Professional Documents

Culture Documents

Sammlung GB Thermodur

Uploaded by

Mogos PaulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sammlung GB Thermodur

Uploaded by

Mogos PaulCopyright:

Available Formats

Thermodur

2329

46CrSiMoV7

C 0.45 Si 0.70 Mn 0.80 Cr 1.80 Mo 0.30 Ni 0.60 V 0.20

Steel properties

Excellent tempering resistance, high-temperature strength, full quenching and tempering properties,

outstanding weldability, nitridable, PVD and CVD coatable, good machinability.

Applications

Hot-work tool steel for forging dies, pressure disks for extrusion, mould press dies, and many other applications.

Heat treatment

Soft annealing C

780 800

Hardening C

880 920

Tempering diagram

Cooling

Furnace or air

Hardness HB

max. 230

Quenching

Air, oil or

hot bath, 200 250 C

Hardness after quenching HRC

53 55

Thermodur 2342 EFS

X35CrMoV5-1-1

C 0.35 Si 0.80 Cr 5.00 Mo 1.00 V 0.85

Steel properties

Excellent high-temperature toughness, thermal conductivity, low susceptibility to hot cracking,

may be water-cooled to a limited extent.

Physical properties

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

10.9

11.9

12.3

Applications

Heat treatment

Thermal conductivity

at C

W/(m K)

20

24.5

20 400 20 500

12.7

13.0

350

26.8

20 600 20 700

13.3

13.5

700

28.8

Mandrel bars, pressure casting dies, and extrusion tools.

Soft annealing C

750 800

Hardening C

1000 1040

Tempering C

HRC

Cooling

Furnace

Hardness HB

max. 230

Quenching

Air, oil or

hot bath, 500 550 C

Hardness after quenching HRC

53

100

52

200

50

300

49

400

49

500

50

550

49

600

46

650

36

700

26

Time-temperaturetransformation

diagram

Reduction of area Z in %

Tempering diagram/

High-temperature

strength diagram

Thermodur 2343 EFS / 2343 EFS Superclean

X37CrMoV5-1

C 0.38 Si 1.00 Cr 5.30 Mo 1.30 V 0.40

Steel properties

Outstanding high-temperature strength and toughness. Excellent thermal conductivity and low susceptibility

to hot cracking. May be water-cooled to a limited extent.

Standards

AISI H11

Physical properties

AFNOR Z38CDV5

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

11.8

12.4

12.6

20 400 20 500

12.7

12.8

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

350

30.0

27.3

20

29.8

26.8

20 600 20 700

12.9

12.9

700

33.4

30.3

Applications

Hot-work tool steel for universal use. Mandrel bars, pressure casting dies, and extrusion tools. Pressure casting

dies and extrusion tools for light metal processing, forging dies, mandrels, shrink rings, hot-shear blades.

For your most challenging requirements, we recommend Thermodur 2343 EFS Superclean (ESR).

Soft annealing C

750 800

Heat treatment

Hardening C

1000 1030

Tempering C

HRC

Time-temperaturetransformation

diagram

Tempering diagram

Cooling

Furnace

Hardness HB

max. 230

Quenching

Air, oil or

hot bath, 500 550 C

Hardness after quenching HRC

54

100

52

200

52

300

52

400

52

500

54

550

52

600

48

650

38

700

31

37055_KFS_T2_neu.qxd:Layout 1

Thermodur

X40CrMoV5-1

Steel properties

Standards

Physical properties

04.02.2009

16:08 Uhr

Seite 9

2344 EFS / 2344 EFS Superclean

Heat treatment

(50CrMoV13-15)

Steel properties

High hot-wear resistance, high hot tensile strength and toughness. Good thermal conductivity and

insusceptibility to hot cracking. Can be water-cooled to a limited extent.

AISI H13

AFNOR Z40CDV5

Coefficient of thermal expansion

at C

20 100 20 200

10-6 m/(m K)

10.9

11.9

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

Applications

Cryodur

C 0.40 Si 1.00 Cr 5.30 Mo 1.40 V 1.00

Standards

20 300

12.3

20 400

12.7

20

27.2

25.5

20 500

13.0

20 600

13.3

350

30.5

27.6

Physical properties

20 700

13.5

700

33.4

30.3

Hot-work steel for universal use. Pressure casting moulds and metal extrusion tools for processing light

metals, forging moulds, moulds, screws and barrels for plastic processing, nitrided ejectors and hot-shear

blades.

