Professional Documents

Culture Documents

Bar Mill ABB Review 4 99

Uploaded by

INDRAJIT SAOCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bar Mill ABB Review 4 99

Uploaded by

INDRAJIT SAOCopyright:

Available Formats

R

Upgrading rod

and bar mills with

state-of-the-art

control technology

Benefits of revamping

Operators of profile mills specializing

in long products, such as rods and bars,

are having to cope with a strong increase

in demand for high-quality finished products. At the same time, steel prices are

being kept down by the large-scale

availability of low-grade products. Traditionally, this is the right time to upgrade

plants to meet future market requirements.

The wisdom of revamping a function-

Profile mill control systems can be upgraded to give mill operators the

ing system can always be questioned,

flexibility and capability they need to meet future demand for high-quali-

but there are many reasons for making

ty finished products. The Advant Open Control System, developed by ABB

such an investment. For example, failures

to take full advantage of state-of-the art control technology, allows re-

are more likely to occur in older equip-

vamp kits to be easily integrated in outdated mill processes. Since the

ment. And while most of the electronic

control is adaptive, optimum results are achieved even when the process

equipment which has survived until today

parameters change. Also, when Advant OCS is installed, ABB Interstand

can be considered to be fairly reliable,

Dimension Control (IDC) can be implemented. IDC continuously monitors

the relatively long time between failures

the main bar and rod dimensions for direct control of the roll gap and in-

means that maintenance crews have only

terstand speed. As a result, mill scrap can be halved and stands can be re-

limited trouble-shooting experience with

calibrated for new products much faster. Drive upgrade kits installed in

the equipment. This is important as

the recently revamped Ovako steel mill in Hllefors, Sweden, give the

rolling mills depend more on the specific

mills owner a competitive edge in the fiercely contested rolled products

skills of maintenance crews than on

market.

organizations. Two other concerns of

profile mill operators with older control

systems are the availability and cost of

lder generations of mill control sys-

Advant Open Control System (OCS), for

spares. A minor fault can result in unnec-

tems were never designed to meet

example, was developed to take full ad-

essarily long and costly downtime.

todays rigorous demands on product

vantage of state-of-the-art ABB control

Older equipment based on analogue

uniformity, quality, productivity and trace-

technology. With Advant OCS, revamp

technology requires a large number of

ability. Even the earliest digital control

kits for drive systems can be easily inte-

adjustments for efficient and profitable

systems do not have the necessary ca-

grated in older processes to ensure that

mill operation. While this has the ad-

pability; based on first-generation micro-

they meet the highest requirements. Fur-

vantage that it makes the engineers

processors with limited memory and

thermore, it facilitates the installation of

familiar with the equipment, it comes at

computing capacity (which may also

Interstand Dimension Control (IDC) in

the expense of additional maintenance

make them susceptible to the millennium

profile mills.

staff. Also, it is difficult to recruit new

bug), they have to be optimized for their

engineers to work with outdated equip-

specific tasks. Such systems were de-

ment.

signed and built to work under narrowly

There are also differences in the

defined conditions, and lack the function-

demands made by todays and to-

al versatility needed to respond quickly

morrows processes that have to be

and accurately to new situations.

considered. In the past, operators used

ABB offers advanced control systems

which have all the capability required to

handle even changing conditions. The

Dag N. Sollander

pushbuttons and potentiometers to con-

ABB Automation Systems AB

trol the mill, and the feedback from the

process was shown on numerical dis-

ABB Review 4/1999

Typical control desk in a profile

mill. Pushbuttons and potentiometers dominate the scene.

