Professional Documents

Culture Documents

SAMPLE MastercamX9 Router TrainingTutorial

Uploaded by

gurdeeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAMPLE MastercamX9 Router TrainingTutorial

Uploaded by

gurdeeCopyright:

Available Formats

R

E

T

U

O

R

Imperial

Router Training Tutorial

To order more books:

Call 1-800-529-5517 or

Visit www.emastercam.com or

Contact your Mastercam dealer

Mastercam X9 Router Training Tutorial

Copyright: 1998 - 2014 In-House Solutions Inc. All rights reserved

Software: Mastercam X9

Author: Mariana Lendel

ISBN: 978-1-77146-051-4

Revision date: July 7, 2015

Notice

In-House Solutions Inc. reserves the right to make improvements to this manual at any time and without

notice.

Disclaimer Of All Warranties And Liability

In-House Solutions Inc. makes no warranties, either express or implied, with respect to this manual or

with respect to the software described in this manual, its quality, performance, merchantability, or

fitness for any particular purpose. In-House Solutions Inc. manual is sold or licensed "as is." The entire risk

as to its quality and performance is with the buyer. Should the manual prove defective following its

purchase, the buyer (and not In-House Solutions Inc., its distributer, or its retailer) assumes the entire

cost of all necessary servicing, repair, of correction and any incidental or consequential damages. In no

event will In-House Solutions Inc. be liable for direct, indirect, or consequential damages resulting from

any defect in the manual, even if In-House Solutions Inc. has been advised of the possibility of such

damages. Some jurisdictions do not allow the exclusion or limitation of implied warranties or liability for

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Copyrights

This manual is protected under International copyright laws. All rights are reserved. This document may

not, in whole or part, be copied, photographed, reproduced, translated or reduced to any electronic

medium or machine readable form without prior consent, in writing, from In-House Solutions Inc.

Trademarks

Mastercam is a registered trademark of CNC Software, Inc.

Microsoft, the Microsoft logo, MS, and MS-DOS are registered trademarks of Microsoft Corporation;

Windows 7 and Windows 8 are registered trademarks of Microsoft Corporation.

MASTERCAM SHORTCUTS

MASTERCAM QUICK REFERENCE CARD

MASTERCAM SHORTCUTS

Icon Function

Keyboard

Shortcut

Icon Function

Keyboard

Shortcut

Analyze entities

F4

Mastercam version, SIM serial number Alt+V

AutoSave

Alt+A

Motion controller rotation point

Alt+F12

C-Hook or user app

Alt+C

Pan

Arrow keys

Configure Mastercam

Alt+F8

Paste from clipboard

Ctrl+V

Copy to clipboard

Ctrl+C

Redo an event that has been undone

Ctrl+Y

Cut to clipboard

Ctrl+X

Repaint

F3

Delete entities

F5

Rotate

Alt+Arrow keys

Drafting global options

Alt+D

Select all

Ctrl+A

Exit Mastercam

Alt+F4

Selection grid parameters

Alt+G

Fit geometry to screen

Alt+F1

Shading on/off

Alt+S

GviewBack

Alt+3

Show/hide all axes (WCS, Cplane,

Tplane)

Alt+F9

GviewBottom

Alt+4

Show/hide coordinate axes

F9

GviewFront

Alt+2

Show/hide displayed toolpaths

Alt+T

GviewIsometric

Alt+7

Show/hide Operations Manager pane Alt+O

GviewLeft

Alt+6

Undo the last creation or event

Ctrl+U, Ctrl+Z

Previous Plane

Alt+P

Unzoom to 80% of original

Alt+F2

GviewRight

Alt+5

Unzoom to previous or 50% of original F2

GviewTop

Alt+1

Zoom around target point

Ctrl+F1

Help

Alt+H

Zoom with window selection

F1

Hide entities

Alt+E

Zoom/unzoom by 5%

Page Up/Page

Down

Level Manager

Alt+Z

Main attributes, set from entity

Alt+X

MASTERCAM QUICK REFERENCE CARD

CUSTOMIZE MASTERCAM

CUSTOMIZE MASTERCAM

Create Your Own Keyboard Shortcuts

Choose Load Workspace to hide or display

toolbars.

Choose Settings >Customize>Key Mapping.

Customize the right-click menu

Select the Category.

Choose Settings > Customize > Context Menu tab

Select the Category and then the function that you

want to add.

Once you click on the Add button the function will

be added to the Right mouse button menu.

Select a Mastercam function and under Press new

shortcut key enter the key combinations you want

to assign to it.

Change Toolbar Layouts

Choose Settings > Customize.

Set the Workspace and then choose the Category.

Select a Mastercam function and add it to the

Toolbar.

WAYS TO GET THE MOST FROM MASTERCAM

Mastercam Training

In-House Solutions offers unsurpassed industrial training for Mastercam and Octopuz. We have training facilities

in a number of cities across Canada and some of our courses can also be offered onsite, depending on trainer

availability. Learn more at eMastercam.com/store.

Our library of Mastercam Training Solutions consists of several product lines that cater to any learning style.

Learn Mastercam at your own pace with our Training Tutorials, teach your students with the help of our

Instructor Kits, learn the theory behind Mastercam with our Handbooks, get projects -la-carte with our Single

Projects, let our instructors show you best practices with our Video Training or go digital with our eBooks.

Mastercam Community

eMastercam is the one-stop web resource for Mastercam users. People from all over the world visit the site

whether they are teaching, learning or working with Mastercam daily. Members can post questions, comments

or share projects and success stories. Visit eMastercam.com and sign up for your free account today!