We recommend the use of Thermodur 2344 EFS Superclean (ESR) for the highest demands.

Applications

Heat treatment

2357

C 0.50 Si 0.30 Mn 0.70 Cr 3.35 Mo 1.60 V 0.25

High toughness and wear resistance, high compression strength combined with dimensional stability and

good polishability.

AISI S7

Coefficient of thermal expansion

at C

20 200

10-6 m/(m K)

12.2

20 400

12.5

Thermal conductivity

at C

W/(m K)

200

30.0

20

28.9

Cold-work tool steel for punching tools, moulds, scrap shears, piercing dies, hobbers, coining dies, deburring

tools, plastic moulds and pelleters.

Soft annealing C

610 650

Cooling

Furnace

Hardness HB

approx. 220

Soft annealing C

750 800

Cooling

Furnace

Hardness HB

max. 230

Stress-relief annealing C

approx. 600

Cooling

Furnace

Hardening C

1010 1030

Quenching

Air, oil or

saltbath, 500 550 C

Hardness after quenching HRC

54

Hardening C

920 970

Quenching

Air or oil

Tempering C

HRC

100

53

Tempering C

HRC

100

60

200

52

300

52

400

54

500

56

550

54

600

50

650

42

700

32

Formadur

X91CrMoV18

Time-temperaturetransformation

diagram

Steel properties

1200

Physical properties

1100

1000

Ac1e

Temperature in C

900

Ac1b

800

700

F+C

3 20

A+C

100

100

600

Applications

500

Heat treatment

400

300

200

100

0

MS

10 15 B

3055

599

Hardness

707 681 673

HV 10

100

Time in s

101

102

100

Time in min

657

642

634 572

103

101

236

488 219

104

102

100

Time in h

105

106

103

101

200

58

300

54

400

53

Coefficient of thermal expansion

at C

20 100

10-6 m/(m K)

10.5

20 200

11.0

Thermal conductivity

at C

W/(m K)

20

29

Soft annealing C

800 850

Cooling

Slow, e.g. furnace

Hardness HB

max. 265

Hardening C

1000 1050

Quenching

Oil

Hardness after quenching HRC

59

Tempering C

HRC

100

58

200

56

300

54

400

54

550

50

600

40

102

Tempering diagram Cryodur 2357

66

62

62

62

58

58

58

Hardness in HRC

66

54

50

46

54

50

46

42

42

42

38

38

38

34

34

34

30

30

100 200 300 400 500 600 700 800

Tempering temperature in C

500

54

104

66

20 400

12.0

Plastic moulds, injection nozzles, valve components and ball bearings.

70

46

600

44

20 300

11.0

70

50

550

50

Corrosion-resistant steel for plastic moulding characterized by a very good wear resistance.

70

54

500

53

C 0.90 Si < 1.00 Cr 18.00 Mo 1.00 V 0.10

Hardness in HRC

Hardness in HRC

Hardness after quenching HRC

60 62

2361

Tempering diagram Formadur 2361

Tempering diagram

400

31.0

30

0

100 200 300 400 500 600 700 800

Tempering temperature in C

100 200 300 400 500 600 700 800

Tempering temperatue in C

Reference numbers in brackets are not standardized in

EN ISO 4957.

39

Thermodur 2365 EFS / 2365 EFS Superclean

32CrMoV12-28

C 0.32 Cr 3.00 Mo 2.80 V 0.50

Steel properties

Excellent high-temperature strength and tempering resistance, thermal conductivity, low susceptibility to

hot cracking. May be water-cooled to a limited extent. Suitable for cold hobbing.

Standards

AISI H10

Physical properties

Applications

Heat treatment

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

11.8

12.5

12.7

20 400 20 500

13.1

13.5

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

350

34.5

32.0

Soft annealing C

750 800

Tempering C

HRC

Tempering diagram

20

32.8

31.4

20 600 20 700

13.6

13.8

700

32.2

29.3

Press and piercing mandrels, die inserts, heavy metal die casting tools.

For your most challenging requirements, we recommend Thermodur 2365 EFS Superclean (ESR).