State-of-the-art control room. The operator, who works in a Windows

environment, supervises the process on-line.

plays 1 . Supervision of the actual rolling

new level of flexibility and depth of in-

and selects functions (eg, logging, analy-

process was basically visual, and relied

formation. Control is adaptive, so that

sis, etc) as he needs them.

on the operators observational abilities.

optimum results are achieved even when

New control systems ( 2 to 4 ) im-

Even the first generations of digital con-

the process parameters vary. In a state-

prove mill performance and safety, en-

trol systems were very restricted in terms

of-the-art mill control room, the role of

sure a higher and more consistent quality

of their flexibility and analytical capability.

the operator is more like that of a process

for the rolled end-products, and increase

Advant OCS and the latest operator

engineer. Working in a Windows environ-

profitability.

station generations offer a completely

ment, he supervises the process on-line

Revamping in stages

A rationally organized workplace incorporating features that improve

mill performance and safety ensures a consistently higher quality for the

rolled products and increases profitability.

Careful planning is a key factor in revamp

projects. Downtimes have to kept as

short as possible to minimize produc-

IMS

Information Management System

tion losses. One solution is to revamp

the control systems in stages, for example:

Optimize

Inform

Analyze

Control

Overall mill control, either analogue or

digital

Sequential logic, relay systems or programmable logic controllers (PLCs)

Drive systems, mainly DC with analogue speed and current control

In addition, the revamp project can concentrate on one process area at a time, in

Automatic corrections

Reliable control

Process analysis

Process-oriented settings

Plain language information

Integration with IMS

the case of a profile rolling mill starting

with the roughing mill area and then continuing with the intermediate and finishing

mill areas 5 .

ABB Review 4/1999

The area revamp is of special interest

mill at SKFs Ovako steel mill in Hllefors,

steel. Nearly two decades later, although

now that new control packages such as

Sweden. This rolling mill, commissioned

still in good shape, the mill no longer met

the Profile Mill IDC are available 5 .

in 1977, was one of the worlds first

modern-day

digitally controlled mills and was based

petitiveness specifications. Key issues,

on state-of-the-art technology at the

such as improved mill supervision, auto

Ovako steel mill revamp

time. It was designed to meet demand by

product changeover, manufacturing in-

A typical example of a successful revamp

the parent company for high-quality

structions,

carried out in stages is the bar and rod

rolled products made of ball-bearing

easier maintenance, subsequently played

Some of the displays supporting

the operator in decision-making

Top right

Analysis of rolling

with stand overview,

providing operator

with information on

mill configuration,

material tracking,

test sequences, etc

Bottom right

Stand maintenance

schedule informing

maintenance crew

about stand

equipment statuses

Left

Analysis display

showing snapshots

of threading

conditions, torque,

loading, speeds, etc

performance

production

and

analysis

com-

and

ABB Review 4/1999

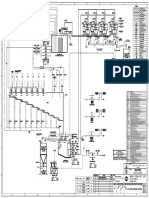

RM

Colour graphics

OS, RM

Operator control and

instruments IM; FM

ABB OS

Existing OS

IM

FM

AC or DC drive systems

Sequence

control

Interstand

Dimension

Control

Old

Min tension

control

ABB RMC

Mill

reference

Auto loop

control

Existing control system

Revamping a profile mill area by area

RM Roughing mill

IM Intermediate mill

FM

OS

an important role in the decision by the

stalled in 1995, increasing the original

means of remote control. In the following

mill owner to select ABBs new-genera-

rolling capacity from 120 mm to 165 mm

year, the control for the walking beam re-

tion Rolling Mill Control (RMC) system.

square billets. This addition also included

heat furnace was replaced by an ABB

The performance enhancement afforded

the ABB RMC 200 system, one Advant

Reheat Furnace Control (RFC) system to

by IDC was also a key factor leading to

Controller 450 and one Advant Operator

optimize performance and fuel consump-

this decision.

Station from the 500 series. The mill is

tion. Also, an ABB Automatic Dimension

operated from the existing pulpit by

Control (ADC) system was added to

A new 3-stand roughing mill was in-

Finishing mill

Operator station

RMC Rolling mill control

achieve narrower final tolerances. The

ADC system controls the roll gap of the

New control room at SKFs Ovako steel mill in Hllefors, Sweden

final two or four stands based on feedback from a rotating ORBIS optical

gauge meter.

