Professional Documents

Culture Documents

SEDIMENTATION BASICS

Uploaded by

RahulRandyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEDIMENTATION BASICS

Uploaded by

RahulRandyCopyright:

Available Formats

11/22/2010

SEDIMENTATION

Water Treatment Course

AAiT, Zerihun Alemayehu

INTRODUCTION

Sedimentation

is removal of particulate materials

suspended in water by quiescent settling due to

gravity

Commonly used unit operation in water and

wastewater treatment plants

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

SEDIMENTATION

Particles

Discrete

Flocculating

Size

Shape

weight

Suspension

displacement of water

velocity field interference

AAiT

Dilute

Concentrated

Water Treatment

By Zerihun Alemayehu

TYPES OF SEDIMENTATION

Type I: Discrete particle settling

No interaction between particles

Settling velocity is constant for individual particles

Dilute solids concentration

Examples: presedimentation in water treatment, grit removal

in wastewater

Type II: Flocculent settling

Particles collide and adhere to each other resulting in particle

growth

Dilute solids concentration

Examples: coagulation/flocculation settling in water treatment

and primary sedimentation in wastewater treatment

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

TYPES OF SEDIMENTATION

Type III: Hindered or zone settling

Particles are so close together movement is restricted

Intermediate solids concentration

Solids move as a block rather than individual particles

Fluidic interference causes a reduction in settling velocity

Distinguishable solids liquid interface

Intermediate solids concentration

Example: settling of secondary effluents

Type IV: Compression settling

Particles physically in contact

Water is squeezed out of interstitial spaces

Volume of solids may decrease

High concentration of solids (sludges)

AAiT

Water Treatment

By Zerihun Alemayehu

DISCRETE PARTICLES SETTLING (TYPE 1)

Characteristics of the particles

Size and shape

Specific gravity

Properties of the water

Specific gravity

Viscosity

Physical environment of the particle

Velocity of the water

Inlet and outlet arrangements of the structure

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

DISCRETE PARTICLES SETTLING (TYPE 1)

Fb

Fd

Fnet = mg - Fd - Fb

Fnet = 0

mg

vs

4 ( s w ) gd

3

w

CD

Re < 1, Cd = 24/Re (Laminar flow)

1<Re<104, Cd = 24/Re + 3/(Re)1/2 + 0.34 (Transition)

103 < Re < 104, Cd = 0.4 (Turbulent)

AAiT

Water Treatment

By Zerihun Alemayehu

STOKES LAW

For Re < 1 (laminar flow) and

Re = wvsd/ (for perfect sphere),

Stokes law:

vs

vs

AAiT

gd 2 ( s w )

18

gd 2 ( S g 1)

18

Water Treatment

By Zerihun Alemayehu

11/22/2010

EXAMPLE

Estimate the terminal settling velocity in water at

a temperature of 15oC of spherical silicon particles

with specific gravity 2.40 and average diameter of

(a) 0.05 mm and (b) 1.0 mm

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 1. Using Stokes equation for (a) at T= 15oC

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

SOLUTION

Step 2. Check with the Reynolds number

Step 3. Using Stokes law for (b)

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 4. Check the Reynolds number

Since R > 2, the Stokes law does not apply. Use Eq. 1 to calculate v

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

SOLUTION

Step 5. Re-calculate Cd and v

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 6. Re-check Re

Step 7. Repeat step 5 with new R

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

SOLUTION

Step 8. Re-check Re

Step 9. Repeat step 7

(b) The estimated velocity is around 0.16 m/s

AAiT

Water Treatment

By Zerihun Alemayehu

SETTLING COLUMN

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

GENERALLY

All particles with d>= do, such that v >= vo, will arrive at

or pass the sampling port in time to.

A particle with dp < do will have a terminal settling

velocity vp < vo and will arrive at or pass the sampling

port in time to, with original position at, or below a point

Zp.

If the suspension is mixed uniformly then the fraction of

particles of size dp with settling velocity vp which will

arrive at or pass the sampling port in time to will be Zp/Zo

= vp/vo.

Thus, the removal efficiency of any size particle from

suspension is the ratio of the settling velocity of that

particle to the settling velocity vo defined by Zo/to.