Hardening C

1030 1050

Time-temperaturetransformation

diagram

AFNOR 32CDV12-28

Cooling

Furnace

Hardness HB

max. 185

Quenching

Oil or

hot bath, 500 550 C

Hardness after quenching HRC

52

100

51

200

50

300

50

400

50

500

52

550

50

600

47

650

40

700

34

Thermodur 2365 EFS / 2365 EFS Superclean

High-temperature

strength diagram

Reduction of area Z in %

Creep behavior

Thermodur 2367 EFS / 2367 EFS Superclean

~X38CrMoV5-3

Steel properties

Physical properties

C 0.37 Cr 5.00 Mo 3.00 V 0.60

Excellent high-temperature strength and tempering resistance, good hardenability, minimal warpage.

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

11.9

12.5

12.6

20 400 20 500

12.8

13.1

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

350

33.5

33.9

20

30.8

29.8

20 600 20 700

13.3

13.5

700

35.1

35.3

Applications

Forging dies, die casting dies, die holders, extrusion dies for heavy metals, inner liner for light metals,

profiling dies, and mandrels.

For your most challenging requirements, we recommend Thermodur 2367 EFS Superclean (ESR).

Soft annealing C

730 780

Heat treatment

Hardening C

1020 1050

Tempering C

HRC

Time-temperaturetransformation

diagram

Tempering diagram

Cooling

Furnace

Hardness HB

max. 235

Quenching

Air, oil or

hot bath, 500 550 C

Hardness after quenching HRC

57

100

57

200

55

300

53

400

52

500

55

550

55

600

52

650

45

700

36

Thermodur 2367 EFS / 2367 EFS Superclean

High-temperature

strength diagram

Reduction of area Z in %

Creep behavior

37058_KAS_GB_T2_neu.qxd:EWK_Imagebroschre-final_21.9.

Thermodur

55NiCrMoV7

Steel properties

Standards

Physical properties

Heat treatment

12:52 Uhr

Seite 31

2714

Cryodur

C 0.56 Cr 1.10 Mo 0.50 Ni 1.70 V 0.10

(50NiCr13)

Tough die steel with high tempering resistance and good through-hardening properties. This grade is

usually supplied in annealed condition or quenched and tempered to a working hardness of 370 to 410 HB

(round) or 355 to 400 HB (square, flat).

AISI ~L6

Steel properties

Physical properties

AFNOR 55NCDVV7

Coefficient of thermal expansion

at C

20 100

10-6 m/(m K)

12.2

Thermal conductivity

at C

W/(m K)

Applications

04.02.2009

20 200

13.0

20 300

13.3

20

36.0

20 400

13.7

20 500

14.2

350

38.0

20 600

14.4

Applications

Heat treatment

700

35.0

Standard steel for forging dies of all types, press dies, extrusion dies, retainer plates, armoured trim dies,

hot-shear blades and tool holders.

Soft annealing C

650 700

Cooling

Furnace

Hardness HB

max. 250

Hardening C

830 870

860 900

Quenching

Oil

Air

Hardness after quenching HRC

58

56

Tempering C

after quenching

in Oil HRC

in Air HRC

100

200

300

400

450

500

550

600

650

57

55

54

52

52

50

49

47

47

45

46

43

43

40

38

36

34

32

Time-temperaturetransformation

diagram

Cooling curves for round bar cores with

50, 100 and 200 mm dia. on oil hardening

1000

C 0.55 Si 0.25 Mn 0.45 Cr 1.00 Ni 3.10

Air or oil-hardenable steel with good machinability and high toughness.

Thermal conductivity

at C

W/(m K)

Cooling

Furnace

Stress-relief annealing C

approx. 600

Cooling

Furnace

Hardening C

840 870

Quenching

Oil or

saltbath, 180 220 C

Hardness after quenching HRC

59

Tempering C

HRC

100

59

400

48

500

44

600

40

A+C

20

500

0,34

0,91

1,28 2,2

50

400

2,5

1,25 0,8

100

0,4

0,2 K/min

5,4

200 mm Dmr.

