Professional Documents

Culture Documents

TManual Chapter 07

Uploaded by

K Vijay Bhaskar ReddyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TManual Chapter 07

Uploaded by

K Vijay Bhaskar ReddyCopyright:

Available Formats

POWER TRANSFORMER - STANDARDISATION MANUAL

Chapter - 7

Design Review

Working Group Members

Mr. M. Vijayakumaran ALSTOM Ltd

Mr. S. K. Negi

GETCO

Mr. Y. V. Joshi

GETCO

261

262

POWER TRANSFORMER - STANDARDISATION MANUAL

POWER TRANSFORMER - STANDARDISATION MANUAL

CHAPTER - 7

DESIGN REVIEW

1. INTRODUCTION

A design review is a planned exercise to ensure that both parties understand the application and the requirements

of the applicable standards and specification. It is the opportunity for both parties to scrutinize the proposed

design to ensure that the requirements will be met not only technical requirements but also those relating to

other aspects of the contract, like quality. The whole emphasis of a design review is directed at establishing

what is being provided is fit for purpose in all respects for the intended performance in service and that the

manufacturer uses proven materials, design tools, methodology and experience to assure the product will meet

this requirement, also in all respects.

Design reviews implies also to strengthen the relationship between the purchaser and manufacturer and a

good opportunity for the purchaser to better understand the technical capabilities of the manufacturer and for

the manufacturer to understand the need of their customers for the sake to have products adapted to their

needs. Hence the design review is a good opportunity to interchange experiences that can be used to propose

enhancements or betterments. For these reasons it is strongly advisable for the purchaser to have expert

transformer engineer(s) with them during the meeting.

A design review, initiated and chaired by the purchaser should be held for the purpose of conducting an indepth review of the ordered Power Transformer and to allow the purchaser to have a clear understanding of the

transformers design, manufacture and test including the likelihood of operating in service as intended.

The following are the pre-requisites for carrying out the design review:

1.

It is desirable to have vendor assessment of the manufacturer before placement of order.

2. Design review should be part of the tender inquiry and it becomes obligatory on the part of the customer

and manufacturer to ensure compliances with the contract specifications.

3. It is to be ensured that all stake holders are involved in the design review. The designer both mechanical

and electrical, ultimate user, production head and if possible, sub vendor also could be invited for the design

review. Agenda is to be prepared by customer and sent to manufacturer well in advance.

4. Review may include certain informations which are of proprietary nature. It is, therefore, desirable to have

mutual agreement between the purchaser and the manufacturer for the confidentiality of information.

5. It is important for the success of design review that both the purchaser and manufacturer are clear on the

requirements and well prepared to have open and frank sharing of information.

2.

OBJECTIVES OF DESIGN REVIEW

Both the purchaser and manufacturer must understand that following objectives are met during the design

review:

1.

To ensure that there is a clear and mutual understanding of the transformer technical requirements according to purchaser specification and applicable industry standards.

2. To understand the application and verify the system and project requirements and to indicate areas where

special attention may be required.

263

264

POWER TRANSFORMER - STANDARDISATION MANUAL

3.

To verify that the design complies with the technical requirements.

4.

To identify any prototype features and evaluate their reliability and risks.

5. To interchange experiences that can be used to identify eventual betterments in the design and / or improvements and changes in the specification.

6.

To better understand the technical capabilities of the manufacturer.

7.

To strengthen the technical relationship between purchaser and manufacturer and eventually to improve

and go deep in the transformers design knowledge by some participant on the purchasers side.

3.

ELEMENTS OF DESIGN REVIEW

Having understood the purpose of design review and objectives, it is important to know the various elements

of design review which will clear all the doubts about the functionality (application), soundness of designs with

margins, selection of material and components and also specific operating requirements for its designed life.

They are broadly as follows:

S. No.

Elements

1.

System data

2.

Environmental data

3.

Transformer parameters

4.

Transformer design

5.

Transformer ancillaries and accessories.

6.

Transformer oil

7.

Fabrication

8.

Testing

9.

Name plate

10.

Transportation

11.

Site erection, testing & commissioning

12.

Health and safety equipments

13.

