Professional Documents

Culture Documents

1 SATIP-D-109-01 Shop Fab Storage Tank PDF

Uploaded by

JithuJohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 SATIP-D-109-01 Shop Fab Storage Tank PDF

Uploaded by

JithuJohnCopyright:

Available Formats

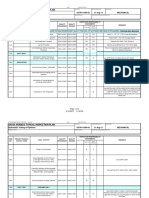

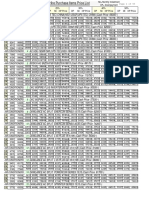

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SHOP FABRICATED STORAGE TANK INSTALLATION

(UL-142 or API SPEC 12F & 12P)

SATIP-D-109-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

Activity Code

1.0

DOCUMENT REVIEW

2.0

WBS/BI/JO/NO.

TASK / ACTIVITY

Tank Data Sheet & Safety Instruction

Sheet

1.1

APPROVED DATE

QUALITY

PROCEDURE

QUALITY

RECORD

SAIC-D-2014

DISCIPLINE:

25-May-05

Mechanical

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

SAIC-D-2014

RH1

RH1

REMARKS

MATERIAL RECEIVING

2.1

External Visual Inspection and

Verification of Tank and its external

appurtenances

SAIC-D-2015

SAIC-D-2015

W1

W1

2.1

Internal Visual Inspection Tank and its

internal appurtenances

SAIC-D-2016

SAIC-D-2016

W1

W1

2.2

Fabricated Piping Spool Inspection (if

applicable) at nozzles.

2.3

Storage, Handling & Tank Preservation

2.4

Verification & Visual inspection of vendor

supplied electrical & instrumentation

Refer to the respective SATIPs for Electrical &

Instrumentation: ( SATIP-P-113-01, P-515-01, J-10001, J-200-01, J-300-01, J-902-03)

3.1

Concrete Placement

Refer to SATIP-Q-001-02

3.2

Trench Preparation and backfilling for

Buried Tanks

Refer to SATIP-S-070-01 & SATIP-A-114-01

3.3

Grounding

Refer to SATIP-P-111-01

3.4

Pre-Installation Inspection

3.5

Cathodic Protection (if required for tank

bottom an/or internal shell)

3.6

Inspection of buried tank installation

SAIC-D-2017

SAIC-D-2017

H1

H1

3.7

Under-Tank Leak detection & Sub-grade

Protection (if required)

SAIC-D-2018

SAIC-D-2018

H1

H1

3.0

Refer to SATIP-L-350-01

SAIC-D-2005

SAIC-D-2005

W1

INSTALLATION

SAIC-D-2006

SAIC-D-2006

H1

W1

Refer to SATIP X-600-02 or J-500-01(Internal CP)

as applicable

Page 1 of 4

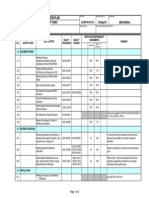

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SHOP FABRICATED STORAGE TANK INSTALLATION

(UL-142 or API SPEC 12F & 12P)

SATIP-D-109-01

PROJECT TITLE:

ITEM

NO.

APPROVED DATE

WBS/BI/JO/NO.

PROJECT PHASE &

Activity Code

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

SAIC-D-2019

SATR-D-2001

OR

SATR-D-2002

SAIC-D-2019

SATR-D-2001

OR

SATR-D-2002

DISCIPLINE:

25-May-05

Mechanical

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

H1

W1

REMARKS

3.8

Tank Erection (above ground)

3.9

Grouting (if required)

Refer to SATIP-Q-010-01

3.10

Hook-up of vendor supplied electrical &

instrumentation

Refer to the respective SATIPs for Electrical &

Instrumentation: ( SATIP-P-113-01, P-515-01, J-10001, J-200-01, J-300-01, J-902-03)

3.11

Piping Installation

Refer to SATIP-L350-01

3.12

Tank Trim installation

3.13

Hydrotesting and Settlement Verification

3.14

Verification & Visual inspection of vendor

supplied electrical & instrumentation

Refer to the respective SATIPs for Electrical &

Instrumentation: ( SATIP-P-113-01, P-515-01, J-10001, J-200-01, J-300-01, J-400-01, J-902-03)

