Professional Documents

Culture Documents

HH125 Pump Installation Manual

Uploaded by

jacklyn ade putraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HH125 Pump Installation Manual

Uploaded by

jacklyn ade putraCopyright:

Available Formats

SYKES GROUP PTY LTD

HH125 PUMPSET

FOR

REF: W/O

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

SYKES GROUP PTY LTD

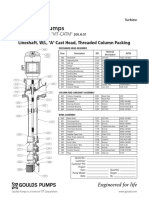

PUMP SPECIFICATION

PUMP TYPE:

PUMP SIZE:

ACTUAL IMPELLER DIAMETER:

HH125

150mm x 125mm

370mm

ENGINE / MOTOR TYPE:

PUMPSET NUMBER:

PUMPEND NUMBER:

JOB NUMBER:

PLANT NUMBER:

ENGINE / MOTOR NUMBER:

DRY WEIGHT:

FUEL CAPACITY:

WET WEIGHT:

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

TECHNICAL DATA SHEET No. 1

DESIGN DETAILS:

Pump Designation:

Pump Description:

Suction Flange:

Delivery Flange:

Nominal Casing Thickness:

Nominal Shaft Diameter:

Impeller Eye Diameter:

Maximum Impeller O.D.:

Minimum Impeller O.D.:

Moment Inertia Impeller:

Solids Handling Size:

Wear Plate Clearances:

Design Speed:

Design Capacity:

Design Efficiency:

Max HP at Design Speed:

Specific Speed:

Operating Speed:

Outrigger Bearing to be fitted

above:

Maximum Head:

Maximum Capacity:

Operating Temperature:

Operating Temperature

Casing:

Permissible Suction Press:

Maximum Hydraulic Test

Press:

Bearing Sizes:

Estimated Bearing Life:

Type of Bearing Lubrication:

Type of Shaft Seal:

HH125(DV)

Single stage, volute type, 3 bladed fully open

Centrifugal pump

6" Table 'D'

5" Table 'D' complete with 5"-6" adaptor

18mm

50mm

90mm at tip, 76mm at eye

370mm (Outlet Width - 33.6mm)

250mm (Hub Dia. 80mm)

1022.8kg/cm

29mm

REAR: 0.50/0.70mm FRONT: 0.50/0.70mm

2200rpm

81m/hr

50%

110HP

460

MIN: 1600rpm

1800rpm

136m (447Ft)

180m/hr (660GPM)

MIN: -20c

MIN: -20c

MAX: 2400rpm

MAX : +100C

MAX : +177C

MIN: Zero ABS

MAX : 2BAR (29 PSI)

20.1 BAR (291 PSI)

DRIVE END:

SKF RMS16 Ball

PUMP END:

SKF CMR16

Roller

MIN. SPEED/MAX. LOAD:

15,000 hours

MAX. SPEED/MIN. LOAD:

11,280 hours

Grease lubrication Shell Alvania RA or

equivalent

Mechanical seal silicon carbide faces dry

running

lubrication from oil reservoir behind seat.

Pump out vanes on rear of impeller shroud.

Balance holes.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

TECHNICAL DATA SHEET No. 2

MATERIALS OF CONSTRUCTION:

Pump Casing:

Suction Cover:

Air Separation Tank:

Bearing Bracket:

Pump Shaft:

Impeller:

Wearplates:

Air Injector:

Seal Housing:

Mechanical Seal:

Lip Seal:

N.R.V. Body:

N.R.V. Rubber:

Compressor Drive Details:

Number & Belt Section:

S.G. IRON TO AS1831 GRADE SG 400/12

S.G. IRON TO AS1831 GRADE SG 400/12

S.G. IRON TO AS1831 GRADE SG 400/12

S.G. IRON TO AS1831 GRADE SG 400/12

431 Stainless Steel

316 Stainless Steel

316 Stainless Steel

316 Stainless Steel

St/Steel 316 Grade

Crane type 1A 2" CODE BJ1S1/D

Nitrile Rubber 2" ID x 3/8" Wide

S.G. IRON TO AS1831 GRADE SG 400/12

Nitrile or Polyurethane Rubber 55/60 Shore

COMPRESSOR PULLEY: Tooth Belt " Pitch Heavy x

40 Teeth (P/N. 26-0830-0243)

DRIVE PULLEY:

Tooth Belt " Pitch Heavy x

32 Teeth (P/N. 10-0000-0049)

1 x Timing Belt 38mm Wide 390H150 (P/N. 26-0840-9912)

Compressor Details:

Bendix 2W 440 R Twin-inline cylinders 75m x 50mm

stroke. Air cooled 15cfm (410L/min) at 1000rpm,

Lubrication from engine oil system.