For downloaded pdf please visit

www.emastercam.com/qrc

ROUTER TRAINING TUTORIAL PROJECTS

Tutorial

Geometry Functions

Surface and Toolpath Creation

#1

Create Polar Line.

Create Perpendicular Line.

Create Parallel Lines.

Trim Entities.

Create Fillets.

Xform Mirror.

Xform Translate.

Create Circle Center Point.

Create Rectangle.

Create a Drilling Toolpath.

Create a Contour Toolpath.

#2

Create Lines.

Create Fillets.

Create Arcs.

Create a Contour Toolpath.

#3

Create Rectangle.

Create Parallel Lines.

Create Circle Center Point.

Xform Rectangular Array.

Trim Geometry.

Delete Construction Lines.

Create a Drilling Toolpath.

Create a Block Drilling Toolpath.

Create a Contour Toolpath.

#4

Create Door.

Xform Translate.

Change Graphic View and

Construction Plane.

Create Parallel Lines.

Create Rectangles.

Delete Construction Lines.

Create Circle Center Point.

Create Rectangular Shapes.

Create a Pocket Toolpath.

Create a Engraving Toolpath.

Create Toolpaths on Left and

Right Plane.

Create Drilling Toolpaths.

Create a Circle Mill Toolpath.

Router Training Tutorial

ROUTER TRAINING TUTORIAL PROJECTS

Tutorial

Geometry Functions

#5

Open Tutorial #1.

Merge Tutorial #2.

Xform Geometry Nesting.

Option #2(True Shape Nesting).

Option #3(Rectangular Nesting

The Toolpaths).

Create Drill Toolpath.

Create a Contour Toolpath.

#6

Download the File.

Use RAST2VEC.DLL to Open The

File.

Create a Point.

Create Letters.

Create a Contour Toolpath.

Create a Engraving Toolpath.

#7

Create Rectangle.

Create Line Parallel.

Create Fillets.

Create Rectangular Shapes.

Create a Custom Tool.

Trim Entities.

Create Arc Endpoints.

Delete Construction Lines.

Create a Slot Mill Toolpath.

Create Contour Toolpath Using

The Custom Tool Created.

#8

Download the File.

Create a Circle Mill Toolpath.

Create a Drilling Toolpath.

Create a Engraving Toolpath.

Create a Contour (Ramp)

Toolpath.

Create a Pocket Toolpath.

Router Training Tutorial

TABLE OF CONTENTS

Table of Contents

Getting Started ........................................................................................................... 1

Tutorials:

Tutorial #1 - Drilling and Contour Toolpaths ........................................................................................13

Tutorial #2 - Contour Toolpath .............................................................................................................87

Tutorial #3 - Drilling, Block Drilling and Contour Toolpaths ................................................................125

GETTING

STARTED

Tutorial #4 - Using Tool Planes to Pocket, Engrave and Circle

Mill the Door

.................................... 189

Tutorial #5 - Geometry Nesting and Toolpath Nesting .......................................................................267

Tutorial #6 - Rast2Vec to Import a Graphic ........................................................................................353

Tutorial #7 - Custom Tool Creation and Slot Mill Toolpath ...............................................................407

Tutorial #8 - Circle Mill, Drilling, Engraving, Contour -Ramp and Pocket Toolpaths ...........................469

General Notes ......................................................................................................... 545

Quiz Answers .......................................................................................................... 601

Router Training Tutorial

TUTORIAL #1

Router Training Tutorial

Page|13

TUTORIAL #11

OVERVIEW OF STEPS TAKEN TO CREATE THE FINAL PART:

OVERVIEW OF STEPS TAKEN TO CREATE THE FINAL PART:

From Drawing to CAD Model:

The student should examine the drawing on the following page to understand what part is being created in the

tutorial.

From the drawing we can decide how to go about creating the geometry in Mastercam.

Create the CAD Model used to generate Toolpaths from:

The student will create the wireframe needed to create the surfaces.

Line, circle, trim and fillet commands will all be used to design the 2-dimensional drawing. The student will also

learn how to mirror and translate the geometry.

Create the necessary Toolpaths to machine the part:

The student will set up the stock size to be used and the clamping method used.

A Drill toolpath will be used to drill an arc.

A Contour toolpath will be used to cut the outside shape of the part.

Backplot and Verify the file:

The Backplot will be used to simulate a step by step process of the tools movements.

The Verify will be used to watch a tool machine the part out of a solid model.

Post Process the file to generate the G-code:

The Student will then post process the file to obtain an NC file containing the necessary code for the machine.

This tutorial takes approximately one hour to complete.

Page |14

Router Training Tutorial

OVERVIEW OF STEPS TAKEN TO CREATE THE FINAL PART:

Router Training Tutorial

TUTORIAL #11

Page|15

TUTORIAL #11

SETTING UP THE GRAPHIC USER INTERFACE

GEOMETRY CREATION

STEP 1: SETTING UP THE GRAPHIC USER INTERFACE

Please refer to the Getting Started section to set up the graphics user interface.

STEP 2: CREATE CONSTRUCTION LINES

In this step you will learn how to create a horizontal line knowing the starting position and the length of the line. As well

you will learn how to create a polar line knowing the angle and length of the line.

Step Preview:

2.1 Create a 5.0" horizontal line

CREATE

Line.

Endpoint.

Enable the Horizontal button in the Ribbon bar.