AAiT

Water Treatment

By Zerihun Alemayehu

PROCEDURE SETTLEABLILITY ANALYSIS

Usually 2m high column

Mix the suspension thoroughly

Measure initial SS concentration, Co

Measure concentrations at certain intervals, Ci

All particles comprising C1 must have settling velocities

less than Z0/t1. Thus the mass fraction of particles with v1

< Z0/t1 is

AAiT

Water Treatment

By Zerihun Alemayehu

11/22/2010

PROCEDURE SETTLEABLILITY ANALYSIS

AAiT

Water Treatment

By Zerihun Alemayehu

PROCEDURE SETTLEABLILITY ANALYSIS

For a given detention time to, an overall percent removal

can be obtained.

All particles with settling velocities greater than v0=Z0/t0

will be 100 percent removed.

Thus, 1 xo fraction of particles will be removed completely in

time t0. The remaining will be removed to the ratio vi/vo,

corresponding to the shaded area in Fig. 4.2. If the equation

relating v and x is known the area can be found by integration:

AAiT

Water Treatment

By Zerihun Alemayehu

10

11/22/2010

EXAMPLE : SETTLING COLUMN ANALYSIS OF

TYPE-1 SUSPENSION

A settling analysis is run on a type-1 suspension. The

column is 2 m deep and data are shown below.

What will be the theoretical removal efficiency in a

settling basin with a loading rate of 25 m3/m2-d (25m/d)?

Water Treatment

By Zerihun Alemayehu

AAiT

SOLUTION

Step 1. Calculate mass fraction remaining and

corresponding settling rates

x=

Ci

189

0.63

Time, min

60

80

100

130

200

240

420

Mass fraction remaining

0.63

0.60

0.56

0.52

0.37

0.26

0.09

3.0

2.5

2.0

1.55

1.0

0.83

0.48

Vt x

102,

Co

300

m/min

AAiT

Water Treatment

By Zerihun Alemayehu

11

11/22/2010

SOLUTION

Step 2. Plot mass fraction vs. settling velocity

X, Wt. fraction remaining

0.7

xo

0.6

0.5

0.4

0.3

0.2

vo = 1.74 x 10-2 m/min

0.1

0

0

0.5

1.5

2.5

3.5

Velocity, m/min X 10-2

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 3. Determine vo

vo = 25m3/m2.d = 1.74 x 10-2 m/min

Step 4. Determine xo = 54 %

AAiT

Water Treatment

By Zerihun Alemayehu

12

11/22/2010

SOLUTION

Step 5. x.vt by graphical integration

x = 0.06

x = 0.06

0.6

x = 0.06

0.5

vo=1.74 x 10-2 m/min

X, Wt. fraction remaining

0.7

x = 0.06

0.4

x = 0.1

0.3

x = 0.1

0.2

x = 0.1

0.1

0

0

0.5

1.5

2.5

3.5

Velocity, m/min x 10-2

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 5. x.vt by graphical

integration

vt

x.vt

0.06

1.50

0.09

0.06

1.22

0.07

0.1

1.00

0.10

0.1

0.85

0.09

0.1

0.70

0.07

0.06

0.48

0.03

0.06

0.16

0.01

x.vt=0.46

Step 6. Determine overall

removal efficiency

X 1 xo

0.46

AAiT

Water Treatment

By Zerihun Alemayehu

x.vt

vo

0.46

1.74

72%

13

11/22/2010

TYPE-2 SETTLING

Involves

flocculating particles in dilute suspension

The Stocks Equation cannot be used flocculating

particles

Column settleability analysis with some alteration to

that of type-1 settling

samples will be taken at several depths at several

time intervals and analyzed for suspended-solids

concentrations.

AAiT

Water Treatment

By Zerihun Alemayehu

TYPE-2 SETTLING

Mass fraction removed is calculated as:

AAiT

Water Treatment

By Zerihun Alemayehu

14

11/22/2010

EXAMPLE: SETTLING COLUMN ANALYSIS OF

FLOCCULATING PARTICLES.

