Professional Documents

Culture Documents

Digital Inkjet Ceramics

Uploaded by

Albert GhobrialCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Digital Inkjet Ceramics

Uploaded by

Albert GhobrialCopyright:

Available Formats

Digital inkjet ceramics

Where do we go from here?

Gillian Ewers, Product Line Manager, Xaar plc

Inkjet printing has revolutionised ceramic tile decoration over a relatively short

period of time. This is an amazing achievement for an industry that for many years

traditionally produced either plain or very unsophisticated patterned tiles using

screen printing and had little use even for computers. Inkjet printing has of course

been used successfully in many other industries over the years, including graphics

(advertising), packaging and textiles. In the packaging and textiles industries over

the same period, the penetration of inkjet has risen to only around 2%,

compared to the ceramics sector where it has reached around 40%.

We will first look into why there is such a difference in the take up between

ceramics and these other industries and then we shall look at what are the next

challenges in ceramics.

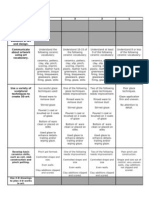

Figure 1: Xaar 1002 printhead with its unique TF Technology

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

The past to the present

Digital printing was not an instant hit in ceramics even though the potential was recognised.

The first inkjet ceramic decoration printers appeared around the year 2000, and these early

printers suffered from poor reliability with blocked or deviant nozzles causing unwanted white

and dark lines on the tiles. The printers required frequent maintenance to clear blocked nozzles

making them unsuitable for full-scale production and printheads had to be replaced repeatedly

at high costs. In addition the images were very grainy and not very attractive.

It was in 2007 when Xaar released the Xaar 1001 that the market really began to take off. The

unique, patented TF Technology in the Xaar 1001 meant that the printers could run for

extended periods of time because the high flow rate of ink past the back of the nozzle during

drop ejection ensured that any unwanted particles or air were removed from the printing nozzle

and the ink was jetted reliably. Now ceramic tile producers could take advantage of the benefits

of digital printing which were so significant that the printer could pay for itself in around six

months.

One immediate advantage was the reduction in waste digital printing is a non-contact

decoration technique (compared to roller or flat screen printing which press on the delicate tile)

so there is no tile breakage. The next advantage is that the minimum batch size became one,

so that the changeover or set up of new designs had no waste of materials or time, therefore

zero cost. In comparison, traditional methods require new silk screens, or roller sleeves, for

each design changeover, plus the time and effort to check the colour consistency. The fact that

a computer was now in control of the colour also meant it was easier to reproduce patterns

time and time again, which lead to a reduction in inventory. All these changes reduced costs

and the amount of money tied up in stock, major financial drivers for mass conversion to digital.

Figure 2: Digital inkjet decorated tiles

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

The next digital advantage was the increase in creativity it gave tile designers. Before digital

inkjet printing took over, a great level of skill was required to produce the most attractive and

highest quality tiles. The Italians and Spanish were held up as the specialists who could create

fantastic designs, but the cost of producing these tiles was very high. The Xaar 1001 introduced

greyscale printing to the industry (early printers offered only large drop binary printing). With its

small drop size of 6 pL*, high native resolution of 360 npi (nozzles per inch) and eight grey

levels, the apparent resolution of the Xaar 1001 was equivalent to more than 1000 dpi, which

appears lifelike to the human eye. Digital printing also removed the high level of pattern

repetition, which had previously been dictated by the size of the roller sleeve or screen. Now

designs are only limited to the size of memory in the printers electronic sub-system; a whole

room could be laid with individually patterned tiles. In addition, as digital inkjet printing was

non-contact, relief or texture could be added to individual tiles, giving them a profile just like with

the materials they were trying to look like. Digital inkjet printing with the Xaar 1001 meant that

tiles became indistinguishable from natural materials, for example marbles and stone. All these

advances were available to everyone who had a digital inkjet printer; everyone could produce

Italian tiles time and time again the process was repeatable.

None of this would have happened without one other element the open ink model used in the

ceramic tile market. This means that the ink is bought independently of the printer manufacturer.

In most other digital inkjet markets, ink is purchased from the manufacturer of the printer who

often likes to keeps the price of their ink high as it produces a good revenue stream. This has

been the major contributor to keeping the price per label high, for example in the packaging

segment. In contrast, as the ceramic tile decoration has an unregulated ink market,

manufacturers are free to purchase their ink from the most competitive source and change that

ink as often as is commercially attractive. Xaar supports this open ink model by working directly

with ink partners to ensure their inks work to maximum capability in the printheads. In addition,

Xaar engineers provide carefully tuned waveforms that jet the ink reliably and accurately. The

open ink model has provided sufficient competitive pressure to reduce the price of digital inks in

the ceramic market and this has been a significant contributor to the adoption of digital printing

in ceramic tile production.