Page |16

Router Training Tutorial

CREATE CONSTRUCTION LINES

TUTORIAL #11

[Specify the first endpoint]: Select the Origin as shown in Figure: 2.1.1.

Figure: 2.1.1

NOTE: Ensure the autocursor changes to highlight the origin as shown in Figure: 2.1.1.

[Specify the second endpoint]: Select a point to the right of the Origin as shown in Figure: 2.1.2.

Figure: 2.1.2

Input a Length of 5.0 in the ribbon bar.

Pick the Apply button to continue using the command.

NOTE: If you can not see the whole line, pick one of the unzoom icons found in the View Manipulation toolbar

or select the Fit icon.

Router Training Tutorial

Page|17

TUTORIAL #11

CREATE CONSTRUCTION LINES

2.2 Create a polar line

Disable the Horizontal line icon.

[Specify the first endpoint]: Select the line Endpoint as shown in Figure: 2.2.1.

Figure: 2.2.1

[Specify the second endpoint]: Sketch a line on any angle and any length.

NOTE: The entity is live until you choose either the Apply button

or the OK button

.

A live entity can be modified.

Mastercam calculates positive angles in a CCW direction. Zero degrees starting at 3 oclock.

Input a line Length of 12.75 and an Angle of 60.0 as shown.

NOTE: If you wish to preview your geometry creation press enter once you have entered the values.

Select the Fit icon.

Choose the OK button to exit the command.

Page |18

Router Training Tutorial

CREATE CONSTRUCTION LINES

TUTORIAL #11

The geometry should look as shown in Figure: 2.2.2.

Figure: 2.2.2

Router Training Tutorial

Page|19

TUTORIAL #11

CREATE A PERPENDICULAR LINE

STEP 3: CREATE A PERPENDICULAR LINE

In this step you will create a perpendicular line.

Step Preview:

CREATE

Line.

Perpendicular.

In the Ribbon bar, enter the line Length of 0.5.

Page |20

Router Training Tutorial

CREATE A PERPENDICULAR LINE

TUTORIAL #11

[Select line, arc or spline]: Select the polar line as shown in Figure: 3.0.1.

[Sketch a point]: Pick the line Endpoint as shown in Figure: 3.0.1.

Figure: 3.0.1

[Select which line to keep]: Choose the line to keep as shown in Figure: 3.0.2.

Figure: 3.0.2

Select the OK button to exit the command.

Router Training Tutorial

Page|21

TUTORIAL #11

CREATE PARALLEL LINES

The geometry should look as shown in Figure: 3.0.3.

Figure: 3.0.3

STEP 4: CREATE PARALLEL LINES

In this step you will learn how to create parallel lines.

Step Preview:

CREATE

Line.

Parallel.

Page |22

Router Training Tutorial

CREATE PARALLEL LINES

TUTORIAL #11

[Select a line]: Pick the horizontal line.

[Select the point to place a parallel line through]: Click somewhere below the line.

In the Ribbon bar, enter a Distance of 1.0.

Select the Apply button to stay within the command.

Select the Fit icon.

Router Training Tutorial

Page|23

TUTORIAL #11

CREATE PARALLEL LINES

[Select a line]: Pick the polar line.

[Select the point to place a parallel line through]: Select a point to the right of it.

In the Ribbon bar enter a Distance of 0.5.

Select the Apply button to stay within the command.

[Select a line]: Choose the original polar line again.

[Select the point to place a parallel line through]: Select a point to the right of it.

Input a Distance of 1.0.

Select the Apply button again to stay within the command.

Page |24

Router Training Tutorial

CREATE PARALLEL LINES

TUTORIAL #11

[Select a line]: Pick the perpendicular line as shown.

[Select the point to place a parallel line through]: Select a point below it.

Input a Distance of 6.0.

Choose the OK button once the parallel lines have been created.

Router Training Tutorial

Page|25

TUTORIAL #11

CREATE A POLAR LINE

The geometry should look as shown in Figure: 4.0.1.

Figure: 4.0.1

STEP 5: CREATE A POLAR LINE

In this step you will create another polar line knowing the first endpoint and angle.

Step Preview:

CREATE

Line.

Endpoint.

Page |26

Router Training Tutorial

CREATE A POLAR LINE

TUTORIAL #11

[Specify the first endpoint]: Select the line Endpoint as shown in Figure: 5.0.1.

Figure: 5.0.1

[Specify the second endpoint]: Sketch the line at any length and any angle.

In the Ribbon bar, enter the Length of 1.0 and the Angle of 240 + 45.

NOTE: Mastercam performs basic math operations in the fields in which you can enter values.

Choose the OK button to exit the command.

The geometry should look as shown in Figure: 5.0.2.

Figure: 5.0.2

Router Training Tutorial

Page|27

TUTORIAL #11

TRIM THE ENTITIES

STEP 6: TRIM THE ENTITIES

In this step you will use the trim two entities command. This will trim the entities to their intersections.

Step Preview:

EDIT

Trim/Break.

Trim/Break/Extend.

Enable the Trim 2 Entities button in the Ribbon bar.

Choose the Zoom Window button.

[Specify zoom window]: Create a rectangle to zoom into the area as shown in Figure: 6.0.1.

Figure: 6.0.1

Page |28

Router Training Tutorial

TRIM THE ENTITIES

TUTORIAL #11

[Select the entity to trim/extend]: Pick the first entity as shown in Figure: 6.0.2.

[Select the entity to trim/extend to]: Pick the second entity as shown in Figure: 6.0.2.

