Professional Documents

Culture Documents

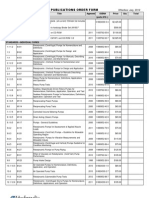

Onshore Natural Gas Pipeline Transportation Alternatives - Capital Cost Comparisons - Campbell Tip of The Month

Uploaded by

afigueredouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Onshore Natural Gas Pipeline Transportation Alternatives - Capital Cost Comparisons - Campbell Tip of The Month

Uploaded by

afigueredouCopyright:

Available Formats

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

PublicCourses

InHouseCourses

OperatorTraining

OnshoreNaturalGasPipelineTransportation

Alternatives:CapitalCostComparisons

Tweet

InrecentTOTMs(JanuarythroughApril,August,andSeptember2012andagaininJanuary2013),we

discussedseveralaspectsofthephysicalbehaviorandtransportationofcarbondioxide(CO2 )andnatural

gasinthedensephase.Weillustratedhowthermophysicalpropertieschangeinthedensephaseand

theirimpactsonpressuredropcalculations.Thepressuredropcalculationutilizingtheliquidphaseand

vaporphaseequationswascompared.

IntheAugust2012(TOTM),westudiedtransportationofrichnaturalgasinthedensephaseregionand

comparedtheresultswiththecaseoftransportingthesamegasusingatwophase(gasliquid)option.

Ourstudyhighlightedtheprosandconsofdensephasetransportation.

InSeptember2012(TOTM),weanalyzedpipelinetransportationofaleannaturalgasatawiderangeof

operatingpressuresfromtherelativelylowpressuretypicalinmanygastransmissionpipelinestomuch

higherpressureswellintothedensephaseregion.

InJanuary2013(TOTM),weestimatedcapitalcosts(CAPEX)asatooltocomparethenselectedtheoperating

conditionsandassociatedfacilitiesforalongdistancehighvolumeflowgastransmissionpipeline.

InthismonthsTipoftheMonth(TOTM),wewillrevisittheJanuary2013(TOTM)andcontinuetoexplorealternatives

specificallyforonshorenaturalgastransportationinpipelines.Thismonthsfocusisalsoontheestimationofcapital

costsasatooltocomparethenselecttheoperatingpressuresandassociatedfacilitiesforalongdistance,highvolume

flowgastransmissionpipeline.

CaseStudy:

WewillcontinuetouseasimilarcasestudybasisasusedintheSeptember2012TOTM.Thegascompositionand

conditionsarepresentedinTable1.Forsimplicity,thecalculationsandsubsequentdiscussionwillbedoneonthedry

basis.Thefeedgasdewpointwasreducedto40C(40F)bypassingitthroughamechanicalrefrigerationdewpoint

controlplant.TheresultingcompositionandconditionsoftheleangasarealsopresentedinTable1.Theleangashas

aGrossHeatingValueof40.33MJ/Sm3(1082BTU/scf).Thepipelineparametersare:

Lengthis1609km(1000miles)long

Pipelineoutsidediameteris1067mm(42inches)forcasesAthroughC.CaseDoutsidediameteris:914mm

(36in)

Steadystateconditionsareassumed.

Pressureatdeliverypointandsuctionateachcompressorstationis7MPa(1015Psia)

Thisisahorizontalpipelinewithnoelevationchange.

OverallHeatTransferCoefficient:1.42W/m2 C(0.25Btu/hrft2 F).

Ambienttemperatureis18.3C(65F).

Compressorpolytropicefficiencyis75%.

Pressuredropincoolers35kPa(5Psia)

Simulationsoftware:ProMaxandusingEquationofStatefromSoaveRedlichKwong(SRK).

Searchfor:

Search

EnglishTOTMHome

SpanishTOTMHome

Archives

November2015

October2015

September2015

August2015

July2015

June2015

May2015

April2015

March2015

February2015

January2015

December2014

November2014

October2014

September2014

August2014

July2014

June2014

May2014

April2014

March2014

Fourcasesofonshoretransportationofthisnaturalgasareconsideredandeachisexplainedbrieflybelow.The

numberofpipelinesegments,segmentlength,andinletpressureofeachsegmentforthefourcasesarepresentedin

Table2intheSI(SystemInternational)andfield(FPS,foot,poundandsecond)setsofunits.

HydraulicsSimulationResultsandDiscussions:

ThefourcasesaresimulatedusingProMax[3]todeterminethepressureandtemperatureprofiles,thecompression

horsepower,andtheaftercoolerduties.Table3presentsasummaryofsimulationresultsforthethreecasesinFPS

andSIsystemsofunits.

CaseA:HighPressure(DensePhase)

February2014

January2014

December2013

November2013

October2013

September2013

August2013

July2013

June2013

May2013

April2013

March2013

February2013

January2013

December2012

November2012

October2012

September2012

August2012

July2012

June2012

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

1/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

Thispipelineisasinglecompressorstationconfiguration.Thepipelineinletpressureisinthedensephasezone.After

processingandpassingthroughthefirststagescrubber,theleangaspressureisraisedfrom4.24to9.363MPa(615to

1358Psia),thencooledto37.8C(100F).Thegasiscompressedfurtherinthesecondstageto20.684MPa(3000

Psia).Thehighpressurecompressedgasiscooledbackto37.8C(100F)andthenpassedthroughaseparator

beforeenteringthelongpipeline.