3.15

Block valves installation

Refer to SATIP-L-108-01

3.16

Relief/Vacuum Valve installation

inspection

Refer to SATIP-J-600-01

3.17

Flange Joint Inspection

3.18

Structural Attachments & Access

Refer to SATIP-M-001-01

3.19

External Coating, Color coding &

Identification

Refer to applicable SATIP-H Series

3.20

Insulation

Refer to SATIP-N-001-01 or SATIP-N-001-02,

whichever is applicable

4.0

SAIC-D-2020

SAIC-D-2020

H1

W1

TBA

TBA

H1

H1

SAIC-L-2014

SAIC-L-2014

W1

W2

See Note 1 of the General Notes and minimum of

10%, thereafter.

PRE-COMMISSIONING

4.1

Tank Closure Inspection

4.2

Instrumentation and electrical precommissioning

SATR-D-2003

SATR-D-2003

H1

H1

Refer to the respective SATIPs for Electrical &

Instrumentation

Page 2 of 4

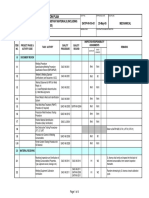

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SHOP FABRICATED STORAGE TANK INSTALLATION

(UL-142 or API SPEC 12F & 12P)

SATIP-D-109-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

Activity Code

APPROVED DATE

WBS/BI/JO/NO.

TASK / ACTIVITY

4.3

Punch Listing/Final Inspection of Tank

Installation

4.4

MCC Punchlisting

4.5

Tightness test or Service test

QUALITY

PROCEDURE

QUALITY

RECORD

SAIC-D-2021

SAIC-D-2021

SATR-A-2011

25-May-05

Mechanical

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

H1

SA-6133

(FEIL)

REMARKS

H1

W1

Page 3 of 4

DISCIPLINE:

W1

Refer to SATIP-A-004-05

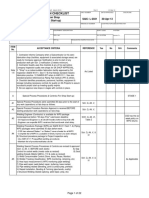

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SHOP FABRICATED STORAGE TANK INSTALLATION

(UL-142 or API SPEC 12F & 12P)

SATIP-D-109-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

Activity Code

APPROVED DATE

WBS/BI/JO/NO.

QUALITY

PROCEDURE

TASK / ACTIVITY

QUALITY

RECORD

DISCIPLINE:

25-May-05

Mechanical

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

REMARKS

SAUDI

ARAMCO

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust

the levels of Saudi Aramco participation based upon the Contractors performance.

Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization

Witness:

QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC organization

representative is not present.

Hold:

QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in

attendance.

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

LEGEND

W1

100% Witness Inspection/Test

H2

Sample Hold Point for QC Inspection or Test

RH1 100% Review and Approval of Documents

W2

Sample Witness Inspection/Test

R1

100% Review of Documents

RH2 Sample Review and Approval of Documents

H1

100% Hold Point for QC Inspection or Test

R2

sample Review of Documents

Page 4 of 4

Surveillance

You might also like

- 175 043600Document2 pages175 043600Abu Anas M.SalaheldinNo ratings yet

- SATIP D 001 01 (Revision 4)Document3 pagesSATIP D 001 01 (Revision 4)Anonymous 4e7GNjzGW100% (1)

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- Pressure Vessel Exm QuestionsDocument4 pagesPressure Vessel Exm QuestionsJithuJohn100% (1)

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- OET Test 3 Listening Answers - Part A and BDocument6 pagesOET Test 3 Listening Answers - Part A and BJithuJohn100% (1)

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Top RCC Questions Asked in SSC JEDocument41 pagesTop RCC Questions Asked in SSC JEaman67% (9)