Contract documents and drawings

14.

Document submission time scale

POWER TRANSFORMER - STANDARDISATION MANUAL

Design review guidelines of Cigre WGA2.36 (Technical brochure 204) have elaborated above elements in detail

as under:

Sr. No.

Elements of

design review

Check Points

1.

System data

System Voltage Variations

Tap changers

System Frequency Variation

System Short Circuit Capacity

System Switching and Transformer Protection

High Frequency Transients (HFT)

Voltage Transients

Current Harmonics

Geomagnetic Induced Currents

2.

Environmental

data

Ambient temperature range, rate of change of temperature and effect on the overload

capability

Lowest Cold Load Start-up (LCLS)

Solar radiation

Site altitude

Humidity

Pollution

Seismic zone and response spectra

Geomagnetic currents

Ultraviolet (UV) radiation

Isoceraunic level

3.

Transformer

parameters

Alternating Current Terminal Voltages

Insulation Levels line to line and line to ground

Winding Impedances

Cooling Provisions

Temperature Limits

Short Circuit Withstand Capability

Cable Connection Bushings and Isolated Phase Bus Bar Connections

Sound Levels

Losses No load and load losses

Excitation

High Temperature Design

4.

Transformer

design

Core

Windings

Thermal design

The short circuit capability

Core, Winding Assembly and Drying

Leads and Cleats

Insulation Design

Leakage Flux Control

Drying and Processing

Sound Level

Seismic

5.

Transformer

ancillaries and

accessories.

Bushings

Bushing and Internal Current Transformers

Tap Changers

Internal Surge Arresters

Control Cabinet and External Cabling

Online Monitoring Equipment

6.

Transformer oil

Review as per exclusive Chapter 6 of this Manual.

7.

Fabrication

General Construction

External Cooling Equipment

Conservators/Preservation Systems

Fabrication Drawings

Gas Collection System Design

Surface Preparation and Planning

265

266

POWER TRANSFORMER - STANDARDISATION MANUAL

Sr. No.

Elements of

design review

Check Points

8.

Testing

As per Annexure - 7.1

9.

Rating Plate

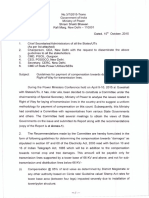

As per figure 7.1

10.

Transportation

Transportation Plan and Handling

Design for Transport

Transportation Shipping Profile

Transportation Routing

Transportation Shipping Impact Withstand

Fixtures on Transformer

Marking of Center of Gravity

Ship and Barge Issues

Rail Car Issues

Road Transport Issues

Transportation monitoring management of transformer

Transportation of transformer accessories, components removed from the transformer

Acceptance criteria for receiving transformer

Transformer Unloading to Foundation

11.

Site erection,

testing &

commissioning

As per the exclusive Chapter 5 of this Manual.

12.

Health and safety

As per guideline and policy of customer. Also refer Chapter - 5 on Erection, Testing and

commissioning of this Manual.

13.

Contract

documents and

drawings

As per Annexure - 7.2.

14.

Document

submission time

scale

As agreed between purchaser and manufacturer.

Design review does not absolve or substitute manufacturers ultimate responsibility for the adequacy of transformer

design and construction, including design limits and margins, quality, performance on test and in service.

POWER TRANSFORMER - STANDARDISATION MANUAL

REFERENCES

The following list may be referred, but this is not a limitation on referring to other standards and codes as long as it

serves the purpose for effective design review.

IEC 60044: Current Transformers.

IEC 60050: International Electrotechnical Vocabulary Chapter 421: Power Transformers and Reactors.

IEC 60060-1: General Definitions and Test Requirements.

IEC 60071-1: Insulation Coordination - Part 1: Definitions, Principles and Rules.

IEC 60071-2: Insulation Coordination - Part 2: Application Guide

IEC 60076-1: Power Transformers - Part 1: General.

IEC 60076-2: Power Transformers - Part 2: Temperature Rise.

IEC 60076-3: Power Transformers - Part 3: Insulation Levels and Dielectric Tests.

IEC 60076-5: Power Transformers - Part 5: Ability to withstand Short-Circuit.