May2012

April2012

March2012

February2012

CaseB:IntermediatePressure

January2012

December2011

Thispipelinehasthreecompressorstationseachequallyspacedat536km(333miles).Thepipelineinletpressureis

nearthedensephasezone.Inthefirststation,thepressureisraisedfrom4.24to12.8MPa(615to1858Psia)andin

thesubsequenttwostations,thepressureisraisedfrom7to12.8MPa(1015to1858Psia)inonestage,thencooledto

37.8C(100F),andfinallypassedthroughaseparatorbeforeenteringeachpipelinesegment.

November2011

October2011

September2011

CaseC:LowPressure

August2011

Thispipelinehasfivecompressorstationsequallyspacedin322km(200mile)segments.Inthefirststation,the

pressureisraisedfrom4.24to10.9MPa(615to1577Psia)andinthesubsequentfourstations,thepressureisraised

from7to10.9MPa(1015to1577Psia)inonestage,thencooledto37.8C(100F),andfinallypassedthrougha

separatorbeforeenteringeachpipelinesegment.Thepipelineinletpressureiswellbelowthatfordensephase.

July2011

June2011

May2011

April2011

March2011

February2011

January2011

December2010

November2010

October2010

September2010

August2010

July2010

June2010

May2010

April2010

March2010

CaseD:HighPressure

February2010

ThiscaseissimilartocaseBexceptitoperatesinthedensephaseandtheoutsidediameteris914mm(36inches).

Thispipelinehasthreecompressorstationseachequallyspacedat536km(333miles).Thepipelineinletpressureisin

thedensephasezone.Afterprocessingandpassingthroughthefirststagescrubber,theleangaspressureisraised

from4.24to8.67MPa(615to1257Psia),thencooledto37.8C(100F).Thegasiscompressedfurtherinthesecond

stageto17.72MPa(2570Psia).Thehighpressurecompressedgasiscooledbackto37.8C(100F)andthenpassed

throughaseparatorbeforeenteringthelongpipeline.Ineachsubsequentstation,thepressureisraisedfrom7to17.7

MPa(1015to2565Psia)inonestage,thencooledto37.8C(100F),andfinallypassedthroughaseparatorbefore

enteringeachpipelinesegment.

January2010

AscanbeseeninTable3,CaseAwithasinglecompressorstationrequirestheleasttotalcompressionpowerand

lowestheatdutyrequirements.ThepowerincreaseforCaseB(withthreecompressorstations)isabout38%compared

toCaseAand54%and89%forCasesC(with5compressorstations)andD(with3compressorstations),respectively.

Theseincreasesinpowerandheatdutyrequirementsaresignificant.Similarly,theheatdutyincreasesareabout6,1,

and59%forcaseBthroughDcomparedtocaseA,respectively.

August2009

VariationofgaspressuresisshownonFigure1forCasesAandB.AsdiscussedinthepreviousTOTM,whenthe

phasediagramandthepressureprofilesarecrossplottedusingthepressureandtemperatureprofilesthepipeline

outletconditionremainstotherightofthedewpointcurvewiththegasremainingassinglephase.

December2009

November2009

October2009

September2009

July2009

June2009

May2009

April2009

March2009

February2009

January2009

December2008

November2008

October2008

September2008

August2008

July2008

June2008

May2008

April2008

March2008

February2008

January2008

December2007

November2007

October2007

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

2/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

MechanicalDesign(WallThicknessandGrade)

September2007

Pipelinewallthicknessisanimportanteconomicfactor.Pipelinematerialshavehistoricallyrepresentedapproximately

40%oftheCapitalExpense(CAPEX)ofapipeline.Constructionhashistoricallyaccountedforapproximately40%of

theCAPEXaswell.TheestimationoftheCAPEXisdevelopedlaterinthisTOTM.Oncethewallthicknessisdetermined,

thenthetotalweight(tonnage)ofthepipelinecanbecalculatedaswellascostsforthepipelinesteel.

August2007

July2007

May2007

Thewallthickness,t,forthethreecasesiscalculatedfromavariationoftheBarlowEquationfoundintheASMEB31.8

StandardforGasTransmissionPipelines:

April2007

June2007

March2007

February2007

January2007

December2006

November2006

October2006

Where,

Pismaximumallowableoperatingpressure,heresetto1.1timestheinletpressure,

ODisoutsidediameter,

Eisjointefficiency(assumedtobe1)sincethepipelinewillbejoinedwiththroughthicknessbuttweldsand

100%inspected,

Fisdesignfactor,(rangesfrom0.4to0.72)andheresettobe0.72(forremotearea),

Tisthetemperaturederatingfactorandisalso1.0withtheinlettemperaturesnomorethan37.8C(100F).

isthepipematerialyieldstress(GradeX70=70,000psior448.2MPa),and

CAisthecorrosionallowance(assumedtobe0inor0mm,forthisdrygas).