A column analysis of a flocculating suspension is run the

apparatus shown below. The initial solids concentration is 250

mg/L. The resulting matrix is shown below. What will be the

overall removal efficiency of a settling basin which is 3 m

deep with a detention time of 1 h and 45 min?

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 1. Determine the removal rate at each depth and time

xij = (1- Ci/Co)x100

x11 = (1 133/250) x 100 = 47

Depth,

m

0.5

1

1.5

2

2.5

3

AAiT

30

47

28

19

15

12

10

Time of sampling, min

60

90

120

150

67

80

85

88

51

63

74

78

40

53

63

72

33

46

56

64

28

42

51

59

25

38

47

55

180

91

83

77

72

68

62

Water Treatment

By Zerihun Alemayehu

15

11/22/2010

SOLUTION

AAiT

Water Treatment

By Zerihun Alemayehu

SETTLING TANKS /SEDIMENTATION TANKS

AAiT

Water Treatment

By Zerihun Alemayehu

16

11/22/2010

SETTLING TANKS /SEDIMENTATION TANKS

AAiT

Water Treatment

By Zerihun Alemayehu

LONG-RECTANGULAR BASINS

AAiT

Water Treatment

By Zerihun Alemayehu

17

11/22/2010

LONG-RECTANGULAR TANK

the inlet zone in which baffles intercept the

oncoming water and spread the flow

uniformity

both

vertically

the

outlet zone

in horizontally

which waterand

flows

across the

upward

andtank

over the outlet weir

settling zone, which occupies the

sludge zone,

which

extends

remaining

volume

of the

tank from the

bottom of the tank to just above the

scraper mechanism

AAiT

Water Treatment

By Zerihun Alemayehu

LONG-RECTANGULAR TANK

Detention time. is the theoretical time that the water is

detained in a settling basin. it is calculated as the volume

of the tank divided by the rate of flow,

and is denoted as = V/Q.

vo or Q/As is called overflow rate or surface loading rate or

surface overflow rate (SOR).

AAiT

Water Treatment

By Zerihun Alemayehu

18

11/22/2010

REMOVAL EFFICIENCY OF PARTICLES

A particle initially at height h with settling velocity of vsh will

just be removed by the time it has traversed the settling zone.

Particles initially at heights less than h will also be removed

and those at greater heights will not reach the bottom before

reaching the outlet zone.

All particles with settling velocity vs < vsh are removed partly,

depending on their position at a height from the top of the

sludge zone.

The efficiency of removal of such particles is given by h/H.

The greater the surface area, the higher the efficiency.

AAiT

Water Treatment

By Zerihun Alemayehu

CIRCULAR BASINS

The flow enters at the center and is baffled to flow radially

toward the perimeter

The horizontal velocity of the water is continually decreasing

as the distance from the center increases the particle path

is a parabola

Simple sludge removal

mechanisms

require less maintenance

no excessive weir overflow

AAiT

Water Treatment

By Zerihun Alemayehu

19

11/22/2010

SHORT-CIRCUITING AND REDUCTION OF

EFFICIENCY

Theoretically detention time, =V/Q.

But in real flow detention time is not V/Q.

Short-circuiting: the deviation of actual flow of the tank

from the flow pattern of an ideal tank

Efficiency of displacement = magnitude of short-circuiting x 100.

It should be greater than 30%.

Currents induced by the inertia of oncoming fluid, turbulent

flow, wind stresses and density, and temperature gradient

reduces the settling basin efficiency.

AAiT

Water Treatment

By Zerihun Alemayehu

INLET ZONE

Inlets should be designed to dissipate the momentum and

accurately distribute the incoming flow

Baffle

Multiple

opening

across

width

Flow distribution

AAiT

Baffle

Multiple

opening

across

width

Typical baffle (diffuser) walls

Water Treatment

By Zerihun Alemayehu

20

11/22/2010

OUTLET STRUCTURE

consist of an overflow weir and a receiving channel or

launder.