IEC 60076-6: Power Transformers - Part 6: Reactors

IEC 60076-7: Power Transformers - Part 7: Loading guide for oil- immersed Power Transformers.

IEC 60076-8: Power Transformers - Part 8: Application Guide for Power Transformers.

IEC 60076-10: Power Transformers - Part 10: Determination of Transformer and Reactor Sound Levels.

IEC 60076-11: Power transformers - Part 11: Dry-type transformers

IEC 60076-18: Power transformers - Part 18: Measurement of frequency response

IEC 60076-16: Power transformers - Part 16: Transformers for wind turbine applications

IEC 60137: Bushings for Alternating Voltage Above 1000 V.

IEC 60214-1: Tap-Changers - Part 1: Performance requirements and Test Methods.

IEC 60214-2: Tap-Changers - Part 2: Application guide.

IEC 60270: High-voltage test techniques - Partial discharge measurements

IEC 60296: Fluids for Electro-technical applications - Unused mineral insulating oils for transformers and switchgear

IEC 60815-1: Selection and dimensioning of high-voltage insulators intended for use in polluted conditions - Part 1:

Definitions, information and general principles

IEC 60815-2: Selection and dimensioning of high-voltage insulators intended for use in polluted conditions - Part 2:

Ceramic and glass insulators for a.c. systems

IEC 62032: Guide for the Application, Specification and Testing of Phase-Shifting Transformers

Other documents of relevance are:

ISO 9001: Quality System Model for Quality Assurance in Design/Development.

CIGR TB 209: Short Circuit Performance of Power Transformers

CIGR TB 528: Guide for Preparation of Specifications for Power Transformers

CIGR TB 530: Guide for Conducting Factory Capability Assessment for Power Transformers.

267

POWER TRANSFORMER - STANDARDISATION MANUAL

10

400

10

XXX Transformer Pvt. Ltd.

315 MVA 400/220KV AUTO TRANSFORMER

REF. STANDARDS

ONAN/ONAF/OFAF

COOLING

RATING

(HV-MV)

MVA 189/252/315

FREQUENCY

(LV)

MVA 63/84/105

PHASES.

FULL LOAD

CURRENT

BASIC INSU.

LEVEL LI/SI/P.F.

HV

400000

MV

220000

IMPEDANCE

VOLTAGE.

HV-MV(315MVA BASE)

33000

HV

A 272.79/363.73/454.66

VECTOR GROUP REF.

MV

A 495.99/661.32/826.66

CORE MASS

LV

A 1102.21/1469.61/1837.02

kV 1300/1050/630

MV

kV 1050/-/460

LV

kV

250/-/ 95

Neutral

kV

95/-/ 38

OIL

50C at ONAN

55C at ONAF/OFAF

55C at ONAN

60C at ONAF/OFAF

VECTOR GROUP

YNa0d11

2U

3U

3V

1V

MV

2V

3W

1W

MV WTI

2V1S1

2V1S2

2V1S3

2V1S4

2V2S1

2V2S2

2V2S3

2V2S4

CT1W

1V1S1

1V1S2

1V1S3

1V1S4

1V2S1

1V2S2

1V2S3

1V2S4

3W1S2

1W

CT2V

CT1V

CT2U

CT1U

2U1S1

2U1S2

2U1S3

2U1S4

2U2S1

2U2S2

2U2S3

2U2S4

3W1S1

1W1S1

1W1S2

1W1S3

1W1S4

1W2S1

1W2S2

1W2S3

1W2S4

2W1S1

2W1S2

2W1S3

2W1S4

2W2S1

2W2S2

2W2S3

2W2S4

kg.

MASS OF TOTAL OIL

(WITHOUT 10% EXTRA OIL)

kg.

10% EXTRA OIL

kg.

kg.

QUANTITY OF OIL IN OLTC

Ltrs.

TRANSFORMER OIL QUANTITY

(WITHOUT 10% EXTRA OIL)

Ltrs.