Ejector Details:

Jet: 23-0415-2016S

Venturi: 23-0414-2036S

OPERATING & MAINTENANCE INSTRUCTIONS

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

DESCRIPTION OF UNIT

The pump is basically a simple end suction pump which has a completely

automatic priming system built into the design. This enables the pump to self

prime from a completely dry condition even with a long suction line. No liquid of

any nature is required to prime the pump and therefore in temporary dry trench

conditions the pump will 'snore' until such time as liquid is available.

The DRI-VAC principal utilises a standard air compressor feeding a pneumatic

ejector mounted above the air/water separation tank. With this device, suction

lifts up to 8.2m (27 ft) can be obtained.

It can handle unscreened sewage, trade effluents, thick slurries and solids up to a

normal limitation of 29mm.

The impeller is a three bladed, stainless steel construction, designed fully open. It

is mounted on a shaft made from 431 stainless steel fitted in a cast iron bearing

bracket; which also provides concentric location for the pump body.

The pump body cast iron construction fitted with stainless steel wearplates.

The mechanical seal is leak tight and suitable for sewage and sludges using a

silicon carbide face on a silicon carbide seat. The arrangement incorporates an

oil-filled seal housing.

The whole unit is mounted on a robust skid base chassis. It is fitted with towing

eyes, lifting frame. The fuel tank has a capacity of 580L.

Guards are fitted as standard to all moving parts.

For any engine details please refer to your engine manual or spare parts manual.

Note: If your HH125 pumpset has been mounted on a trailer chassis it is

recommended that after approx. 5 km of travel that all wheel nuts be inspected

and re-tightened.

OPERATING & MAINTENANCE INSTRUCTIONS

Operation

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Before attempting to start the unit familiarise yourself with the engine controls as

mentioned in the Manufacturers Handbook and also the starting procedure. It is

advisable to turn the unit over slowly by hand before starting, to ensure that all

components are free and easy to turn. Once started the compressor will

automatically come in at the correct speed to prime the pump unit. When the

engine has started the pump requires no adjustment as the engine speeds are set

at WORKS.

Bearing Bracket And Pump

When replacing any castings, before use check for burrs, bruising, foreign bodies,

porosity i.e. Bearing Bracket, Pump Body, Impeller, Shaft, Suction Cover, Seal

Housing and Components.

Check the fit of the inner race for a reasonable transitional fit. When replacing the

inboard ball bearing it is fitted on the inner race only with Loctite "Bearing Fit" and

cured with Loctite Grade T. Check the inner and outer race for excessive wear

and rough spots in rotation and if still present reject the ball race. If alright repack

approximately two thirds with new grease. Shell Alvania RA or No. 2 or near

equivalent grade. Do not over-grease. Check grease cups for condition of grease

and quantity. Check seal are not excessively worn. Check water thrower is

present and in reasonable condition.

The bearings used are ball bearings

Roller bearings (adj to pump)

4" x 2" x 1.1/16"

RMS16 S.K.F.

4" x 2" x 1.1/16"

C.R.M. 16 S.K.F.

Examine the shaft end over which the seal is fitted for burrs, bruises, etc. which

are likely to damage the seal during fitting.

Preparation And Seal Fitting Of Mechanical Seal

Inspect seal seat face for blow holes, scores, or wear marks, etc. Ensure that

there is a minimum lead-in radius of 1mm into the seal seat recess on seal

extension housing.

When a seal is reconditioned, it should be ground to a surface finish of 10-20

C.L.A. and lapped to within 3 sodium light bands. Seals with only a ground finish

are unsatisfactory, and will result in excessive wear of the faces.

Check that the lip seal in the rear of the seal housing is not excessively worn,

renew if required.

Extreme care should be taken when fitting the silicon carbide faced seal as this

material is very brittle and easily chipped.

OPERATING & MAINTENANCE INSTRUCTIONS

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Preparation And Seal Fitting Of Mechanical Seal - Cont'd

If the seal cannot be inserted with fingers it should be pushed home with a length of

soft tube or wood large enough in diameter to make contact around the outer edge of

the seat; clear of the sealing area.

Before fitting the rotating seal unit ensure that all surfaces are clean and that all edges

over which the bellows have to pass are rounded-off to approximately 1mm radius. All

working faces must be clean and free from any foreign matter.

Smear pump shaft with light oil (not grease). Fit the taper tool over the shaft (Fig. 1)

and mount seal face ring on the bellow unit. For assembly purposes it is permissible

to put a smear of grease behind the ring, to hold it in place during assembly over the

taper sleeve and into place on the shaft. A soluble grease is preferable e.g. Swarfega.

Before fitting the seal housing dampen the joint with water.