So with all these positive factors, we have seen a rapid take up of digital inkjet tile decoration

since 2007, reaching now, as noted earlier, approximately 40%. The revolution began in Europe

where the majority of production lines are now converted to digital, but it rapidly spread to other

large production areas, such as China, India and now Brazil, Iran and Turkey.

During this time Xaar has expanded its printhead family, by offering the Xaar 1001 GS12 in

2012, which is a larger drop version (12 pL smallest drop) of the original Xaar 1001 GS6

(6pL smallest drop). The larger drop increased the amount of colour that could be achieved

and has been perfect for floor tiles, where deep, rich browns or dark stone colours are

preferred. Alternatively the Xaar 1001GS12 can be used to increase the speed of printing whilst

still achieving the same level of colour as the Xaar 1001 GS6. More recently in March 2014 Xaar

released the All New Xaar 1002 family of printheads incorporating multiple innovative technology

features, drawing on Xaars many years in the ceramics industry to improve drop volume

uniformity and drop placement accuracy for an even higher quality printed image.

* All drop sizes are measured with Xaars test fluid, the final drop size achieved will be dependent upon the ink.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

The Xaar 1002 printheads feature 1000 Optimised Geometry nozzles that can jet and place

drops with the highest precision on the market. As a result the new printheads produce the

smooth tones and solid areas needed to replicate natural materials that are stunning

replications of the real thing.

At Xaar we expect that the conversion of production lines to digital decoration will continue as it

offers such great rewards, and in fact it is business critical for the tile manufacturers to remain in

the industry. In parallel we have also been thinking about what else could happen in the ceramic

tile industry, what are the next challenges? Where else can digital inkjet technology provide

benefits? Leading ceramic tile manufacturers are also looking for ways in which they can add

differentiation to their products again; since as everyone is able to decorate digitally, they can all

learn to manufacture the same patterned tiles.

Figure 3: Digital inkjet decorated tiles and Xaar 1002 printhead

The future

In Xaar we see a future where the whole of the production line is digital with multiple printers

linked to a common command and control centre.

Structure and relief

The first of these printers will be used to add the structure to a flat tile body. The present

technique to achieve the relief on a tile is to use a mould attached to the press. These moulds

are created by milling the required pattern on to metal pads, which are then used to stamp the

same pattern on to each tile as it is produced. This is an expensive process as it is expensive to

design the mould and also to set up, so that once mounted in the press a mould will be used to

produce many tiles. If we could do this digitally we could change the pattern of relief on every

tile, in the same way that the coloured decorative pattern can be changed on every tile using

digital inkjet printing today. The structure and coloured pattern could then be synchronised to

improve the realism of the natural material. Bringing digital technology to this area of ceramic tile

production would further reduce the set up costs and time and we predict it would increase the

number of tiles produced with structure.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

This technique is also required in another emerging area of ceramic tile manufacture: that of

large, thin tiles. These tiles are manufactured by extruding the base material, rather than by

pressing it. Digital inkjet printing could be used to add structure or texture to these tiles as it

would be an additive, non-contact process. This would increase the attractiveness and natural

look of these tiles at the same time as avoiding breakage of the thinner, less robust tiles.

Such a digital printer would need to be significantly different from the printers used today to add

the coloured decoration to tiles. The present digital inkjet printers put down on average between

2 and 8 g/m2 of coloured ink. To add structure (relief) to a tile would require hundreds of

grammes per square metre; in addition the particle size would be significantly larger than that

used today. The new Xaar 001 printhead will achieve these goals by jetting drops in the

nanolitre not picolitre range. It will have a drop size of between 70 and 200 nL, more than 1000x

greater than that of the present drop-on-demand printheads.

A printer capable of this level of fluid laydown could also be used in other applications, for

example applying the engobe and glaze to the tile body. Using digital technology in these

applications could reduce the amount of fluid used and allow further creativity to mix effects on

a tile. In the future a large volume digital printing technique could also be used to add technical

coatings to tiles, for example non-slip, antibacterial, water repellent or other coatings. Tiles

could also become more functional, for example embedding conductive elements to make

sensors for alarms, lighting or other systems.

