Professional Documents

Culture Documents

G-209 / S-209 Screw Pin Anchor Shackles

Uploaded by

aizzi1989Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G-209 / S-209 Screw Pin Anchor Shackles

Uploaded by

aizzi1989Copyright:

Available Formats

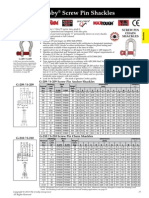

Crosby Screw Pin Shackles

Capacities 1/3 thru 55 metric tons, grade 6.

Forged - Quenched and Tempered, with alloy pins.

Working Load Limit and grade 6 permanently shown on every shackle.

Hot Dip galvanized or self colored.

Fatigue rated.

Shackles 25t and larger are RFID EQUIPPED.

Shackles can be furnished proof tested with certificates to designated standards,

such as ABS, DNV, Lloyds, or other certification. Proof testing and certification available

when requested at the time of order, charges will apply.

Approved for use at -40 degrees C (-40 degrees F) to 204 degrees C (400 degrees F).

3.25t through 25t G209 anchor shackles are type approved to DNV Certification Notes

2.7-1- Offshore Containers. These shackles are statistical proof and impact tested to

G-210 / S-210

42 joules (31 ft-lbs.) min. avg. at -20 degrees C (-4 degrees F). The tests are conducted

G-210 Screw pin anchor shackles

by Crosby and 3.1 test certification is available upon request.

meet the performance requirements

All other 209 and all 210 shackles can meet charpy requirements of 42 joules(31 ft-lbs)

of Federal Specification RR-C-271F

Type IVA, Grade A, Class 2, except

avg. at -20 degrees C (-4 degrees F) upon special request.

for those provisions required of the

Meets or exceeds all requirements of ASME B30.26.

contractor. For additional information,

Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules

see page 452.

1-1-17.7, and ABS Guide for Certification of Cranes.

Crosby 3.25t through 25t G209 anchor shackles are type approved to DNV Certification Notes 2.7-1

- Offshore Containers. These Crosby shackles are statistical proof and impact tested. The tests are

conducted by Crosby and 3.1 test certification is available upon request.

Look for the Red Pin. . . the mark of genuine Crosby quality.

G-209 / S-209

G-209 Screw pin anchor shackles

meet the performance requirements

of Federal Specification RR-C-271F

Type IVA, Grade A, Class 2, except

for those provisions required of the

contractor. For additional information,

see page 452.

SEE APPLICATION INFORMATION

On Page 92 of the Genral Catalog

Para Espaol: www.thecrosbygroup.com

G-209 / S-209 Screw Pin Anchor Shackles

Dimensions

(mm)

A

9.65

11.9

13.5

16.8

19.1

20.6

26.9

31.8

36.6

42.9

46.0

51.5

57.0

60.5

73.0

82.5

105

B

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

41.4

51.0

57.0

70.0

C

22.4

28.7

31.0

36.6

42.9

47.8

60.5

71.5

84.0

95.5

108

119

133

146

178

197

267

D

4.85

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

29.5

32.8

36.1

39.1

46.7

53.0

69.0

E

15.2

19.8

21.3

26.2

29.5

33.3

42.9

51.0

58.0

68.5

74.0

82.5

92.0

98.5

127

146

184

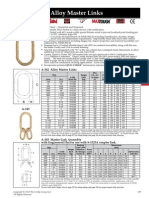

G-210 / S-210 Screw Pin Chain Shackles

Stock No.

Nominal Working

Weight Each

Size

Load

S-210

(kg)

(in.)

Limit (t)* G-210

1/4

1/2

1019150 1019169

.05

5/16

3/4

1019178 1019187

.08

3/8

1

1019196 1019203

.13

7/16

1-1/2 1019212 1019221

.20

1/2

2

1019230 1019249

.27

5/8

3-1/4 1019258 1019267

.57

1.20

3/4

4-3/4 1019276 1019285

7/8

6-1/2 1019294 1019301

1.43

1

8-1/2 1019310 1019329

2.15

1-1/8

9-1/2 1019338 1019347

3.06

1-1/4

12

1019356 1019365

4.11

1-3/8

13-1/2 1019374 1019383

5.28

1-1/2

17

1019392 1019409

7.23

1-3/4

25

1019418 1019427

12.1

1019436 1019445

19.2

2

35

2-1/2

55

1019454 1019463

32.5

F

14.2

15.5

19.1

23.1

26.9

30.2

38.1

46.0

53.0

60.5

68.5

76.0

84.0

92.0

106

122

145

G

24.9

32.5

37.3

45.2

51.5

58.5

74.5

89.0

102

119

131

146

162

175

225

253

327

Tolerance

+/H

37.3

46.7

53.0

63.0

74.0

83.5

106

126

148

167

190

210

233

254

313

348

453

L

4.06

4.85

5.60

6.35

7.85

9.65

11.2

12.7

12.7

14.2

16.0

17.5

19.1

20.6

25.4

31.0

35.1

M

28.4

35.1

42.2

51.5

60.5

68.5

85.0

101

114

129

142

156

174

187

231

263

330

P

4.85

6.35

7.85

9.65

11.2

12.7

17.5

20.6

24.6

26.9

31.8

35.1

38.1

41.1

57.0

61.0

79.5

Dimensions

(mm)

