Professional Documents

Culture Documents

Guidance On Appendix Ia PDF

Uploaded by

Aboytes Macoy0 ratings0% found this document useful (0 votes)

134 views2 pagesApendice de FSSC-22000,

Original Title

guidance-on-appendix-ia.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentApendice de FSSC-22000,

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

134 views2 pagesGuidance On Appendix Ia PDF

Uploaded by

Aboytes MacoyApendice de FSSC-22000,

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

FSSC 22000 guidance on Appendix IA

The following provides additional information relating to questions arising from

the revised requirements

Appendix 1A item 3 Specific Regulatory Requirements

Organizations seeking certification shall assure that specifications for ingredients

and materials take account of any applicable regulatory requirements [e.g. control

of prohibited substances].

This new requirement is essentially an extension of the requirements given in ISO22000

7.3.3.1, to assure that all applicable statutory and regulatory requirements are identified

and incorporated into specifications.

ISO22000 7.3.3.1 states All raw materials, ingredients and product contact materials

shall be described in documents to the extent needed to conduct the hazard analysis

and goes on to say The organization shall identify statutory and regulatory food safety

requirements related to the above.

The difference between the ISO requirement and the revised FSSC 22000 scheme text is

due to the limitations incorporated in the ISO text:

A] The ISO text is limited to information needed to carry out the hazard analysis, and it

is therefore possible that some substances may be omitted, and

B] The ISO text is limited to identifying statutory and regulatory food safety

requirements, not all statutory and regulatory requirements.

Requirements that need to be considered for inclusion in the specifications may include,

but are not limited to: specific micro requirements, mycotoxin levels, glycoalkaloid levels,

prohibited colours and/or flavours, maximum or minimum preservative levels and

migration potential.

Appendix 1A item 4 Announced but unscheduled Audits of Certified

Organizations

The certification body will participate in a risk-based programme of office audits

and announced, but unscheduled audits of certified organizations. These audits

shall be carried out in accordance to the GFSI requirements.

The question arises as to what is meant by announced, but unscheduled audits of

certified organizations. The GFSI GD Section 2.5.6 gives no further explanation or

guidance, but there is a definition given later in the GD that describes: Unscheduled

Supplier Audits: Audits planned within a defined programme, but without the allocation of

a specific programme date.

We have interpreted this as for a given year we will announce to CBs that we will

"witness" audit an X number of certified organizations. The dates and locations for these

audits will be chosen from the CBs audit schedule (list of audit dates, auditor names and

client locations).

FSSC 22000 guidance on Appendix IA

Appendix 1A item 5 Management of inputs

The organization shall implement a system to assure that analysis of inputs

critical to the confirmation of product safety is undertaken. The analyses shall be

performed to standards equivalent to those described in ISO 17025.

Note: The requirement wording is very specific: it is not about the achievement or

maintenance of product safety, but about the confirmation of product safety.

Inputs critical to the confirmation of product safety may include any material that is

added to the product or used as a processing aid. What makes the input critical is the

potential to introduce contamination such as pathogens, aflatoxins, pesticide residues,

heavy metals etc. or a specific property that affects the product such as pH value or

moisture content.

Raw and packaging materials will normally be subject to specified requirements and are

tested to assure that they present no risk to the product or process. Where testing may

not be the norm [for example in the case of water, steam or ice] the organization has to

determine if there is potential risk to the safety of the product.

In cases where risk is identified [for example, by application of HACCP principles], an

appropriate testing protocol must be put in place. The testing must be carried out to

standards equivalent to those described in the laboratory accreditation standard

ISO17025.

This does not mean that the testing has to be carried out by an accredited laboratory,

but non-accredited laboratories must be able to demonstrate that they follow the

principles of the standard. This will include, but is not limited to use of recognized,

validated test methods, calibration of instruments, proficiency testing of analysts,

traceability of samples and results etc.

FSSC 22000 guidance on Appendix IA

You might also like

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19From EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19No ratings yet

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- FSSC 22000 Audit TemplateDocument15 pagesFSSC 22000 Audit Templatedakalo8375% (8)

- ISO - IEC 17065 - 2012 (En), Conformity Assessment - VocabularioDocument5 pagesISO - IEC 17065 - 2012 (En), Conformity Assessment - VocabularioFCBNo ratings yet

- G 2408 Accreditation Criteria For Inspection of Food Inspection BodiesDocument7 pagesG 2408 Accreditation Criteria For Inspection of Food Inspection Bodiessafeer ahmadNo ratings yet

- FSSC 22000: Foundation For Food Safety CertificationDocument14 pagesFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedNo ratings yet

- Quality ManualDocument28 pagesQuality Manualanon_217857558100% (8)