Ceramic inkjet ink colour space

Coming back to adding the decorative pattern to the tile, at Xaar we have also been looking at

what can be done to improve this area of digital printing. One of the challenges during the

uptake in digital inkjet printing was that a new type of digital ink had to be developed. Previously

with screen printing, colour had been applied in pastes with large particle sizes, putting down

up to 50 or 100 g/m2 (rotary and flat screen respectively) of material onto the ceramic tile before

firing. The drop-on-demand inkjet printheads have internal dimensions measured in tens of

microns, which meant that the pigments for digital printing had to be delivered in a liquid and

that the particle size had to be carefully controlled to avoid particles blocking the channels and

nozzles in the printheads. The particle size and amount of pigment being deposited had an

impact on the range of colours that could be achieved.

The range of colours that can be achieved in printing are usually described using a Lab

diagram. The Lab colour space is made up of the L dimension which represents the lightness

of a colour and the a and b dimensions that represent the colour components. These

dimensions are calculated from the colour co-ordinates in a standard specified by the

International Commission on Illumination (a French Commission called the Committee

Internationale de l'Eclairage, or CIE) and are said to be the closest match to how humans

perceive colour and brightness. The full colour space is shown in Figure 4.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

Figure 4: The Lab colour space

If we represent this purely in the 2D colour space, ie not using L, then we can map out the

colour space that can be achieved with the standard colour sets for computer displays (the

RGB scale) and for standard digital inkjet printing with CMYK colours (Cyan, Magenta, Yellow

and blacK), which are used in desktop, label and other segments.

The three different shaded areas in Figure 5 show that with the RGB or CMYK colour sets it is

not possible to reproduce the complete range of colours that the eye can see. The only point at

which this becomes an issue is when you are trying to use the two different mediums to display

the same picture or image. It can be clearly seen that if you want the two images to look exactly

the same then it is necessary to restrict the range of colours on the computer display to match

that of the printer.

Visible

RGB

CMYK

Figure 5: Computer display and standard inkjet CMYK colour space

So what about the ceramic colours? Ceramic inks cannot use the same pigments as those

used in other digital inkjet applications ceramic tiles are subject to very high temperatures

during the firing process, up to 1200 C, in order to fuse the glass frit in the glaze to the body of

the tile. Therefore the pigments used in digital inkjet decoration of ceramic tiles have to be

capable of withstanding these high temperatures. The only pigments that will not be destroyed

by such a process are inorganic ones, for example metal oxides.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

The colour set used in the ceramics market is also different from that used in desktop, label or

wide-format printing; it generally consists of brown, beige, blue, black, yellow and pink due to

the limitations in the type of inorganic pigments used. This is further restricted to avoid pigments

made from toxic heavy metals. Although there are techniques to enable encapsulation of these

pigments to reduce their effective toxicity, many companies or countries insist on inks that do

not utilise these components. The sum of all these constraints is that the colour gamut (or range

of colours in a colour space) available from a set of ceramic inks is compromised.

There are no standard colour profiles available. These have to be sought from individual

suppliers of ceramic pigments, but in general terms we can say that ceramic pigments used in

traditional screen printing inks are challenged in mostly yellow and red colours (greens are not

as popular for tiles, roughly in the proportion shown below in Figure 6:

Figure 6: Computer display and standard inkjet CMYK colour space

For the majority of ceramic tiles this is acceptable. We all expect representations of natural

materials, which in general have a limited colour space stone is generally grey with some

variation, wood is generally brown/beige.

Traditional roller, or flat, screen printing inks (pastes) contain high concentrations of solids, made

up of inorganic pigments and frits, suspended in either mineral oil or glycols. The particle size of

these inks has a D90 of approximately 10 to 15 m. D90 is the standard method of describing

pigments and/or inks for many industries, it means that 90% of all particles in that set have a

diameter less than that value. D90 is chosen as the level of particles that can accurately be

measured by the available equipment. Scientists and experts who manufacture the equipment

advise against using D99 or D100 measurements; they state that any slight disturbance during

the measurement such as an air bubble or thermal fluctuation can significantly influence those

values. Plus the statistical methods that are used to calculate these values are not robust

because the actual numbers of particles at these extreme levels is by definition small.