Whether the wear plates or impeller have been replaced or not, the following

procedures should be observed:* Ensure that the impeller will screw-up to the shaft shoulder and that the thread

form has not been damaged.

* Using adjusting shim washers behind the impeller boss (if necessary) set the front

and back clearance to within 0.50/0.70mm.

* Before finally fitting the impeller, grease shaft areas and pump casing bore where

seal assembly passes through. This will also assist future removal of impeller and

seal assembly. The recommended grades of lubricant for this are:- 'Copperslip' or

'Shell Alvania' grease plus Molybdenum Disulphide or Rocal Anti-Seize compound

J166.

* Non-adhesive sealant to be used on all plugs including filler and drain plug e.g.

Boss White, Non-Adhesive Hermatite, Loctite Hydraulic Sealant.

If pump units are to remain in stock unused for long periods of time, all adjacent close

clearance surfaces should be sprayed with an aerosol can of Molyslip A.D.F. to

prevent rust and seizure.

Separation Tank And Ejector

Dri-Prime Ejector Pack Assembly:

Check ejector and jet sizes:

Nozzle

23-0414-2036S

Jet

23-0415-2016S

Clean the jet and nozzle with paraffin or similar cleaner. On no account should stiff

wire be used as this will enlarge the bores.

OPERATING & MAINTENANCE INSTRUCTIONS

Separation Tank And Ejector - Cont'd

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Check the nozzle and jet bores for any sharp edges, burrs or rough surfaces. If

damaged and no replacement is readily available, smooth and polish as well as possible

to original form.

Alignment of jet and nozzle is important but this is preset by machining tolerances and

the use of standard copper-asbestos washers.

Assemble ejector unit and check performance on test unit. Operation Air Pressure: 40

psi approx. Minimum Pass Vacuum: 24" Mercury (27.24ft)

When the above figure is not obtained, the distance between the nozzle and ejector may

be slightly adjusted by an additional copper washer with one or both to obtain the

vacuum required.

A satisfactory arrangement for carrying out the performance test on the ejector unit is a

plate fitted with a vacuum gauge as illustrated.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

OPERATING & MAINTENANCE INSTRUCTIONS

NON-RETURN VALVE

Ensure that all items are clean and free from burrs.

Visually check for porosity and blow holes in the castings and for scores or

chaffing of the valve.

COMPRESSOR

The standard compressor pack assembly comes complete with timing belts and

pulleys and is a direct drive off the pump shaft.

As an option a compressor, driven directly from the engine is also available.

TEST PROCEDURE

VACUUM TEST

When the bearing bracket and complete pump end have been assembled and

before the cavity behind the mechanical seal seat has been filled with oil, the

pump should be subjected to a vacuum test to show up any air leaks.

Air leaks may occur from the mechanical seal, non-return valve, the ball N.R.V., in

the ejector plate, pump joints, porous castings or from filling and drain plugs.

The assembled pump end should seal against a minimum vacuum of 81kPa (8m).

With closed valves, the vacuum should hold for a minimum of 5 minutes.

Fill seal housing after test is completed with Shell engine oil or equivalent until the

level reaches the threads of the filler hole.

Pressure test complete; pump unit to 1 times maximum working pressure i.e.

2052kPa (300 psi).

DYNAMIC TEST

Rotate engine on starter for a minimum of six complete revolutions, listen for

injector 'creak' - indicating the injector pump is working.

Start pump and run completely dry for a minimum period of 10 minutes. During

this period generally check and observe for any unusual vibrations, overheating,

fuel, oil or air leaks.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

OPERATING & MAINTENANCE INSTRUCTIONS

DYNAMIC TEST- Cont'd

After the dry running period check that the pump unit will raise a minimum vacuum

of 81kPa ie. 8m.

Couple hoses to the pump suction and delivery; test from a deep well pit at a

suction lift of approximately 7.5m. Record priming time.

This hydraulic test should be repeated several times until satisfied that all

components are functioning correctly. The duration of the hydraulic test should be

a minimum of 20 minutes.

At the end of the hydraulic test again check that the pump will raise a vacuum of

81kPa.

.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

GENERAL MAINTENANCE

BEARINGS (GREASE CAPS)

CHECK FOR GREASE QUANTITY AND QUALITY AT EACH START UP

OPERATION. USE SHELL ALVANIA RA OR NO. 2 OR EQUIVALENT

GREASE.

(REFER ITEM BB22 IN PARTS LISTING).

MECHANICAL SEAL

-

CHECK OIL LEVEL AT EACH START UP OPERATION

FILL WITH A LIGHT ENGINE OIL TO WITHIN 25MM FROM

THE TOP OF THE RESERVOIR.