Controls for the 21st century

In 1997 it was decided to revamp the mill

6 to make it capable of meeting future

demand for consistently high-quality production of low-tolerance rods and bars.

The old control system was based on

DS8, an 8-bit microprocessor system for

control and numerical data presentation,

PLC 700 logic control and TYRAK 73

analogue thyristor converters. The equipment chosen to replace it was the ABB

RMC, DCV 700 digital drive upgrade kits

and IDC.

ABB Review 4/1999

Integrated, solid-state U-gauge sensors create magnetic fields which are distorted to a greater or lesser degree,

depending on the dimensions of the steel bar or rod passing through them.

The IDC system automatically adjusts the set-up of the mill stands and interstand speed on the basis of

the data received from these gauges.

IDC control principle. Continuous supervision and control eliminates the risk of underfill and overfill rolling.

Ain

Aout

vi

vo

Area in

Area out

Inlet speed

Outlet speed

R

Rinc

vinc

Wdev

Leader

Reducing

pass

A in

Reduction factor

Reduction factor increment

Speed increment

Width deviation

Final

Forming

pass

y

x

A out

vi

U-gauge

x = Width ( W )

y = Height ( H )

vi

Gap

vo

Leader

Reducing

pass

U-gauge

vo

x = W idth ( W )

y = Height ( H )

R

Wact Actual width

Wsch Scheduled width

ypos y-position (height)

Gap

vo

Roll wear adjustment

between bars

Roll wear adjustment

between bars

ypos

Push supervision

Wdev = Wact Wsch

Rinc = Gain x Wdev

Alarm: downstream guide

W > limit; H > limit

Tail out

v inc = Gain x Wdev

Alarm: downstream guide

W > limit; H > limit

ABB Review 4/1999

Simple installation of RMC

needed. In-line installation of the gauge is

The RMC concept is designed for easy

simple on account of the specially de-

installation and upgrading. Since the new

signed inlet and outlet guides and the

roughing mill was already equipped with

sensor base-plate. No on-site calibration

an Advant Controller 450, the whole mill

is necessary.

could be controlled from the same

processor rack by adding more processor capacity, with the I/O units remotely

First step towards fully

located in the relevant process areas.

automated mills

The revamp was carried out in three

The Interstand Dimension Control system

stages.

is the first step on the road towards fully

In the first stage the DS8 and its oper-

automated rolling mills. By integrating the

ator communication were replaced by

data generated by the IDC with other op-

adding software to the Advant OS for the

erational information and then linking it

roughing mill. The second stage involved

into a mill-wide process control system,

such as the ABB Advant system, steel

revamping the analogue thyristor converters with digital control. By retaining

the power supply and thyristor modules,

it was possible to restrict the revamp

The new controller is quickly

connected, using existing process

cabling, by bus communication

to the Advant Controller.

mills could become self-monitoring and

self-correcting. IDC improves mill performance in accordance with owners requirements without having to modify the

work to replacement of the control sys-

mechanical equipment 9 .

tems, protection and field converters. All

the components were mounted on a

losophy of maintaining a low, constant

panel and pre-tested prior to fitting in the

tension along the bar/rod. This approach

control cabinet door.

generally works well, but does not allow

Short pay-back time

In the third stage the old PLC logic

for the adjustments needed to compen-

Although the cost of the electrical equip-

control was replaced by the Advant RMC.

sate for the deviations created by the

ment amounts to only a small fraction of

The existing PLC circuits were located in

temperature and dimensional variations

the total investment in a modern, highly

one cabinet with all process cabling ter-

along the bar/rod. In addition, there are

automated rod and bar mill, the correct

minated in an adjacent cabinet. This ca-

certain shortcomings due to the lack of

choice of systems helps to determine a

bling was retained and wired to the new

on-line feedback from process para-

mills overall performance and profitabili-

ABB S800 remote I/Os with bus commu-

meters, such as material dimensions and

ty. It is estimated that the increase in pro-

nication to the Advant Controller.