So how does this compare with the inks that were developed for digital inkjet application of

pigments to ceramic tiles? Well the carrier fluids are generally the same oil or glycol both for

traditional and digital inkjet ceramic inks. The choice of carrier fluid enables the surface tension

and viscosity of the ceramic ink to be carefully controlled, which is important to ensure reliable

printing or jetting of the ink, both for traditional and digital inks.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

The significant difference between traditional and digital inks is the particle size allowed and the

concentration of solids in the inks. We mentioned before that traditional inks were pastes; the

carrier fluid is generally of the order of 10-15% by weight, the pigment 20-40% and the rest is

mostly made up by frit, with smaller amounts of other materials to adjust surface tension and

inhibit agglomeration, etc. Digital inks are liquids, still with high pigment loadings of over 20%

and more by weight, but without the high frit loading.

The particle size in digital inks is dictated by the internal dimensions of the printhead.

Drop-on-demand printheads from Xaar and other manufacturers have dimensions that are tens

of micro-meters, as they eject drops with volumes from as small as 6 pL. A 6 pL ceramic ink

drop will have a diameter of approximately 25 m so it is easy to see that the particles used in

traditional inks with a D90 of 10-15 m cannot be used with digital inkjet printing as they would

block the internal structures and the nozzles. In practice digital inks have particle sizes with a

D90 of less than 1 m. Part of this restriction is also due to the tendency of digital ceramic inks

to sediment. Remember, we have a high particle loading kept in suspension. In fact one of the

reasons that the Xaar 1001 (and now the Xaar 1002) was so successful is that its

TF Technology ensures that the ink is always kept in constant motion through the narrow

spaces in the printhead, there are no dead spots where the ink can sit and start to sediment

and any unwanted particles due to agglomeration are swept away from the printing nozzle and

can be removed by filters in the ink system.

Compare this to traditional inkjet printheads with no recirculation past the back of the nozzle

where inks sit in the firing chamber and can start to settle; the only way out of that firing

chamber is the nozzle.

The reduction in particle size affects the colour space that can be achieved with digital inks. In

some cases when pigments are ground to this small size they lose the majority of their ability to

reflect light; alternatively some can be destroyed by the melting process in the kiln. All this

makes it a challenge for ink manufacturers to find pigments that have good colour and are

non-toxic. The final result is a much reduced colour space for digital inks.

Figure 7: Computer display and standard inkjet CMYK colour space

The diagram in Figure 7 outlines the main colour challenges with digital ceramic inks versus

traditional colours. We can see that again yellow and red colours are the most affected. Better

reds can be achieved using cadmium, but as mentioned earlier the use of this is restricted.

Reds containing small amounts of gold can also improve the colour, but these are expensive.

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

More colour with inkjet

So what can be done? The final colour achieved by digital printing can be improved by two

methods. The first is increasing the amount of ink that is put down by the printing process. The

Xaar 1002 GS6 printhead has 6-42 pL drops and can place these in a 360 x 360 dpi grid when

running at approximately 25 m/min.

If we calculate the weight of fluid laid down when running at 100% of the largest available drop

size, with an ink of 1.2 g/cm3 density we can conclude that this will put down approximately

10 g/m2 per ink colour. So if there are 5 colours used on the tile, the maximum weight will be

50 g/m2 for this printhead. Needless to say when printing a ceramic image, it is not a 100 % full

coverage with all colours, so the laydown with a real image will be less than this, but it is all

lower than what can be achieved with traditional ceramic screen printing pastes.

This is why Xaar introduced the Xaar 1001 GS12 in 2012. With its 12-84 pL drops it was

capable of laying down up to 20 g/m2 per ink, significantly improving the colour that could be

achieved. There is always a trade-off to be made of course, larger drops are more visible to the

eye and can make the printed image appear more grainy. This is why the Xaar1001GS6 (now

Xaar 1002 GS6) remains a popular printhead when fine detail is required in wall tiles where they

are often viewed from a closer range.

This principle can be extended even further. Later in 2014, printers will be available with the

new Xaar 1002 GS40 which will have drop sizes ranging from 40 to 160 pL. This will further

extend the laydown to up to 40 g/m2 per colour which is close to the capability of rotary screen

printers. Xaars modelling/research predicts this will have a significant impact on the colour

gamut that can be achieved. Again, though this will come with large drops so it will not

replace the need for the Xaar 1002 GS6 or GS12, merely complement them, offering

enhancements in colour where required.

