Professional Documents

Culture Documents

Notes ch.11.1b Tooth Modification PDF

Uploaded by

fiemsabyasachiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes ch.11.1b Tooth Modification PDF

Uploaded by

fiemsabyasachiCopyright:

Available Formats

Traian CICONE

11.3.1.

MEM 2005-2006

Gear modification

Gear modification includes any change of the standard geometry of a gear introduced to agree with

technological or functional requirements as well as to improve gear operating performance characteristics. There

are many ways to modify a gear which can be included into two categories: (a) face modification affecting the

profile in any axial cross-section respectively (b) axial modification (which affects the profile along the teeth).

The most important axial modification is gear bulging that makes barrel teeth, gear crowning or gear end relief.

gear axial direction

crowning

end relief

Face modification changes the tooth profile but it will be still the same in any axial cross-section. It can be

divided, at its turn, into two main categories:

(a1) modifications induced by rack modification, which includes any change in standard rack dimensions:

pressure angle, 0, addendum, h0f, bottom clearance, c0, or tip relief1.

(a2) modifications made without changing standard rack include: profile shifting, tooth addendum shortening, or

some other manufacturing procedures.

Gear modifications are made for the following reasons:

(1) to agree with design restrictions like: a given distance between axes (usually a standard value) or to

accomodate within a given overall dimensions

(2) to improve performance characteristics like

(a) smooth and quiet operation by increasing the contact ratio,

(b) uniform repartition of the load on the tooth

(c) increased efficiency and reduced wear by diminishing the relative sliding velocity

(d) increased strength for contact and bending stresses

(e) improve lubrication conditions

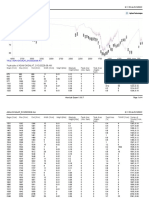

Gear profile shifting (or simply gear shifting)is the most efficient gear modification to improve gear

performances which does not require a modified rack. Gear shifting is made by changing the relative position of

the generating rack in respect with the blank, by shifting the rack radially (Fig. ). An unshifted tooth (or

unshifted gear) is generated with the rack axis tangent to the gear reference diameter (pitch diameter). A

positive shifted gear (plus gear) is cut with the rack outwardly shifted, whilst a negative (minus gear) is

cut with a inwardly shifted rack. The amount of shifting is defined by the shifting coefficient, x, times the

module.

Correspondingly if shifted gears are included in a gear set, we have shifted gear set which can be (Fig. 11.X):

(a) positive shifted gear set x=x1+ x2 >0

(b) negative shifted gear set x=x1+ x2 <0

(c) zero shifted gear set x=x1+ x2 =0 which means that x1 = -x2.

Most of the shifted gears are made positive. Positive shifting of gear has the following important consequences:

(a) increased tooth thickness at the root which gives improved strength at bending

Tip relief = a discretionary modification of the tooth profile near the tip of the tooth to eliminate tip interference. It is

considered desirable for the involute to be a few thousandths minus at the tip - never plus.

Cap. 9 GEARS

26.06.06

Traian CICONE

MEM 2005-2006

(b) increased radius of curvature that gives improved strength at contact

(c) the possibility to avoid undercutting for gears with small numbers of teeth (z < zmin) see Fig. 11.Y.

(d) tooth sharpening on the addendum circle

On the other hand, positive shifting of a gear set has, besides the previous characteristics of positive gears, the

following shortcomings:

(a) reduced relative slip speed that gives increased efficiency

(b) reduced contact ratio which is undesired especially for high speed gearings.

In order to compensate the shortcoming of tooth sharpening, usually the teeth are shortened; consequently the

bottom clearance increases, which is also favorable for positive shifted gear set, where, normally, clearances are

reduced. Usually the shortening of the teeth is calculated to assure the standard clearance c=0.25m.

x = 0 unshifted gear

x > 0 pozitive shifted gear

x < 0 negative shifted gear

mx

mx

h0

h0f

Fig. 11.X. Gear shifting

pitch circle

base circle

Fig. 11.Y. Undercut tooth

Cap. 9 GEARS

26.06.06

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Surface Treatments For MG Alloys in Aerospace and DefenceDocument16 pagesSurface Treatments For MG Alloys in Aerospace and DefenceJinsoo KimNo ratings yet

- Types of ThermometerDocument39 pagesTypes of ThermometerJasmin Trasmil VillagraciaNo ratings yet

- Semi-Detailed Lesson Plan in Grade 7 ScienceDocument5 pagesSemi-Detailed Lesson Plan in Grade 7 ScienceAnna Marie Ledesma Urrutia100% (10)

- Thermosiphon ReboilersDocument7 pagesThermosiphon Reboilerssj_scribd100% (1)

