Professional Documents

Culture Documents

Table 15: Distribution of Waste Plastics: Packaging Verses Non-Packaging

Uploaded by

MBA103003Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 15: Distribution of Waste Plastics: Packaging Verses Non-Packaging

Uploaded by

MBA103003Copyright:

Available Formats

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

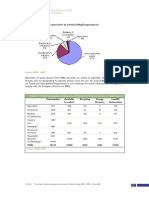

Table 15: Distribution of waste plastics: packaging verses non-packaging

Packaging

Non-packaging

Total

kg/inh

kg/inh

kg/inh

Austria

7.0

4.3

11.3

Belgium

9.8

4.2

14.0

Denmark

12.2

4.9

17.1

Finland

4.6

2.5

7.1

France

7.1

1.7

8.8

Germany

7.9

1.1

9.0

Greece

5.2

0.6

5.8

Ireland

8.7

5.6

14.3

Italy

10.3

0.8

11.1

The Netherlands

12.9

4.2

17.1

Portugal

9.6

4.0

13.6

Spain

7.0

0.7

7.7

Sweden

10.6

0.7

11.3

United Kingdom

10.7

2.5

13.2

European Union

8.8

1.8

10.6

Norway

5.6

4.7

10.3

Switzerland

8.4

1.8

10.2

Western Europe

8.7

1.8

10.5

38

Source: Taylor Nelson Sofres Data 2000

Packaging represents more than 80 per cent of the collectable waste plastics produced by those

sectors. For packaging, the European average is 8.7 kg/inh/year, with strong variation between

countries. The Netherlands is the highest waste producer for this category with 12.9 kg/inh/year,

while Finland is the lowest with only 4.6 kg/inh/year. The same source indicates that the most common polymers used for these packaging applications are LDHE and LDPE.

Table 16: Polymer types in packaging applications

LDPE/HDPE

PP

Stretch and shrink film for goods

Heavy duty bags

Crates, pallets, pails, boxes

Drums and containers

PS/EPS

Source: Taylor Nelson Sofres Data 2000

38- Includes the data of Luxembourg

35

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

It is important to note that in contrast to household packaging, commercial/ industrial packaging

has a higher rate of re-use; pallets, crates, drums and heavy-duty bags may all be specifically

manufactured for re-use. In Belgium, it is estimated that for each kg of one-way industrial plastic

packaging, there is an equivalent 3.5 kg of reusable industrial plastic packaging. Reusable packaging

is easier to collect and to recycle than one-way packaging because it:

is homogeneous (and clean flow)

often retains an economic value

remain in the same distribution circuit (no geographical dispersion)

can be recycled for the same applications, which avoids the search of new outlets

However, the material/product which plastic drums and other containers package may prevent the

material from being recycled, i.e. when it is used to package hazardous substances. In such cases,

mechanical recycling is not recommended (and even prohibited in some countries) leaving feedstock

or energy recovery the best environmental option.

Barriers to recycling

The main barriers affecting commercial and industrial waste plastics concern commercial and

distribution films and EPS, as opposed to rigid plastic applications, such as pallets, drums and crates

(with the exception of containers used for the packaging of hazardous substances).

Commercial and distribution films are mainly LDPE (stretch and shrink wrap) and HDPE (bags and

sacks). Barriers towards recycling include:

down-gauging

low weight/volume ratio

The main features that makes the recycling of commercial and industrial films attractive is that the

waste is relatively homogenous, clean and is concentrated amongst a limited number of outlets.

Packaging weight reduction, or down-gauging reduces the thickness and therefore weight of the

film, in order to optimise resource efficiency. However, as the films become thinner, and weigh less,

collection and recycling efficiency may be compromised.

For EPS, the main barriers are associated with the low volume to weight ratio of the material and

the costs involved in collection and transport if efficient systems are not established. Contamination

is also an important issue and usually only clean, dry label-free material is accepted.

Agriculture

The use of plastics in agriculture has grown dramatically in recent years. It has replaced glass in

greenhouses and become the material of choice for many packaging applications; it is also used

widely for animal food conservation (silage) and agricultural (crop cover) applications.

