

12

25

50

100

200

400

800

1600

ISO 5211

Mounting plate*

Height

F04

F04 or F05+F04 (45 )*

F05 F07

F05 F07

F07 F10

F10 F12

F10 F12

F14

F16

F16 F25

F25 F30

24

24

30

32

40

45

55

65

80

95

110

Driving

by square

11

11

16

19

22

27

36

50

60

70

90

* Direct adaptation onto identical mounting plate.

Adaptation by intermediate flange onto different plate (different size or shape).

Driving

by flat

11

11

14

17

22

27

36

46

55

75

85

Driving

by key

Please

Please,

consult us

ACTAIR 1.5 to 1600

Output torques (Nm) relating to control fluid pressure

The output torque of the actuator depends on the pressure of the control fluid.

The table below shows different output torques as a function of control fluid pressure.

Type

Maximum

allowable

output

torque

(Nm)

1.5

3

6

12

25

50

Control fluid pressure in bar

20

55

105

170

385

640

9

25

48

89

178

357

12

33

64

115

237

475

Rack and pinion kinematics

15

40

80

140

290

520

18

50

96

155

350

580

20

55

105

170

385

640

Scotch--yoke kinematics

100

200

0

600

1200

1320

2640

45

360

720

90

600

1200

0

800

1600

45

480

960

90

800

1600

0

1000

2000

45

600

1200

90

1000

2000

0

1200

2400

45

720

1440

90

1200

2400

0

1320

2640

45

792

1584

90

1320

2640

Yoke patented kinematics

400

800

1600

4400

8800

17600

0

30

2700 2970

5160 5676

9500 10450

60

90

0

2700 700 3200

5160 1300 6800

9500 2500 12500

30

60

3520 3200

7480 6800

13750 12500

90

0

800

4000

1700 8600

3150 15500

30

4400

9460

17050

60

4000

8600

15500

90

0

1000 4400

2150 8800

3900 17600

30

4840

9680

19360

60

4400

8800

17600

90

0

1100 4400

2200 8800

4400 17600

30

4840

9680

19360

60

4400

8800

17600

90

1100

2200

4400

Control fluid pressure

Air or any neutral gas, filtered, dry or lubricated and compressed to a pressure 3 to 8 bar:

-- filtration: 50 m,

-- drying: dew point at max. working pressure 4 C and min. temperature --5 C

If a lubrification is required -- the lubrification increases the actuator life -- the use of a non detergent oil without aggressive additive is

recommended:

-- viscosity 2 to 3 ENGLER at 50 C

-- anhiline point 90 C to 105 C

-- flow 1 to 3 drop for 500 NL/mn.

Operating time

The table below defines the minimum operation times under control air pressure 5 bar and the operation rates per minute of

the ACTAIR on/off function.

Mini operation time

ACTAIR

On/off function

Type

ACTAIR

ACTAIR with distributor

ACTAIR

Operation rates

+ AMTRONIC

ISO--1 or NAMUR

direct connexion

per minute

onto the housing

1.5

3

6

12

25

50

100

200

400

800

1600

1 second

1 second

2 seconds

4 seconds

5 seconds

6 seconds

9 seconds

25 seconds

50 seconds

90 seconds

12 seconds

25 seconds

45 seconds

0,5 second

0,5 second

0,5 second

1 second

1,5 seconds

2 seconds

3 seconds

4 seconds

60 max.

60 max.

60 max.

30 max.

20 max.

15 max.

10 max.

7 max.

4 max.

2 max.

1 max.

8 seconds

15 seconds

20 seconds

Adjust construction on request for:

-- other operation times,

-- high operation rates.

Consult us.

Capacity

ACTAIR

Type

1.5

3

6

12

25

50

Capacity in cm3

For opening

For closing

72

240

570

1 180

2 400

4 700

100

305

660

1 265

2 508

4 680

ACTAIR

Type

100

200

400

800

1600

Capacity in cm3

For opening

For closing

5 280

9 800

15 960

35 300

62 500

4 380

8 500

15 720

35 300

62 500

ACTAIR 1.5 to 1600

Construction

In the standard version, ACTAIR actuators are designed to ensure clockwise valve closure.

On request, anticlockwise arrangement is available.

The ACTAIR 1.5 to 200 are equipped with adjustable end--stops on only one position: adjustment range 2,5.

In standard, adjustable end--stop on close position.

In option, adjustable end--stop on open position.

The ACTAIR 400 to 1600 are equipped with adjustable end--stops on both positions: adjustment range 2.

ACTAIR 1.5 to 50: Rack and pinion kinematics

The rack and pinion kinematics develop a constant output torque.

The movement of the rack/pistons secured by the pressure causes a turn clockwise rotation of the pinion integral with the valve

shaft.

Curve of the rack and pinion kinematics

Constant output torque

Clockwise closure version Adjustable mechanical travel stop at the closed position

Opening operation

Actuator/Valve closed

Actuator/Valve open

Closure operation

Actuator/Valve open

Actuator/Valve closed

Clockwise closure version Adjustable mechanical travel stop at the open position

Opening operation

Actuator/Valve closed

Actuator/Valve open

Closure operation

Actuator/Valve open

Actuator/Valve closed

ACTAIR 1.5 to 1600

ACTAIR 100 and 200: Scotch--yoke kinematics

The scotch--yoke kinematics develop a variable output torque very well suited to the operation of turn valves.

The movement transmission is achieved by means of the piston

system , rollers , scotch--yoke and shaft .