- Production Engineering: (Third Edition)Document20 pagesProduction Engineering: (Third Edition)Rishabh Gehlot0% (1)

- 05-17 QCS 2014Document8 pages05-17 QCS 2014Raja Ahmed Hassan100% (2)

- Engineering and Design Hydraulic Design of SpillwaysDocument170 pagesEngineering and Design Hydraulic Design of Spillwaysekaamf100% (1)

- Zither Chuck Gripping CapacityDocument5 pagesZither Chuck Gripping CapacityfiemsabyasachiNo ratings yet

- Abhay Pratap Singh Sengar: Phone: - +91-9329883200Document4 pagesAbhay Pratap Singh Sengar: Phone: - +91-9329883200fiemsabyasachiNo ratings yet

- Spec FinalBGBERlyDocument64 pagesSpec FinalBGBERlyfiemsabyasachiNo ratings yet

- THK Profilsin Vezetekek Katalogus ENG PDFDocument682 pagesTHK Profilsin Vezetekek Katalogus ENG PDFfiemsabyasachiNo ratings yet

- A 6Document64 pagesA 6Dastaggir KarimiNo ratings yet

- Section Modulus & Stress Calculation of Rail SectionDocument13 pagesSection Modulus & Stress Calculation of Rail SectionfiemsabyasachiNo ratings yet

- T3905-390-02 SG-Ins Exc EN PDFDocument104 pagesT3905-390-02 SG-Ins Exc EN PDFfiemsabyasachiNo ratings yet

- Rep2X One SheetDocument2 pagesRep2X One SheetfiemsabyasachiNo ratings yet

- Inspection & Testing of Elastic Rail Clips PDFDocument5 pagesInspection & Testing of Elastic Rail Clips PDFfiemsabyasachi0% (1)

- Camtasia 7 PDFDocument2 pagesCamtasia 7 PDFfiemsabyasachiNo ratings yet

- Acrylic Acid Paper-1Document18 pagesAcrylic Acid Paper-1somya sharmaNo ratings yet

- Asam Oksalat PDFDocument4 pagesAsam Oksalat PDFfadhilNo ratings yet

- Literature ReviewDocument7 pagesLiterature ReviewDeepa Chitralekha RanaNo ratings yet

- Lecture 32 PDFDocument4 pagesLecture 32 PDFBhavesh Dilip ChanchlaniNo ratings yet

- CSIR Physics Sciences Solved December 2012Document43 pagesCSIR Physics Sciences Solved December 2012kesavavamsikrishnaNo ratings yet

- Crumb Rubber Data - October 2021 - AFPADocument14 pagesCrumb Rubber Data - October 2021 - AFPAAlexandru LetNo ratings yet

- Radiograph InterpretationDocument12 pagesRadiograph InterpretationnithingrmeNo ratings yet

- Andi Mandi ShandiDocument6 pagesAndi Mandi ShandiSundar LalNo ratings yet

- Metallurgy of Iron and SteelmakingDocument13 pagesMetallurgy of Iron and SteelmakingAgustine SetiawanNo ratings yet

- CH ETDocument2 pagesCH ETRiddhi ShreeNo ratings yet

- Barabrine SiDocument2 pagesBarabrine SiRohan SahniNo ratings yet

- HT14-IM2655 - Lecture 1 PDFDocument33 pagesHT14-IM2655 - Lecture 1 PDFDiego Manuel Hernández AcostaNo ratings yet

- Phase 1Document32 pagesPhase 1KamarajanNo ratings yet

- Anti Fouling SystemsDocument3 pagesAnti Fouling SystemsSunny RaghavNo ratings yet

- Wave-X HEAT Shrink Tube Solutions: Ultra Thin EMI Sheet SolutionsDocument10 pagesWave-X HEAT Shrink Tube Solutions: Ultra Thin EMI Sheet SolutionsstrubbelsNo ratings yet

- IgsDocument6 pagesIgsmrjn1367No ratings yet

- Vessel Standard Operating ProceduresDocument23 pagesVessel Standard Operating ProceduresMaria OsawaNo ratings yet

- Week 02Document10 pagesWeek 02Arfin FardiansyahNo ratings yet

- Kval Hu SteelDocument2 pagesKval Hu Steelgorane11No ratings yet

- Emr439r White Mica PDFDocument41 pagesEmr439r White Mica PDFGabriel Erazo FierroNo ratings yet

- Ana Bruker Scion TQ Spec SheetDocument2 pagesAna Bruker Scion TQ Spec SheetmdananicNo ratings yet

- 1.4 Eqa 1974Document17 pages1.4 Eqa 1974andreyNo ratings yet

- TeflonDocument19 pagesTeflonPappuRamaSubramaniamNo ratings yet