A

11.9

13.5

16.8

19.1

20.6

26.9

31.8

36.6

42.9

46.0

51.5

57.0

60.5

73.0

82.5

105

B

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

41.4

51.0

57.0

70.0

C

6.35

7.85

9.65

11.2

12.7

15.7

20.6

24.6

25.4

31.8

35.1

38.1

41.1

54.0

60.0

66.5

D

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

44.5

51.0

66.5

E

24.6

29.5

35.8

41.4

46.0

58.5

70.0

81.0

93.5

103

115

127

137

162

184

238

F

15.5

19.1

23.1

26.9

30.2

38.1

46.0

53.0

60.5

68.5

76.0

84.0

92.0

106

122

145

G

22.4

26.2

31.8

36.6

41.4

51.0

60.5

71.5

81.0

91.0

100

111

122

146

172

203

C

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

A

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

3.30

3.30

3.30

3.30

6.35

Tolerance

+/K

40.4

48.5

58.5

67.5

77.0

95.5

115

135

151

172

191

210

230

279

312

377

L

4.85

5.60

6.35

7.85

9.65

11.2

12.7

12.7

14.2

16.0

17.5

19.1

20.6

25.4

31.0

35.1

M

35.1

42.2

51.5

60.5

68.5

85.0

101

114

129

142

156

174

187

231

263

330

G

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

A

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

3.30

3.30

3.30

3.30

3.30

6.35

* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. For Working Load

Limit reduction due to side loading applications, see page 94.

Copyright 2016 The Crosby Group LLC All Rights Reserved

SHACKLES

Nominal Working

Stock No.

Size

Load

Weight Each

(in.)

Limit (t)* G-209

(kg)

S-209

3/16

1/3

1018357

.03

1/4

1/2

1018375 1018384

.05

5/16

3/4

1018393 1018400

.09

3/8

1

1018419 1018428

.14

7/16

1-1/2

1018437 1018446

.17

1/2

2

1018455 1018464

.33

5/8

3-1/4

1018473 1018482

.62

3/4

4-3/4

1018491 1018507

1.07

7/8

6-1/2

1018516 1018525

1.64

1

8-1/2

1018534 1018543

2.28

1-1/8

9-1/2

1018552 1018561

3.36

1-1/4

12

1018570 1018589

4.31

1-3/8

13-1/2 1018598 1018605

6.14

1-1/2

17

1018614 1018623

7.80

1-3/4

25

1018632 1018641

12.6

2

35

1018650 1018669

20.4

2-1/2

55

1018678 1018687

38.9

77

You might also like

- CrosbyDocument1 pageCrosbybdispoNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Crosby ShacklesDocument18 pagesCrosby ShacklesAnjar DarundriyaNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesMikiNo ratings yet

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13No ratings yet

- Crosby G2140 ShackleDocument1 pageCrosby G2140 Shacklepgarrett775814233No ratings yet

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1No ratings yet

- Screw Pin Anchor ShacklesDocument1 pageScrew Pin Anchor Shacklesnikka2012No ratings yet

- Crosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150Document2 pagesCrosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150gdgfdNo ratings yet

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Document1 pageCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupNo ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraNo ratings yet

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Crosby® TurnbucklesDocument11 pagesCrosby® TurnbucklesMidfiild CosminNo ratings yet

- Crosby Wide Body Metric For ReferenceDocument1 pageCrosby Wide Body Metric For ReferenceshazanNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- Crosby ShacklesDocument12 pagesCrosby Shacklesj_herndzNo ratings yet

- G2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFDocument2 pagesG2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFSonhaji11No ratings yet

- Crosby Value Added: All Rights Reserved 75Document1 pageCrosby Value Added: All Rights Reserved 75tarun1976No ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- Load Capacity Table for Crosby ShacklesDocument1 pageLoad Capacity Table for Crosby ShacklesVisas Siva100% (2)

- Chapter01 ShacklesDocument48 pagesChapter01 Shacklescalculus pussNo ratings yet

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDocument1 pageCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraNo ratings yet

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Wide ShackleDocument1 pageWide ShacklerahulNo ratings yet

- QQ S 775eDocument5 pagesQQ S 775eMike FiorenNo ratings yet

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDocument1 pageBolt Type Anchor Shackles Bolt Type Chain ShacklesdanamuanNo ratings yet

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (1)