100

MS

5 15

95

88

60

80 38

RA =

Hardness

8 8 740

101

102

100

Time in min

103

101

12

14

16 7

380 345 270

104

102

100

Time in hr

240

105

106

103

101

1.0

2.5

6.8

B

MS

45

2 30

M

831

HV 10

100

Time in sec

101

100

786

730 709

102

100

Time in min

2,5 K/min

5 K/min

1.25 K/min

497 469 345

101

70

Hardness in HRC

58

54

Oil

46

Air

54

50

46

42

42

38

38

34

34

Reference numbers in

brackets are not standardized

in EN ISO 4957.

30

0

100 200 300 400 500 600 700 800

Tempering temperature in C

69

297

268

104

102

100

Time in hr

58

0.4 K/min

65

103

102

62

Ac1b

100

100

661

Hardness

104

62

100 200 300 400 500 600 700 800

Tempering temperature in C

0.28

2 F

90

20 K 10 K

400

66

30

0.16

500

66

50

+C

100

Tempering diagram

70

600

200

8

760 760 758 755 705 560 450 410

HV 10

700

300

100

10

100

Ac1e

800

Time in sec

Hardness in HRC

300

52

1100

Temperature in oC

Temperature in oC

Ac1b (0,4 K/min)

P

15 60

600

200

56

900

200

Tempering diagram

Hardness HB

max. 250

1200

Ac1e (0,4 K/min)

700

700

31.8

1000

800

100

350

31.2

Soft annealing C

610 650

900

300

20

31.0

Cold heading dies, hobbers, cutlery dies, reinforcements and pelleters.

Time-temperaturetransformation

diagram

1200

1100

2721

246

105

106

103

101

104

102

Thermodur 2740

28NiCrMoV10

C 0.28 Cr 0.70 Mo 0.60 Ni 2.50 V 0.30

Steel properties

Air-hardening special steel for hot working. Outstanding high-temperature toughness and thermal shock

resistance.

Applications

Special steel for mandrels and pilger mandrels. We generally supply the rough-machined or fully machined

tools in tempered condition.

Soft annealing C

670 700

Cooling

Furnace

Hardness HB

max. 240

Hardening C

840 870

Quenching

Air or oil

Hardness after quenching HRC

49

Heat treatment

Tempering diagram

Thermodur 2782 Superclean

X16CrNiSi25-20

C 0.15 Si 2.00 Mn 0.80 Cr 25.00 Ni 20.00

Steel properties

Non-scaling, austenitic hot-work tool steel, which is resistant to oxidizing environments and displays good

cold workability. Resistant to scaling in air up to approx. 1150 C. Delivered in precipitation hardened

condition 650 800 MPa.

Physical properties

Coefficient of thermal expansion

at C

10-6 m/(m K)

20 200

16.5

Thermal conductivity

at C

W/(m K)

20

13.0

20 400

17.0

20 600

17.5

700

19.0

Applications

Tools for glass product manufacturing, such as punches, couplers, blowing iron heads and mandrels,

orifices, blowpipes, and gathering irons.

Soft annealing C

1000 1100

Heat treatment

Quenching

Air or water

Hardness after quenching MPa

495 705

Thermodur 2787 / 2787 Superclean

X23CrNi17

C 0.22 Si 0.40 Mn 0.50 Cr 16.50 Ni 1.70

Steel properties

Physical properties

Applications

Heat treatment

Corrosion and scaling resistant hot-work tool steel, which can easily be tempered.

Coefficient of thermal expansion

at C

20 100 20 200

10-6 m/(m K)

10.0

10.5

Thermal conductivity

at C

W/(m K)

20 500

11.0

20

25.0

Tools for glass product manufacturing

For your most challenging requirements, we recommend Thermodur 2787 Superclean.

Soft annealing C

710 750

Hardening C

990 1020

Tempering C

after quenching

in oil HRC

Tempering diagram

20 300 20 400

11.0

11.0

Cooling

Ofen

Hardness HB

max. 245

Quenching

Oil or

hot bath, 200 C

Hardness after quenching HRC

47

100

200

300

400

500

600

46

45

45

44

43

36

Thermodur 2999 EFS Superclean

X45MoCrV5-3-1

C 0.45 Si 0.30 Mn 0.30 Cr 3.00 Mo 5.00 V 1.00

Steel properties

Maximum high-temperature strength, good high-temperature wear resistance, excellent thermal shock

resistance and thermal conductivity across the entire range of service temperatures.