The movement of the pistons secured by the pressure

causes the sliding of the rollers in the grooves of the yoke .

The yoke allows the rotation of the shaft integral with the

valve shaft.

Curve of the Scotch yoke kinematics

Output torque for F constant C = F x D

Clockwise closure version Adjustable mechanical travel stop at the closed position

Opening operation

Actuator/Valve closed

Actuator/Valve open

Closure operation

Actuator/Valve open

Actuator/Valve closed

Clockwise closure version Adjustable mechanical travel stop at the open position

Opening operation

Actuator/Valve closed

Actuator/Valve open

Closure operation

Actuator/Valve open

Actuator/Valve closed

ACTAIR 1.5 to 1600

ACTAIR 400 to 1600: Yoke AMRI patented kinematics

The yoke AMRI patented kinematics develop a variable output torque very well suited to the operation of turn valves with

hydrodynamic torque.

The movement transmission is achieved by means of the piston

system ,the slide operating nut , the rolling pad and the

yoke .

The movement of the piston secured by the pressure in the

actuator cylinder causes the linear travel of the operating nut .

This movement drives the sliding of the pads in the 2 slides of

the operating nut and allows the rotation of the yoke integral with the valve shaft.

Curve of the yoke AMRI patented kinematics

Output torque for F constant C = F x D

0,25

ACTAIR 400

Opening operation

Actuator/Valve closed

Actuator/Valve open

E

Closure operation

Actuator/Valve open

Actuator/Valve closed

P

E

P

P

E

ACTAIR 800 and 1600

Opening operation

Actuator/Valve closed

P

Actuator/Valve open

E

P

Closing operation

Actuator/Valve open

E

P

Actuator/Valve closed

E

P

E

P

E

ACTAIR 1.5 to 1600

ACTAIR 1.5 to 50

Construction

Direct pneumatic connection G.

Section A--A

Item

103

163

300.1

300.2

314

410

412.1

412.2

412.3

412.4

412.6

486

554

55--2

593

595

629

81--68

877

903

904

909

914.1

916

920

932

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Designation

Housing

Cylinder head

Upper bearing

Lower bearing

Thrust washer

Cylinder head gasket

O--ring

O--ring

Piston O--ring

O--ring

O--ring

Ball

Washer

Friction washer

Piston bearing

Piston

Pointer

Piston guide

Pinion

Plug

Socket screw

Adjusting screw

Hexagon socket head screw

Plug

Hexagonal nut

Spring retaining ring

Section B--B

Materials

Light alloy with 50 m hard anodization

Light alloy with 30 m cataphoresis coating

Acetal

Acetal

Stainless steel type 316

Nitrile

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile

Nitrile

Stainless steel

Stainless steel A4--70

Acetal

Acetal

Light alloy

Polyamide 6--6 + treatment against U.V. rays

Acetal

Zinc coated steel

Polyamide 6--6

Stainless steel with cladding

Stainless steel A4--70

Stainless steel A4--70

Polyethylene

Stainless steel A4--70

Stainless steel

Q Parts included in the spare parts kit

* Alternative: Special Nitrile (40 to +80 C) or Viton (20 to +120 C)

ACTAIR 1.5 to 1600

ACTAIR 100 and 200

Construction

Direct pneumatic connection G

Section A--A

Item

103

163

210

300.1

300.2

310

314

412.1

412.2

412.3

412.4

412.6

412.7

486

554.2

55--2

560

593

595

59--26

59--30

629

81--68.1

81--68.2

900

903

904

909

914.1

916.1

916.2

916.3

920

932

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Designation

Housing

Cylinder shaft

Shaft

Upper bearing

Lower bearing

Self lubricating bearing

Thrust washer

O--ring

O--ring

Piston O--ring

O--ring

O--ring

O--ring

Ball

Washer

Friction washer

Pin

Piston bearing

Piston

Scotch--yoke

Roller

Pointer

Piston guide

Piston guide

Cheese head screw

Plug

Socket screw

Adjusting screw

Hexagon socket head screw

Plug

Cylindric plug

Triangular plug

Hexagonal nut

Circlips

Section B--B

Materials

Light alloy with 50 m hard anodization

Light alloy with 30 m cataphoresis coating

Zinc coated treated steel

Acetal

Stainless steel + PTFE

PTFE filled

Zinc coated treated steel

Nitrile

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile (Working temperature range: from 20 up to +80 C)*

Nitrile

Nitrile

Stainless steel

Stainless steel A4--70

Acetal

Stainless steel

Acetal

JS 1030 spheroidal graphite cast iron

Treated steel

Treated steel

Polyamide 6--6 + treatment against U.V. rays

Acetal

Acetal

Stainless steel A4--70

Polyamide 6--6

Stainless steel

Stainless steel A4--70

Stainless steel A4--70

Polyethylene

Nitrile

Nitrile

Stainless steel A4--70

Stainless steel

Q

Q Parts included in the spare parts kit

* Alternative: Special Nitrile (40 to +80 C) or Viton (20 to +120 C)