The launder to the exit channel or pipe.

re-suspension of settled solids must be prevented

flow velocity in upward direction has to be limited

Increase the length of the overflow overflow weir

AAiT

Water Treatment

By Zerihun Alemayehu

DESIGN DETAILS

Detention period: for plain sedimentation: 3 to 4 h, and for

coagulated sedimentation: 2 to 2 1/2 h

Velocity of flow: < 18 m/h (horizontal flow tanks)

Tank dimensions: L : B : 3 to 5 : 1

Depth 2.5 to 5.0 m (3 m)

Surface loading (or) overflow rate or (SOR)

Generally L = 30 m (common) maximum 100 m.

Breadth: 6 m to 10 m.

Circular: Dia < 60 m, Generally 20 to 40 m

For plain sedimentation- 12,000 to 18,000 1/d/m2

for thoroughly flocculated water 24,000 to 30, 000 1/d/m2

horizontal flow circular tank 30,000 to 40,000 1/d/m2

Slopes: Rectangular 1 % towards inlet and circular 8%

Weir loading rate, m3/m/d < 248

AAiT

Water Treatment

By Zerihun Alemayehu

21

11/22/2010

EXAMPLE

Find the dimensions of a rectangular sedimentation basin

for the following data:

Volume of water to be treated = 3 MLD

Detention period = 4 hrs

Velocity of flow = 10 cm/min

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

AAiT

Water Treatment

By Zerihun Alemayehu

22

11/22/2010

SOLUTION

AAiT

Water Treatment

By Zerihun Alemayehu

EXAMPLE

Design a circular basin. A circular sedimentation tank is to have a

minimum detention time of 4 h and a maximum overflow rate of 20

m3/m2.d. Determine the required diameter of the tank and the

depth if the average flow rate through the tank is 6 ML/d.

AAiT

Water Treatment

By Zerihun Alemayehu

23

11/22/2010

SOLUTION

V=6000x4/24=1000

Depth=20x4/24=3.33=3.5m

As=V/d=1000/3.5=285.7m2

As=xD2/4

Diameter=19m

Hence provide 5 m deep (1 m for sludge and 0.5 m free

board) by 19 m diameter tank

AAiT

Water Treatment

By Zerihun Alemayehu

EXAMPLE

Design a long-rectangular settling basin for type-2

settling. A city must treat about 15,000 m3/d of water.

Flocculating particles are produced by coagulation,

and a column analysis indicates that an overflow rate

of 20 m/d will produce satisfactory removal at a depth

of 2.5 m. Determine the size of the required settling

tank.

AAiT

Water Treatment

By Zerihun Alemayehu

24

11/22/2010

HIGH-RATE SETTLING MODULES

AAiT

Water Treatment

By Zerihun Alemayehu

TUBE SETTLERS

AAiT

Water Treatment

By Zerihun Alemayehu

25

11/22/2010

TUBE SETTLERS

AAiT

Water Treatment

By Zerihun Alemayehu

PLATE /LAMELLA PLATE SETTLER

AAiT

Water Treatment

By Zerihun Alemayehu

26

11/22/2010

PLATE /LAMELLA PLATE SETTLER

Water Treatment

By Zerihun Alemayehu

AAiT

DESIGN OF INCLINED SETTLERS

H

u

sin

=

( cos + 2 )

=

AAiT

Water Treatment

By Zerihun Alemayehu

27

11/22/2010

EXAMPLE

A water treatment work treats 1.0 m3/s and removes flocs

larger than 0.02 mm. The settling velocity of the 0.02mm

flocs is measured in the laboratory as 0.22 mm/s at 15 oC.

Tube settlers of 50 mm square honeycombs are inclined at a

50o angle and its vertical height is 1.22 m. Determine the

basin are required for the settler module.