It is likely that this large drop printhead will also be used to add decorative glazes to the tiles,

replacing the single roller printer sometimes used to add these after the decoration stage of the

production line. Either this could be added as one or two extra printbars to an existing

machine, with perhaps a gloss glaze in one and a matt glaze in the other or as a stand-alone

machine in order to allow the colours to dry first. Removing this last roller machine would bring

all the usual digital benefits to that area: reduction in set up time and costs, ability to change

the glaze effect as often as you want, and of course enhance the range of creative effects that

can be achieved on the tile. For example more of the fusion tiles, where natural materials are

mixed with modern overprints. Moving into 2015, Xaar will release a further printhead in its Xaar

1002 family which will be capable of laying down more than 100 g/m2 on a tile.

The other area we are investigating is what can be achieved with particle size. We said that the

maximum particle size was limited by the size of the internal printhead structures and the

nozzle size, referring to the fact that the diameter of a 6 pL drop is around 25 m, the diameter

of a 12 pL drop is around 35 m and a 40 pL drop is around 55 m. What is the relationship

between the mechanical dimensions of the printhead and nozzle and the ability to reliably print

pigmented inks?

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

10

Some conventional pumping experts suggest as a rule of thumb that a ratio of 20:1

aperture:particle is necessary to enable free and uninhibited flow, but others say it is as low as

2:1. There is also reference to the velocity of flow that is required dependent on the size of the

pipe and the particle size, so it is not a simple calculation. Is that the same at our microfluidic

levels? Probably not. Xaar will be releasing further technical papers on this subject in the

coming months.

Xaar has been working with Instituto de Tecnologa Cermica in Castellon, Spain, as well as its

ink partners, firstly to understand the impact of particle size on colour and cost and secondly

on what improvements to the present inks can be attained. The cost of an ink is dependent on

many factors including the cost of the carrier medium, the cost of the additives and the cost of

preparing the pigments. Again it is not a simple calculation. Changing the carrier medium can

have two effects. Firstly it can make the ink harder or easier to prepare; secondly it will impact

the additives required. It cannot be assumed that reducing the cost of the carrier will definitively

reduce the final cost of the ink. What is true though is that if we can reduce the preparation

time of the ink it will help reduce the cost and one way we could do that is to reduce the milling

time of the pigment. A large particle size would further improve the colour gamut of the inks on

top of that, which can be achieved by increasing the amount of ink laid down.

If it was all so easy, then why hasnt it already happened? Of course it isnt that easy! We know

that digital ceramic inks are already heavily loaded and have a tendency to sediment. If we can

increase the particle size, then the tendency to sediment also increases. If we then have to

reduce the concentration of the pigment in the ink to regain stability, then we could be back to

the same point at which we started. There is a significant body of work to do to get the correct

balance of particle size, carrier fluid, additives to achieve the viscosity, surface tension and drop

velocities required to accomplish stable and reliable jetting of inks. Xaars TF Technology will

be vital in all of this. The constant circulation of the inks through the printhead and the ink

systems is critical if we increase particle size and ink volumes.

The flow-rate may also have an impact on the fluid behaviour and TF Technology delivers not

only the highest flow rate, but also the widest range of flow-rates to accommodate techniques

such as shear-thinning if required.

Glaze

Xaar 1002 001

Figure 8: Digitalisation of ceramics production line

Decoration

printer

Xaar 1002 GS6

Xaar 1002 GS12

Xaar 1002 GS40

Protective

glaze

Xaar 1002 GS40

Xaar 1002 SBX

Xaar 1002 001

DIGITAL INKJET CERAMICS WHERE DO WE GO FROM HERE?

11

Summary

Head Office / Europe + 44 1223 423 663 info@xaar.com

Hong Kong + 852 3690 8555 info@xaar.com

USA + 1 972 606 2520 americas@xaar.com

India + 91 124 668 8055 india@xaar.com

www.xaar.com

Issue 4 January 2015

In summary we have outlined the Xaar roadmap for ceramics for the near future. The new

members of the Xaar 1002 family available in 2014 and 2015 will be simple to add for Xaars

existing printer partners as they will be capable of being driven by the same Xaar electronics

and software that are available today. This will ensure that they will be rapidly available and can

even be added to existing printers where there are available printbars to put them in. These

printheads, along with the very large drop Xaar 001, form part of our continuing investment in

R&D targeted to moving along our vision of digitalising the entire deposition process in the

ceramic tile production line as far as possible.

