Professional Documents

Culture Documents

RHS1 Connection (Rev 0) - M12 (5th & 7th Sty)

Uploaded by

Boon FuiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RHS1 Connection (Rev 0) - M12 (5th & 7th Sty)

Uploaded by

Boon FuiCopyright:

Available Formats

Profis Anchor 2.4.

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

10/06/2015

Specifier's comments:

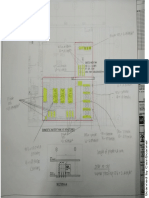

1 Input data

Anchor type and diameter:

HSA M12 hnom3

Dynamic set or any suitable annular gap filling solution

Effective embedment depth:

hef = 100 mm, hnom = 114 mm

Material:

Evaluation Service Report:

ETA 11/0374

Issued I Valid:

19/07/2012 | 19/07/2017

Proof:

SOFA design method + fib (07/2011) - after ETAG testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 10 mm

Anchor plate:

lx x ly x t = 250 mm x 300 mm x 10 mm; (Recommended plate thickness: not calculated)

Profile:

Rectangular hollow; (L x W x T) = 150 mm x 100 mm x 6 mm

Base material:

uncracked concrete, , fc = 31.94 N/mm2; h = 750 mm

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

10/06/2015

Case

1

Description

Combination 1

Forces [kN] / Moments [kNm]

N = 0.000; Vx = 0.000; Vy = -11.542;

Mx = 6.263; My = 0.000; Mz = 0.000

Seismic

no

Fire

no

Max. Util. [%]

90

Combination 2

N = 0.000; Vx = 0.000; Vy = -9.985;

Mx = -5.221; My = 0.000; Mz = 0.000

no

no

65

2 Load case/Resulting anchor forces

Load case: Design loads

y

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

19.589

2.886

0.000

2

0.000

2.886

0.000

3

0.000

2.886

0.000

4

19.589

2.886

0.000

max. concrete compressive strain:

0.34 []

max. concrete compressive stress:

10.30 [N/mm2]

resulting tension force in (x/y)=(0/20):

39.178 [kN]

resulting compression force in (x/y)=(0/-140): 39.178 [kN]

Shear force y

-2.886

-2.886

-2.886

-2.886

Tension

3

Compression

3 Tension load SOFA (fib (07/2011), section 10.1)

Load [kN]

19.589

Capacity [kN]

29.571

Utilization bN [%]

67

Status

OK

Pullout Strength*

19.589

29.515

67

OK

Concrete Breakout Strength**

39.178

50.767

78

OK

39.178

61.160

65

OK

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

41.400

gM,s

1.400

NRd,s [kN]

29.571

NSd [kN]

19.589

yc

1.265

gM,p

1.500

NRd,p [kN]

29.515

NSd [kN]

19.589

3.2 Pullout Strength

NRk,p [kN]

35.000

3.3 Concrete Breakout Strength

Ac,N [mm2]

122500

A0c,N [mm2]

90000

yA,N

1.361

ccr,N [mm]

150

scr,N [mm]

300

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

0

yec2,N

1.000

ys,N

0.900

N0Rk,c [kN]

62.164

gM,c

1.500

NRd,c [kN]

50.767

NSd [kN]

39.178

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

yre,N

1.000

k1

11.000

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

10/06/2015

3.4 Splitting failure

Ac,N [mm2]

127500

A0c,N [mm2]

96100

yA,N

1.327

ccr,sp [mm]

155

scr,sp [mm]

310

yh,sp

1.245

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

0

yec2,N

1.000

ys,N

0.894

yre,N

1.000

N0Rk,c [kN]

62.164

gM,sp

1.500

NRd,sp [kN]

61.160

NSd [kN]

39.178

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

k1

11.000

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

10/06/2015

4 Shear load SOFA (fib (07/2011), section 10.2)

Load [kN]

2.886

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

23.600

Utilization bV [%]

13

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

11.542

111.011

11

OK

Concrete edge failure in direction y-**

5.771

16.173

36

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

29.500

gM,s

1.250

VRd,s [kN]

23.600

VSd [kN]

2.886

Ac,N [mm2]

147000

A0c,N [mm2]

90000

yA,N

1.633

ccr,N [mm]

150

scr,N [mm]

300

k4

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

0.820

yre,N

1.000

N0Rk,c [kN]

62.164

gM,c,p

1.500

VRd,c1 [kN]

111.011

VSd [kN]

11.542

4.2 Pryout Strength

4.3 Concrete edge failure in direction ylf [mm]

100

dnom [mm]

12.0

kV

2.400

a

0.129

c1 [mm]

60

Ac,V [mm2]

32400

A0c,V [mm2]

16200

yA,V

2.000

ys,V

1.000

yh,V

1.000

ya,V

1.000

ec,V [mm]

0

V0Rk,c [kN]

12.130

gM,c

1.500

VRd,c [kN]

16.173

VSd [kN]

5.771

b

0.072

yec,V

1.000

yre,V

1.000

y90,V

2.000

5 Combined tension and shear loads SOFA (fib (07/2011), section 10.3)

steel

concrete

a

bN

a

bV

bN

0.662

bV

0.122

a

2.000

Utilization bN,V [%]

46

Status

OK

0.772

0.357

1.500

90

OK

<= 1

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

10/06/2015

6 Displacements (highest loaded anchor)

Short term loading:

NSk

14.510 [kN]

dN

1.998 [mm]

VSk

2.137 [kN]

dV

0.269 [mm]

dNV

2.016 [mm]

Long term loading:

NSk

14.510 [kN]

dN

2.346 [mm]

VSk

2.137 [kN]

dV

0.410 [mm]

dNV

2.381 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements are

valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not included in

this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

The design method ETAG (filled holes) assumes that no hole clearance between the anchors and the fixture is present. This can be

achieved by

filling the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to be

followed to ensure a proper installation.