Physical properties

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

11.3

11.9

12.2

20 400 20 500

12.6

13.0

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

350

39.5

35.2

20

37.8

31.4

20 600 20 700

13.3

13.5

700

39.5

36.2

Applications

Die inserts and high-speed forging tools exposed to severe wear stresses, heavy metal die casting,

hot-work tool steels for use at highest temperatures.

Soft annealing C

750 800

Heat treatment

Hardening C

1070 1100

Tempering C

HRC

Time-temperaturetransformation

diagram

Tempering diagram

Cooling

Furnace

Hardness HB

max. 230

Quenching

Oil or

hot bath, 500 550 C

Hardness after quenching HRC

57

100

55

200

54

300

54

400

55

500

56

550

57

600

53

650

46

Thermodur E 38 K

approx. X35CrMoV5-1

C 0.35 Si 0.30 Mn 0.30 S < 0.003 Cr 5.00 Mo 1.35 V 0.45

Steel properties

Outstanding high-temperature strength and improved toughness. Excellent thermal conductivity and low

susceptibility to hot cracking. May be water-cooled to a limited extent.

Physical properties

Coefficient of thermal expansion

at C

20 100 20 200 20 300

10-6 m/(m K)

11.8

12,4

12,6

20 400 20 500

12,7

12,8

Thermal conductivity

at C

W/(m K) Annealed

W/(m K) Quenched and tempered

350

30.0

27.3

20

29.8

26.8

20 600 20 700

12,9

12,9

700

33.4

30.3

Applications

Hot-work tool steel for universal use, which is particularly suitable for applications involving high flexural

stresses due to its outstanding toughness.

Extrusion tools for light metal processing

Die casting tools for light metal processing

Soft annealing C

740 780

Heat treatment

Hardening C

1000 1030

Tempering C

HRC

Time-temperaturetransformation

diagram

Tempering diagram

Cooling

Furnace

Hardness HB

max. 200

Quenching

Oil or

hot bath, 500 550 C

Hardness after quenching HRC

53

100

51

200

51

300

51

400

51

500

52

550

50

600

47

650

34

You might also like

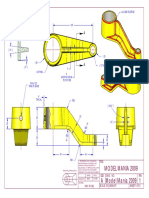

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- Model Mania 2009Document1 pageModel Mania 2009Mogos PaulNo ratings yet

- Model Mania 2009 PDFDocument1 pageModel Mania 2009 PDFMogos PaulNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- Contribution To Improving The Durability of The Refractory Lining of The Steel LadlesDocument20 pagesContribution To Improving The Durability of The Refractory Lining of The Steel LadlesMogos PaulNo ratings yet

- Journal of Asian Ceramic Societies: Pardeep Sharma, Satpal Sharma, Dinesh KhandujaDocument5 pagesJournal of Asian Ceramic Societies: Pardeep Sharma, Satpal Sharma, Dinesh KhandujaMogos PaulNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Document1 pageProduced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Mogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Tabla 3 MMDocument1 pageProduced by An Autodesk Educational Product: Tabla 3 MMMogos PaulNo ratings yet

- Din 332 PDFDocument5 pagesDin 332 PDFMogos Paul100% (2)

- Produced by An Autodesk Educational Product: Pozitia 7 - 1 Bucati Desen: 24399851Document1 pageProduced by An Autodesk Educational Product: Pozitia 7 - 1 Bucati Desen: 24399851Mogos PaulNo ratings yet

- 6 PDFDocument1 page6 PDFMogos PaulNo ratings yet

- 1.2714 55NiCrMoV7Document2 pages1.2714 55NiCrMoV7Mogos PaulNo ratings yet

- 27 PDFDocument1 page27 PDFMogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Document1 pageProduced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Mogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Document1 pageProduced by An Autodesk Educational Product: Pozitia 3 - 2 Bucati Desen: 24399851Mogos PaulNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- 6 PDFDocument1 page6 PDFMogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Tabla 3 MMDocument1 pageProduced by An Autodesk Educational Product: Tabla 3 MMMogos PaulNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMogos PaulNo ratings yet

- Produced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Document1 pageProduced by An Autodesk Educational Product: Pozitia 4 - 1 Bucati Desen: 24399851Mogos PaulNo ratings yet