You might also like

- Digital decoration advantages and economic benefits of Colorobbia inksDocument75 pagesDigital decoration advantages and economic benefits of Colorobbia inksHoonteck ChongNo ratings yet

- Fire More For Less PDFDocument5 pagesFire More For Less PDFJose Vicente Nuguid ErictaNo ratings yet

- Adjusting Engobe Layer to Avoid Water MarksDocument16 pagesAdjusting Engobe Layer to Avoid Water MarkserrairachidNo ratings yet

- Slip CastingDocument13 pagesSlip CastingRishi DasguptaNo ratings yet

- Textile Printing IIDocument25 pagesTextile Printing IIProfessorTextechNo ratings yet

- 0 Method For Effective Color Change in Extrusion Blow Molding Accumulator HeadsDocument5 pages0 Method For Effective Color Change in Extrusion Blow Molding Accumulator HeadsOscar ArellanoNo ratings yet

- Ceramic Tiles Manufacturing ProcessDocument29 pagesCeramic Tiles Manufacturing ProcessAlexia Vargas100% (1)

- Multiplate DemoDocument5 pagesMultiplate Demoapi-444451473No ratings yet

- How To Design, Make, and Install and Murals: Ceramic TilesDocument19 pagesHow To Design, Make, and Install and Murals: Ceramic TilesChanrathNo ratings yet

- Firing of Porcelain TilesDocument5 pagesFiring of Porcelain TilesRajarshi Dionysus BhattacharyyaNo ratings yet

- Glass-Ceramic Glazes For Ceramic Tiles PDFDocument53 pagesGlass-Ceramic Glazes For Ceramic Tiles PDFKristanto WahyudiNo ratings yet

- 15 RakuglazesDocument9 pages15 Rakuglazespotteryart54No ratings yet

- Deformations in CeramicsDocument6 pagesDeformations in Ceramicsashutoshgoel100% (1)

- Delayed Curvatures in Porous PDFDocument13 pagesDelayed Curvatures in Porous PDFerrairachidNo ratings yet

- Advanced Ceramics SyllabusDocument4 pagesAdvanced Ceramics Syllabusapi-285550989No ratings yet

- Glaze MaterialsDocument7 pagesGlaze MaterialssmiNo ratings yet

- 15 Cone 10 RecipesDocument10 pages15 Cone 10 RecipesInga NowakNo ratings yet

- Esmaltes Varios en Inglés FABIDocument8 pagesEsmaltes Varios en Inglés FABIclaul66100% (1)

- Ceramic Tile Drying AnalysisDocument10 pagesCeramic Tile Drying Analysismap vitcoNo ratings yet

- Printing ProcessDocument28 pagesPrinting ProcessGagan Hasija100% (1)

- Basic Slip CastingDocument3 pagesBasic Slip Castingnataliebuffalo100% (1)

- Tieng Anh Chuyen Nganh SilicatDocument77 pagesTieng Anh Chuyen Nganh SilicatChết SợNo ratings yet

- Ceramic Tiles Industry in IndiaDocument9 pagesCeramic Tiles Industry in Indiaaltaf_catsNo ratings yet

- Mason High - Ceramics 2 - Centerpiece Lesson PlanDocument4 pagesMason High - Ceramics 2 - Centerpiece Lesson Planapi-267189611No ratings yet

- White Wares by K-H SchullerDocument17 pagesWhite Wares by K-H SchullerChuff123No ratings yet

- Introduction To CeramicsDocument29 pagesIntroduction To CeramicsShrikrishna BirajdarNo ratings yet

- CHARU Ceramics Industry Ltd BackgroundDocument8 pagesCHARU Ceramics Industry Ltd BackgroundZareen Rashid ChoudhuryNo ratings yet

- Polishing Up On Finishing How To Stay Competitive Due To Optimized Surface FinishingDocument33 pagesPolishing Up On Finishing How To Stay Competitive Due To Optimized Surface Finishingชนพัทธ์ คงพ่วงNo ratings yet

- Ceramics - Engineer's HandbookDocument5 pagesCeramics - Engineer's HandbookhatharasingheNo ratings yet

- Year 9 Clay VocabularyDocument2 pagesYear 9 Clay Vocabularyapi-333348168No ratings yet

- Firing Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2Document5 pagesFiring Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2stueferNo ratings yet

- Curvature Evolution in Porcelain Tile During FiringDocument12 pagesCurvature Evolution in Porcelain Tile During Firingمحمد رمضانNo ratings yet

- Manufacturing of TilesDocument14 pagesManufacturing of TilesLino Tom Lino TomNo ratings yet

- Electric Kiln Firing TechDocument13 pagesElectric Kiln Firing TechStefan Van CleemputNo ratings yet

- Japanese Teabowl RubricDocument2 pagesJapanese Teabowl Rubricapi-95763097No ratings yet