CUSTOMER

CHOICE

3

4

5

6

7

8

9

10

11

12

12

3

4

5

6

7

8

9

10

11

12

4

3

12

CTNBF

VN1S4

VN1S3

VN1S2

VN1S1

VN2S4

VN2S3

VN2S2

VN2S1

OFAF

315 MVA

440000

330.66

413.33

13 - 11

435000

250.84

334.46

418.08

13 - 10

430000

253.76

338.35

422.94

13 - 9

425000

256.75

342.33

427.91

13 - 8

420000

259.80

346.41

433.01

13 - 7

415000

262.93

350.68

438.22

13 - 6

410000

266.14

354.85

443.57

13 - 5

405000

269.43

359.24

449.05

9a

13 - 4

400000

272.79

363.73

454.66

9b

13 - 3

400000

272.79

363.73

454.66

9c

13 - 12

400000

272.79

363.73

454.66

10

13 - 11

395000

276.25

368.33

460.41

11

13 - 10

390000

279.79

373.05

466.32

12

13 - 9

385000

283.42

377.90

472.37

13

13 - 8

380000

287.15

382.87

478.59

14

13 - 7

375000

290.98

387.97

484.97

15

13 - 6

370000

294.91

393.22

491.52

16

13 - 5

365000

298.95

398.60

17

13 - 4

360000

303.10

404.14

3-4

3-12

VOLTAGE

L.V

CURRENT VOLTAGE

(V)

220000

(A)

ONAN

495.99

ONAF

661.32

OFAF

826.66

(V)

33000

CURRENT

(A)

ONAN

1102.21

(@63MVA)

ONAF

1469.61

(@84MVA)

OFAF

1837.02

(@105MVA)

498.26

RATIO

AMP.

CORE

NO.

ACC.

CLASS

BURDEN

(VA)

505.18

kpV

(Volt)

Imag

at Vk/2

@2000/1ATap

(in mA)

>

MAX

SEC.RES.

(OHM)

@2000/1ATap

500-1000-2000/1

PS

2000

30

10

CT1W

500-1000-2000/1

PS

2000

30

10

CT2U

500-1000-2000/1

PS

2000

30

10

2000

30

10

CT2V

CTNBF

WN1S4

WN1S3

WN1S2

WN1S1

WN2S4

WN2S3

WN2S2

WN2S1

CT2W

500-1000-2000/1

PS

CTNBF

BEFORE

NEUTRAL

FORMATION

500-1000-2000/1

PS

2000

30

10

500-1000-2000/1

PS

2000

30

10

500-1000-2000/1

MEASURED (KW)

TERMINAL

MARKING

1U1S1-1U1S2-1U1S3-1U1S4

1V1S1-1V1S2-1V1S3-1V1S4

1W1S1-1W1S2-1W1S3-1W1S4

1U2S1-1U2S2-1U2S3-1U2S4

1V2S1-1V2S2-1V2S3-1V2S4

1W2S1-1W2S2-1W2S3-1W2S4

2U1S1-2U1S2-2U1S3-2U1S4

2V1S1-2V1S2-2V1S3-2V1S4

2W1S1-2W1S2-2W1S3-2W1S4

2U2S1-2U2S2-2U2S3-2U2S4

2V2S1-2V2S2-2V2S3-2V2S4

2W2S1-2W2S2-2W2S3-2W2S4

UN1S1-UN1S2-UN1S3-UN1S4

VN1S1-VN1S2-VN1S3-VN1S4

WN1S1-WN1S2-WN1S3-WN1S4

UN2S1-UN2S2-UN2S3-UN2S4

VN2S1-VN2S2-VN2S3-VN2S4

WN2S1-WN2S2-WN2S3-WN2S4

Application

REF.

Differential

REF.

Differential

REF.

Differential

PS

2000

30

10

500-1000-2000/1

PS

2000

30

10

HV WTI

506/2

15

1U3S1-1U3S2

MEASURING

MV WTI

827/2

15

2V3S1-2V3S2

MEASURING

TV WTI

1837/2

15

3W1S1-3W1S2

MEASURING

TMS CT

827/1

2U3S1-2U3S2

MEASURING

CTN

TYPE OF OIL :

VACUUM WITHSTAND CAPABILITY 760 Hg

OLTC RATING & MAKE:

GTD.(KW)

ONAF

252 MVA

247.99

N1S1-N1S2-N1S3-N1S4

N2S1-N2S2-N2S3-N2S4

UN1S4

UN1S3

UN1S2

UN1S1

UN2S4

UN2S3

UN2S2

UN2S1

ONAN

189 MVA

M.V.