- Comparison of Iso 9001 and Iso 22000Document4 pagesComparison of Iso 9001 and Iso 22000Eddie Ajalcriña Bocangel100% (1)

- Welcome: ISO 13485:2016 & MDRDocument75 pagesWelcome: ISO 13485:2016 & MDR601026100% (1)

- Key Changes in ISO 22000Document4 pagesKey Changes in ISO 22000miz baigNo ratings yet

- FSSC Harmonisation 2018Document38 pagesFSSC Harmonisation 2018victoria3goNo ratings yet

- Gap ToolDocument204 pagesGap Toolazire carlosNo ratings yet

- Is 14489 1998Document19 pagesIs 14489 1998Imran Bagwan100% (1)

- Quality Control and Quality AssuranceDocument25 pagesQuality Control and Quality AssuranceArshad Khan100% (1)

- What Is A Validation Master Plan (VMP) and How Do You Write OneDocument12 pagesWhat Is A Validation Master Plan (VMP) and How Do You Write One王仁宏No ratings yet

- ISO - IsO 9008 - 2000 - Guidance On 'Outsourced Processes'Document2 pagesISO - IsO 9008 - 2000 - Guidance On 'Outsourced Processes'97explorerNo ratings yet

- Iso 22003 1 and Iso 22003 2 Presentation GeneralDocument25 pagesIso 22003 1 and Iso 22003 2 Presentation Generaldenisenko.marina2017No ratings yet

- SOP For Regulatory Annual Product Quality ReviewDocument9 pagesSOP For Regulatory Annual Product Quality ReviewisralmayoorNo ratings yet

- Noblitt Rueland ISO13485 2003 Part1Document4 pagesNoblitt Rueland ISO13485 2003 Part1Omnex Inc.No ratings yet

- Chapter 5.0 HALAL INTERNAL AUDIT FACILITATIONDocument88 pagesChapter 5.0 HALAL INTERNAL AUDIT FACILITATIONprincess sabbyNo ratings yet

- A Review of The Changes in ISO 13485Document4 pagesA Review of The Changes in ISO 13485Ola Gf OlamitNo ratings yet

- fssc22000 Part1 v3.2 2015Document15 pagesfssc22000 Part1 v3.2 2015Jose Lopez100% (1)

- Guidance For Industry: Process ValidationDocument18 pagesGuidance For Industry: Process ValidationBruno DebonnetNo ratings yet

- Iso 22000 DocumentationDocument3 pagesIso 22000 DocumentationBAlaNo ratings yet

- Training On ISO-TS 22003 Part 1 of 2Document50 pagesTraining On ISO-TS 22003 Part 1 of 2Ariv - GRNo ratings yet

- Questions and Answers About The FSSC 22000 CertificationDocument4 pagesQuestions and Answers About The FSSC 22000 CertificationediasianagriNo ratings yet

- How To Establish An FSSC 22000 ProgramDocument16 pagesHow To Establish An FSSC 22000 ProgramfaisalNo ratings yet

- FSSC 22000: Requirements and Regulations For Certification BodiesDocument41 pagesFSSC 22000: Requirements and Regulations For Certification BodiesJose LopezNo ratings yet

- Nbog-2010-1 (Auditing Suppliers)Document7 pagesNbog-2010-1 (Auditing Suppliers)DO KHNo ratings yet

- Process Validation Guidelines PDFDocument13 pagesProcess Validation Guidelines PDFran_ooNo ratings yet

- 1 API Q1 and API 6D Welding RequirementsDocument25 pages1 API Q1 and API 6D Welding RequirementsSiva100% (1)

- Food Safety FrostDocument2 pagesFood Safety FrostPepe ValdiviaNo ratings yet

- FOOD SAFETY MANAGEMENT SYSTEM MANUALDocument44 pagesFOOD SAFETY MANAGEMENT SYSTEM MANUALYoneto Yasuhiko78% (23)

- OHSAS PresentationDocument72 pagesOHSAS PresentationMahendraNo ratings yet

- OutsourcingDocument2 pagesOutsourcingNarayana Rao PuppalaNo ratings yet

- Audit Report Requirements FSSC 22000 Version 6 1685175466Document48 pagesAudit Report Requirements FSSC 22000 Version 6 1685175466Ruben VenturaNo ratings yet

- FSC Audit GuidelinesDocument86 pagesFSC Audit GuidelinesroostercockburnNo ratings yet

- GHTF-Quality Management System - Medical Devices - Guidance On The Control of Products and Services Obtained From SuppliersDocument21 pagesGHTF-Quality Management System - Medical Devices - Guidance On The Control of Products and Services Obtained From SuppliersSam MosesNo ratings yet