- Antibacterial Additive For GlazeDocument1 pageAntibacterial Additive For Glazemd azizur RahamanNo ratings yet

- Preparing & Storing GlazeDocument4 pagesPreparing & Storing GlazeGianmarcoMolinaNo ratings yet

- La Meridiana Notes Paperclay PDFDocument3 pagesLa Meridiana Notes Paperclay PDFAnonymous FF4JjPdgNo ratings yet

- The Production Process of Ceramic TilesDocument4 pagesThe Production Process of Ceramic TilesjozsefczNo ratings yet

- Ceramic Technology - 2 PDFDocument90 pagesCeramic Technology - 2 PDFFA Ay50% (2)

- Applying Ceramic TransfersDocument8 pagesApplying Ceramic TransfersbeadysamNo ratings yet

- Slips and GlazesDocument3 pagesSlips and GlazesKelley_Eggert_800No ratings yet

- Roller KilnsDocument3 pagesRoller Kilnsjohan_nieuwoudtNo ratings yet

- Screen PrintingDocument11 pagesScreen PrintingRaja Pathamuthu.GNo ratings yet

- Discover the History and Uses of Ceramic MaterialsDocument7 pagesDiscover the History and Uses of Ceramic Materialsletter_ashish4444No ratings yet

- Porcelain Casting Slip and Plaster Mold TechniquesDocument4 pagesPorcelain Casting Slip and Plaster Mold TechniquesLauraNo ratings yet

- Narrative Ceramic Sculpture PressDocument24 pagesNarrative Ceramic Sculpture PressCannon Beach Arts Association100% (1)

- Large Pots - Bill ShinnDocument4 pagesLarge Pots - Bill ShinnStefan Van Cleemput100% (2)

- Basic Info About Glaze FormulationsDocument3 pagesBasic Info About Glaze FormulationsThongMaVanNo ratings yet

- CeramicColor PDFDocument12 pagesCeramicColor PDFSiddharthapachisiaNo ratings yet

- Ceramics: Windows To The FutureDocument75 pagesCeramics: Windows To The FuturevishwanathanskNo ratings yet

- Tool Techniques: Ceramic DecoratingDocument21 pagesTool Techniques: Ceramic DecoratingPatricia Daniela DiezNo ratings yet

- 43vocabulary Basic CeramicsDocument6 pages43vocabulary Basic CeramicsReshmi VarmaNo ratings yet

- 0 York Dec15cmDocument4 pages0 York Dec15cmapi-24483605No ratings yet

- Car Paint MaterialDocument1 pageCar Paint MaterialAbriel HaqqaniNo ratings yet

- Clay and GlazeDocument25 pagesClay and Glazelatinow100% (1)

- Salt Glaze SurfaceDocument11 pagesSalt Glaze SurfaceStefan Van Cleemput100% (1)

- 2ceramics Monthly Jun62 Cei0662dDocument44 pages2ceramics Monthly Jun62 Cei0662dMariana Pavan100% (1)

- Offset TrialDocument64 pagesOffset TrialOgi Permana PutraNo ratings yet

- Technical Data Sheet: Rheological Additive For Water Borne SystemDocument2 pagesTechnical Data Sheet: Rheological Additive For Water Borne SystemAlbert GhobrialNo ratings yet

- Plastic Quality ControlDocument13 pagesPlastic Quality ControlAlbert GhobrialNo ratings yet

- QC ManagerDocument11 pagesQC ManagerAlbert GhobrialNo ratings yet

- ASTM C 309 Curing CompoundDocument3 pagesASTM C 309 Curing CompoundAlbert Ghobrial0% (1)

- QC ManagerDocument11 pagesQC ManagerAlbert GhobrialNo ratings yet

- AkzoNobel Cembinder W Colloidal Silica Dispersions Tcm135-59253Document4 pagesAkzoNobel Cembinder W Colloidal Silica Dispersions Tcm135-59253Albert GhobrialNo ratings yet

- Eru201309 PDFDocument6 pagesEru201309 PDFEkaEmanNo ratings yet

- Msds - Cemex PortlandDocument7 pagesMsds - Cemex PortlandaniesbaekNo ratings yet

- TestDocument22 pagesTestAlbert GhobrialNo ratings yet

- d281-95 (2007) Standard Test Method For Oil Absorption of Pigments by Spatula Rub-OutDocument2 pagesd281-95 (2007) Standard Test Method For Oil Absorption of Pigments by Spatula Rub-OutAlbert Ghobrial100% (2)