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step 1. Determine the area needed for the settler modules

Q = (1m3 /s)/2 = 0.5 m3/s = 30 m3 /min

w = 50.8 mm = 0.0508 m

H = 1.22 m

= 50o

=

( cos cos 2 )

0.5(0.0508)

(1.22 0.643 + 0.0508 0.6432 )

0.312

=

AAiT

Water Treatment

By Zerihun Alemayehu

28

11/22/2010

SOLUTION

A safety factor of 0.6 may be applied to determine the designed settling

velocity. Thus,

= 0.6 0.00022/ =

0.0312

= 2362 ( 240 2 )

Step 2. find surface loading rate Q/A

0.5 24 60 603

=

= 1803 /(2 )

2402

Step 3. Compute flow velocity in the settlers

v = Q/A sin = 180/0.766

= 235 m/d

= 0.163 m/min

= 0.0027 m/s

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

Step

4. Determine size of the basin

Two identical settling basins are designed. Generally, the

water depth of the tank is 4 m. The width of the basin is

chosen as 8.0 m. The calculate length of the basin

covered by the setter is

l = 240 m2/8 m = 30 m

In practice, one-forth of the basin length is left as a

reserved volume for future expansion, to settle heavy

flocs, for access and improve inlet condition. The total

length of the basin should be

30

AAiT

4

= 40

3

Water Treatment

By Zerihun Alemayehu

29

11/22/2010

SOLUTION

R=

0.05082

= 0.0127

4 0.0508

(0.0027/)(0.0127)

=

0.0000011312

30 < 2000, !

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

AAiT

Water Treatment

By Zerihun Alemayehu

30

11/22/2010

SOLUTION

10 m

30 m (covered with tubes)

16 m

Launder

Baffle wall

Outlet channel

Diffuser wall

Inlet channel

AAiT

Water Treatment

By Zerihun Alemayehu

SOLUTION

AAiT

Water Treatment

By Zerihun Alemayehu

31

11/22/2010

FIELD TRIP: Dec., 24th to 26th, 2010

Wenji

Gilbel Gibe 3

Adama, Nazareth

Addis Ababa

AAiT

Water Treatment

By Zerihun Alemayehu

32

You might also like

- Sedimentation 1672959678 PDFDocument34 pagesSedimentation 1672959678 PDFAbderrazak AmiriNo ratings yet

- Treatment of Water & WastewaterDocument40 pagesTreatment of Water & WastewaterAli RazaNo ratings yet

- Water Treatment: Monroe L. Weber-Shirk S Civil Environmental EngineeringDocument80 pagesWater Treatment: Monroe L. Weber-Shirk S Civil Environmental EngineeringamoNo ratings yet

- SEDIMENTATION PresentationDocument45 pagesSEDIMENTATION PresentationShai Sta CatalinaNo ratings yet

- Envirenmental EngineeringDocument87 pagesEnvirenmental Engineering4919404No ratings yet

- SedimentationDocument8 pagesSedimentationAnkush AgarwalNo ratings yet

- Chapt5 - Theory of Sedimentation PDFDocument18 pagesChapt5 - Theory of Sedimentation PDFNgoni Mukuku100% (1)

- SedimentationDocument20 pagesSedimentationEyuelAdamNo ratings yet

- PHE NotesDocument21 pagesPHE NotesThomas BwahiNo ratings yet

- Water TreatmentDocument45 pagesWater TreatmentSarim ChNo ratings yet

- CE 408 Sedimentation and Skimming TanksDocument12 pagesCE 408 Sedimentation and Skimming TanksMuhammad AmirNo ratings yet

- Settling DWDocument13 pagesSettling DWLenin MaldonadoNo ratings yet

- Water Treatment-1BDocument13 pagesWater Treatment-1BPrateek Soumya SharmaNo ratings yet

- TreatDocument49 pagesTreatHussen MohammedNo ratings yet

- Engr. Abaid UllahDocument37 pagesEngr. Abaid UllahminahilNo ratings yet

- CHAPTER 1 Engineered Water TreatmentDocument140 pagesCHAPTER 1 Engineered Water TreatmentPMNo ratings yet

- Stoke's LawDocument6 pagesStoke's Lawjlcheefei9258No ratings yet

- Wastewater TreatmentDocument49 pagesWastewater TreatmentAshwani Kumar Pati TripathiNo ratings yet

- Unit 5.13 SedimentationDocument17 pagesUnit 5.13 SedimentationMutale InongeNo ratings yet

- Design of sedimentation tanksDocument4 pagesDesign of sedimentation tankstadagidsNo ratings yet