The design method fib (07/2011) assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by filling

the gap with mortar of sufficient sompressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

The anchor plate overlaps the concrete plate edges. A local concrete spalling due to compression has to be checked separately!

Checking the transfer of loads into the base material is required in accordance with fib (07/2011)!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

10/06/2015

8 Installation data

Anchor plate, steel: Anchor type and diameter: HSA M12 hnom3

Profile: Rectangular hollow; 150 x 100 x 6 mm

Installation torque: 0.050 kNm

Hole diameter in the fixture: df = 14 mm

Hole diameter in the base material: 12 mm

Plate thickness (input): 10 mm

Hole depth in the base material: 122 mm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 180 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

8.1 Required accessories

Cleaning

Manual blow-out pump

Setting

Dynamic set

Installation torque control bar with suitable

screw driver or torque wrench

Hammer

125

100

130

125

150

Drilling

Suitable Rotary Hammer

Properly sized drill bit

150

140

3

30

30

190

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

95

-95

95

-95

y

20

-120

-120

20

c-x

-

c+x

-

c-y

200

60

60

200

c+y

100

240

240

100

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

30

Profis Anchor 2.4.8

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

7

10/06/2015

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and

security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly

complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using

the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in.

Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you.

Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to

compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms

and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific

application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the

regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use

the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case

by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or

programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1st Order & 2nd Order AnalysisDocument19 pages1st Order & 2nd Order AnalysisBoon Fui0% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CH 6 Answers (All) PDFDocument29 pagesCH 6 Answers (All) PDFAhmed SideegNo ratings yet

- Engine Interface ModuleDocument3 pagesEngine Interface ModuleLuciano Pereira0% (2)

- Final Project Part-3 Marketing PlanDocument8 pagesFinal Project Part-3 Marketing PlanIam TwinStormsNo ratings yet

- Shaira Narrative Report (Final)Document7 pagesShaira Narrative Report (Final)Sheryll TamangNo ratings yet

- BS en 571 1 1997 Non Destructive Testing Penetrant Testing Part 1 General Principles PDFDocument16 pagesBS en 571 1 1997 Non Destructive Testing Penetrant Testing Part 1 General Principles PDFHamza TarikNo ratings yet

- Digestive System Lesson PlanDocument5 pagesDigestive System Lesson PlanSachi Summers100% (2)

- A320 Abnormal Notes: Last UpdatedDocument13 pagesA320 Abnormal Notes: Last UpdatedDevdatt SondeNo ratings yet

- Epri Guide For Transmission Line Groundingpdf PDF FreeDocument188 pagesEpri Guide For Transmission Line Groundingpdf PDF FreeHolman Wbeimar Suarez Niño100% (1)

- New Life in Christ - Vol05 - Engl - Teacher GuideDocument29 pagesNew Life in Christ - Vol05 - Engl - Teacher GuideOliver Angus100% (1)

- The Future of Comparative Literary StudiesDocument14 pagesThe Future of Comparative Literary StudiesNabeesath ArifaNo ratings yet

- Overall View Mullion E1A PDFDocument3 pagesOverall View Mullion E1A PDFBoon FuiNo ratings yet

- Overall View Mullion E1A PDFDocument3 pagesOverall View Mullion E1A PDFBoon FuiNo ratings yet

- Structure 1Document3 pagesStructure 1Boon FuiNo ratings yet

- Load CombinationDocument1 pageLoad CombinationBoon FuiNo ratings yet

- Overall View Mullion E1A PDFDocument3 pagesOverall View Mullion E1A PDFBoon FuiNo ratings yet

- Buckling of Simple ColDocument9 pagesBuckling of Simple ColBoon FuiNo ratings yet

- Circular Appbca 2017 15 - 14dec PDFDocument9 pagesCircular Appbca 2017 15 - 14dec PDFBoon FuiNo ratings yet

- Diaphragm Wall Supported by Ground Anchors and Inclined Struts PDFDocument7 pagesDiaphragm Wall Supported by Ground Anchors and Inclined Struts PDFBoon FuiNo ratings yet

- 001 Bizgram Daily DIY PricelistDocument6 pages001 Bizgram Daily DIY PricelistBoon FuiNo ratings yet

- Load CombinationDocument1 pageLoad CombinationBoon FuiNo ratings yet

- Euler Bernoulli EquationDocument16 pagesEuler Bernoulli EquationBoon FuiNo ratings yet