8

ACTAIR 1.5 to 1600

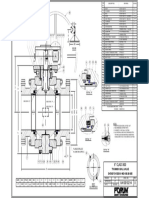

ACTAIR 400

Construction

Q 412.4

970.3

920.4

Section A--A

554.1

553

920.2

Q 412.8

Q

593

595

Q 412.9

914

574.1

Q 554

Q 412.1

310.1

Q 412.2

412.7

486

310.2

142

412.5

Q 415

141

726.1

901.1

901.2

901.3

893

920.3

103

970.1

904

Q 412.3

574.2

Q 310.1

Q 412.10

Q 554.2

920.3

893

901.1

920.1

81--68

412.6

59--40

310.3

52--8

Q Parts included in the spare parts kit

ACTAIR 1.5 to 1600

ACTAIR 400

Standard construction

Direct pneumatic connection1/2 G

Item

103

Designation

141

142

Cylinder

Housing

Cover

310.1

Self--lubricating bearing

310.2

Q Self--lubricating bearing

310.3

Self--lubricating bearing

412.1

Q O--ring

412.2

Q O--ring

412.3

Q O--ring

412.4

Q O--ring

412.5

Q O--ring

412.6

O--ring

412.7

Q O--ring

412.8

Q O--ring

412.9

Q O--ring

412.10

Q O--ring

415

Q Leap seal ring

486

Q Ball

52.8

Protection sleeve

553

Thrust insert

554

Q Washer

554

Washer

554.2

Washer

574.1

Piston rod

574.2

Rod

593

Q Guiding strip

595

Piston

59--40

Chuck

726.1

Flange

81--68

Pressure pad

893

Soleplate

901.1

Hexagon head screw

901.2

Hexagon head screw

901.3

Hexagon head screw

904

Grub screw

914

Screw

920.1

Operating nut

920.2

Hexagon nut

920.3

Hexagon nut

920.4

Hexagon nut

970.1

Identity plate

970.3

Stiker for mechanical stop use

Q Parts included in the spare parts kit

10

Materials

JL 1040 grey cast iron or

JS 1030 spheroidal graphite cast iron

JS 1030 spheroidal graphite cast iron

JL 1040 grey cast iron or

JS 1030 spheroidal graphite cast iron

PTFE filled on steel casing

PTFE filled on steel casing

PTFE filled on steel casing

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Stainless steel

Treated steel

Stainless steel 316

Nylon

Stainless steel A4--70

Stainless steel A4--70

Chromed steel

Chromed steel

PTFE + Bronze

Steel

JS 1030 spheroidal graphite cast iron + stainless steel

Steel + cataphoresis coating

Nitrured steel

Steel + cataphoresis coating

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

JS 1060 spheroidal graphite cast iron

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

Stainless steel

Adhesive

ACTAIR 1.5 to 1600

ACTAIR 800

Construction

Q 412.4

970.3

553

920.2

Q 412.8

Q

593

Q 920.4

Q 554.1

Q 412.9

Q 415

141

914

574

Q 554

726.1

Q 412.1

310.1

Q 412.2

Section A--A

595

310.2

412.7

486

142

901.1

920.1

310.3

81--68

59--40

310.3

412.5

901.2

901.3

893

920.3

970.1

103

574

Q 412.2

310.1

Q 412.1

Q

726.1

593

Q 412.8

141

595

553

970.3

Q 412.4

920.3

893

901.3

901.2

554

914

Q 415

Q 412.9

920.2

554.1

920.4

Q Parts included in the spare parts kit

11

ACTAIR 1.5 to 1600

ACTAIR 800

Standard construction

Direct pneumatic connection1/2 G

Item

103

Designation

141

142

Cylinder

Housing

Cover

310.1

Self--lubricating bearing

310.2

Q Self--lubricating bearing

310.3

Self--lubricating bearing

412.1

Q O--ring

412.2

Q O--ring

412.4

Q O--ring

412.5

Q O--ring

412.7

Q O--ring

412.8

Q O--ring

412.9

Q O--ring

412.10

Q O--ring

415

Q Leap seal ring

486

Q Ball

52.8

Protection sleeve

553

Thrust insert

554

Q Washer

554.1

Washer

574

Rod

593

Q Guiding strip

595

Piston

59--40

Chuck

726.1

Flange

81--68

Pressure pad

893

Soleplate

901.1

Hexagon head screw

901.2

Hexagon head screw

901.3

Hexagon head screw

914

Screw

920.1

Operating nut

920.2

Hexagon nut

920.3

Hexagon nut

920.4

Hexagon nut

970.1

Identity plate

970.3

Stiker for mechanical stop use

Q Parts included in the spare parts kit

12

Materials

JL 1040 grey cast iron or

JS 1030 spheroidal graphite cast iron

JS 1030 spheroidal graphite cast iron

JL 1040 grey cast iron or

JS 1030 spheroidal graphite cast iron

PTFE filled on steel casing

PTFE filled on steel casing

PTFE filled on steel casing

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Stainless steel

Treated steel

Stainless steel 316

Nylon

Stainless steel A4--70

Chromed steel

PTFE + Bronze

Steel

JS 1030 spheroidal graphite cast iron + stainless steel

Steel + cataphoresis coating

Nitrured steel

Steel + cataphoresis coating

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

JS 1060 spheroidal graphite cast iron

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

Stainless steel

Adhesive

ACTAIR 1.5 to 1600

ACTAIR 1600

Construction

932.1

920.2

553

Q 412.1

920.4

554.1

901.2

554.3

Q 412.8

Q 176

412.9

Q 593

141

Section A--A

310.2 412.7

486

142

901.1 412.5

595

Q 415

574

914

Q 412.1

Q 554.2

932.1

901.2

893

726.1

574

Q 412.2

970.1

103

310.1

Q 412.2

932.1

914

Q 554.2

Q 412.1

901.2

893

726.2

Q

920.1

81--68 59--40 412.6 310.3