Figure: 6.0.2

NOTE: The dotted line represents the entity that will be trimmed and removed.

[Select the entity to trim/extend]: Pick the first entity as shown in Figure: 6.0.3.

[Select the entity to trim/extend to]: Pick the second entity as shown in Figure: 6.0.3.

Figure: 6.0.3

Choose the Fit button to view the geometry.

Router Training Tutorial

Page|29

TUTORIAL #11

CREATE A LINE KNOWING THE ENDPOINTS

[Select the entity to trim/extend]: Pick the first entity as shown in Figure: 6.0.4.

[Select the entity to trim/extend to]: Pick the second entity as shown in Figure: 6.0.4.

Figure: 6.0.4

Once complete pick the OK button to exit the command.

STEP 7: CREATE A LINE KNOWING THE ENDPOINTS

Create a line knowing the two line endpoints.

Step Preview:

Page |30

Router Training Tutorial

CREATE A LINE KNOWING THE ENDPOINTS

TUTORIAL #11

CREATE

Line.

Endpoint.

[Specify the first endpoint]: Pick Endpoint 1 as shown in Figure: 7.0.1.

[Specify the second endpoint]: Pick Endpoint 2 as shown in Figure: 7.0.1.

Figure: 7.0.1

Choose the OK button to exit the command.

Router Training Tutorial

Page|31

TUTORIAL #11

CREATE A 1/4" FILLET

STEP 8: CREATE A 1/4" FILLET

In this step you will create a fillet. A fillet is used to break a corner and create a smooth round corner.

Step Preview:

CREATE

Fillet.

Entities.

Input a fillet Radius of 0.25. Ensure the fillet style is set to Normal and Trim is enabled.

[Fillet: Select an entity]: Select Entity A as shown in Figure: 8.0.1.

[Fillet: Select another entity]: Select Entity B as shown in Figure: 8.0.1.

Figure: 8.0.1

Page |32

Router Training Tutorial

CREATE A 1/4" FILLET

TUTORIAL #11

[Fillet: Select an entity]: Select Entity C as shown in Figure: 8.0.2.

[Fillet: Select another entity]: Select Entity D as shown in Figure: 8.0.2.

Figure: 8.0.2

Choose the OK button to exit the command.

Router Training Tutorial

Page|33

TUTORIAL #11

SETUP SHEET:

TOOLPATH CREATION

SETUP SHEET:

Page |52

Router Training Tutorial

SELECT THE MACHINE AND SETUP THE STOCK

TUTORIAL #11

STEP 17: SELECT THE MACHINE AND SETUP THE STOCK

In Mastercam, you select a Machine Definition before creating any toolpaths. The Machine Definition is a model of your

machines capabilities and features. It acts like a template for setting up your machine. The machine definition ties

together three main components: The schematic model of your machines components, the control definition that models

your control capabilities, and the post processor that will generate the required machine code (G-code). For a Router

exercise (2D toolpaths) we need just a basic machine definition.

NOTE: For the purpose of this tutorial, we will be using the Router Default .

17.1 Display the Toolpaths Manager if needed

VIEW

Toggle Toolpaths Manager.

17.2 Select the machine type

MACHINE TYPE

Router.

Default.

Select the plus sign in front of Properties in the Toolpaths Manager to expand the Toolpaths Group Properties

as shown.

Select Tool Settings to set the tool parameters as shown.

Router Training Tutorial

Page|53

TUTORIAL #11

SELECT THE MACHINE AND SETUP THE STOCK

Change the parameters to match the Figure: 17.2.1

Figure: 17.2.1

Program # is used to enter a number if your

machine tool requires a number for a

program name.

Assign tool numbers sequentially allows

you to overwrite the tool number from the

library with the next available tool number

(First operation tool number 1; Second

operation tool number 2, etc.).

Warn of duplicate tool numbers allows you

to get a warning if you enter two tools with

the same number.

Override defaults with modal values

enables the system to keep the values that

you enter.

Feed Calculation set From tool uses feed

rate, plunge rate, retract rate and spindle

speed from the tool definition.

Page |54

Router Training Tutorial

SELECT THE MACHINE AND SETUP THE STOCK

TUTORIAL #11

Select the Stock setup tab to define the stock. Set the stock shape (Rectangular), enable Display, Fit screen and

enter the stock dimensions as shown in Figure: 17.2.2.

Figure: 17.2.2

The Stock Origin values adjust the

positioning of the stock, ensuring that you

have equal amount of extra stock around

the finished part.

Display options allow you to set the stock

as Wireframe and to fit the stock to the

screen (Fit Screen).

NOTE: The stock model that you create can be displayed with the part geometry when viewing the file or the

toolpaths, during backplot, or while verifying toolpaths. In the graphics, the plus shows you where the stock

origin is. The default position is the middle of the stock.

Click on the corner of the stock to set it as the stock origin as shown in Figure: 17.2.2.

Select the OK button to exit the Machine Group Properties.

Router Training Tutorial

Page|55

TUTORIAL #11

SELECT THE MACHINE AND SETUP THE STOCK

Select the Isometric view from the Graphics view toolbar to see the stock.

Use the Fit icon to fit the drawing to the screen.

The stock model will appear as shown in Figure: 17.2.3.

Figure: 17.2.3

NOTE: The stock is not geometry and can not be selected.

Select the Top view to view the part in the orientation we will be machining it in.

Page |56

Router Training Tutorial

DRILL TOOLPATH

TUTORIAL #11

STEP 18: DRILL TOOLPATH

Drill Toolpath allows you to create a hole, typically using a drill bit.