the speed. Rugged U-gauge solid-state

ductivity, plant yield and availability made

This upgrade laid the foundation for

sensors 7 , which are insensitive to the

possible by IDC will allow the cost of the

the installation of the Interstand Dimen-

harsh conditions in mills, are required to

investment to be paid back in most cases

sional Control (IDC) system, which brings

provide accurate on-line information

within one year.

a whole a new concept to rod and bar mill

about the bar dimensions. Measurement

control.

data from these sensors are fed into the

control system and used to control the

bar dimensions by adjusting the inter-

Interstand Dimension Control

stand speed 8 . IDC also ensures maxi-

Author

U-gauge sensors provide bar

mum roll utilization, thereby increasing

Dag N. Sollander

data on-line

the mill capacity, as the material width is

ABB Automation Systems AB

A key element of control engineering is

continuously supervised and controlled.

S-721 67 Vsters

the accurate, rapid feedback of dimen-

This eliminates risks of under- and overfill

Sweden

sional data and effective, continuous

rolling. The U-gauge measurement prin-

Telefax: +46 21 41 25 95

control of the mill stands. In the past, all

ciple allows a wide measuring range, so

E-mail:

control methods were based on the phi-

that only a few different gauge sizes are

dag.n.sollander@se.abb.com

ABB Review 4/1999

You might also like

- Gearless Mill Drives - 3BHT 490 275 R0001 RevD - 1212 - LowDocument7 pagesGearless Mill Drives - 3BHT 490 275 R0001 RevD - 1212 - LowWisnu IndriyantoNo ratings yet

- Steel PlantDocument21 pagesSteel PlantKaran Sagar KathuriaNo ratings yet

- Processes and Types of Rolling MillsDocument7 pagesProcesses and Types of Rolling Millsdroy21No ratings yet

- 1890 - Double Rotating ChannelDocument51 pages1890 - Double Rotating Channelkar_simNo ratings yet

- Chaitanya IntroductionDocument7 pagesChaitanya Introductionanon_647217551No ratings yet

- SBP7 Indar MotorsDocument16 pagesSBP7 Indar Motorsamk2009No ratings yet

- W3-311E Bar and Wire Rod Mills PDFDocument32 pagesW3-311E Bar and Wire Rod Mills PDFMohammed IrfanNo ratings yet

- Eesar Steel ReportDocument34 pagesEesar Steel ReportchinmaiNo ratings yet

- Total Plant Monitoring For An Integrated Steel Plantfin PDFDocument15 pagesTotal Plant Monitoring For An Integrated Steel Plantfin PDFJohnNo ratings yet

- Msi Belt ScaleDocument21 pagesMsi Belt ScaleApriasanNo ratings yet

- Pickling & Tandem Cold MillDocument12 pagesPickling & Tandem Cold MillKalai Selvan100% (1)

- Technical Specification - Continuous Copper Up-Casting FurnaceDocument13 pagesTechnical Specification - Continuous Copper Up-Casting FurnaceVardaShahidNo ratings yet

- Working Function of Steel Plant, New ORE Handling Plant and Mechanical Equipment ErectionDocument38 pagesWorking Function of Steel Plant, New ORE Handling Plant and Mechanical Equipment ErectionHimanshu Shekhar PandeyNo ratings yet

- ABB - Induction MotorDocument12 pagesABB - Induction Motorikuzma_1No ratings yet

- Geared VS Gearless Drive Solutions For Grinding MillsDocument15 pagesGeared VS Gearless Drive Solutions For Grinding MillsLuis B100% (1)

- Wire Tensions in Stranding MachinesDocument30 pagesWire Tensions in Stranding MachinesShrikant DeshpandeNo ratings yet

- AC 800PEC Control SystemDocument12 pagesAC 800PEC Control SystemlazcanoferNo ratings yet