Q 593

415

920.2

Q 412.8

176

595

Q 412.1

Q 412.9

932.1

141

970.3

553

920.4 -- 554.1

901.2

554.3

Q Parts included in the spare parts kit

13

ACTAIR 1.5 to 1600

ACTAIR 1600

Standard construction

Direct pneumatic connection 3/4 G

Item

Designation

103

Housing

141

Cylinder

142

Cover

176

Q Cylinder head

310.1

Self--lubricating bearing

310.2

Q Self--lubricating bearing

310.3

Self--lubricating bearing

412.1

Q O--ring

412.2

Q O--ring

412.5

Q O--ring

412.6

O--ring

412.7

Q O--ring

412.8

Q O--ring

412.9

Q O--ring

415

Q Leap seal ring

486

Q Ball

553

Thrust insert

554.1

Washer

554.2

Q Washer

554.3

Washer

574

Piston rod

593

Q Guiding strip

595

Piston

59--40

Chuck

726.1

Flange

726.2

Flange

81--68

Pressure pad

893

Soleplate

901.1

Hexagon head screw

901.2

Hexagon head screw

914

Screw

920.1

Operating nut

920.2

Hexagon nut

920.4

Hexagon nut

932

Retaining ring

970.1

Identity plate

970.3

Stiker for mechanical stop use

Q Parts included in the spare parts kit

14

Materials

JS 1030 spheroidal graphite cast iron

Steel

JS 1030 spheroidal graphite cast iron

Steel + cataphoresis coating

PTFE filled on steel casing

PTFE filled on steel casing

PTFE filled on steel casing

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Nitrile

Stainless steel

Stainless steel 316

Stainless steel A4--70

Stainless steel A4--70

Nylon

Chromed steel

PTFE + Bronze

Steel

JS 1030 spheroidal graphite cast iron + stainless steel

Steel + cataphoresis coating

Steel + cataphoresis coating

Nitrured steel

Steel + cataphoresis coating

Stainless steel A4--70

Stainless steel A4--70

Stainless steel A4--70

JS 1060 spheroidal graphite cast iron

Stainless steel A4--70

Stainless steel A4--70

Treated steel

Stainless steel

Adhesive

ACTAIR 1.5 to 1600

Mounting on valve

The actuator can be positioned in four positions, at intervals of 90 .

Unless otherwise stated, the actuator is mounted according to the arrangement N position1.

ACTAIR 1.5 to 200

Arrangement N

Position 1

Arrangement M

Position 2

Flow direction

Valve shown in closed position

Position 1

Position 2

Interface A: direct connection to control fluid or via a NAMUR distributor

Interface B: electric and pneumatic connections of AMTRONIC box

ACTAIR 400 to 800

Arrangement N

Position 1

Arrangement M

Position 2

Position 1

Position 2

Flow direction

Valve shown in closed position

These actuators are equipped with interchangeable inserts manufactured to the size and the form of different valve shafts for

motorized operation (square end, flat end, key).

ACTAIR 1.5 to 50

Pinion with star driving allowing mounting of the insert at

intervals of 45

ACTAIR 100 to 1600

Shft or yoke with driving square and insert

Flat end

Key end

Flat end

Square end

Square end

The actuators can be delivered with or without the coupling parts.

15

ACTAIR 1.5 to 1600

Overall dimensions (mm) and weights (kg)

ACTAIR 1.5 to 50

NAMUR connection

(dtail)

ACTAIR 100 and 200

NAMUR connection

(dtail)

ACTAIR

Type

1.5

16

A

143

B

76

C

96

D

66

E

44

F

76

194

100

119

98

55

100

218

114

137

116

65

118

12

272

132

163

142

65

138

25

344

156

197

176

90

166

50

424

174

238

217

125

200

100

505

157

216

195

122

170

200

592

174

258

237

144

210

ISO 5211 mounting plate

ref

d1

d2

F04

42

M5

F04 (45)

42

M5

F05

50

M6

F05

50

M6

F07

70

M8

F05

50

M6

F07

70

M8

F07

70

M8

F10

102

M10

F10

102

M10

F12

125

M12

F10

102

M10

F12

125

M12

F14

140

M16

n

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Weight

kg

1.2

2.8

3.9

6.0

11.0

18.3

30.0

48.0

ACTAIR 1.5 to 1600

Overall dimensions (mm) and weights (kg)

ACTAIR 400 (Standard version -- Direct connection)

NAMUR VDI/VDE 3845 interface

1/2 gas

115

95

125

246

380

315

drilling diameter d1

530

n equidistant holes d2

434

ACTAIR 800 (Standard version -- Direct connection)

NAMUR VDI/VDE 3845 interface

1/2 gas

155

140

280

330

109

383

n equidistant holes d2

drilling diameter d1

622

680

ACTAIR 1600 (Standard version Direct connection)

NAMUR VDI/VDE 3845 interface

3/4 gas

180

180

330

406

130

383

692

n equidistant holes d2

drilling diameter d1

765

ISO 5211 Mounting plate

ACTAIR

Type

400

800

1600

ref

F16

F16

F25

F25

F30

d1

165

165

254

254

298

d2

M20

M20

M16

M16

M20

n

4

4

8

8

8

Weight

kg

160.0

290.0

504.0

17

ACTAIR 1.5 to 1600

Indication function

H1

H1

Limit switch box IP 67 AMTROBOX

The function provided by AMTROBOX is as follow:

Position detection:

-- On/off position detection by means of microswitches or inductive proximity detectors (1/O, 1/C, 1 on intermediate position

on request).