Step Preview:

TOOLPATHS

Drill.

Select the OK button to accept the NC name.

Router Training Tutorial

Page|57

TUTORIAL #11

DRILL TOOLPATH

When the Drill Point Selection dialog box appears select Entities as shown in Figure: 18.0.1.

Figure: 18.0.1

[Select entities]: Select the 1/2" circle as shown in Figure: 18.0.2.

Figure: 18.0.2

Select the OK button to exit the Drill Point Selection.

Page |58

Router Training Tutorial

DRILL TOOLPATH

TUTORIAL #11

On the Toolpath Type page ensure Drill is selected.

NOTE: Mastercam updates the pages as you modify them and then marks them, in the Tree view list, with a

green check mark.

Pages that are not enabled are marked with a red circle and slash.

If by mistake you click the OK button

the toolpath will be generated without all the parameters set

properly. To go back in the parameters area, in the Toolpaths Manager, click on the Parameters as shown.

18.1 Select a 1/2" Drill from the library and set the Tool parameters

Select Tool from the Tree view list.

Click on the Select library tool button.

To be able to see all the tools from the library disable Filter Active.

Router Training Tutorial

Page|59

TUTORIAL #11

DRILL TOOLPATH

Scroll down and select the 1/2" Drill (no 51) as shown in Figure: 18.1.1.

Figure: 18.1.1

Select the OK button.

Page |60

Router Training Tutorial

DRILL TOOLPATH

TUTORIAL #11

Make the necessary changes as shown in Figure: 18.1.2.

Figure: 18.1.2

Router Training Tutorial

Page|61

TUTORIAL #11

DRILL TOOLPATH

18.2 Set the Cut Parameters

Select the Cut Parameters page and make the necessary changes as shown in Figure: 18.2.1.

Figure: 18.2.1

Drill/Counterbore recommended for drilling holes with depths of less than three times the tool diameter.

Page |62

Router Training Tutorial

DRILL TOOLPATH

TUTORIAL #11

18.3 Set the Linking Parameters

Choose Linking parameters, enable Clearance and set the Depth as shown in Figure: 18.3.1.

Figure: 18.3.1

Router Training Tutorial

Page|63

TUTORIAL #11

DRILL TOOLPATH

18.4 Set the Tip Comp

From the Tree View area, select Tip Comp. Enable the option and input a Break Through amount of 0.05 as

shown in Figure: 18.4.1.

Figure: 18.4.1

Tip Comp ensures the toolpath drills past the final depth to break through the stock.

Once the parameters have been set choose the OK button to exit the 2D Toolpaths - Drill Parameters and

generate the toolpath.

Page |64

Router Training Tutorial

BACKPLOT THE TOOLPATHS

TUTORIAL #11

STEP 19: BACKPLOT THE TOOLPATHS

Backplotting shows the path the tools take to cut the part. This display lets you spot errors in the program before you

machine the part. As you backplot toolpaths, Mastercam displays additional information such as the X, Y, and Z

coordinates, the path length , the minimum and maximum coordinates and the cycle time. It also shows any collisions

between the workpiece and the tool.

Make sure that the toolpaths are selected (signified by the green check mark on the folder icon). If the

operation is not selected choose the Select all operations icon.

Select the Backplot selected operations button.

NOTE: Mastercam launches a new window that allows you to check the part using Backplot or Verify.

Select the Backplot tab and have the following settings enabled as shown.

Select the Home tab and make sure that you have the following settings on as shown.

Router Training Tutorial

Page|65

TUTORIAL #11

BACKPLOT THE TOOLPATHS

To see the part in an Isometric view, right mouse click in the graphics window and select Isometric as shown.

To fit the workpiece to the screen, right mouse click again in the graphics window and select Fit as shown.

You can step through the Backplot by using the Step forward

or Step back

You can adjust the speed of the Backplot.

Select the Play (R) button in the VCR bar to run Backplot.

Observe the part in the Isometric orientation. The toolpath should look as shown.

Page |66

Router Training Tutorial

buttons.

SIMULATE THE TOOLPATH IN VERIFY

TUTORIAL #11

STEP 20: SIMULATE THE TOOLPATH IN VERIFY

Verify Mode shows the path the tools take to cut the part with material removal. This display lets you spot errors in the

program before you machine the part. As you verify toolpaths, Mastercam displays additional information such as the X, Y,

and Z coordinates, the path length , the minimum and maximum coordinates and the cycle time. It also shows any

collisions between the workpiece and the tool.

From Mastercam Backplot Home tab, switch to Verify and leave the settings for the Visibility and Focus as

shown in Figure: 20.0.1.

Figure: 20.0.1

Select the Play (R) button in the VCR bar to run Verify.

The part should look as shown in Figure: 20.0.2.

Figure: 20.0.2

NOTE: To rotate the part, move the cursor to the center of the part and click and hold the mouse wheel and

slowly move it in one direction.

To Zoom In or Out hold down the mouse wheel and scroll up or down as needed.

Router Training Tutorial

Page|67

TUTORIAL #11

SIMULATE THE TOOLPATH IN VERIFY

Right mouse click in the graphics window and select Isometric and then right mouse click again and select Fit to

see the part in the original position if needed.

To check the part step by step, click first on the Start icon.

Click on the Step Forward (S) to see the tool moving one step at a time.

Click on the Step Forward (S) until the toolpath is completed.

To go back to Mastercam window, minimize Mastercam Simulator window as shown.