(REFER ITEM BB11 IN PARTS LISTING).

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

PUMP PROBLEMS - Systems & Likely Causes

1. Pump does not prime

Suction lift too great.

Insufficient water at suction inlet.

Suction inlet or strainer blocked.

Suction line not air tight.

Suction hose collapsed.

Non return valve ball not seating

Mechanical seal drawing air into pump

Ejector jet or nozzle blocked or badly worn.

Ejector non-return valve ball stuck.

Separation tank cover blocked.

Compressor pipe leaking air.

Compressor no delivering sufficient air

Compressor belt drive faulty.

2. Not enough liquid

Incorrect engine speed.

Discharge head too high.

Suction lift too great.

Suction inlet or strainer blocked.

Suction line not air tight.

Suction hose collapsed.

Mechanical seal drawing air into pump.

Obstruction in pump casing/impeller.

Impeller excessively worn.

Delivery hose punctured or blocked.

3. Pump ceases to deliver liquid Suction lift too great.

after a time.

Insufficient water at suction inlet.

Suction inlet or strainer blocked.

Suction hose collapsed.

Excessive air leak in suction line.

Mechanical seal drawing air into pump.

Obstruction in pump casing/impeller.

Delivery hose punctured or blocked.

4. Pump takes excessive power Engine speed too high.

Obstruction between impeller and casing.

Viscosity and SG of liquid being pumped too

high.

5. Pump vibrating or

Engine speed too high.

overheating

Obstruction in pump casing/impeller.

Impeller damaged.

Cavitation due to excessive suction lift.

6. Pump leaking at seal housing Mechanical seal damaged or worn.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

THIS PUMP IS DEFINED IN SUB-ASSEMBLIES

Volute

BB

Bearing Bracket

EP

Ejector Pack

ST

Separation Tank

DR

Flywheel Coupling

Non-Return Valve

Chassis

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

PARTS LISTS

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS.No.

H1

H2

H3

H4a

H4b

H4c

H5

H6

H8

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H26

H28a

H28b

H29

H31

H50

H66

H68

H83

DESCRIPTION

Body

Impeller

Front Cover

Joint (Body)

Joint (Body)

Joint (Body)

Wearplate (Front)

Setscrew M12 x 36

Wearplate (Rear)

Seal Unit

Dowel Pin

Seal Extension Joint

Seal Housing

Bolt M6 x 55

Spring Washer M12

Stud M12 x 50

Nut M12

Spring Washer M12

Flat Washer M12

Plug

Impeller Shim

Impeller Shim

O Ring Sealing Washer SS

Viton O Ring

Setscrew M12x35 SS Sockethead

Oil Seal

Seal Spacer

O-ring (Seat)

Hose

PART No.

11-0195-0155

12-0244-3015

11-0196-0000

38-0300-5413

38-0300-5423

38-0300-5433

12-0243-0915

12-0251-0915

38-0814-BJ1S1/D

10-0000-0025

38-0333-5413

14-0303-2911

36-0557-8213

36-0557-8223

38-0785-4412

38-0787-4112V

38-0533-1913

24-0168-6111

38-1067-4112

346-5371

QTY.

1

1

1

A/R

A/R

A/R

1

8

1

1

1

1

1

4

4

12

12

12

2

A/R

A/R

4

4

1

1

1

1

12

VOLUTE

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS.No.

BB1

BB2

BB2a

BB3

BB3a

BB4

BB5

BB6

BB6a

BB7

BB8

BB8

BB9

BB11

BB12

BB13

BB14

BB15

BB16

BB17

BB19

BB20

BB21

BB26

BB10

BB18

Not Shown

DESCRIPTION

PART No.

13-1118-0125

13-0063-0125

13-0063-0135

13-0010-0145

13-0010-0165

39-0009-9912

39-0057-9912

Bracket

Bearing Cover (Inner)

Bearing Cover (Inner Pump End)

Bearing Cover (Outer)

Bearing Cover (Outer Pump End)

Ball Bearing

Roller Bearing

Setscrew Outer Cover M10 x 25

Setscrew Outer Pump End M10 x90

Setscrew Inner Cover M10 x 65

Oil Seal

38-1069-9912

Oil Seal

38-1069-9912

Springwasher M10

Brearing Bracket

27-6000-8211

Oil Reservoir (Removable)

27-5000-8211

Setscrew M10 x 25

Shaft

16-0410-8611

Circlip 2"

345-4520

Stud M12 x 45

Nut M12

Springwasher M12

Springwasher M10

Flatwasher M10

1/8" BSP Grease Nipple

51-0003-8112

Bearing Housing

13-0179-0115

o

10-0000-0024

1/8" BSP x 90 Grease Nipple

Flatwasher

Extension Piece 1/8BSP M/F

10-0000-0025

QTY.