ACTAIR 1.5 to 200

ACTAIR 400 to 1600

Interface

Consult type series booklet AMTROBOX ref. 8525.1

Control and supervision functions

H2

H2

Piloting--servo control by AMTRONIC/SMARTRONIC

The functions provided are as follows :

AMTRONIC :

On/off pneumatic distribution: 4/2 or 4/3 configuration, spring return or double acting, A.C. or D.C. supply.

Operating time adjustment.

SMARTRONIC :

Proportional distribution for autocalibration seting, 4--20 mA pilot.

Operating time adjustment

Options :

On/off position detection (2 microswitches or inductive proximity detectors),

Proportional position detection (4--20 mA).

Field bus: AS--i, Profibus DP, Device Net.

ACTAIR 1.5 to 200

ACTAIR 400 to 1600

Interface

Consult type series booklets AMTRONIC ref. 8512.1 and SMARTRONIC MA 8527.1

ACTAIR

Type

H1

H2

M

1.5

144

3

168

235

6

185

252

12

211

278

25

245

312

50

286

353

100

264

331

200

306

373

400

293

390

580

800

328

425

672

1600

378

475

742

18

434

730

815

Weight

kg

2,9

4.5

5.5

8.0

13.0

20.0

32.0

50.0

170.0

300.0

514.0

ACTAIR 1.5 to 1600

Options :

Visual position indicator type BEACON

Direct NPT air connection

Instead of the standard pointer.

1/4 NPT connection plate made of anodised Aluminium,

fitted onto the Namur interface of the standard actuator.

ACTAIR 3 to 1600

ACTAIR 1.5 to 200

ACTAIR 400 to 1600

NPT air connection directly threaded on the cylinder:

--1/2 NPT on ACTAIR 400 and 800,

-- 3/4 NPT on ACTAIR 1600

Declutchable manual override: ACTAIR 3 to 1600

The manual override using a declutchable gear box may be fitted between the valve mounting plate and the actuator.

This manual override will override with the pneumatic actuator and can be set in clutched or declutched positions.

This device is based on worm wheel and screw kinematics.

Please consult us.

Note: The manual override should only be used under the following recommendations:

- absence of air pressure in the actuator,

- Leakage to air free of all the cylinders of the actuator.

The manual override should not be declutched when pressure is in the actuator.

Construction :

------

Housing, cover and extension in JL 1040 grey cast iron,

Handwheel in welded iron,

Screw in steel,

Worm in JS 1030 spheroidal graphite cast iron,

Drive shaft, clutch lever, locking pointer, adjustable mechanical travel

stops (+/--5 ) and external bolting in 13 % chromium steel.

Protection :

They are hose and fine dust proof (protection degree: IP 65).

Construction for protection degree IP 67 on request: please, consult

us.

External coating:

Polyurethane paint (colour dark grey RAL 7016, 80 m thickness).

Working temperature range:

From 20 C to +80 C.

Please refer to the type series booklet manual override ref. no.5350.1.

19

ACTAIR 1.5 to 1600

Options

Stroke limiter

ACTAIR 1.5 to 200

Stroke limiter adjustable between 0 and 90 in only one direction.

The device is fitted instead of the standard adjustment end--stop.

Available on open or close direction.

Consult us.

ACTAIR 3 to 12

Stroke limiter adjustable in both directions (open

and close).

The device is fitted between the valve top flange

and the actuator.

Consult us.

ACTAIR actuators can be equipped with different accessories instead of AMTRONIC instrumentation box.

This switchbox is fitted onto the top of the actuator

housing by means of a yoke with interface in accordance with VDI/VDE 3845 NAMUR specification.

Please consult us.

A positioner with a 3--15 PSI pneumatic piloting signal

or a 4--20 mA electric signal (standard or with intrinsically safety) can be mounted onto the top of actuator

housing by means of a yoke with VDI/VDE 3845.

Please consult us.

NAMUR distributor

ACTAIR 1.5 to 200

This leaflet is not contractual

and may be amended without notice.

Positioner

ACTAIR 1.5 to 1600

Limit switch box

ACTAIR 1.5 to 1600

ISO size 1 distributor

ACTAIR 3 to 1600

ISO size 2 distributor

ACTAIR 400 to 1600

A distributor with electric or pneumatic piloting with

NAMUR interface can be fitted directly onto the side of

the actuator housing.

Please consult us.

KSB S.A.S.

4, alle des Barbanniers 92635 Gennevilliers Cedex (France)

Tel.: +33 1 41 47 75 00 Fax: +33 1 41 47 75 10 www.ksb.com

8515.1/8--10

11.07.05

A distributor with an ISO 5599 size 1 or size 2

interface can also be fitted to the actuator by means

of a distributor plate.