Press Alt + T to remove the toolpath display.

Page |68

Router Training Tutorial

CONTOUR TOOLPATH

TUTORIAL #11

STEP 21: CONTOUR TOOLPATH

Contour toolpaths remove the material along a path defined by a chain of curves. Contour toolpaths only follow a chain;

they do not clean out an enclosed area.

Step Preview:

TOOLPATHS

Contour.

NOTE: A chain of entities consists of one or more entities linked together in order and direction. The distance between

the endpoints of two consecutive entities of the chain has to be equal or less than the chaining tolerance (0.0001"). In an

open chain, the start point is placed at the end of the chain closest to the selection point and the chain direction points to

the opposite end of the chain. See the General Notes chapter for more information on chaining.

Router Training Tutorial

Page|69

TUTORIAL #11

CONTOUR TOOLPATH

When the Chaining dialog box appears leave the default settings as shown.

Page |70

Router Training Tutorial

CONTOUR TOOLPATH

TUTORIAL #11

Select the chain. Ensure the chaining direction is ClockWise (CW) as shown in Figure: 21.0.1.

Figure: 21.0.1

Once the entities have been chained choose the OK button to exit the Chaining dialog box.

In the toolpath type page ensure Contour is selected.

21.1 Select a 1/4" Straight Bit from the library and set the tool parameters

From the Tree view area select Tool as shown.

Click on the Select library tool button.

Router Training Tutorial

Page|71

TUTORIAL #11

CONTOUR TOOLPATH

To be able to see all the tools from the library disable Filter Active as shown.

Click on the # to ensure that the tool list is displayed in order, starting with tool number 1 as shown.

Scroll down the list, find and select the 1/4"Straight Bit (number 145) as shown in Figure: 21.1.1.

Figure: 21.1.1

Select the OK button to exit the Tool Selection.