- Looper-Tension Control 2Document13 pagesLooper-Tension Control 2almen_matanovic1675100% (1)

- SIROLL CM Solutions For Cold Rolling Mills enDocument36 pagesSIROLL CM Solutions For Cold Rolling Mills enashbasalNo ratings yet

- Slitting Machine Manufacturer in NoidaDocument13 pagesSlitting Machine Manufacturer in NoidaNIRMAL OVERSEAS LIMITEDNo ratings yet

- Gearless Mill Drive - Operation and Maintenance: Ring MotorDocument18 pagesGearless Mill Drive - Operation and Maintenance: Ring MotorIrving Dirzo CarrilloNo ratings yet

- PSR Cycloconverter: Active Classic Limited ObsoleteDocument2 pagesPSR Cycloconverter: Active Classic Limited Obsoletearh ,No ratings yet

- Bokaro Steel PlantDocument3 pagesBokaro Steel PlantSayan ChatterjeeNo ratings yet

- Technical Specification For Rollling Mill-20200922Document15 pagesTechnical Specification For Rollling Mill-20200922Nilton Bruno Salazar MartinezNo ratings yet

- Light and Medium Merchant MillDocument35 pagesLight and Medium Merchant MillPeram Bharath Kumar Reddy100% (1)

- Bar MillDocument27 pagesBar MillRakesh Karan SinghNo ratings yet

- ABB Industrial Drives: ACS880, Single Drives 0.55 To 2800 KW CatalogDocument40 pagesABB Industrial Drives: ACS880, Single Drives 0.55 To 2800 KW Catalogstp01No ratings yet

- An Over View of Visakhapatnam Steel PlantDocument45 pagesAn Over View of Visakhapatnam Steel PlantS Bharadwaj Reddy67% (3)

- D2.03 15 Bar and Merchant Bar Mills enDocument36 pagesD2.03 15 Bar and Merchant Bar Mills enLymeParkNo ratings yet

- DaNews 168Document92 pagesDaNews 168PeterJamesNo ratings yet

- Calculation of % Slip in Mill During Rolling by Ajmal (10.09.2014)Document15 pagesCalculation of % Slip in Mill During Rolling by Ajmal (10.09.2014)Rakesh Karan SinghNo ratings yet

- Sub ControlDocument4 pagesSub ControlAndres CavazosNo ratings yet

- Modeling and Control of An Electric Arc FurnaceDocument6 pagesModeling and Control of An Electric Arc FurnaceChristopher LloydNo ratings yet

- Section MillDocument7 pagesSection MillArth SumagueNo ratings yet

- Kaiser Aluminum Florence Wire and Rod ProductsDocument2 pagesKaiser Aluminum Florence Wire and Rod ProductsСтанислав ПодольскийNo ratings yet

- 2139 12021 1 PB PDFDocument9 pages2139 12021 1 PB PDFSantosh Kumar PandeyNo ratings yet

- DaNews164 PDFDocument0 pagesDaNews164 PDFClaire Hamant100% (1)

- Sinamics gl150Document148 pagesSinamics gl150Santhosh Reddy BNo ratings yet

- 60 Years of Rolling MillsDocument28 pages60 Years of Rolling MillsAnurag Ramdas100% (2)

- FINDER Catalogue 2014-15Document564 pagesFINDER Catalogue 2014-15Yiannis MinoglouNo ratings yet

- Ramsey Conveyor Protection SwitchesDocument6 pagesRamsey Conveyor Protection SwitchesArif AmirNo ratings yet

- Install Desc 800xa RMC FuncDocument8 pagesInstall Desc 800xa RMC FuncwillgangNo ratings yet

- Medium Frequency Coreless Induction Furnaces MFTDocument16 pagesMedium Frequency Coreless Induction Furnaces MFTCem AlpaslanNo ratings yet