Although agricultural plastics account for just 2.5 per cent , 953,000 tonnes, of the total plastics

consumed in Europe in 2002, they have a pivotal role to play in this sector. Plastics-based irrigation

and drainage systems provide effective solutions to crop growing. For example, in the Almeria

region of Southern Spain, plastics-based irrigation systems, greenhouses and films have helped

boost horticultural output three-fold. Plastics growth between 2000 and 2002 in this sector was 3

per cent.

36

You might also like

- Advanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesFrom EverandAdvanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesNo ratings yet

- Plastic Waste Management: Is Circular Economy Really The Best Solution?Document3 pagesPlastic Waste Management: Is Circular Economy Really The Best Solution?MEnrique ForocaNo ratings yet

- Cutting plastics pollution: Financial measures for a more circular value chainFrom EverandCutting plastics pollution: Financial measures for a more circular value chainNo ratings yet

- KH0420187ENN enDocument238 pagesKH0420187ENN enConstantin Isabela CatalinaNo ratings yet

- Recycling Plastics in GermanyDocument24 pagesRecycling Plastics in GermanyEvanCamilleriNo ratings yet

- Food and Beverage Packaging Technology - (2011) (1) (223-227)Document5 pagesFood and Beverage Packaging Technology - (2011) (1) (223-227)Aracely Flores GarmaNo ratings yet

- Biodegradablr PackagingDocument15 pagesBiodegradablr PackagingSarfrazNo ratings yet

- ReportDocument7 pagesReportRaja HarjaiNo ratings yet

- Plastic - Docx - As Revised After ValidationDocument47 pagesPlastic - Docx - As Revised After ValidationMark RiveraNo ratings yet

- Plastic FilmsDocument30 pagesPlastic FilmsAbhineet ShrivastavaNo ratings yet

- Recycling of Plastics - A Materials Balance Optimisation Model PDFDocument14 pagesRecycling of Plastics - A Materials Balance Optimisation Model PDFLeoChokNo ratings yet

- Journal Plastic IntroductionDocument12 pagesJournal Plastic IntroductionNiammMbladdushNo ratings yet

- Plastic Recycling: Science Progress February 2007Document25 pagesPlastic Recycling: Science Progress February 2007Mohammed Mostafa El HaddadNo ratings yet

- The Seven Laws of Efficient PackagingDocument12 pagesThe Seven Laws of Efficient Packagingsbaker@cinqpet.co.zaNo ratings yet

- Plastics: Too Valuable To Be Thrown Away Recovery, Recycling and Resource ConservationDocument8 pagesPlastics: Too Valuable To Be Thrown Away Recovery, Recycling and Resource ConservationNancy Daniel100% (1)

- Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesWaste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Scienceprogress Vannessa GoodshipDocument25 pagesScienceprogress Vannessa Goodshipbereket woredeNo ratings yet

- Introduction: Go ToDocument20 pagesIntroduction: Go ToDipu KhanNo ratings yet

- Polystyrene and Env.Document3 pagesPolystyrene and Env.redaelwanNo ratings yet

- Recycling, PackagingDocument12 pagesRecycling, PackagingFan Ray AunNo ratings yet

- What Is Plastic? Use of Plastics Plastics Industry Information CentreDocument3 pagesWhat Is Plastic? Use of Plastics Plastics Industry Information CentreNancy DanielNo ratings yet

- Eco-Friendly Packaging in Supply Chain: Suyog DharmadhikariDocument13 pagesEco-Friendly Packaging in Supply Chain: Suyog DharmadhikariSantanu RoyNo ratings yet

- Checking Out On Plastics 2 ReportDocument40 pagesChecking Out On Plastics 2 ReportTharki AccountNo ratings yet

- Plastic RecyclingDocument24 pagesPlastic Recyclingjohão BagrielNo ratings yet

- Figure 7: Waste Plastics Generation by Activity (50kg/european/year)Document2 pagesFigure 7: Waste Plastics Generation by Activity (50kg/european/year)MBA103003No ratings yet