(V)

CT1V

13

13

13

VOLTAGE

3

4

5

6

7

8

9

10

11

12

4

3

H.V.

CURRENT(A)

13 - 12

CT1U

TO OLTC

CTNBF

TANK & FITTINGS MASS

CT

1W3S1

kg.

2V3S2

1V

CT2W

2U3S2

1W3S2

HV

3U

3V

3W

2V3S1

1U

TV WTI

2W

2U3S1

12

kg.

TRANSPORTATION MASS

5

2V

2U

CORE & COIL MASS

PRE

OLTC

TAP

CONECTION SELEPOSN.

IN EACH

CTOR

NO.

POSI.

PHASE

2W

HV WTI

kg.

600

1U

CTN

kg.

MV

PAINT SHADE

PO . NO. & DATE

1U1S1

1U1S2

1U1S3

1U1S4

1U2S1

1U2S2

1U2S3

1U2S4

HV

WORK ORDER NO.

N1S1

N1S2

N1S3

N1S4

N2S1

N2S2

N2S3

N2S4

YNa0d11

kg.

TOTAL MASS

YEAR OF MANUFACTURE

TMS CT

REG kg.

MAKER'S SR. NO.

1N

COPPER MASS (BARE)

HV

WDG

TAP.NO.1

TAP NO.9

TAP NO.17 %

LV

GTD. TEMP. RISE

50

3/3

RATED

VOLTAGE

IS:2026

Hz

>

268

REF.

REF.

NOISE LEVEL: ________dB

NO LOAD LOSS

LOAD LOSS

STRAY LOSS

AUXILLIARY LOSS

TAN DELTA OF WINDING : ________%

MOISTURE CONTENT IN ACTIVE PART : ________% of wt.

PROPERTY OF CUSTOMER NAME

7

6-6 Holes.

TYPICAL RATING PLATE FOR POWER TRANSFORMER

A

E

J

Fig. 7.1: Typical Rating Plate

POWER TRANSFORMER - STANDARDISATION MANUAL

ANNEXURE 7.1

TESTING

Sr. no.

Tests, measurements & checks

Dimensions, fittings and equipment

Turns ratio

Polarity & phase relationship

Insulation resistances

Winding resistances

Insulation power factor

Capacitances

Load loss & impedance voltage

Impedance characteristic across tap range

10

Zero-phase-sequence impedance

11

No-load loss & magnetizing current

12

Audible sound

13

Temperature rise

14

Gas in oil analyses

15

Lightning impulse voltage tests

16

Switching impulse voltage tests

17

Applied voltage tests

18

Induced voltage test & partial discharge

19

Single-phase magnetizing current test

20

Oil pressure

21

Control system, components, instruments

22

Ancillary equipment power losses

23

CT checks

24

RSO

25

Frequency Response Analysis (FRA)

26

Tap changer

27

Secondary wiring insulation resistances

28

Oil samples

29

Inventory

30

Contract documents

31

QA records

269

270

POWER TRANSFORMER - STANDARDISATION MANUAL

ANNEXURE 7.2

Contract Documents and Drawings for approval

Sr. No.

Documents

Contract drawings

Certificates

a. ISO Quality Assurance

b. ISO Environmental

c. OHSAS

Product Source Schedule

Production Plan & Reporting Programme

Design Review Minutes

Quality System

Quality Plan

Test Plan

Factory Acceptance Test (FAT) Reports

Transport Plan

10

Transformer Site Commissioning Plan

11

Method Statements

12

Risk Assessments

13

Training

14

Site Works

15

Site Contractor(s) & Supervision.