1

1

1

1

1

1

1

3

3

6

1

1

12

1

1

4

1

1

8

8

8

4

4

1

1

1

8

1

BEARING BRACKET

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS. No.

DESCRIPTION

EP1

Ejector Jet

EP2

Ejector Nozzle

PART No.

QTY

23-0415-2016S

1

23-0414-2036S

1

EJECTOR PACKAGE

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS. No.

ST1

ST2

ST5

ST6

ST8

ST9

ST10

ST11

ST12

ST13

ST14

ST16/17

ST21

Not Shown

DESCRIPTION

"T" Piece

Tank/Body Joint

Flat Washer M20

Ejector Carrier Plate

Stud M12 x 50

Nut M12

Flat Washer M12

Ball Seat

Ball

Plug 1" BSP

Filter

Elbow BSP FM to 3/4 Hosetail

Bolt M20 x 75

Vacuum Gauge

PART No.

348-4006

500-4051

23-0411-0115

23-0412-2011

39-0641-4113

P16

23-0413-2113

E12SBF

001-0003

QTY

1

2

16

1

4

8

8

1

1

1

1

1

8

1

SEPARATION TANK / EJECTOR

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS. No.

AC1

AC2

AC3

AC4

AC5

AC6

AC7

AC8

AC9

AC10

AC11

AC13

AC14

AC15

DESCRIPTION

Compressor (Bendix)

Gasket

Setscrew M10 x 25

Springwasher M10

Pulley - Pump ( bored to suit TLB) c/w

2517 x 1-7/8 Taper Lock Bush

Pulley (Compressor)

Belt 38 wide x 78 teeth (1/2 Heavy Pitch)

Fan Washer

Relief Valve

Air Cleaner

Adaptor (Air Cleaner)

Compressed Air Hose

Elbow BSP x BSP

Pulley/Belt Guard

PART No.

49-0523-9915

KX2542/1

10-0000-0039

10-0000-0035

26-0830-0243

26-0840-9912

36-0556--8111

10-0000-0004

54-0556-9912

A1212

42-0000-0009

E1208HMM

QTY

1

1

4

4

1

1

2

1

1

1

1

1

1

1

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS. No.

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

V16

DESCRIPTION

REFLUX BOX COMPLETE

Reflux Box Body

Stud M20 x 65

Nut M20

Stud M20 x 70

Flat Washer M20

Nut M20

Reflux Box Cover

O-Ring

Reflux Box Seat

Reflux Box Ball

Drain Cock

Joint

Nut M20

Flat Washer M20

Bolt M20 x 70

PART No.

356-2124HH

356-4061HH

356-4062

356-4153

356-4063

313-4169

920-9242

500-4051

QTY

1

1

8

8

4

4

4

1

1

1

1

1

1

8

8

8

REFLUX BOX ASSEMBLY 150MM HIGH HEAD

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ILLUS.No.

C1

C2

C3

C4

C5

C6

C7

DESCRIPTION

Trailer Chassis

Battery Box

Filler Cap 2" BSP

Plug 2" BSP

Fuel Suction & Delivery Pipe

Fuel Hose Return & Delivery

Plug " BSP

PART No.

SPA-400

346-5372

340-6041

QTY.

1

1

1

3

2

2

1

CHASSIS

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ACCESSORIES

Description

Part No.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

Sykes Group Pty Ltd

.

Installation, Operation and Maintenance Manual.

ENGINE

Sykes Group Pty Ltd

.

You might also like

- DV100 SMDocument51 pagesDV100 SMjacklyn ade putraNo ratings yet

- Pump ZM B PDFDocument12 pagesPump ZM B PDFRamon PachecoNo ratings yet

- Hda Operational ManualDocument48 pagesHda Operational ManualDouglas DuarteNo ratings yet

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Multistage SpiroglideDocument4 pagesMultistage SpiroglidedestinyrestartNo ratings yet

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDocument105 pagesHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- HH160i Spec Sheet USLETTER PrintDocument2 pagesHH160i Spec Sheet USLETTER PrintFaisal RijaniNo ratings yet

- Aace PmiDocument274 pagesAace PmiRichard PaulNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- Top Entry Mixer Features For EkatoDocument2 pagesTop Entry Mixer Features For EkatoShankarNo ratings yet

- Bettis CBA 725Document16 pagesBettis CBA 725kutts76100% (1)

- BPCL CYLINDER MANUFACTURINGDocument34 pagesBPCL CYLINDER MANUFACTURINGVishalVaishNo ratings yet