- Rules and Refulation For The Classification of Special Service Craft July 2015 - Piping Systems and Presure Plant - ConstructionDocument4 pagesRules and Refulation For The Classification of Special Service Craft July 2015 - Piping Systems and Presure Plant - ConstructionmarboledtNo ratings yet

- G-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklesDocument1 pageG-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklessaurabhsubhuNo ratings yet

- Am GF Gi-Gg Gi-Gg AmDocument3 pagesAm GF Gi-Gg Gi-Gg AmYesid Ruiz cañónNo ratings yet

- Comparing Steel Water Tank TypesDocument11 pagesComparing Steel Water Tank TypesaladinsaneNo ratings yet

- d260barlockweldablecouplerDocument2 pagesd260barlockweldablecouplerGustavo Brea MalavéNo ratings yet

- STD Spec For Piping WeldingDocument14 pagesSTD Spec For Piping WeldingknsaravanaNo ratings yet

- R S P J: Otary Ubs Up OintsDocument1 pageR S P J: Otary Ubs Up OintsAnuranjanNo ratings yet

- VKVC Launcher-Receiver PDFDocument3 pagesVKVC Launcher-Receiver PDFKRUNAL SHAHNo ratings yet

- AOT Sucker RodDocument20 pagesAOT Sucker RodJose Gabriel Hernandez FelixNo ratings yet

- 102-V-5 QipDocument8 pages102-V-5 QipSaleemSahabNo ratings yet

- Shackles Carbines and Karabiners 2013Document7 pagesShackles Carbines and Karabiners 2013sealion72No ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Is 13349Document20 pagesIs 13349raji357100% (1)

- Technical Information Series BVMM General Description: Ball ValvesDocument6 pagesTechnical Information Series BVMM General Description: Ball ValvesAliArababadiNo ratings yet

- Welding: Subpart "E"Document57 pagesWelding: Subpart "E"DiNo ratings yet

- POLEAS en V - Classical - DrivesDocument100 pagesPOLEAS en V - Classical - DrivesAriel Linder Ureña MontenegroNo ratings yet

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- Grilletes G-2140, S-2140 CrosbyDocument1 pageGrilletes G-2140, S-2140 CrosbyLuis Manuel Montoya RiveraNo ratings yet

- ASTM F1554 Specification - Portland BoltDocument2 pagesASTM F1554 Specification - Portland BoltRob MouzasNo ratings yet

- Crosby ShacklesDocument1 pageCrosby Shacklesroy sihalohoNo ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- Industrial Ball Valve Price Sheet 12-18-20Document33 pagesIndustrial Ball Valve Price Sheet 12-18-20John Cally PrudenteNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Crane Akh-Dem-13Document43 pagesCrane Akh-Dem-13ochoa_chessNo ratings yet

- Dry Gas SealDocument15 pagesDry Gas Seal5skyNo ratings yet

- 38aks 2WDocument16 pages38aks 2Waizzi1989No ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- HR Chapter 08Document13 pagesHR Chapter 08andresboy123No ratings yet

- Micronor Manual Mr221-Mr222Document27 pagesMicronor Manual Mr221-Mr222aizzi1989No ratings yet

- FA150 KGisdfsfDocument2 pagesFA150 KGisdfsfaizzi1989No ratings yet

- PL Crane - Luff Limit Override Button Relocation PlanDocument2 pagesPL Crane - Luff Limit Override Button Relocation Planaizzi1989No ratings yet

- FA2i WinfdsaDocument2 pagesFA2i Winfdsaaizzi1989No ratings yet

- HR Chapter 08Document13 pagesHR Chapter 08andresboy123No ratings yet

- Hydraulic FiltersDocument1 pageHydraulic Filtersaizzi1989No ratings yet

- Altec AtfjtfgjthjhDocument7 pagesAltec Atfjtfgjthjhaizzi1989No ratings yet

- Motherboard Manual Ga-ep31-Ds3l eDocument88 pagesMotherboard Manual Ga-ep31-Ds3l eaizzi1989No ratings yet

- Brochure PTWDocument2 pagesBrochure PTWaizzi1989No ratings yet

- FSCDVDVSCDocument1 pageFSCDVDVSCaizzi1989No ratings yet

- Cap 741 Unlock Inssue 2Document41 pagesCap 741 Unlock Inssue 2Hafiz BakarNo ratings yet

- Volt FC1 FC2 FC3 Table 12: The Volt-to-Fuel Cell ResultsDocument1 pageVolt FC1 FC2 FC3 Table 12: The Volt-to-Fuel Cell Resultsaizzi1989No ratings yet

- Airline IndustryDocument16 pagesAirline Industryben_aizziNo ratings yet

- An 1101Document8 pagesAn 1101spider_apexNo ratings yet

- Grader 14 M Caterpillar BrouchorDocument2 pagesGrader 14 M Caterpillar Brouchorjude tallyNo ratings yet