16

Site Tests

17

Operation & Maintenance Manuals

You might also like

- Sweep Frequency Response Analyser For Power Transformer DiagnosisDocument4 pagesSweep Frequency Response Analyser For Power Transformer DiagnosisK Vijay Bhaskar ReddyNo ratings yet

- Mart 113Document4 pagesMart 113K Vijay Bhaskar ReddyNo ratings yet

- JS530 Indian Association of Physics Teachers National Standard Examination in Junior Science 2016 - 17Document18 pagesJS530 Indian Association of Physics Teachers National Standard Examination in Junior Science 2016 - 17Mayanka SaxenaNo ratings yet

- Solutions To Concepts Chapter 12Document45 pagesSolutions To Concepts Chapter 12dharmender thalorNo ratings yet

- Dynamic Thermal Modelling of Power Transformers: Doctoral DissertationDocument131 pagesDynamic Thermal Modelling of Power Transformers: Doctoral DissertationK Vijay Bhaskar Reddy100% (1)

- MV Circuit Protection DevicesDocument21 pagesMV Circuit Protection DevicesGeetha_jagadish30No ratings yet

- Sel311c 1 & 3 PH Trip & ArDocument5 pagesSel311c 1 & 3 PH Trip & ArK Vijay Bhaskar ReddyNo ratings yet

- Test Procedure Ar Relay p841 ProcedureDocument23 pagesTest Procedure Ar Relay p841 ProcedureK Vijay Bhaskar ReddyNo ratings yet

- HCV Solutions SssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssDocument3 pagesHCV Solutions SssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssAditi SahaiNo ratings yet

- AP Transmission Substation Feeder Metering Circuit Testing ReportDocument2 pagesAP Transmission Substation Feeder Metering Circuit Testing ReportK Vijay Bhaskar ReddyNo ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- 66kV NER PDFDocument5 pages66kV NER PDFDEADMANNo ratings yet

- CT Sizing For Distance RelayDocument6 pagesCT Sizing For Distance Relayjm.mankavil6230No ratings yet

- 33KV Breaker Test ReportDocument2 pages33KV Breaker Test ReportK Vijay Bhaskar ReddyNo ratings yet

- 2.GSM Based Automatic Energy Meter Reading System With Instant BillingDocument6 pages2.GSM Based Automatic Energy Meter Reading System With Instant BillingK Vijay Bhaskar ReddyNo ratings yet

- Guidelines For Payment of Compensation Towards Damages in RegardDocument52 pagesGuidelines For Payment of Compensation Towards Damages in RegardK Vijay Bhaskar ReddyNo ratings yet

- Current Transformer Test ReportDocument3 pagesCurrent Transformer Test ReportK Vijay Bhaskar ReddyNo ratings yet

- Automatic Meter Reading PDFDocument6 pagesAutomatic Meter Reading PDFK Vijay Bhaskar ReddyNo ratings yet

- Design and Implementation of Automatic Meter Reading System Using GSM, ZIGBEE Through GPRSDocument5 pagesDesign and Implementation of Automatic Meter Reading System Using GSM, ZIGBEE Through GPRSReeta DuttaNo ratings yet

- Ijetae 0512 76Document3 pagesIjetae 0512 76Reeta DuttaNo ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- Contribution 295Document6 pagesContribution 295K Vijay Bhaskar ReddyNo ratings yet

- BFP BasicsDocument30 pagesBFP BasicsNeelakandan Masilamani100% (1)

- Capacitor Switching Transient Modeling and Analysis On An ElectriDocument90 pagesCapacitor Switching Transient Modeling and Analysis On An ElectrimemoNo ratings yet

- Sel 311C ArDocument1 pageSel 311C ArK Vijay Bhaskar ReddyNo ratings yet

- Mart 113Document4 pagesMart 113K Vijay Bhaskar ReddyNo ratings yet

- Trip Circuit SupervisionDocument6 pagesTrip Circuit SupervisionNeelakandan MasilamaniNo ratings yet

- E1EEFQ 2010 v5n4 522Document8 pagesE1EEFQ 2010 v5n4 522PatricioNo ratings yet

- Sel311c 1 & 3 PH Trip & ArDocument5 pagesSel311c 1 & 3 PH Trip & ArK Vijay Bhaskar ReddyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit 37: Virtual EngineeringDocument29 pagesUnit 37: Virtual Engineeringamdan srlNo ratings yet