- C 1197 - 04 - QzexotcDocument5 pagesC 1197 - 04 - QzexotcDipesh Chandra BaruaNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- 1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFDocument4 pages1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFWIZKHALIFANo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Document3 pages1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- 175 010700 PDFDocument2 pages175 010700 PDFAbu Anas M.SalaheldinNo ratings yet

- PIPELINE WELD NUMBERING SYSTEMDocument9 pagesPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- 175 060100Document1 page175 060100Abu Anas M.SalaheldinNo ratings yet

- 175 030100Document2 pages175 030100Abu Anas M.Salaheldin100% (1)

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Reinstatement Procedure ChecklistDocument5 pagesSaudi Aramco Reinstatement Procedure ChecklistpravinNo ratings yet

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saudi Aramco pipe inspection requirementsDocument1 pageSaudi Aramco pipe inspection requirementsAbu Anas M.Salaheldin100% (1)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanAhdal NoushadNo ratings yet

- 01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsDocument18 pages01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsWHWEN100% (1)

- Saes W 011Document2 pagesSaes W 011hendraox3996No ratings yet

- SAUDICO Pipe Fabrication Shop Approval ChecklistDocument22 pagesSAUDICO Pipe Fabrication Shop Approval Checklistabdulgafoor54100% (2)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- Juba Export Refinery Piping Quality ProcedureDocument15 pagesJuba Export Refinery Piping Quality ProcedureMd ShariqueNo ratings yet

- Inspection Report: Vaccum Test RecordDocument21 pagesInspection Report: Vaccum Test RecordWahyudi MetrizaNo ratings yet

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- SAIC-W-2006 Rev 0Document4 pagesSAIC-W-2006 Rev 0philipyap100% (2)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saudi Aramco PMI checklist ensures alloy purityDocument5 pagesSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNo ratings yet

- QC Piping Inspector Duties & ResponsibilitiesDocument11 pagesQC Piping Inspector Duties & Responsibilitiesmohammad atif aliNo ratings yet

- Inspection and Test Plan For Pressure Vessel Repair, Modification, AlterationDocument5 pagesInspection and Test Plan For Pressure Vessel Repair, Modification, AlterationMuhammed Abo-Fandood50% (2)

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection ChecklistAhdal NoushadNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- Pressure Vessel Dimension InspectionDocument2 pagesPressure Vessel Dimension InspectionNorman MoralesNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANDocument3 pagesSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- 2015 Rev-Ect Feb 17 ListDocument7 pages2015 Rev-Ect Feb 17 ListJithuJohnNo ratings yet

- 2015 Rev-Ect Feb 17 ListDocument7 pages2015 Rev-Ect Feb 17 ListJithuJohnNo ratings yet

- Canada RN CCNDocument1 pageCanada RN CCNJithuJohnNo ratings yet

- Canada RN CCNDocument1 pageCanada RN CCNJithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- Hy Are Jews So SmartDocument2 pagesHy Are Jews So SmartJithuJohnNo ratings yet

- 21a1004 02Document1 page21a1004 02JithuJohnNo ratings yet

- Resume Ofjithu John (API, CSWIP & ASNT)Document6 pagesResume Ofjithu John (API, CSWIP & ASNT)JithuJohnNo ratings yet

- Hy Are Jews So SmartDocument2 pagesHy Are Jews So SmartJithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- 1-3 Email Nurse - Role PlayDocument2 pages1-3 Email Nurse - Role PlayJithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionJithuJohn100% (3)

- Aramco QuestionDocument72 pagesAramco QuestionZuberYousuf100% (1)

- Aramco QuestionDocument72 pagesAramco QuestionZuberYousuf100% (1)

- Pumps API 610Document2 pagesPumps API 610JithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- QADocument3 pagesQAJithuJohnNo ratings yet

- Aramco vendor inspection for line pipe API standardsDocument3 pagesAramco vendor inspection for line pipe API standardsJithuJohnNo ratings yet

- CopyDocument2 pagesCopyJithuJohnNo ratings yet

- Welding AnswersDocument4 pagesWelding AnswersJithuJohnNo ratings yet

- Resume Ofjithu John (API, CSWIP & ASNT)Document6 pagesResume Ofjithu John (API, CSWIP & ASNT)JithuJohnNo ratings yet