- SChedule VIDocument88 pagesSChedule VIbhushan2011No ratings yet

- Hydrostatic Test ReportsDocument3 pagesHydrostatic Test ReportsHanuman RaoNo ratings yet

- Impact of Digitalisation Online FinalDocument72 pagesImpact of Digitalisation Online FinalBanon KekeNo ratings yet

- INTERNSHIP DIARY - SESSION 2019-2020Document28 pagesINTERNSHIP DIARY - SESSION 2019-2020Nilotpal RaiNo ratings yet

- Ngos' Due Diligence and Risk Mitigation: A Holistic ApproachDocument54 pagesNgos' Due Diligence and Risk Mitigation: A Holistic ApproachMichel KozahNo ratings yet

- DAY 12 13 ExcerciseDocument3 pagesDAY 12 13 ExcercisevishnuselvaNo ratings yet

- Calculus Early Transcendentals 10th Edition Anton Solutions ManualDocument35 pagesCalculus Early Transcendentals 10th Edition Anton Solutions Manualcrenate.bakshish.7ca96100% (16)

- Computational Methods For Fracture PDFDocument135 pagesComputational Methods For Fracture PDFDiego PinoNo ratings yet

- Negligence PRIMA FACIE CASEDocument107 pagesNegligence PRIMA FACIE CASEHarry KastenbaumNo ratings yet

- Informatica Administrator Interview Questions and AnswersDocument3 pagesInformatica Administrator Interview Questions and Answersatoztarget100% (2)

- Financial Analysis P&GDocument10 pagesFinancial Analysis P&Gsayko88No ratings yet

- Earth / Ground Test (Version 1) : Za'immul Na'imDocument4 pagesEarth / Ground Test (Version 1) : Za'immul Na'imMd Rodi BidinNo ratings yet

- Soap Making BooksDocument17 pagesSoap Making BooksAntingero0% (2)

- Barangay Budget Authorization No. 11Document36 pagesBarangay Budget Authorization No. 11Clarissa PalinesNo ratings yet

- Process - st-dMAIC The Complete Guide To Lean Six Sigma in 5 Key StepsDocument25 pagesProcess - st-dMAIC The Complete Guide To Lean Six Sigma in 5 Key Stepslipsy25No ratings yet

- BITUMINOUS MIX DESIGNDocument4 pagesBITUMINOUS MIX DESIGNSunil BoseNo ratings yet

- 2 Jurnal Internasional (2019) PDFDocument9 pages2 Jurnal Internasional (2019) PDFDwi KrisnawatiNo ratings yet

- 3 Human Resource ManagementDocument10 pages3 Human Resource ManagementRonaldNo ratings yet

- Completing The Accounting Cycle: © 2009 The Mcgraw-Hill Companies, Inc., All Rights ReservedDocument57 pagesCompleting The Accounting Cycle: © 2009 The Mcgraw-Hill Companies, Inc., All Rights ReservedPham Thi Hoa (K14 DN)No ratings yet

- Accounting Income and Assets: The Accrual ConceptDocument40 pagesAccounting Income and Assets: The Accrual ConceptMd TowkikNo ratings yet

- International Journal of Computer Science and Innovation - Vol 2015-n1 - Paper1Document6 pagesInternational Journal of Computer Science and Innovation - Vol 2015-n1 - Paper1sophiaNo ratings yet

- Lecture 6-Measure of Central Tendency-ExampleDocument36 pagesLecture 6-Measure of Central Tendency-ExampleamirhazieqNo ratings yet

- Flyrock Prediction FormulaeDocument5 pagesFlyrock Prediction FormulaeAmy LatawanNo ratings yet

- Marguerite Musica, Mezzo Soprano - Upcoming Roles, Training & MoreDocument1 pageMarguerite Musica, Mezzo Soprano - Upcoming Roles, Training & MoreHaley CoxNo ratings yet

- Nanotechnology Applications in Viscoelastic Surfactant Stimulation FluidsDocument10 pagesNanotechnology Applications in Viscoelastic Surfactant Stimulation FluidsNircarlomix OrtegaNo ratings yet

- FINAL REPORT WV Albania Buiding Futures PotentialDocument30 pagesFINAL REPORT WV Albania Buiding Futures PotentialVasilijeNo ratings yet

- Repair Guides - Wiring Diagrams - Wiring DiagramsDocument18 pagesRepair Guides - Wiring Diagrams - Wiring DiagramsAlvaro PantojaNo ratings yet

- Knowledge Mgmt in BPO: Capturing & Sharing Valuable InsightsDocument3 pagesKnowledge Mgmt in BPO: Capturing & Sharing Valuable InsightsameetdegreatNo ratings yet

- III International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaDocument8 pagesIII International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaIshita KotakNo ratings yet