- Early Diagenesis Concepts and 14C DatingDocument35 pagesEarly Diagenesis Concepts and 14C DatingRe BazNo ratings yet

- WTP Design 3.12 MLDDocument21 pagesWTP Design 3.12 MLDSandeep VaishnavNo ratings yet

- SedimentationDocument26 pagesSedimentationDavid Charles Meissner100% (1)

- Chapter 3D (Sedimentation)Document18 pagesChapter 3D (Sedimentation)Syamim BakriNo ratings yet

- Lecture 6Document7 pagesLecture 6Hamza SawalmehNo ratings yet

- BS 3 MembraneDocument33 pagesBS 3 MembranePratyush GoelNo ratings yet

- Chapter 4Document13 pagesChapter 4selambante shiferawNo ratings yet

- Sedimentation Reservoir GuidlineDocument14 pagesSedimentation Reservoir GuidlineHector AlfonsoNo ratings yet

- 04012016LSWCJE5EFeasabilityEMP PDFDocument8 pages04012016LSWCJE5EFeasabilityEMP PDFPrashu PrashanthNo ratings yet

- Tutorial and AssignmentsDocument8 pagesTutorial and Assignmentstedy yidegNo ratings yet

- Water TreatmentDocument19 pagesWater TreatmentMelannie Adante100% (2)

- Sedimentation 2023Document19 pagesSedimentation 2023Francis Mutema Mahofa100% (1)

- Basic Water Treatment Methods ExplainedDocument33 pagesBasic Water Treatment Methods ExplainedKubaNo ratings yet

- Design of Mixing BasinDocument5 pagesDesign of Mixing BasinShekh Muhsen Uddin AhmedNo ratings yet

- Zero BlowdownDocument7 pagesZero BlowdownprakashNo ratings yet

- Batch Sedimentation Lab ReportDocument16 pagesBatch Sedimentation Lab Reportlucas67% (3)

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Lecture Notes Clarification, Filtration, Adsorption (Activated Carbon, and Water Stability CEG8103Document22 pagesLecture Notes Clarification, Filtration, Adsorption (Activated Carbon, and Water Stability CEG8103yusufNo ratings yet

- Chapter Four SedimantationDocument52 pagesChapter Four SedimantationJarso buke Buke GalgaloNo ratings yet

- !32303037Document16 pages!32303037Luis Benitez100% (1)

- Groundwater HydrologyDocument52 pagesGroundwater HydrologyErik AdamsNo ratings yet

- WASTE WATER TREATMENT: GRIT REMOVAL PROCESSDocument22 pagesWASTE WATER TREATMENT: GRIT REMOVAL PROCESSsarfaNo ratings yet

- Calculation V-Notch For Sedimentation TankDocument34 pagesCalculation V-Notch For Sedimentation TankDavid LambertNo ratings yet

- Ecw567 WastewaterDocument71 pagesEcw567 Wastewaterhanif aiyadNo ratings yet

- Unit 3 EEDocument9 pagesUnit 3 EEA MaqsoodNo ratings yet

- Sedimentation PresentationDocument30 pagesSedimentation PresentationShepherd Nhanga100% (3)

- Water Treatment (Water Supply Engineering)Document40 pagesWater Treatment (Water Supply Engineering)Shuvanjan Dahal100% (11)

- Wastewater QuestionDocument18 pagesWastewater Questionth3mannnNo ratings yet

- Environmental Engg - Water TreatmentDocument14 pagesEnvironmental Engg - Water TreatmenthitkcivilNo ratings yet

- Sediment Tank Design GuideDocument7 pagesSediment Tank Design GuideMichael Asmith Unique67% (3)

- Case 01Document19 pagesCase 01Rushanth ChandraboseNo ratings yet

- Water Treatment Lecture 4 EENVDocument35 pagesWater Treatment Lecture 4 EENVEllina TehNo ratings yet

- 29th Oct Wangfei Sewage Sludge Treatment and DisposalDocument100 pages29th Oct Wangfei Sewage Sludge Treatment and Disposalnebex12No ratings yet