You might also like

- O-Ring Troubleshooting Guide O-Ring Failure Analysis PDFDocument3 pagesO-Ring Troubleshooting Guide O-Ring Failure Analysis PDFharshpatel18No ratings yet

- Hydrodynamics induced vibration of trash-racksDocument10 pagesHydrodynamics induced vibration of trash-rackssunnytouchNo ratings yet

- Piping Class: Standard Specification For Pipe, Valves & FittingsDocument8 pagesPiping Class: Standard Specification For Pipe, Valves & Fittingsxavier lopezNo ratings yet

- Fluid Induced Vibration of Composite Natural Gas PipelinesDocument16 pagesFluid Induced Vibration of Composite Natural Gas PipelinesSimon Achink LubisNo ratings yet

- Pump Sizing and Selection GuideDocument18 pagesPump Sizing and Selection GuideJessicalba LouNo ratings yet

- Shear Ram Bop MaintenanceDocument1 pageShear Ram Bop Maintenanceayman akrabNo ratings yet

- Fundamentals of AerodynamicsDocument25 pagesFundamentals of AerodynamicsPaul Timothy Hao100% (3)

- NON-DESTRUCTIVE TESTING: OVERVIEW OF LIQUID PENETRANT AND MAGNETIC PARTICLE INSPECTIONDocument30 pagesNON-DESTRUCTIVE TESTING: OVERVIEW OF LIQUID PENETRANT AND MAGNETIC PARTICLE INSPECTIONshuklahouseNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Flanges Carbon Chrome Blind RTJWN SMDocument11 pagesFlanges Carbon Chrome Blind RTJWN SMvalli rajuNo ratings yet

- Repair Parts Kit List: L2125 Rev. A 05/97Document12 pagesRepair Parts Kit List: L2125 Rev. A 05/97RonaldNo ratings yet

- Oilfield Products - Valves & Wellheads: YyycwuvtcnkcprkrgnkpgxcnxgeqocwDocument48 pagesOilfield Products - Valves & Wellheads: Yyycwuvtcnkcprkrgnkpgxcnxgeqocwjhonny barrantesNo ratings yet

- Butterfly Valves ENGDocument40 pagesButterfly Valves ENGPanagiotis PanagosNo ratings yet

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- GST Complete CatalogDocument306 pagesGST Complete CatalogAmy FischerNo ratings yet

- KSB Acto ActuatorsDocument16 pagesKSB Acto ActuatorsCardoso MalacaoNo ratings yet

- Id35 Honda GX630 GX660 GX690Document20 pagesId35 Honda GX630 GX660 GX690RodrigoChaves0% (1)

- Value Added Products From PFAD PDFDocument60 pagesValue Added Products From PFAD PDFJessicalba LouNo ratings yet

- Catalogo Valvulas Forged Velan PDFDocument36 pagesCatalogo Valvulas Forged Velan PDFCarlosEduardoMorenoManceraNo ratings yet

- Sigma Fasteners - Hex NutDocument9 pagesSigma Fasteners - Hex Nutdavorp1402No ratings yet

- CP Rotork Actuator - Catalogue PDFDocument8 pagesCP Rotork Actuator - Catalogue PDFLai HuynhNo ratings yet

- Blakeborough X-Stream Brochure PWDocument12 pagesBlakeborough X-Stream Brochure PWAnderson SiqueiraNo ratings yet

- RB 4700 BrochureDocument6 pagesRB 4700 Brochuretuan pham minhNo ratings yet

- 12 - 16 60f-2n-GoDocument1 page12 - 16 60f-2n-GoBryan QuirozNo ratings yet

- Butter Valve Thickness PDFDocument10 pagesButter Valve Thickness PDFAnand KumarNo ratings yet

- The Range of Valves-DataDocument70 pagesThe Range of Valves-DataAshraf SalehNo ratings yet

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDocument8 pagesCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaNo ratings yet

- SY Y StranerDocument2 pagesSY Y StranerPhú Song LongNo ratings yet

- Anchor Fluid Power CatalogDocument128 pagesAnchor Fluid Power CatalogJustinNo ratings yet

- TRC - Lesson Plan Plant and Animal Cell 2Document10 pagesTRC - Lesson Plan Plant and Animal Cell 2Armaan0% (1)

- Hot Crude Oil StorageDocument13 pagesHot Crude Oil Storagesachinumarye100% (1)

- Softwood and Hardwood in Dissolving PulpDocument126 pagesSoftwood and Hardwood in Dissolving PulpAlan KurniawanNo ratings yet

- ACTAIR 100 and 200 - MAINTENANCEDocument16 pagesACTAIR 100 and 200 - MAINTENANCEtommyNo ratings yet

- Datasheet Pneumatic Actuator Pa 11 21 PDFDocument4 pagesDatasheet Pneumatic Actuator Pa 11 21 PDFFuad OtsutsukiNo ratings yet

- VAG Absperrklappen02-05Document27 pagesVAG Absperrklappen02-05Muhamad FajriNo ratings yet

- Pricelist Merck 2013Document1,404 pagesPricelist Merck 2013Poppy Siska IsabellaNo ratings yet

- Fluid Compatibility GuideDocument18 pagesFluid Compatibility GuideNazirul FariqNo ratings yet

- Orbit Parts List and Ordering InstructionsDocument24 pagesOrbit Parts List and Ordering Instructionskeertiraj09No ratings yet

- 32 25 Coefficient Friction TesterDocument1 page32 25 Coefficient Friction TestercalocalareNo ratings yet

- Compresor Ariel KBU Fase 4Document211 pagesCompresor Ariel KBU Fase 4Jorge SanchezNo ratings yet

- Valves Price List Feb 2016Document8 pagesValves Price List Feb 2016baldevNo ratings yet

- Design Calculation of Worm and Worm Gear Tangential LoadDocument5 pagesDesign Calculation of Worm and Worm Gear Tangential LoadVenkateswaran venkateswaranNo ratings yet