- Aerospace Quality Management SystemsDocument10 pagesAerospace Quality Management SystemsvarishaNo ratings yet

- 05 Guidance On Outsourced ProcessesDocument4 pages05 Guidance On Outsourced ProcessesNavnath TamhaneNo ratings yet

- Audit Checklist TemplateDocument18 pagesAudit Checklist TemplateDesi AgustiniNo ratings yet

- 2) IAF Communique ISO 9001Document2 pages2) IAF Communique ISO 9001loraxreaderNo ratings yet

- Guidance For Industry and FDA Staff Assayed and Unassayed Quality Control MaterialDocument13 pagesGuidance For Industry and FDA Staff Assayed and Unassayed Quality Control Materialsyparab1977No ratings yet

- AAPG ExpectedOutcomesDocument6 pagesAAPG ExpectedOutcomesArnulfo Guerrero MartinezNo ratings yet

- Diff 9001 - 2000 & 9001 - 2008Document4 pagesDiff 9001 - 2000 & 9001 - 2008ranjans1234567890No ratings yet

- TC 176 SC 2 N 630R3 Guidance On Outsourced ProcessesDocument4 pagesTC 176 SC 2 N 630R3 Guidance On Outsourced ProcessesGraciliano Francisco LourençoNo ratings yet

- Definitive Expected Outcomes Iso9001Document2 pagesDefinitive Expected Outcomes Iso9001ozgursurNo ratings yet

- Guide To Implementing Iso 22000Document34 pagesGuide To Implementing Iso 22000getaneh abebeNo ratings yet

- Food Safety AuditingDocument20 pagesFood Safety AuditingBrian Estrada100% (1)

- Implementation Example For PO-PROC-WIDocument9 pagesImplementation Example For PO-PROC-WIEsheshNo ratings yet

- Guidance Document Verification For TMHS ManufacturersDocument25 pagesGuidance Document Verification For TMHS ManufacturersNurul amirahNo ratings yet

- The New ISO IEC 17025 2017Document9 pagesThe New ISO IEC 17025 2017Saraswanto33% (3)

- The New ISO IEC 17025 2017Document9 pagesThe New ISO IEC 17025 2017Omar SalasNo ratings yet

- Validation in Pharmaceutical ManufacturingDocument6 pagesValidation in Pharmaceutical ManufacturingDharmesh PatelNo ratings yet

- FSSC 22000-Q: Quality ModuleDocument9 pagesFSSC 22000-Q: Quality ModuleJose LopezNo ratings yet

- Audit Risk Alert: General Accounting and Auditing Developments, 2017/18From EverandAudit Risk Alert: General Accounting and Auditing Developments, 2017/18No ratings yet

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- A Guide to Effective Internal Management System Audits: Implementing internal audits as a risk management toolFrom EverandA Guide to Effective Internal Management System Audits: Implementing internal audits as a risk management toolRating: 3 out of 5 stars3/5 (5)

- PAPER LEAN The Application of Value Stream Mapping BasedDocument7 pagesPAPER LEAN The Application of Value Stream Mapping BasedFrancis ParedesNo ratings yet

- Proceedings of The 15th International Conference On Industrial Engineering and Industrial Management and XXV CIO-with-cover-page-V2Document263 pagesProceedings of The 15th International Conference On Industrial Engineering and Industrial Management and XXV CIO-with-cover-page-V2Aboytes MacoyNo ratings yet

- The Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997Document29 pagesThe Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997Aji Putra PNo ratings yet

- PAPER LEAN The Application of Value Stream Mapping BasedDocument7 pagesPAPER LEAN The Application of Value Stream Mapping BasedFrancis ParedesNo ratings yet

- VSM ApicsDocument22 pagesVSM ApicsPedro Gabriel GonzálezNo ratings yet

- PDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (103-107)Document5 pagesPDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (103-107)Aboytes MacoyNo ratings yet

- PDVSM v.1 2005 VSM para Desarrollo de Producto (001-100)Document100 pagesPDVSM v.1 2005 VSM para Desarrollo de Producto (001-100)Aboytes MacoyNo ratings yet

- PDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (101-102)Document2 pagesPDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (101-102)Aboytes MacoyNo ratings yet

- PDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (108-116)Document9 pagesPDVSM - V.1 - 2005 - VSM - para Desarrollo de Producto (108-116)Aboytes MacoyNo ratings yet

- PDVSM v.1 2005 VSM para Desarrollo de Producto (001-100)Document100 pagesPDVSM v.1 2005 VSM para Desarrollo de Producto (001-100)Aboytes MacoyNo ratings yet

- Iso 9000 No Es Una Enfermedad EconomicaDocument9 pagesIso 9000 No Es Una Enfermedad EconomicaAboytes MacoyNo ratings yet