Page |72

Router Training Tutorial

INDEX

Symbols

Example On How To Use A Shortcut ............. 556

# FINISH CUTS ............................................... 520

Numerics

FEED RATE (OVERRIDE) ................................. 486

FILL DIRECTION .....................................275, 313

FILLER QUANTITY .......................................... 317

Fillet Entities ................................................... 32

FINAL DEPTH ................................................. 486

FINISHING ..................................................... 486

Function Prompt ............................................... 4

2D / 3D Construction ........................................ 7

A

A .................................................................... 556

About Construction Depth (Z Depth) ............ 580

About The Tool Plane ................................... 575

Absolute ........................................................ 495

ACCURACY .................................................... 280

ADD PART LABELS ......................................... 317

ADJUST PARAMS ........................................... 362

ALL DEPTHS ................................................... 486

ANGLE ........................................................... 487

AREA ............................................................. 498

Attributes .......................................................... 7

AUTOMATIC (TAB POSITION) ........................ 306

C

CHAIN ........................................................... 362

Chaining Options .......................................... 590

Circle Center Point .......................................... 41

Clear Color ...................................................... 38

Color ................................................................. 7

CONTOUR TOOLPATHS ................................... 69

C-PLANE ........................................................ 498

Cplane ........................................................... 574

Create a polar line .......................................... 18

CREATE CENTER LINES .................................. 361

CREATE LETTERS ........................................... 367

CREATE OUTLINES ......................................... 361

CUSTOM TOOL .............................................. 421

Customizing Drop Down Menus ................... 550

Customizing Toolbars ................................... 547

D

D ................................................................... 556

Data Entry Shortcuts ..................................... 556

DELETE ENTITIES ............................................. 46

DELETE ORIGINAL CHAINS ............................ 280

DEPTH CUTS .................................................. 520

DOOR GEOMETRY ......................................... 192

DRILL TOOLPATH ............................................ 57

E

Edit ..........................................................82, 120

ENGRAVING .................................................. 223

ENTRY/EXIT ARC SWEEP ............................... 487

G

GRAIN DIRECTION ......................................... 275

Graphic Area ..................................................... 4

Grid ................................................................. 11

Groups .............................................................. 7

GUI - Graphical User Interface .......................... 4

Gview ................................................................ 7

H

HELICAL ENTRY ............................................. 485

HELIX ............................................................. 528

HIGH SPEED ENTRY ....................................... 487

How To Chain ................................................ 587

I

Incremental .................................................. 495

INSIDE TO OUTSIDE NESTED CHAINS ............ 300

K

KEEP TOOL DOWN ........................................ 486

Key Mapping ................................................. 553

L

L .................................................................... 556

Level .................................................................. 7

LINE STYLE ..................................................... 431

Line Style ........................................................... 7

Line Width ........................................................ 7

LOAD DEFAULT SHEET .................................. 280

lt + 2 .............................................................. 546

M

MACHINE DEFINITION .................................... 53

Machine Group Properties ........................... 598

MANUALLY TRACE BITMAP IMAGE .............. 361

MAX ROUGH STEP ........................................ 520

MAXIMUM RADIUS ....................................... 485

Menu ................................................................ 4

MINIMUM QUANTITY NESTING .................... 278

MINIMUM RADIUS ....................................... 485

MORPH SPIRAL ............................................. 518

Router Training Tutorial

Page|607

INDEX

MRU Toolbar ..................................................... 4

N

NC File .....................................................82, 120

NEST IN HOLES BEFORE NESTING ON SHEET 312

NEST SMALLER PARTS IN HOLES OF LARGER 312

NOISE FILTER ................................................. 362

NUMBER ....................................................... 486

O

OPEN POCKET TOOLPATH ............................. 230

Operation List Area ....................................... 594

OPTIMIZED PAIRS ......................................... 317

Origin ................................................................ 4

OUTPUT ARC MOVES .................................... 485

OUTPUT GEOMETRY TYPE ............................ 362

OVERLAP ....................................................... 487

P

Parallel Lines ................................................... 22

PARALLEL SPIRAL CLEAN CORNERS ............... 527

PARTIAL TAB MOTION .................................. 306

PART-PART DISTANCE ................................... 278

PERPENDICULAR ENTRY ................................ 487

Perpendicular Line .......................................... 20

Planes ............................................................... 7

PLUNGE ANGLE ............................................. 485

POCKET TOOLPATH ....................................... 213

Point Style ......................................................... 7

Posting A File ..........................................81, 120

PRIORITY ....................................................... 278

Q

Quick Mask Toolbar .......................................... 4

Quiz Answers ................................................ 601

R

R .................................................................... 556

RAST2VEC ..................................................... 358

RECTANGULAR NESTING ............................... 280

RECTANGULAR SHAPES ................................ 200

Reorganizing Toolbars ...................................... 6

RESOLUTION DPI ........................................... 361

REVERSE INNER CHAINS ............................... 300

Ribbon Bar ........................................................ 4

Right Mouse Click In Toolpaths Manager ..... 595

ROUGHING .................................................... 485

S

S .................................................................... 556

SAVE SHEET SCRAP ....................................... 280

Page |608

Scale .................................................................. 4

SEGMENT ...................................................... 362

SLOT MILL TOOLPATH ................................... 439

SMOOTH ....................................................... 362

SMOOTH ALL ................................................ 362

SMOOTH FILTER ............................................ 362

Solids Menu Commands ............................... 581

SPACING ........................................................ 486

SPINDLE SPPED (OVERRIDE) ......................... 486

SPIRAL INSIDE TO OUTSIDE ........................... 518

SPLINE CORNER BREAK ................................. 362

SPLINE PARAMETERS .................................... 361

SPLINE TOLERANCE ....................................... 362

START AT CENTER ......................................... 487

Status Bar .......................................................... 4

STEP ANGLE .................................................. 278

STEPOVER ..................................................... 485

STOCK SETUP .................................................. 55

Stock Setup ................................................... 600

T

TAB ALL ......................................................... 306

TABS ................................................................ 77

TOOL SETTINGS ...............................53, 101, 144

Tool Settings ................................................. 599

Toolbars ............................................................ 4

Toolpath Manager ........................................ 591

Toolpaths/Solid Manager ................................. 4

Trim 2 Entities ................................................. 28

TRIM DIVIDE ................................................. 430

TRUESHAPE NESTING .................................... 311

U

Using the Menu ................................................ 5

Using the Toolbars ............................................ 5

V

VERTICAL MOVES .......................................... 306

View Port XYZ Axes ........................................... 4

W

Window Selection ......................................... 589

Work Coordinate System (WCS) ....................... 7

X

X .................................................................... 556

XFORM GEOMETRY NESTING ....................... 275

Xform Mirror ................................................... 34

XFORM MOVE TO ORIGIN ............................... 49

Xform Translate .............................................. 39

XY CLEARANCE .............................................. 485

Router Training Tutorial

INDEX

Y .................................................................... 556

Z .................................................................... 556

Z CLEARANCE ................................................ 485

Z Depth .....................................................7, 580

Router Training Tutorial

Page|609

INDEX

Page |610

Router Training Tutorial

Router Tutorial

You might also like

- Sample ST1 Application Instructions Spring1617Document3 pagesSample ST1 Application Instructions Spring1617gurdeeNo ratings yet

- Passport Application Form and GuidelineDocument4 pagesPassport Application Form and Guidelinegurdee100% (1)

- BLS CAN10Vancouver PassportRe Issue ChecklistDocument4 pagesBLS CAN10Vancouver PassportRe Issue ChecklistgurdeeNo ratings yet

- Adult General Passport Application: For Canadians 16 Years of Age or Over Applying in Canada or The USADocument7 pagesAdult General Passport Application: For Canadians 16 Years of Age or Over Applying in Canada or The USAgurdeeNo ratings yet

- 12 PDFDocument1 page12 PDFgurdeeNo ratings yet

- State Load Despatch Centre: SLDC Surcharge Bill For The Period FY 11-12 & FY 12-13Document6 pagesState Load Despatch Centre: SLDC Surcharge Bill For The Period FY 11-12 & FY 12-13gurdeeNo ratings yet

- NZ FormDocument12 pagesNZ FormgurdeeNo ratings yet

- Application For Schengen Visa: This Application Form Is FreeDocument4 pagesApplication For Schengen Visa: This Application Form Is FreegurdeeNo ratings yet

- BRPLDocument195 pagesBRPLgurdeeNo ratings yet

- Mastercam2018 Tool Manager TutorialDocument100 pagesMastercam2018 Tool Manager TutorialgurdeeNo ratings yet

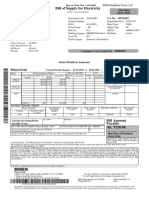

- Bill of Supply For Electricity: Due Date: 24-03-2018Document2 pagesBill of Supply For Electricity: Due Date: 24-03-2018gurdeeNo ratings yet

- Film Making ClearanceDocument4 pagesFilm Making ClearancegurdeeNo ratings yet

- Miscellaneous Services Form1Document1 pageMiscellaneous Services Form1gurdeeNo ratings yet