- TICO Pipe SupportsDocument8 pagesTICO Pipe SupportsEjeantengNo ratings yet

- US211M Flow Meter: Quantitative ControllerDocument4 pagesUS211M Flow Meter: Quantitative Controllerhw606No ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- AISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedDocument4 pagesAISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedLinus LooNo ratings yet

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 pagesInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Referencia Descripción PVP /UD Raee: TargettiDocument54 pagesReferencia Descripción PVP /UD Raee: TargettiVEMATEL50% (2)

- Item 4 - GA10010214 PN 400804Document1 pageItem 4 - GA10010214 PN 400804Pablo GarcíaNo ratings yet

- Velan ABV: Delivering Value Through PerformanceDocument16 pagesVelan ABV: Delivering Value Through PerformanceAnanto Yusuf WNo ratings yet

- Pneumatic Actuated Ball Valve PE4320Document2 pagesPneumatic Actuated Ball Valve PE4320Fa ChNo ratings yet

- Balon Full Valve CatalogDocument51 pagesBalon Full Valve CatalogVictor Muñoz0% (1)

- Devlon V- API Physical Properties and Test DataDocument1 pageDevlon V- API Physical Properties and Test DataCarlosIkedaNo ratings yet

- Pneumatic, Piston Type: Needle Valve ActuatorsDocument20 pagesPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahNo ratings yet

- DWG ST 418-20 - Sockolets - WeldoletDocument11 pagesDWG ST 418-20 - Sockolets - WeldoletLis RincónNo ratings yet

- Dual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594Document2 pagesDual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594unknownNo ratings yet

- CST-1 Design HistoryDocument2 pagesCST-1 Design HistoryJefferson OliveiraNo ratings yet

- Bonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesDocument17 pagesBonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesozkanhasanNo ratings yet

- Sferova API6 Ball Valve CatalogueDocument27 pagesSferova API6 Ball Valve CatalogueWong JowoNo ratings yet

- 4JH3 HteDocument2 pages4JH3 HteIvana Muratti JerkovicNo ratings yet

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- Expansion Bellow Tech ComparisonDocument10 pagesExpansion Bellow Tech ComparisonSabariMechyNo ratings yet

- ActairDocument16 pagesActairvj100% (1)

- Frese OPTIMA Compact DN10-DN50 Pressure Independent Balancing & Control Valve TechnoteDocument13 pagesFrese OPTIMA Compact DN10-DN50 Pressure Independent Balancing & Control Valve TechnoteFareedeeNo ratings yet

- ACTAIR 1.5 to 800 pneumatic actuators technical selection guideDocument16 pagesACTAIR 1.5 to 800 pneumatic actuators technical selection guideedark2009No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- LP1 - Razmah Ghazali PDFDocument56 pagesLP1 - Razmah Ghazali PDFJessicalba LouNo ratings yet

- Panel 1 - 2 Datuk M NagarajanDocument32 pagesPanel 1 - 2 Datuk M NagarajanJessicalba LouNo ratings yet

- Effect of Service Water Temperature On Capacity of Liquid Ring Vacuum PumpsDocument4 pagesEffect of Service Water Temperature On Capacity of Liquid Ring Vacuum PumpsJessicalba LouNo ratings yet

- OS1 - Karl LintnerDocument33 pagesOS1 - Karl LintnerJessicalba LouNo ratings yet

- Panel 1 - 1 Prof Pietro PaganiniDocument32 pagesPanel 1 - 1 Prof Pietro PaganiniJessicalba LouNo ratings yet

- C6 - DR Azis AriffinDocument19 pagesC6 - DR Azis AriffinJessicalba LouNo ratings yet

- Carbon Reduction in Malaysian Palm Oil IndustryDocument27 pagesCarbon Reduction in Malaysian Palm Oil IndustryJessicalba LouNo ratings yet

- Evening Forum PDFDocument50 pagesEvening Forum PDFJessicalba LouNo ratings yet

- C5 - DrChongDocument28 pagesC5 - DrChongJessicalba LouNo ratings yet

- C7 - Dehua Liu PDFDocument28 pagesC7 - Dehua Liu PDFJessicalba LouNo ratings yet

- MSPO Certifying Sustainable Malaysian Palm OilDocument6 pagesMSPO Certifying Sustainable Malaysian Palm OilJessicalba LouNo ratings yet

- LP3 - AbdulRochim PDFDocument53 pagesLP3 - AbdulRochim PDFJessicalba LouNo ratings yet

- LP2 Goh Swee Hock PDFDocument52 pagesLP2 Goh Swee Hock PDFJessicalba LouNo ratings yet

- C4 Noor Hidayu OthmanDocument20 pagesC4 Noor Hidayu OthmanJessicalba LouNo ratings yet

- LP1 - Ahmad Jaril AsisDocument28 pagesLP1 - Ahmad Jaril AsisJessicalba LouNo ratings yet

- Panel 1 - 1 Prof Pietro PaganiniDocument30 pagesPanel 1 - 1 Prof Pietro PaganiniJessicalba LouNo ratings yet

- C3 - Hong Wai OnnDocument22 pagesC3 - Hong Wai OnnJessicalba LouNo ratings yet

- Oleochemical Outlook Conference Highlights Changing Industry TrendsDocument14 pagesOleochemical Outlook Conference Highlights Changing Industry TrendsJessicalba LouNo ratings yet

- Plenary 1 - 2 UR UnnithanDocument27 pagesPlenary 1 - 2 UR UnnithanJessicalba LouNo ratings yet