- Resources, Conservation & Recycling: X: Patricia Megale Coelho, Blanca Corona, Roland Ten Klooster, Ernst Worrell TDocument11 pagesResources, Conservation & Recycling: X: Patricia Megale Coelho, Blanca Corona, Roland Ten Klooster, Ernst Worrell TAngelica PostreNo ratings yet

- Increasing The Quality and Quantity of Plastic Recycling in AustriaDocument72 pagesIncreasing The Quality and Quantity of Plastic Recycling in AustriaBen SmitsNo ratings yet

- RecyclingDocument14 pagesRecyclingAbhay S ZambareNo ratings yet

- Fact Sheet Paper Bags As Packaging of The Future en FinalDocument3 pagesFact Sheet Paper Bags As Packaging of The Future en FinalBharathNo ratings yet

- Plastics: Dept. of Mechanical Engineering, MBITSDocument36 pagesPlastics: Dept. of Mechanical Engineering, MBITSVishnu V NairNo ratings yet

- Reading Practice 8Document3 pagesReading Practice 8Vy PhạmNo ratings yet

- Review PaperDocument21 pagesReview PaperShar KhanNo ratings yet

- Pagbasa at Pagsusuri WEEK 7-8Document3 pagesPagbasa at Pagsusuri WEEK 7-8Wends HahaNo ratings yet

- PalletTrends09 PDFDocument12 pagesPalletTrends09 PDFJosé Manuel Alvarado100% (1)

- Decomposition of Paper and PlasticDocument8 pagesDecomposition of Paper and PlasticJohnny BlazeNo ratings yet

- PaverDocument29 pagesPaverJeevan Landge PatilNo ratings yet

- Final Denkstatt Report (Vers 1 3) September 2010Document45 pagesFinal Denkstatt Report (Vers 1 3) September 2010Yesid Nieto MuñozNo ratings yet

- Plastic Recycling - WikipediaDocument18 pagesPlastic Recycling - Wikipediadavid manuelNo ratings yet

- A Mini-Review On Expanded Polystyrene Waste RecyclDocument15 pagesA Mini-Review On Expanded Polystyrene Waste RecyclSy Nguyen VietNo ratings yet

- Packaging and Recyclability Nov 09 PRAG.03784b30Document23 pagesPackaging and Recyclability Nov 09 PRAG.03784b30Gull GillNo ratings yet

- BIOD CompressedDocument13 pagesBIOD Compressedelias llamasNo ratings yet

- Chapter 2Document11 pagesChapter 2MarkNo ratings yet

- Decarbonizing Plastic Recycling ProcessesDocument15 pagesDecarbonizing Plastic Recycling ProcessesAnthonyNo ratings yet

- Paper Bags The Natural ChoiceDocument2 pagesPaper Bags The Natural ChoiceJoshua Delos ReyesNo ratings yet

- Plastic Recycle SystemDocument13 pagesPlastic Recycle SystemTin Htut OoNo ratings yet

- EuPR Strategy Paper 2012 - 0Document20 pagesEuPR Strategy Paper 2012 - 0Mayra Alejandra Cordova GilesNo ratings yet

- Plastic Recycling Research PaperDocument8 pagesPlastic Recycling Research Paperehljrzund100% (1)

- Annex 1: Fruit: Figure 1: Orange Used in The UK Soft Drinks Supply ChainDocument21 pagesAnnex 1: Fruit: Figure 1: Orange Used in The UK Soft Drinks Supply ChainRafael BarrosNo ratings yet

- Topic:: RecyclingDocument15 pagesTopic:: RecyclingmahiraNo ratings yet

- Plastic Waste ManagementDocument12 pagesPlastic Waste Managementikhamate emmanuelNo ratings yet

- Sachet Disposal: Group 5Document25 pagesSachet Disposal: Group 5Benedick Jayson MartiNo ratings yet

- Glass Guide UkDocument75 pagesGlass Guide Uksaherhcc4686No ratings yet

- Fdocuments - in - A Use Based Approach To Decision and Policy Making Blue Planet II Coverage ofDocument93 pagesFdocuments - in - A Use Based Approach To Decision and Policy Making Blue Planet II Coverage ofYash JoglekarNo ratings yet