- Circular Appbca 2017 15 - 14dec PDFDocument9 pagesCircular Appbca 2017 15 - 14dec PDFBoon FuiNo ratings yet

- Cyber MindDocument8 pagesCyber MindBoon FuiNo ratings yet

- Cyber MindDocument8 pagesCyber MindBoon FuiNo ratings yet

- Excel VBA Learning Web PDFDocument1 pageExcel VBA Learning Web PDFBoon FuiNo ratings yet

- Building CalculatorDocument1 pageBuilding CalculatorBoon FuiNo ratings yet

- Lysaght Zed Cees Part 1 July 2014Document32 pagesLysaght Zed Cees Part 1 July 2014Kirk ReynoldsonNo ratings yet

- Utopia Age 7 War 2Document34 pagesUtopia Age 7 War 2Boon FuiNo ratings yet

- RHS1 Connection (Rev 0) - M12 (5th & 7th Sty)Document7 pagesRHS1 Connection (Rev 0) - M12 (5th & 7th Sty)Boon FuiNo ratings yet

- Column Force ListingDocument47 pagesColumn Force ListingBoon FuiNo ratings yet

- International Codes 2Document13 pagesInternational Codes 2Boon FuiNo ratings yet

- Equipment Loading at 4th StyDocument2 pagesEquipment Loading at 4th StyBoon FuiNo ratings yet

- Microsoft PowerPoint - Eurocode 9 Brussels 2008 Torsten HoglundDocument79 pagesMicrosoft PowerPoint - Eurocode 9 Brussels 2008 Torsten HoglundBoon FuiNo ratings yet

- Parallel FlangeDocument1 pageParallel FlangeBoon FuiNo ratings yet

- Water Quality ConsiderationDocument5 pagesWater Quality ConsiderationBoon FuiNo ratings yet

- Greenery Provisions For RoadsideDocument25 pagesGreenery Provisions For Roadsidelwin_oo2435No ratings yet

- AutoCAD 2013-2014 DGN Hotfix ReadmeDocument3 pagesAutoCAD 2013-2014 DGN Hotfix ReadmeKodali Naveen KumarNo ratings yet

- A Single-Stage Asymmetrical Half-Bridge Flyback CoDocument16 pagesA Single-Stage Asymmetrical Half-Bridge Flyback CoSantosh KumarNo ratings yet

- Assessment 3 Comparative Analysis Primary Vs Secondary SourcesDocument5 pagesAssessment 3 Comparative Analysis Primary Vs Secondary SourcesMATOZA, YLJOE V.No ratings yet

- Healthy Body CompositionDocument18 pagesHealthy Body CompositionSDasdaDsadsaNo ratings yet

- Exploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelDocument9 pagesExploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelPablo GuerraNo ratings yet

- PTPL Ir 2018Document383 pagesPTPL Ir 2018Guan WenhaiNo ratings yet

- Kalbelia Dance Rajasthan - Kalbelia Rajasthani Folk Dance KalbeliaDocument6 pagesKalbelia Dance Rajasthan - Kalbelia Rajasthani Folk Dance KalbeliarahulgabdaNo ratings yet

- FPI - Study Permit Application GuideDocument9 pagesFPI - Study Permit Application GuideKian Mark DarioNo ratings yet

- Metric Conversion WorksheetDocument3 pagesMetric Conversion WorksheetKaiden HughesNo ratings yet

- Free Vibration of SDOFDocument2 pagesFree Vibration of SDOFjajajajNo ratings yet

- Learn To Write Chapter 1 ProposalDocument52 pagesLearn To Write Chapter 1 Proposalrozaimihlp23No ratings yet

- UntitledDocument45 pagesUntitledjemNo ratings yet

- Case 07-53: #REF! #REF! #REF! #REF! #REF!Document6 pagesCase 07-53: #REF! #REF! #REF! #REF! #REF!saad bin sadaqatNo ratings yet

- Grade 7 - R & C - Where Tigers Swim - JanDocument15 pagesGrade 7 - R & C - Where Tigers Swim - JanKritti Vivek100% (3)

- Navigation - Star FinderDocument31 pagesNavigation - Star FinderPrasadtNo ratings yet

- Samsung LN55C610N1FXZA Fast Track Guide (SM)Document4 pagesSamsung LN55C610N1FXZA Fast Track Guide (SM)Carlos OdilonNo ratings yet

- Kibera Mirror JULYDocument8 pagesKibera Mirror JULYvincent achuka maisibaNo ratings yet

- D D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsDocument16 pagesD D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsJADERSONNo ratings yet

- Newsite KPI Check. - Ver2Document4,183 pagesNewsite KPI Check. - Ver2nasircugaxNo ratings yet

- Ayaw at GustoDocument4 pagesAyaw at GustoJed VillaluzNo ratings yet

- Guidance UDI Compliance DatesDocument13 pagesGuidance UDI Compliance DatesGigi EssegiNo ratings yet

- Repeater Panel User GuideDocument24 pagesRepeater Panel User Guideamartins1974No ratings yet