- LPG Falkiner PDFDocument29 pagesLPG Falkiner PDFrschirtNo ratings yet

- Comments - MSEL 25072017 Rod Mill RequirementDocument14 pagesComments - MSEL 25072017 Rod Mill RequirementHarshGuptaNo ratings yet

- Project Modification of Coke Discharge Chute at Battery-8&9Document30 pagesProject Modification of Coke Discharge Chute at Battery-8&9Rahul Kumar100% (1)

- Year Minimills 2010Document8 pagesYear Minimills 2010mishtinilNo ratings yet

- Ladle Heating FurnaceDocument34 pagesLadle Heating FurnaceAnusha Rao100% (5)

- AC10P Catalog 5.41Document16 pagesAC10P Catalog 5.41cocacolapepsiNo ratings yet

- Italvibras VB MVB MVB-FLC MTF Manual - 1Document28 pagesItalvibras VB MVB MVB-FLC MTF Manual - 1Estefanny ArispeNo ratings yet

- Arccess EAF PDFDocument30 pagesArccess EAF PDFradynasrNo ratings yet

- Electrode Regulation in Furnace 1Document8 pagesElectrode Regulation in Furnace 1Harshvardhen Singh ThakurNo ratings yet

- Turret Bearing Deflection MonitoringDocument1 pageTurret Bearing Deflection MonitoringVinay RajputNo ratings yet

- August 2013 Wire Rope ExchangeDocument84 pagesAugust 2013 Wire Rope ExchangeWire Rope Exchange100% (1)

- Dynamic Braking ResistorsDocument2 pagesDynamic Braking Resistorsjsrplc7952No ratings yet

- Hot RollingDocument8 pagesHot Rollingshah naumanNo ratings yet

- Information Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981From EverandInformation Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981No ratings yet

- Control & InstrumentationDocument10 pagesControl & InstrumentationHarshit AggarwalNo ratings yet

- BR - HV Pass Family (En) D - 2gja708398 08.2013Document22 pagesBR - HV Pass Family (En) D - 2gja708398 08.2013hansamvNo ratings yet

- Understanding Infrared Thermography Reading 6 (PDFDrive) PDFDocument510 pagesUnderstanding Infrared Thermography Reading 6 (PDFDrive) PDFINDRAJIT SAONo ratings yet

- Action Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!Document1 pageAction Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!INDRAJIT SAONo ratings yet

- V-Imp - USA-Diagonostics Important PaperDocument81 pagesV-Imp - USA-Diagonostics Important PaperINDRAJIT SAONo ratings yet

- Three Common Mistakes in LubricationDocument11 pagesThree Common Mistakes in LubricationINDRAJIT SAONo ratings yet

- Estad-Jsi 2014Document3 pagesEstad-Jsi 2014INDRAJIT SAONo ratings yet

- Tags and Labels Billet MarkingDocument2 pagesTags and Labels Billet MarkingINDRAJIT SAONo ratings yet

- A Practical Approach For Evaluating Oil Analysis Results With Limit ValuesDocument12 pagesA Practical Approach For Evaluating Oil Analysis Results With Limit ValuesINDRAJIT SAONo ratings yet

- Kaizen TrainingDocument5 pagesKaizen TrainingINDRAJIT SAONo ratings yet

- Coke Making in Byproduct Coke Oven Batteries - e Plant MaintenanceDocument13 pagesCoke Making in Byproduct Coke Oven Batteries - e Plant MaintenanceINDRAJIT SAO0% (1)

- Billet MarkerDocument4 pagesBillet MarkerINDRAJIT SAONo ratings yet

- NASA - Safety For Oxygen Systems GuidelinesDocument288 pagesNASA - Safety For Oxygen Systems GuidelinesINDRAJIT SAO100% (1)

- Ox Ygen System Safety: ScopeDocument4 pagesOx Ygen System Safety: ScopeINDRAJIT SAONo ratings yet

- Ash Handling P&IDDocument1 pageAsh Handling P&IDINDRAJIT SAONo ratings yet

- Hiller DECANTERDocument4 pagesHiller DECANTERINDRAJIT SAO100% (1)