- Proposal of OelDocument10 pagesProposal of OelJoan MaryNo ratings yet

- Sludge processing steps and dewateringDocument21 pagesSludge processing steps and dewateringShubham BansalNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Reverse Osmosis Treatment of Drinking WaterFrom EverandReverse Osmosis Treatment of Drinking WaterRating: 3.5 out of 5 stars3.5/5 (4)

- 4 Types of BankingDocument7 pages4 Types of BankingPandian MangalNo ratings yet

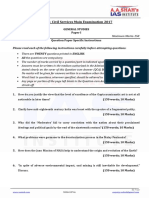

- UPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250Document3 pagesUPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250RahulRandyNo ratings yet

- 13 Capital Markets Part 2Document9 pages13 Capital Markets Part 2RahulRandyNo ratings yet

- Activity Week in Which Activity Is Done Scheduled DurationDocument6 pagesActivity Week in Which Activity Is Done Scheduled DurationRahulRandyNo ratings yet

- GSTDocument146 pagesGSTRahulRandyNo ratings yet

- 01 Analysis of Relationship Between Time and Cost OverrunsDocument22 pages01 Analysis of Relationship Between Time and Cost OverrunsRahulRandyNo ratings yet

- Registration Under GST ADocument9 pagesRegistration Under GST ARahulRandyNo ratings yet

- UPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250Document3 pagesUPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250RahulRandyNo ratings yet

- Assessment of Tender Risks - Red Flag ClausesDocument35 pagesAssessment of Tender Risks - Red Flag ClausesRahulRandyNo ratings yet

- Fulltext01 PDFDocument40 pagesFulltext01 PDFRahulRandyNo ratings yet

- Indian GST Reference ManualDocument594 pagesIndian GST Reference ManualY M Shah & Co100% (5)

- UPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250Document3 pagesUPSC - Civil Services Main Examination 2017: Time Allowed: Three Hours Maximum Marks: 250RahulRandyNo ratings yet

- World Map PDFDocument1 pageWorld Map PDFJeff Adlouie SuarezNo ratings yet

- Fulltext01 PDFDocument40 pagesFulltext01 PDFRahulRandyNo ratings yet

- Read 1Document7 pagesRead 1RahulRandyNo ratings yet

- SOLUTIONS FOR TUTORIAL - 4 (September 13,2012) : CN S PDocument7 pagesSOLUTIONS FOR TUTORIAL - 4 (September 13,2012) : CN S PRahulRandyNo ratings yet

- PDFDocument219 pagesPDFRahulRandyNo ratings yet

- Packet DOWNDocument26 pagesPacket DOWNRahulRandyNo ratings yet

- PPP Experiences in Indian States: Bottlenecks, Enablers and Key IssuesDocument14 pagesPPP Experiences in Indian States: Bottlenecks, Enablers and Key IssuesJagruti NiravNo ratings yet

- Excel Solver Cut & Fill Optimization ReportDocument11 pagesExcel Solver Cut & Fill Optimization ReportRahulRandyNo ratings yet

- Stock Market Basics PDFDocument10 pagesStock Market Basics PDFRahulRandyNo ratings yet

- Limit State Design Flanged BeamsDocument13 pagesLimit State Design Flanged BeamsRahulRandyNo ratings yet

- Case Analysis Operations Research Red Brand Canners (Download To View Full Presentation)Document12 pagesCase Analysis Operations Research Red Brand Canners (Download To View Full Presentation)mahtaabk83% (12)

- SignalDocument62 pagesSignalVishnupriya AryabhumiNo ratings yet

- TE II Project Report Group 3Document11 pagesTE II Project Report Group 3RahulRandyNo ratings yet

- Module 6Document2 pagesModule 6RahulRandyNo ratings yet

- Module 2Document2 pagesModule 2RahulRandyNo ratings yet

- Case Biglow Toy CompanyDocument3 pagesCase Biglow Toy CompanyAravind SankarNo ratings yet

- Assignment 2Document3 pagesAssignment 2RahulRandyNo ratings yet

- Assignment 1: 15 Financial Problems with SolutionsDocument2 pagesAssignment 1: 15 Financial Problems with SolutionsJeevan GonaNo ratings yet