- Pas 223 2011Document28 pagesPas 223 2011Aboytes Macoy50% (2)

- Normas TAPPI - ListadoDocument92 pagesNormas TAPPI - Listadoclaudio ponceNo ratings yet

- BRC Packaging Quick Guide Screen PDFDocument4 pagesBRC Packaging Quick Guide Screen PDFAboytes MacoyNo ratings yet

- FSSC 22000Document75 pagesFSSC 22000Sonia Esperanza80% (5)

- Haccp and HarpcDocument21 pagesHaccp and HarpcAboytes MacoyNo ratings yet

- Use of The Internet in EducationDocument23 pagesUse of The Internet in EducationAlbert BelirNo ratings yet

- There Will Come Soft RainsDocument8 pagesThere Will Come Soft RainsEng ProfNo ratings yet

- Management PriniciplesDocument87 pagesManagement Priniciplesbusyboy_spNo ratings yet

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDocument4 pages147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNo ratings yet

- Sheet-Metal Forming Processes: Group 9 PresentationDocument90 pagesSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNo ratings yet

- 2013-01-28 203445 International Fault Codes Eges350 DTCDocument8 pages2013-01-28 203445 International Fault Codes Eges350 DTCVeterano del CaminoNo ratings yet

- G.Devendiran: Career ObjectiveDocument2 pagesG.Devendiran: Career ObjectiveSadha SivamNo ratings yet

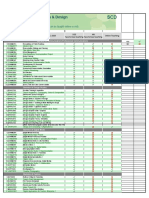

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Topic: Grammatical Issues: What Are Parts of Speech?Document122 pagesTopic: Grammatical Issues: What Are Parts of Speech?AK AKASHNo ratings yet

- CE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Document6 pagesCE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Angelice Alliah De la CruzNo ratings yet

- Management Accounting by Cabrera Solution Manual 2011 PDFDocument3 pagesManagement Accounting by Cabrera Solution Manual 2011 PDFClaudette Clemente100% (1)

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- Basic Terms/Concepts IN Analytical ChemistryDocument53 pagesBasic Terms/Concepts IN Analytical ChemistrySheralyn PelayoNo ratings yet

- FINAL SMAC Compressor Control Philosophy Rev4Document6 pagesFINAL SMAC Compressor Control Philosophy Rev4AhmedNo ratings yet

- Service Quality Dimensions of A Philippine State UDocument10 pagesService Quality Dimensions of A Philippine State UVilma SottoNo ratings yet

- Peter Szekeres-Solutions To Problems of A Course in Modern Mathematical Physics - Groups, Hilbert Space and Differential Geometry PDFDocument382 pagesPeter Szekeres-Solutions To Problems of A Course in Modern Mathematical Physics - Groups, Hilbert Space and Differential Geometry PDFMed Chouaybi0% (1)

- Uniform Motion WorksheetDocument8 pagesUniform Motion Worksheetnikhil patro100% (1)

- Civil Rights Vocabulary Lesson PlanDocument4 pagesCivil Rights Vocabulary Lesson PlanKati ArmstrongNo ratings yet

- Abnt NBR 16868 1 Alvenaria Estrutural ProjetoDocument77 pagesAbnt NBR 16868 1 Alvenaria Estrutural ProjetoGIOVANNI BRUNO COELHO DE PAULANo ratings yet

- Accessoryd-2020-07-31-185359.ips 2Document20 pagesAccessoryd-2020-07-31-185359.ips 2Richard GarciaNo ratings yet

- Structural Design Basis ReportDocument31 pagesStructural Design Basis ReportRajaram100% (1)

- Pam8610 PDFDocument15 pagesPam8610 PDFRaka Satria PradanaNo ratings yet

- Department of Ece, Adhiparasakthi College of Engineering, KalavaiDocument31 pagesDepartment of Ece, Adhiparasakthi College of Engineering, KalavaiGiri PrasadNo ratings yet

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDocument9 pages2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNo ratings yet

- Audi A4-7Document532 pagesAudi A4-7Anonymous QRVqOsa5No ratings yet

- RH-A Catalog PDFDocument1 pageRH-A Catalog PDFAchmad KNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Passage To Abstract Mathematics 1st Edition Watkins Solutions ManualDocument25 pagesPassage To Abstract Mathematics 1st Edition Watkins Solutions ManualMichaelWilliamscnot100% (50)

- Chapter 2 Short-Term SchedulingDocument49 pagesChapter 2 Short-Term SchedulingBOUAZIZ LINANo ratings yet

- Sabian Aspect OrbsDocument8 pagesSabian Aspect Orbsellaella13100% (2)