- Plastic Sorting PDFDocument9 pagesPlastic Sorting PDFJamie RandolphNo ratings yet

- Carbon Footprint Analysis in Plastics ManufacturingDocument9 pagesCarbon Footprint Analysis in Plastics ManufacturingClint FosterNo ratings yet

- Polymers 11 00696Document19 pagesPolymers 11 00696LaLa HaNo ratings yet

- Plastic Production: Plastics Have Many Practical QualitiesDocument2 pagesPlastic Production: Plastics Have Many Practical QualitiesNancy DanielNo ratings yet

- 1 s2.0 S0921344919303684 MainDocument8 pages1 s2.0 S0921344919303684 MainAhmad ZakiNo ratings yet

- Revised Plumbing Code of The Philippines - Part16Document2 pagesRevised Plumbing Code of The Philippines - Part16MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part11Document2 pagesRevised Plumbing Code of The Philippines - Part11MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part15Document2 pagesRevised Plumbing Code of The Philippines - Part15MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part14Document2 pagesRevised Plumbing Code of The Philippines - Part14MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part12Document2 pagesRevised Plumbing Code of The Philippines - Part12MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part10Document2 pagesRevised Plumbing Code of The Philippines - Part10MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part14Document2 pagesRevised Plumbing Code of The Philippines - Part14MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part13Document2 pagesRevised Plumbing Code of The Philippines - Part13MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part26Document2 pagesRevised Plumbing Code of The Philippines - Part26MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part25Document2 pagesRevised Plumbing Code of The Philippines - Part25MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part24Document2 pagesRevised Plumbing Code of The Philippines - Part24MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part23Document2 pagesRevised Plumbing Code of The Philippines - Part23MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part28Document2 pagesRevised Plumbing Code of The Philippines - Part28MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part27Document2 pagesRevised Plumbing Code of The Philippines - Part27MBA103003No ratings yet

- Type of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)Document2 pagesType of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)MBA103003No ratings yet

- ACRRReport Part41Document2 pagesACRRReport Part41MBA103003No ratings yet

- 2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pages2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part29Document1 pageRevised Plumbing Code of The Philippines - Part29MBA103003No ratings yet

- Revised Plumbing Code of The Philippines - Part1Document2 pagesRevised Plumbing Code of The Philippines - Part1MBA103003No ratings yet

- ACRRReport Part48Document2 pagesACRRReport Part48MBA103003No ratings yet

- ACRRReport Part45Document2 pagesACRRReport Part45MBA103003No ratings yet

- ACRRReport Part39Document2 pagesACRRReport Part39MBA103003No ratings yet

- Ban of Landfilling And/or Incineration: FranceDocument2 pagesBan of Landfilling And/or Incineration: FranceMBA103003No ratings yet

- Selective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesSelective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Ban of Landfilling And/or Incineration: FranceDocument2 pagesBan of Landfilling And/or Incineration: FranceMBA103003No ratings yet

- Economic Instruments: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesEconomic Instruments: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Collection Sorting Processing Transport Total: PVC PipesDocument2 pagesCollection Sorting Processing Transport Total: PVC PipesMBA103003No ratings yet

- Selective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesSelective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Nictef PDFDocument140 pagesNictef PDFZhel DianingNo ratings yet

- Developing Sustainable Building Assessment Scheme For SaudiArabia PDFDocument12 pagesDeveloping Sustainable Building Assessment Scheme For SaudiArabia PDFCristina BlajinNo ratings yet

- HSEQ S7 Environmental Posters 2023 V02Document4 pagesHSEQ S7 Environmental Posters 2023 V02Robert PilloraNo ratings yet

- KKE (Solar Energy - Solar - Basics)Document38 pagesKKE (Solar Energy - Solar - Basics)Iqbal Al FuadyNo ratings yet

- Suggestions and Solutions To Sustainable BiodiversityDocument3 pagesSuggestions and Solutions To Sustainable BiodiversityFarah DiyanaNo ratings yet