- Consent Form For Minor Visa Applicant: (Father)Document1 pageConsent Form For Minor Visa Applicant: (Father)gurdeeNo ratings yet

- Ontario: Balanced Budget: Mission Accomplished! Now What?Document6 pagesOntario: Balanced Budget: Mission Accomplished! Now What?gurdeeNo ratings yet

- Imco End MillsDocument36 pagesImco End MillsgurdeeNo ratings yet

- Mastercam2018 Interface TutorialDocument92 pagesMastercam2018 Interface Tutorialgurdee0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Virtual Metaverse Project Proposal by Slidesgo 2Document5 pagesVirtual Metaverse Project Proposal by Slidesgo 2AGS INFOTECHNo ratings yet

- Secretarial CorrespondenceDocument6 pagesSecretarial CorrespondenceSlobodan GaracaNo ratings yet

- Openera ProfileDocument2 pagesOpenera ProfilejnonesixNo ratings yet

- CloudAIR Main SlidesDocument7 pagesCloudAIR Main SlidesThang Dang100% (1)

- Get PipDocument565 pagesGet PipJuan GarciaNo ratings yet

- Partner List - NagpurDocument6 pagesPartner List - Nagpurggzanwar86No ratings yet

- KuppingerCole - Executive View - Illusive - Platform-Technical Validation of Illusive PlatformDocument11 pagesKuppingerCole - Executive View - Illusive - Platform-Technical Validation of Illusive PlatformShahram SametNo ratings yet

- Social Media and Security: How To Ensure Safe Social NetworkingDocument3 pagesSocial Media and Security: How To Ensure Safe Social NetworkingIshfaq MajidNo ratings yet

- Wavecom Brochure W CODE 25Document12 pagesWavecom Brochure W CODE 25Leon LellaNo ratings yet

- CSLA4 Cheat SheetDocument1 pageCSLA4 Cheat SheetMuhammad AliNo ratings yet

- Google Calender Case StudyDocument21 pagesGoogle Calender Case StudyAnkith naiduNo ratings yet

- ITAC001 MahimaDocument3 pagesITAC001 Mahimamridul bhasinNo ratings yet

- Increased Value Through Innovation and Security: Optimum SolutionDocument2 pagesIncreased Value Through Innovation and Security: Optimum SolutionSuhrowardi RasyidNo ratings yet

- E LESF GRADE 3 07 14 20 2MALE 151 2FEMALE 131 Tunay EditedDocument282 pagesE LESF GRADE 3 07 14 20 2MALE 151 2FEMALE 131 Tunay EditedGervinBulataoNo ratings yet

- Laguna Northwestern College: San Lorenzo Ruiz Montessori CenterDocument6 pagesLaguna Northwestern College: San Lorenzo Ruiz Montessori CentermikedrewNo ratings yet

- Competitors ResearchDocument21 pagesCompetitors ResearchRayat UllahNo ratings yet

- CS502 Quiz-2Document43 pagesCS502 Quiz-2Shahbaz AliNo ratings yet

- Bell Canada ProgramDocument5 pagesBell Canada ProgramKrishnaKumar BrahmarouthuNo ratings yet

- Performance vs. Load vs. Stress TestingDocument4 pagesPerformance vs. Load vs. Stress TestingBanhiNo ratings yet

- Implementation of FPGA Based Fault Injection Tool (FITO) For Testing Fault Tolerant DesignsDocument5 pagesImplementation of FPGA Based Fault Injection Tool (FITO) For Testing Fault Tolerant DesignsPardhasaradhi DamarlaNo ratings yet

- Full Catalogue 2006 10Document53 pagesFull Catalogue 2006 10Harchet BrarNo ratings yet

- I. Project Initiation Activities:: Diacenco Margareta, FAF-171 Ivanova Anastasia, FAF-172 Țurcanu Ana, FAF-171Document5 pagesI. Project Initiation Activities:: Diacenco Margareta, FAF-171 Ivanova Anastasia, FAF-172 Țurcanu Ana, FAF-171Anastasia WagnerNo ratings yet

- Blended Learning Models 2002 ASTD PDFDocument4 pagesBlended Learning Models 2002 ASTD PDFRinny BanggurNo ratings yet

- Searching and Sorting AlgorithmsDocument9 pagesSearching and Sorting AlgorithmsMartine Mpandamwike Jr.No ratings yet

- CSPII Lab InstructionsDocument8 pagesCSPII Lab InstructionsSadiqur Rahaman SumonNo ratings yet

- Ajila AdatadrivenpriorityschedulingtechniqueforDocument120 pagesAjila AdatadrivenpriorityschedulingtechniqueforfmaachadooNo ratings yet

- Software Performance Testing Handbook - A Comprehensive Guide For BegineersDocument124 pagesSoftware Performance Testing Handbook - A Comprehensive Guide For BegineersNageshNo ratings yet

- 8086 Microprocessor LEC - 1: Topic: Why 8086 Was Required? Various Features of 8086 MicroprocessorDocument58 pages8086 Microprocessor LEC - 1: Topic: Why 8086 Was Required? Various Features of 8086 MicroprocessorDivyes PNo ratings yet

- Idea StaticaDocument18 pagesIdea StaticayasirjurabaNo ratings yet

- N00-341 IEC 60870-5-101 Protocol Technical Manual CAPM4-5Document88 pagesN00-341 IEC 60870-5-101 Protocol Technical Manual CAPM4-5ndtdlhagiangNo ratings yet