- 55 Nicrmov 7Document2 pages55 Nicrmov 7Mogos PaulNo ratings yet

- E 355Document3 pagesE 355Mogos PaulNo ratings yet

- 57nicrmov7 7Document2 pages57nicrmov7 7Mogos PaulNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Supplier Assesment MaxionDocument23 pagesSupplier Assesment Maxionesivaks2000No ratings yet

- BarillaDocument3 pagesBarillaMohit Pandey0% (1)

- Promo Mors Smitt enDocument20 pagesPromo Mors Smitt enYigit SarıkayaNo ratings yet

- Fast Reactive FashionDocument9 pagesFast Reactive FashionBetty Tang100% (2)

- President P&L Aerospace Manufacturing in Washington DC Resume Rick HundleyDocument3 pagesPresident P&L Aerospace Manufacturing in Washington DC Resume Rick HundleyRickHundleyNo ratings yet

- 280 Group Brochure Catalog Data Sheets 2014Document28 pages280 Group Brochure Catalog Data Sheets 2014kamayani_prNo ratings yet

- Chapter 12 - Inventory ManagementDocument46 pagesChapter 12 - Inventory ManagementHuzaifa AzamNo ratings yet

- 7 Managing of Economics of Scale Ekstensi2014Document45 pages7 Managing of Economics of Scale Ekstensi2014Ghassani Herning PraditaNo ratings yet

- January, 31, 2008: Starbucks Will Open 75 More Stores Abroad ThanDocument25 pagesJanuary, 31, 2008: Starbucks Will Open 75 More Stores Abroad ThanRosalbaRodriguezSandovalNo ratings yet

- Assignment 6 CH 16 OM12EDocument11 pagesAssignment 6 CH 16 OM12EMuhammad FauzanNo ratings yet

- Lean Chapter 4Document15 pagesLean Chapter 4WinterMist11No ratings yet

- ESKA Brochure enDocument4 pagesESKA Brochure enfdstrdhgtrgNo ratings yet

- FLinfo ENDocument146 pagesFLinfo ENAbhishek NaikNo ratings yet

- Ballou 01Document10 pagesBallou 01Laila NaqviNo ratings yet

- EY Re Engineering The Supply Chain For The Omni Channel of TomorrowDocument39 pagesEY Re Engineering The Supply Chain For The Omni Channel of Tomorrowtluo001No ratings yet

- TPAO-KTHDB PremiumThread TubingTechSpecSheet PH6Document1 pageTPAO-KTHDB PremiumThread TubingTechSpecSheet PH6ilkerkozturkNo ratings yet

- Guidelines For Waste Management SystemDocument3 pagesGuidelines For Waste Management SystemHero MondaresNo ratings yet

- G CODES For VMC and HMCDocument4 pagesG CODES For VMC and HMCNIkhileshNo ratings yet

- Product Units Sold Unit Price Total Order Date Ship DateDocument67 pagesProduct Units Sold Unit Price Total Order Date Ship DateBHAVESH KHOMNENo ratings yet

- MMR - Supply Chain Management and Demand Chain ManagementDocument7 pagesMMR - Supply Chain Management and Demand Chain Managementmadhpan100% (1)

- Iatf 16949Document149 pagesIatf 16949Mahardhika Frangeidie100% (1)

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Document1 pageEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraNo ratings yet

- Kaoru Ishikawa - The Man Behind The Fishbone DiagramDocument3 pagesKaoru Ishikawa - The Man Behind The Fishbone DiagramMuhammad Tahir NawazNo ratings yet

- B2B Marketing & Tetra PakDocument30 pagesB2B Marketing & Tetra PakVivek DwivediNo ratings yet

- Contoh Company ProfileDocument28 pagesContoh Company ProfileSendy Rindi FebriyantoNo ratings yet

- ITIL Guidance Kanban WebsiteDocument28 pagesITIL Guidance Kanban WebsiteLuis GonzálezNo ratings yet

- Tsinukal BezabihDocument101 pagesTsinukal BezabihGetahunNo ratings yet

- Sanmina PCB CasestudyDocument2 pagesSanmina PCB CasestudysmalcomNo ratings yet

- Lean GlossaryDocument7 pagesLean GlossaryJorge VicenteNo ratings yet

- SAP Production Planning TutorialDocument83 pagesSAP Production Planning TutorialRamanpal Singh Anand89% (9)