- Experiment 101 Newton's Second Law of MotionDocument9 pagesExperiment 101 Newton's Second Law of MotionQuirino Arzadon IVNo ratings yet

- JEE Main Sample Paper 5Document13 pagesJEE Main Sample Paper 5SK.KaleshaNo ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- Smart Gels: What Is A Smart Gel and How Do They Work?Document19 pagesSmart Gels: What Is A Smart Gel and How Do They Work?Bharat GargNo ratings yet

- 9 PD Measurement On CablesDocument17 pages9 PD Measurement On CablesTXEMANo ratings yet

- GTGB - Start Up - Ric8955863 Rev 0.1Document44 pagesGTGB - Start Up - Ric8955863 Rev 0.1Mohamed El Amine BouazzaNo ratings yet

- MDM BeamDocument19 pagesMDM BeamBrian chunguliNo ratings yet

- 1 s2.0 0013794486900366 Main PDFDocument9 pages1 s2.0 0013794486900366 Main PDFEmanuel CarvalhoNo ratings yet

- Introduction To Quantizer and Llyod Max QuantizerDocument10 pagesIntroduction To Quantizer and Llyod Max QuantizerNeha SenguptaNo ratings yet

- Microwave Link DesignDocument47 pagesMicrowave Link Designsanjaybhad50% (2)

- Physics Linx Class 11 Logarithm ProblemsDocument3 pagesPhysics Linx Class 11 Logarithm ProblemsPartha PrustyNo ratings yet

- Monitoring of Highway Wind Power ParameterDocument4 pagesMonitoring of Highway Wind Power Parameteraruriza100% (2)

- Converters and InterfacesDocument140 pagesConverters and InterfacesMartin LundeenNo ratings yet

- Mahasudarshan ChurnaDocument6 pagesMahasudarshan Churnadrsa2100% (1)

- UCAT AR Cheat SheetDocument3 pagesUCAT AR Cheat Sheetmatthewgao78No ratings yet

- Building Hot Air Balloon ModelsDocument11 pagesBuilding Hot Air Balloon ModelsOkotie-Eboh ToritsejuNo ratings yet

- Dell 1815dn Service Manual PDFDocument150 pagesDell 1815dn Service Manual PDFHugo Manuel Sánchez MartínezNo ratings yet

- MtdbooksDocument4 pagesMtdbooksabraham_imam_muttaqinNo ratings yet

- Experiment Simple Harmonic Motion Group 4Document13 pagesExperiment Simple Harmonic Motion Group 4el lyyNo ratings yet

- S. R. Davies - Spreadsheets in Structural Design 1995 # PDFDocument201 pagesS. R. Davies - Spreadsheets in Structural Design 1995 # PDFNunoNo ratings yet

- Aerodynamic Heating Effects On A Flying Object atDocument5 pagesAerodynamic Heating Effects On A Flying Object atGözde Yıldırım KaradaşNo ratings yet

- Load and Resistance Factor Design (LRFD) For Highway Bridge SubstructuresDocument592 pagesLoad and Resistance Factor Design (LRFD) For Highway Bridge Substructuresv100% (3)

- Electronic Controls in KnittingDocument20 pagesElectronic Controls in KnittingProfessorTextechNo ratings yet

- Laplace TransformDocument28 pagesLaplace TransformLoku VelNo ratings yet

- Siemens Motor Cat.Document92 pagesSiemens Motor Cat.Alberto Villegas50% (2)

- Continuous Stirred Tank Reactor CSTR in Series PDFDocument15 pagesContinuous Stirred Tank Reactor CSTR in Series PDFMuhamad Hafifi AjwadNo ratings yet

- NeQuick Ionospheric Model SoftwareDocument29 pagesNeQuick Ionospheric Model SoftwarePaul DupontNo ratings yet

- CFM and Capacity Calcs 4.5Document9 pagesCFM and Capacity Calcs 4.5hvacrmedicNo ratings yet

- Knight Ch34Document24 pagesKnight Ch34Taylor NicoleNo ratings yet

- FVM Witch OpenFOAM-MatlabDocument817 pagesFVM Witch OpenFOAM-MatlabDavid Mestanza100% (1)