- Sterling Sihi GMBH: Product Identification Folder PT Sihi MSLDocument3 pagesSterling Sihi GMBH: Product Identification Folder PT Sihi MSLRini Yuni SaraNo ratings yet

- ITT Gould PumpsDocument2 pagesITT Gould PumpsBilly ZununNo ratings yet

- DB 40-20 PDFDocument22 pagesDB 40-20 PDFMahendra AsawaleNo ratings yet

- Experience List - PT. Bumi Cahaya UnggulDocument5 pagesExperience List - PT. Bumi Cahaya UnggulRais RijalNo ratings yet

- Centrifugal Pumps: Gardner DenverDocument15 pagesCentrifugal Pumps: Gardner DenverjulioramcaNo ratings yet

- Performance Data CurveDocument57 pagesPerformance Data Curveedwin nolberto100% (1)

- Agitadores PlentyDocument16 pagesAgitadores Plentyrolando tapiaNo ratings yet

- Sulzer Pumps Finland Oy Product Specification: GeneralDocument3 pagesSulzer Pumps Finland Oy Product Specification: GeneralGerman Zuleta100% (1)

- Operating Manual for Centrifugal PumpsDocument65 pagesOperating Manual for Centrifugal PumpsJúlia LinoNo ratings yet

- Dean Pump® Series PHDocument12 pagesDean Pump® Series PHEnrique FuentesNo ratings yet

- HD150 Pump Maintenance ManualDocument35 pagesHD150 Pump Maintenance Manualjacklyn ade putraNo ratings yet

- Trouble Shoot HydraulicsDocument2 pagesTrouble Shoot Hydraulicsandreis3kNo ratings yet

- Etanorm KSBDocument28 pagesEtanorm KSBAlusine Tarawally100% (1)

- Tyre-Flex Coupling DeatilsDocument19 pagesTyre-Flex Coupling DeatilsDnyanesh BhaleraoNo ratings yet

- Transfluid Fluid Coupling CatalougeDocument32 pagesTransfluid Fluid Coupling CatalougeNaeem KhanNo ratings yet

- Pump Start Up ChecklistDocument14 pagesPump Start Up ChecklistSharif Mohammad AdwanNo ratings yet

- Pumping Plumbing - Diesel Pumps - Pumpcent 6in HF HH160i - Operation Manual PDFDocument114 pagesPumping Plumbing - Diesel Pumps - Pumpcent 6in HF HH160i - Operation Manual PDFSyaiful Azhar SchmidwaldNo ratings yet

- Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2Document1 pageWpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2risa ridmaNo ratings yet

- SPbloc & SPnormDocument18 pagesSPbloc & SPnormsmita reddyNo ratings yet

- EagleBurgmann - Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFDocument58 pagesEagleBurgmann - Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFAnh VoNo ratings yet

- Kirloskar Brothers LimitedDocument36 pagesKirloskar Brothers Limitedgopalakrishnannrm1202No ratings yet

- Instructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Document50 pagesInstructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Denar PurnamaNo ratings yet

- RSV Series BookletDocument24 pagesRSV Series BookletmajidNo ratings yet

- Zulzer Ohh E00581 PDFDocument8 pagesZulzer Ohh E00581 PDFJorge OportoNo ratings yet

- Installation, operation and maintenance manual for SJD-API ASSY w BRG 0909Document1 pageInstallation, operation and maintenance manual for SJD-API ASSY w BRG 0909dave fowlerNo ratings yet

- Single Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Document47 pagesSingle Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Karoline EnríquezNo ratings yet

- A7 PumpDocument14 pagesA7 PumpIr Go JarNo ratings yet

- Schedule Large Vertical TurbineDocument1 pageSchedule Large Vertical TurbineGodwin ChagotaNo ratings yet

- Blackmer Maintenance ScheduleDocument16 pagesBlackmer Maintenance ScheduleAbrar HussainNo ratings yet

- Catalogo de Conectores Hidraulicos PARKER PDFDocument86 pagesCatalogo de Conectores Hidraulicos PARKER PDFgbobadillaNo ratings yet

- Manual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFDocument27 pagesManual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFmuahdibNo ratings yet

- Manual Techniflo TB - All Pumps PDFDocument28 pagesManual Techniflo TB - All Pumps PDFJorge Gustavo Goyechea100% (1)

- C15C18T4F PDFDocument126 pagesC15C18T4F PDFomarNo ratings yet

- Acople Nara CatalogDocument48 pagesAcople Nara Catalogmarcelo castillo100% (1)

- Oim UlncDocument38 pagesOim UlncHendi HendriansyahNo ratings yet

- For Impeller BalancingDocument4 pagesFor Impeller BalancingAmit SharmaNo ratings yet