- Panel 2 - 1 Dato' Carl Bek-NielsenDocument4 pagesPanel 2 - 1 Dato' Carl Bek-NielsenJessicalba LouNo ratings yet

- Panel 1 - 1 Prof Pietro PaganiniDocument30 pagesPanel 1 - 1 Prof Pietro PaganiniJessicalba LouNo ratings yet

- MSPO Certifying Sustainable Malaysian Palm OilDocument6 pagesMSPO Certifying Sustainable Malaysian Palm OilJessicalba LouNo ratings yet

- Plenary 2 - 1 DR James Fry PDFDocument16 pagesPlenary 2 - 1 DR James Fry PDFJessicalba LouNo ratings yet

- Plenary 2 - 4 Arif Rachmat PDFDocument24 pagesPlenary 2 - 4 Arif Rachmat PDFJessicalba LouNo ratings yet

- Plenary 2 - 3 G ChandrashekharDocument10 pagesPlenary 2 - 3 G ChandrashekharJessicalba LouNo ratings yet

- Pakistan Edible Oil Market OutlookDocument9 pagesPakistan Edible Oil Market OutlookJessicalba LouNo ratings yet

- Plenary 2 - 6 Thomas MielkeDocument27 pagesPlenary 2 - 6 Thomas MielkeJessicalba LouNo ratings yet

- Thermophysical property prediction for acylglycerolsDocument9 pagesThermophysical property prediction for acylglycerolsJessicalba LouNo ratings yet

- Guidance For Robustness/Ruggedness Tests in Method ValidationDocument48 pagesGuidance For Robustness/Ruggedness Tests in Method ValidationonastasaNo ratings yet

- Introduction To Soldering and Desoldering Techniques.Document6 pagesIntroduction To Soldering and Desoldering Techniques.Arsalan Ahmed100% (1)

- Mixing Eductors Mixing EductorsDocument1 pageMixing Eductors Mixing Eductorsdetreomycyna100% (1)

- ABB CorrosionDocument8 pagesABB CorrosionForexFFNo ratings yet

- Orthovoltage Vs MegavoltageDocument7 pagesOrthovoltage Vs MegavoltageEmmanuel Cuevas MisNo ratings yet

- NJ DEP Guidance on Process Hazard Analysis and Risk AssessmentDocument17 pagesNJ DEP Guidance on Process Hazard Analysis and Risk AssessmentaakashtrivediNo ratings yet

- NDA Chemistry MCQs For PracticeDocument9 pagesNDA Chemistry MCQs For Practicekumar HarshNo ratings yet

- Chemistry 6941, Fall 2007 Synthesis Problems I - Key Dr. Peter NorrisDocument9 pagesChemistry 6941, Fall 2007 Synthesis Problems I - Key Dr. Peter NorrisQuốc NguyễnNo ratings yet

- TS - X Chemistry All DCEB Papers Chapter Wise Academic Standard Wise Prefinal - I & 2 QuestionsDocument40 pagesTS - X Chemistry All DCEB Papers Chapter Wise Academic Standard Wise Prefinal - I & 2 Questionsc18180707No ratings yet

- Types of Fuels and Their Characteristics for Internal Combustion EnginesDocument26 pagesTypes of Fuels and Their Characteristics for Internal Combustion EnginesMuhammad HarisNo ratings yet

- Method Statement: LokfixDocument3 pagesMethod Statement: Lokfixkamalxd100% (1)

- Dental Unit CS 300B Chair MountedDocument3 pagesDental Unit CS 300B Chair MountedCatrin AfriliaNo ratings yet

- BS EN 15408-2011 Solid Recovered Fuels - Determination of Sulphur (S), C...Document22 pagesBS EN 15408-2011 Solid Recovered Fuels - Determination of Sulphur (S), C...fadhil muhamadNo ratings yet

- Btu Analysis Using A Gas ChromatographDocument5 pagesBtu Analysis Using A Gas Chromatographlutfi awnNo ratings yet

- Cablofil Catalog2014Document116 pagesCablofil Catalog2014Gustavo Montalvo MoralesNo ratings yet

- Piht0f402 Icmts Icad600tsDocument2 pagesPiht0f402 Icmts Icad600tsamruta21No ratings yet

- The Effect of Different Fertilizers On Plant GrowthDocument2 pagesThe Effect of Different Fertilizers On Plant GrowthVeerath தமிழன்0% (2)

- PMTC Guidance on Cleaning Validation PracticeDocument15 pagesPMTC Guidance on Cleaning Validation PracticehhNo ratings yet

- Total Solutions For Electrocatalysis Research: Discover The ECAT-packagesDocument2 pagesTotal Solutions For Electrocatalysis Research: Discover The ECAT-packagescipta irawanNo ratings yet

- VTF Filtro BolsilloDocument7 pagesVTF Filtro BolsilloArmandoMiquilenaNo ratings yet

- Large-Particle CompositesDocument25 pagesLarge-Particle CompositesLexNo ratings yet

- E 155 - 00 - Rte1nq - PDFDocument4 pagesE 155 - 00 - Rte1nq - PDFLeón SuárezNo ratings yet

- Banana Peels As Paper Final OutputDocument20 pagesBanana Peels As Paper Final OutputA - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- VRF Duct Indoor Unit Type GMV-RH P: Air Conditioning and HeatpumpsDocument3 pagesVRF Duct Indoor Unit Type GMV-RH P: Air Conditioning and Heatpumpsdino_pNo ratings yet