- XVS950 Catalogo de Partes 5S71 - 2009Document72 pagesXVS950 Catalogo de Partes 5S71 - 2009Exiquio SánchezNo ratings yet

- 03232-En-30 Production Capacity PlanDocument4 pages03232-En-30 Production Capacity PlanVivek DhanarajanNo ratings yet

- AWP FinalDocument63 pagesAWP FinalColab PracticalNo ratings yet

- C236Y69AdmitCard PDFDocument1 pageC236Y69AdmitCard PDFvineet tokasNo ratings yet

- CC2500 RF Transceiver ModuleDocument4 pagesCC2500 RF Transceiver ModuleSuraj Vinod NayakNo ratings yet

- N-Bit Shift Register PDFDocument232 pagesN-Bit Shift Register PDFAnuradha KhalkhoNo ratings yet

- NDT Technician Qualification RegisterDocument1 pageNDT Technician Qualification RegisterAli TalebiNo ratings yet

- Vibration Isolation Group ProjectDocument14 pagesVibration Isolation Group ProjectChrispen MapapaNo ratings yet

- Manual Del Operador MILWAUKEEDocument13 pagesManual Del Operador MILWAUKEEING. ZUNIBENo ratings yet

- Carregadro de BateriaDocument5 pagesCarregadro de BateriaDomRuanNo ratings yet

- Python Lists TutorialDocument8 pagesPython Lists Tutorialdnyaneshwar patilNo ratings yet

- Application of 8D Methodology For ProducDocument3 pagesApplication of 8D Methodology For ProducLaura RSNo ratings yet

- The Institute of Computer Accountants: Full Marks: 100 Time: 60 MinDocument2 pagesThe Institute of Computer Accountants: Full Marks: 100 Time: 60 MinLIBIN JOSENo ratings yet

- Find Erotic Novels and Sex Stories PDFsDocument2 pagesFind Erotic Novels and Sex Stories PDFsoggy jack50% (2)

- Install Pacs OneDocument30 pagesInstall Pacs OnePedro OliveiraNo ratings yet

- iFIX Database WhitepaperDocument6 pagesiFIX Database WhitepaperjavierleraNo ratings yet

- GCP Architect Interview QuestionsDocument4 pagesGCP Architect Interview Questionsvardhan72chNo ratings yet

- Broadband Bill JuneDocument1 pageBroadband Bill JunekarthikNo ratings yet

- Restore SAP Oracle Database Backup To Another SAP SystemDocument4 pagesRestore SAP Oracle Database Backup To Another SAP SystemSrinivasarao gadiparthiNo ratings yet

- Laboratory Manual: Analogue and Digital Communication LabDocument16 pagesLaboratory Manual: Analogue and Digital Communication LabData Communication&NetworkNo ratings yet

- Vestel 17mb70 SMDocument68 pagesVestel 17mb70 SMFly Ku0% (1)

- Easypet EP380R User ManualDocument13 pagesEasypet EP380R User Manualea1dofNo ratings yet

- Siddesh ResumeDocument3 pagesSiddesh ResumeSiddesh SrikantaiahNo ratings yet

- Isb DT BrochureDocument23 pagesIsb DT BrochureयोगेशपवारNo ratings yet

- DAMA TechnologyDocument58 pagesDAMA TechnologyAnish BidlanNo ratings yet

- API-1164 Compliance - WhitePaper - AVEVA - Enterprise - SCADA - and - Pipeline - Management - Security - 11-21Document13 pagesAPI-1164 Compliance - WhitePaper - AVEVA - Enterprise - SCADA - and - Pipeline - Management - Security - 11-21marlonlujanNo ratings yet

- W202 Manual Owners C230 Up P99-419 PDFDocument1 pageW202 Manual Owners C230 Up P99-419 PDFpras0% (1)

- WARN 2597 Philips - Neurology Solutions 1.27.20Document4 pagesWARN 2597 Philips - Neurology Solutions 1.27.20Sinclair Broadcast Group - EugeneNo ratings yet

- MCA OU SyllabusDocument55 pagesMCA OU Syllabusnslchandu100% (1)