- SA 07.1 - SA16.1 SAR 07.1 - SAR 16.1 Dimensions Multi-Turn Actuators AUMA NORMDocument2 pagesSA 07.1 - SA16.1 SAR 07.1 - SAR 16.1 Dimensions Multi-Turn Actuators AUMA NORMyzNo ratings yet

- Salomix SLG GearDrive E00506 PDFDocument4 pagesSalomix SLG GearDrive E00506 PDFgilbertogatoNo ratings yet

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDocument4 pagesWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesNo ratings yet

- Sulzer EPD MD 150 360 SkidDocument4 pagesSulzer EPD MD 150 360 SkidAdolfo CanceloNo ratings yet

- Vertical Turbine Pump InstallationDocument34 pagesVertical Turbine Pump InstallationElaine Aubrey BardelosaNo ratings yet

- Heavy Duty Oil & Gas Pump SolutionsDocument6 pagesHeavy Duty Oil & Gas Pump Solutionsvrider81No ratings yet

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- CP150 SMDocument50 pagesCP150 SMjacklyn ade putra100% (1)

- Piston Instrc4032Document2 pagesPiston Instrc4032RickracerNo ratings yet

- 4032 Installation Tips: Piston To Cylinder Wall ClearanceDocument2 pages4032 Installation Tips: Piston To Cylinder Wall ClearanceMihneaStefanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 307E Collage HYD SchemaDocument15 pages307E Collage HYD Schemajacklyn ade putraNo ratings yet

- Doosan Trauble ShootingDocument7 pagesDoosan Trauble Shootingjacklyn ade putra100% (1)

- Spare Parts Pc3Document1 pageSpare Parts Pc3jacklyn ade putraNo ratings yet

- Lamp CircuitDocument1 pageLamp Circuitjacklyn ade putraNo ratings yet

- Troubleshoot Sumitomo excavator fault codesDocument10 pagesTroubleshoot Sumitomo excavator fault codesjacklyn ade putra100% (24)

- Troubleshooting Zaxis 3Document15 pagesTroubleshooting Zaxis 3jacklyn ade putra83% (18)

- d65-15 Errors PDFDocument5 pagesd65-15 Errors PDFjacklyn ade putra100% (1)

- Terbilang Untuk Pembayaran Pembayaran 1 (Satu) Unit Kubota Mini Excavator TIPE U-50-5 S/N 71772 E/N: 7GF7193Document1 pageTerbilang Untuk Pembayaran Pembayaran 1 (Satu) Unit Kubota Mini Excavator TIPE U-50-5 S/N 71772 E/N: 7GF7193jacklyn ade putraNo ratings yet

- Sticker Ready To ShipDocument1 pageSticker Ready To Shipjacklyn ade putraNo ratings yet

- Movie HitachiDocument10 pagesMovie Hitachijacklyn ade putraNo ratings yet

- 'Docslide - Us - Caterpillar 320d2 Direct Injection TechnologyDocument2 pages'Docslide - Us - Caterpillar 320d2 Direct Injection Technologyjacklyn ade putraNo ratings yet

- Aircraft Maintenance Log TemplateDocument1 pageAircraft Maintenance Log Templatejacklyn ade putraNo ratings yet

- Hitachi Trouble ShootingDocument18 pagesHitachi Trouble Shootingjacklyn ade putra75% (4)

- SampleDocument1 pageSamplejacklyn ade putraNo ratings yet

- Service SupportDocument52 pagesService SupportAnonymous n06MGR193% (28)

- Kit Hyd Control TransDocument2 pagesKit Hyd Control Transjacklyn ade putraNo ratings yet

- Hitachi Trouble ShootingDocument18 pagesHitachi Trouble Shootingjacklyn ade putra75% (4)

- Transfer PartsDocument3 pagesTransfer Partsjacklyn ade putraNo ratings yet

- Chapter 18 - Air Conditioning: Service ManualDocument48 pagesChapter 18 - Air Conditioning: Service Manualjacklyn ade putra100% (1)

- Spicification TransDocument4 pagesSpicification Transjacklyn ade putra100% (1)

- Spec Trans Old CarrierDocument4 pagesSpec Trans Old Carrierjacklyn ade putra100% (1)

- Hitachi Trouble ShootingDocument18 pagesHitachi Trouble Shootingjacklyn ade putra75% (4)

- List of Module HEMMDocument2 pagesList of Module HEMMjacklyn ade putraNo ratings yet