- Introduction TwinCATDocument14 pagesIntroduction TwinCATAntonio Carlos de SouzaNo ratings yet

- Operation & Maintenance Manual (CNG Compressor) - SC21007Document153 pagesOperation & Maintenance Manual (CNG Compressor) - SC21007Ahmed Elaraby100% (5)

- PLC QuestionsDocument17 pagesPLC QuestionsbahyNo ratings yet

- SCE EN 010-050 R1209 S7-1200 Analog ValuesDocument34 pagesSCE EN 010-050 R1209 S7-1200 Analog ValuesAlu menzikenNo ratings yet

- Wago-I/O-System 750: ManualDocument270 pagesWago-I/O-System 750: ManualLeandro ArvattiNo ratings yet

- Transdutor de PressãoDocument10 pagesTransdutor de PressãodalmohvacNo ratings yet

- Control and Instrumentation EngineerDocument3 pagesControl and Instrumentation EngineerEgbert EncarguezNo ratings yet

- 300 Series User GuideDocument84 pages300 Series User GuideJason Jones100% (1)

- Festo DidacticDocument420 pagesFesto DidacticJavier RodriguezNo ratings yet

- Wiring Diagram s7-200 SiemensDocument126 pagesWiring Diagram s7-200 Siemensgeco87No ratings yet

- ch-11 - Math FunctionsDocument16 pagesch-11 - Math FunctionsSwati MadheNo ratings yet

- Syslib Rm014 en eDocument80 pagesSyslib Rm014 en eElton SitumeangNo ratings yet

- BSTe B404 EN Controllers 2018 LowDocument6 pagesBSTe B404 EN Controllers 2018 LowAtul Kumar MauryaNo ratings yet

- Inovance Servo Inovance Inotorque Ismd Series Torque MotorDocument6 pagesInovance Servo Inovance Inotorque Ismd Series Torque Motorwaddah.brNo ratings yet

- Oracle MOC - Excellant White PaperDocument7 pagesOracle MOC - Excellant White Papervenvimal1No ratings yet

- HW FunctionalityDocument35 pagesHW FunctionalityBeto MurguiaNo ratings yet

- ResumeDocument4 pagesResumeAmal Dev SNo ratings yet

- PLC Question PapersDocument5 pagesPLC Question PaperskammeshNo ratings yet

- DCP7310 Controller (Full Spec)Document3 pagesDCP7310 Controller (Full Spec)Service Brags & Hayes, Inc.No ratings yet

- Programming Examples 1Document17 pagesProgramming Examples 1Dr-Amit Kumar SinghNo ratings yet

- Basic Concept of Process Control SystemDocument29 pagesBasic Concept of Process Control Systemhabtemariam mollaNo ratings yet

- F2 08TRSDocument5 pagesF2 08TRSManrique FloresNo ratings yet

- MA KR C5 Micro enDocument146 pagesMA KR C5 Micro enEmanuel CazanNo ratings yet

- 1Document2 pages1DollaRaiNo ratings yet

- TIA Portal Programming 1Document524 pagesTIA Portal Programming 1Jean Paul Lopez RiosNo ratings yet

- Siemens S7 1200/tia Portal: 12 Modules Over 3 MonthsDocument3 pagesSiemens S7 1200/tia Portal: 12 Modules Over 3 MonthsbariNo ratings yet

- Boiler Control Using SCADADocument9 pagesBoiler Control Using SCADAAdarsh Sunkad0% (1)

- Automatic Reveting Machine ReportDocument42 pagesAutomatic Reveting Machine Reportakash bardeNo ratings yet

- LECTURE 5: IEC61850 Standard For SCADADocument3 pagesLECTURE 5: IEC61850 Standard For SCADAYogesh BadheNo ratings yet

- SiemensDocument59 pagesSiemenssybaritzNo ratings yet