- Mpi Q-2Document3 pagesMpi Q-2JithuJohnNo ratings yet

- RGUHS MSc Nursing Exam Fee Notification April 2016Document7 pagesRGUHS MSc Nursing Exam Fee Notification April 2016JithuJohnNo ratings yet

- Ut Q 5Document4 pagesUt Q 5JithuJohnNo ratings yet

- Basic 4 QDocument8 pagesBasic 4 QJithuJohnNo ratings yet

- Akira Ct-29nx9 Chassis-5n11 SMDocument14 pagesAkira Ct-29nx9 Chassis-5n11 SMKhairul Nizam Anuarul HakimNo ratings yet

- ICMSETDocument9 pagesICMSETPramudyo BayuNo ratings yet

- Report Template I3 GIMDocument19 pagesReport Template I3 GIMPan ThonvuthNo ratings yet

- Engineered Over 10,000 km Transmission LinesDocument2 pagesEngineered Over 10,000 km Transmission Linesmhergonzales100% (1)

- Teaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesDocument5 pagesTeaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesConnie RodriguezNo ratings yet

- Top Aerospace Companies & Organizations in IndiaDocument10 pagesTop Aerospace Companies & Organizations in IndiakPrasad8No ratings yet

- C3 - Process Selection, Design, and AnalysisDocument54 pagesC3 - Process Selection, Design, and AnalysisMinh Thuận VõNo ratings yet

- Span Thickness Limits For Deflection ControlDocument8 pagesSpan Thickness Limits For Deflection Controlf81lNo ratings yet

- IITH Advertisement For Faculty Recruitment March10 2022 v3Document10 pagesIITH Advertisement For Faculty Recruitment March10 2022 v3kotes jerryNo ratings yet

- Standard Equipment Capability Estimates: Item No. Type of Work Equipment Used Capability AdoptedDocument22 pagesStandard Equipment Capability Estimates: Item No. Type of Work Equipment Used Capability AdopteddaphneNo ratings yet

- Electrical/Lighting Design Engineer-CVDocument3 pagesElectrical/Lighting Design Engineer-CVMohamed67% (6)

- TCD Undergraduate Courses 2011Document208 pagesTCD Undergraduate Courses 2011julieannagormanNo ratings yet

- Ms DrainagesDocument3 pagesMs DrainagesdeanicoNo ratings yet

- WideFlange All PDFDocument19 pagesWideFlange All PDFDede HerdiantoNo ratings yet

- Catalogo Serie G Iec Septiembre 2005 PDFDocument59 pagesCatalogo Serie G Iec Septiembre 2005 PDFRicardo Astocondor RabanalNo ratings yet

- Updtaed CV - Y.vikas Singla-2018Document6 pagesUpdtaed CV - Y.vikas Singla-2018yv singlaNo ratings yet

- CourseInfo BookletDocument48 pagesCourseInfo BookletArindam MohantaNo ratings yet

- Simplify drive solutions up to 2,400 kWDocument12 pagesSimplify drive solutions up to 2,400 kWcatalinccNo ratings yet

- Definition and Types of Bridges PDFDocument34 pagesDefinition and Types of Bridges PDFHivet Jurieta Mamani100% (1)

- VIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementDocument85 pagesVIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementOnkar BagariaNo ratings yet

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- Leak Test PDFDocument48 pagesLeak Test PDFdaniel oliveira100% (1)

- Civil Engineering Orientation ModuleDocument108 pagesCivil Engineering Orientation ModuleRingor Fam100% (2)

- Chapter 5Document78 pagesChapter 5Retno Yuniarsih Marekhan IINo ratings yet

- Jntua r13 Eee SyllabusDocument116 pagesJntua r13 Eee SyllabusRayapati Devi PrasadNo ratings yet

- SOP For OLDocument9 pagesSOP For OLTahir Ur RahmanNo ratings yet