- Kit Input TransDocument1 pageKit Input Transjacklyn ade putraNo ratings yet

- Gasket KitDocument3 pagesGasket Kitjacklyn ade putraNo ratings yet

- Bearing KitDocument2 pagesBearing Kitjacklyn ade putraNo ratings yet

- Presentation 11Document1 pagePresentation 11jacklyn ade putraNo ratings yet

- Logo TKJDocument1 pageLogo TKJjacklyn ade putraNo ratings yet

- Hitachi Trouble ShootingDocument18 pagesHitachi Trouble Shootingjacklyn ade putra75% (4)

- Engine Stop DiagramsDocument2 pagesEngine Stop Diagramsjacklyn ade putra100% (2)

- S50me-B9 5Document367 pagesS50me-B9 5TestNo ratings yet

- CAT 3516B Parts CatalogueDocument209 pagesCAT 3516B Parts CatalogueSergei Kurpish100% (18)

- 4 Case Adt - Tran PDFDocument85 pages4 Case Adt - Tran PDFBaciu Nicolae80% (5)

- Local Media1133470422700059155Document6 pagesLocal Media1133470422700059155Billy JhunNo ratings yet

- NNPCDocument21 pagesNNPCtsar_philip2010100% (1)

- Tesla Motors, Inc. 2015Document29 pagesTesla Motors, Inc. 2015Uveer DwarkapersadNo ratings yet

- Sotera 825p-850 OriginalDocument64 pagesSotera 825p-850 OriginalPaul Mcallister BelloNo ratings yet

- HVAC Unit Alarm Code GuideDocument3 pagesHVAC Unit Alarm Code GuidePAVLOS80% (5)

- Process STD 400-1.2 PDFDocument71 pagesProcess STD 400-1.2 PDFBassemNo ratings yet

- Piston RingsDocument14 pagesPiston RingsFrimpong Justice AlexNo ratings yet

- Technology Development, Design and Safety Features of PHWR and Their Operating PerformanceDocument57 pagesTechnology Development, Design and Safety Features of PHWR and Their Operating PerformanceLuptonga100% (2)

- GT Load Effect On HRSGDocument3 pagesGT Load Effect On HRSGsatishchemeng100% (1)

- Ford Rescue Cards Guide Emergency ServicesDocument127 pagesFord Rescue Cards Guide Emergency ServicesDragos PicuNo ratings yet

- Summer Training ReportDocument24 pagesSummer Training Reportruman ahmadNo ratings yet

- Valtra's Dual Fuel Biogas Tractors Cut Costs and EmissionsDocument9 pagesValtra's Dual Fuel Biogas Tractors Cut Costs and EmissionsAaravGuptaNo ratings yet

- 2009 CHERY A1 Service Manual PDFDocument1,080 pages2009 CHERY A1 Service Manual PDFArelysParra82% (11)

- Lab 6 - Gas TurbineDocument8 pagesLab 6 - Gas TurbinehaziqsajjadNo ratings yet

- Operation and Startup ProceduresDocument4 pagesOperation and Startup ProceduresAtanasio PerezNo ratings yet

- Competence 8 Oic-Ew ReviewerDocument16 pagesCompetence 8 Oic-Ew ReviewerCristine Ann Javier100% (1)

- Extraction Condensing Steam TurbineDocument3 pagesExtraction Condensing Steam TurbineNaeemSiddiquiNo ratings yet

- DRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARDocument30 pagesDRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARADITYA SRIKAR KOTANo ratings yet

- TEC 08 - Bunkering Operations Checklist PDFDocument5 pagesTEC 08 - Bunkering Operations Checklist PDFnmospan100% (1)

- The Fundamentals of Rocket Stoves - Permaculture Principles PDFDocument6 pagesThe Fundamentals of Rocket Stoves - Permaculture Principles PDFHermes Montenegro Delgado100% (1)

- Specialized coal and pet-coke combustion designDocument6 pagesSpecialized coal and pet-coke combustion designary.engenharia1244No ratings yet

- (Gross Calorific Value - GCV) (Net Calorific Value - NCV) @0°C/32°F, 1 BarDocument4 pages(Gross Calorific Value - GCV) (Net Calorific Value - NCV) @0°C/32°F, 1 BarEduardo AguilarNo ratings yet

- Bombas de Desagues New OneDocument2 pagesBombas de Desagues New OneJose Alberto Muñoz FloresNo ratings yet

- SWOT Analysis On Power Generation IndustriesDocument43 pagesSWOT Analysis On Power Generation Industriesmakwanarahul100% (2)

- Motor KA24E PDFDocument32 pagesMotor KA24E PDFJose Pichinte100% (2)

- 01 GAS TURBINE BasicsDocument84 pages01 GAS TURBINE BasicsRizky NugrahaNo ratings yet

- KDK Me Catalogue 2014Document30 pagesKDK Me Catalogue 2014Anggarasukma PalmadiNo ratings yet