- Development Finance: Dr. Eliseo S. Dela Cruz Professor Don Honorio Ventura State UniversityDocument12 pagesDevelopment Finance: Dr. Eliseo S. Dela Cruz Professor Don Honorio Ventura State UniversityRafael ChuaNo ratings yet

- Corporate Social ResponsibilityDocument93 pagesCorporate Social ResponsibilityAugustine BeniolaNo ratings yet

- EU BEST PRACTICES Hannover, Kronsberg, GermanyDocument28 pagesEU BEST PRACTICES Hannover, Kronsberg, Germanymuhammad ramadhan bin zakariaNo ratings yet

- 7F Syngas Turbine - Fact SheetDocument2 pages7F Syngas Turbine - Fact SheetSergio EscobarNo ratings yet

- Social Learning Towards A Sustainable WorldDocument541 pagesSocial Learning Towards A Sustainable WorldGabriela Santos Tibúrcio100% (1)

- Victoria Planning Provisions (VPP)Document638 pagesVictoria Planning Provisions (VPP)HCAG01No ratings yet

- 1 Environmental InterrelationshipDocument66 pages1 Environmental InterrelationshipDee MarieNo ratings yet

- De Thi Tieng Anh Lop 7 Hoc Ki 2 de So 2Document4 pagesDe Thi Tieng Anh Lop 7 Hoc Ki 2 de So 2kiu yuiNo ratings yet

- 2017 - Impact of Green HRM Practices On Organizational Sustainability & Employee RetentionDocument6 pages2017 - Impact of Green HRM Practices On Organizational Sustainability & Employee RetentionHussniNo ratings yet

- Rebirthing Philippine ForestsDocument50 pagesRebirthing Philippine Forestsfpe_scribdNo ratings yet

- Case Study - Sumatran Orangutan - National Wildlife GeographyDocument2 pagesCase Study - Sumatran Orangutan - National Wildlife GeographyTerror WizardNo ratings yet

- EIA1Document67 pagesEIA1Nithin SanthoshNo ratings yet

- Participatory Irrigation Management (Pim) in Thailand: 7 International Micro Irrigation CongressDocument6 pagesParticipatory Irrigation Management (Pim) in Thailand: 7 International Micro Irrigation CongressfarhanNo ratings yet

- B.Tech MME Syllabus PDFDocument201 pagesB.Tech MME Syllabus PDFPreetiNo ratings yet

- Bio SNG Feasibility StudyDocument99 pagesBio SNG Feasibility Studycrcodreanu382No ratings yet

- Europe 2020Document203 pagesEurope 2020Марияна КолеваNo ratings yet

- Giz Factsheets 01 Aref Giz Support of Mediterranean Solar Plan and UnionDocument2 pagesGiz Factsheets 01 Aref Giz Support of Mediterranean Solar Plan and UnionChristine E. GermanNo ratings yet

- Biodiversity Hotspots and Ecoregions: Earth's Biologically Richest and Most Endangered Terrestrial EcoregionsDocument3 pagesBiodiversity Hotspots and Ecoregions: Earth's Biologically Richest and Most Endangered Terrestrial EcoregionsHamid AwanNo ratings yet

- English Essay On EnvironmentDocument2 pagesEnglish Essay On Environmentamanda_chia96No ratings yet

- Och752 Energy Technology 1Document11 pagesOch752 Energy Technology 1Aravind AravindNo ratings yet

- IMech EDocument14 pagesIMech EHariharanNo ratings yet

- IFC's Guidance Note 6: Biodiversity Conservation and Sustainable Natural Resource ManagementDocument18 pagesIFC's Guidance Note 6: Biodiversity Conservation and Sustainable Natural Resource ManagementIFC Sustainability0% (1)

- TE4a Solar Light Bank DatasheetDocument2 pagesTE4a Solar Light Bank Datasheetניסן בורוכובNo ratings yet

- Hydro EnergyDocument15 pagesHydro EnergyvidhyaaravinthanNo ratings yet

- báo cáo bền vững COSCO PDFDocument70 pagesbáo cáo bền vững COSCO PDFTrương Tuyết MaiNo ratings yet