- Big BjarkeDocument118 pagesBig BjarkeDragos Cristian Smau100% (2)

- Jackson Patrick Banman Sileci Susan Everybody Up 2 Student BDocument83 pagesJackson Patrick Banman Sileci Susan Everybody Up 2 Student Bminakirolos100% (3)

- Tambour Beading PDFDocument4 pagesTambour Beading PDFmaineknitter100% (4)

- Art Key Contemporary Thinkers PDFDocument225 pagesArt Key Contemporary Thinkers PDFgeox12100% (3)

- EstridentópolisDocument27 pagesEstridentópolisArt DNo ratings yet

- Munsell Soil Colour Book 07.08Document2 pagesMunsell Soil Colour Book 07.08Karthik GokulNo ratings yet

- LLU Landscape Architecture and ArtDocument92 pagesLLU Landscape Architecture and ArtIeva GgNo ratings yet

- PDF Catalogue Product Range 2009 PDFDocument26 pagesPDF Catalogue Product Range 2009 PDFAlita SativaNo ratings yet

- Nift-Thesis Synopsis UpdatedDocument11 pagesNift-Thesis Synopsis UpdatedMuhammed Faris100% (1)

- Auguste Rodin BiographyDocument2 pagesAuguste Rodin Biographyactenfen100% (1)

- Past Form Ing' Form Abide Arise Awake Be Bear Beat Past Participle FormDocument12 pagesPast Form Ing' Form Abide Arise Awake Be Bear Beat Past Participle FormBalkrishnaSangoleNo ratings yet

- EXPRESSIONISM PowerpointDocument35 pagesEXPRESSIONISM PowerpointJayzeel Castor Casaria - FarillonNo ratings yet

- CollageDocument84 pagesCollageVirgilio Biagtan100% (1)

- Aluflam Fixed Windows MarineDocument3 pagesAluflam Fixed Windows MarinenookboatNo ratings yet

- SculptureDocument23 pagesSculpturezayn malinkNo ratings yet

- Late Gothicearly Renaissance Gilding Technology and The Traditional Poliment Material Armenian Bole-Truly Red Clay or Rather BauxiteDocument11 pagesLate Gothicearly Renaissance Gilding Technology and The Traditional Poliment Material Armenian Bole-Truly Red Clay or Rather BauxitedudaNo ratings yet

- Landmarks and Attractions in ArmeniaDocument6 pagesLandmarks and Attractions in ArmeniaGatis PavilsNo ratings yet

- Paint Data Sheet - National Synthetic Enamel Gloss IDocument3 pagesPaint Data Sheet - National Synthetic Enamel Gloss Iaakh0% (1)

- Famo Afrika KorpsDocument10 pagesFamo Afrika KorpsGustavo Urueña A100% (6)

- Connelly, Parthenon and ParthenoiDocument29 pagesConnelly, Parthenon and ParthenoiMichael SanchesNo ratings yet

- Rock Garden, Chandigarh: Case Study ofDocument21 pagesRock Garden, Chandigarh: Case Study ofHarsh DadheechNo ratings yet

- Afo Perspective 2 Point LegosDocument2 pagesAfo Perspective 2 Point Legosapi-417919455No ratings yet

- 01 Ner Ideas Geom Nonmeta BookDocument10 pages01 Ner Ideas Geom Nonmeta BookNivedita SharmaNo ratings yet

- American Tube and Controls, Inc. v. General Fittings Company, 407 F.2d 1291, 1st Cir. (1969)Document3 pagesAmerican Tube and Controls, Inc. v. General Fittings Company, 407 F.2d 1291, 1st Cir. (1969)Scribd Government DocsNo ratings yet

- 032c MK 2012Document6 pages032c MK 2012Matteo GiordanoNo ratings yet

- History of Art Timeline (1) - Compressed-CompressedDocument86 pagesHistory of Art Timeline (1) - Compressed-CompressedRamya shriNo ratings yet

- Reference by Anis Daraghma OkDocument2 pagesReference by Anis Daraghma OkAnonymous s0lDen9VJWNo ratings yet

- Ajanta ElloraDocument11 pagesAjanta EllorabalakumaranarchNo ratings yet

- Paint DetackificationDocument15 pagesPaint DetackificationbexigaobrotherNo ratings yet

- Foundations of A Visual MusicDocument15 pagesFoundations of A Visual MusicVicente Barba VarelaNo ratings yet