Aftercalculatingthewallthickness,thediametertowallthicknessratio(D/t)ischeckedagainsttheserulesofthumb:

OnshorepipelineswillhaveamaximumD/tof72.

IftheD/tcalculatedistoohigh,thewallthicknesswillbeincreasedtoyieldthemaximumallowedD/t.

September2006

August2006

July2006

June2006

May2006

April2006

March2006

February2006

January2006

December2005

November2005

October2005

September2005

August2005

July2005

June2005

CompleteArchives

FreeSubscription

Topics

GasProcessing

Mechanical

Pipeline

Usingthecalculatedpipelineinletpressuresfromthehydraulicsasthestartingpoint,theMAOP,andthenthewall

thicknesscanbecalculated.ThecalculatedwallthicknessisthencheckedagainstthemaximumD/tcriteria.Table4

summarizesthesecalculationsforthefourcasesofonshorelocations.

Knowingthewallthicknessanddiameterallowstheweightperlineallength(footormeter)tobecalculated.Thetotal

weightofthesteelforthe1609km(1000mile)longcanthenbecalculatedaswell.Theunitweightisgiveninkg/m

(lbm/ft)andthetotalweightinmetrictonnes(1000kg)andshorttons(2000pounds).Theresultsoftheseweight

calculationsareinTable5.

ProcessFacilities

ProcessSafety

Refining

ReliabilityEngineering

SupplyChain

Management

Uncategorized

WaterandCorrosion

Meta

Register

Login

EntriesRSS

CommentsRSS

WordPress.org

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

3/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

Someobservationsfromthesecalculationsare:

Decreasingthepipelinediameterfrom42inchto36inchdoesNOTdramaticallyreducethetotalsteeltonnage.

Thisisduetotheincreasedpressuresneededtoflowthesamevolumeofgasinthesmallerdiameter,hence

increasingthewallthickness.

Increasingthesteelgrade(SMYSSpecifiedMinimumYieldStress)fromX70toX80woulddecreasethesteel

tonnageapproximately14%.Asthecostcalculationswillshow,thisreductionwouldlowerthecostsignificantly.

Thevolumeofsteelcombinedwiththediameterandwallthicknesseswillrequireamajorportionofpipe

manufacturingcapacity.Ifthiswereasanctionedproject,pipesteelprocurementwouldneedtobidwellin

advanceoftheplannedconstruction.

WallthicknessesareNOTraisedtonextstandardAPIthicknesses.Thelargequantityofsteelneededallowsthe

buyertodictateanonstandardthickness.Thepipemillswillbegladtoaccommodatesucharequirement.

EstimatedCapitalCosts

Thecapitalcosts(CAPEX)fortheseestimatesarebasedontwokeyvariables:pipelinewallthicknessandthe

compressionpowerrequired.Botharedependentofthepipelinepressureprofilewhichisdictatedbythenumberof

compressorstations.Theestimatedcostwillbecalculatedfromthefollowingassumptions:

LinepipeispricedatUS$1200pershorttonwitha15%adderforcoatings.

Pipelinetotalinstalledcostis2.5timesthepipesteelpluscoatingscost.Thisfactorhasbeensurprisingly

consistenthistoricallyforbothonshoreandoffshorelongdistanceandlargerdiameterpipelines.Projectspecific

factorssuchasmountainousterrainforonshorepipelinescanimpactthiscostmultiplier.

Noadditionalcostdifferenceistakenintoaccountforthisestimatemanyoftherealconditionsthataredealtwith

fortheonshoredesignconstruction.Inrealitythereisadifferencethatcanbesignificant.Thesedifferencesare

largelydependentontheprojectlocationwithfactorsthatcouldincludeweatherandseasonalchallenges,

terrainforonshoreprojects,availableinfrastructureanditsimpactonlogistics,andavailabilityofconstruction

equipmentandlabor.

Compressorsandassociatedequipment(drivers,coolers,andancillaries)arepricedatUS$1500perdemand

horsepower.

OnshorecompressorstationsarepricedatUS$25millioneachforsiteworks,buildingsandequipmentnot

directlyrelatedtogascompression.

Withthesecostassumptions,anorderofmagnitudeestimate(OME)forthetotalinstalledcost(TIC)isdevelopedforthe

pipeline,thenthecompressorstations,andfinallycombinedforthetotalONSHOREpipelinesysteminTable6

PipelineEstimate,Table7CompressorStationEstimate,andTable8TotalSystemOME.

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

4/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

Theresultsareindicativeoffindingasetofoperatingpressures,pipediameterandnumberofcompressorstationsthat

showrelativelylittlechangewithdifferentcombinationsofthekeyparameters(CasesB,CandD).Theselectionofthe

optimumsystemconfigurationwillinvolvemoreengineeringdefinition,considerationofconstructionchallenges,and

evaluationofotherparameterssuchastheoperatingcosts(OPEX),environmentalandpermittingchallenges,andmore

depthinevaluatingtheconstructionplanandcosts.

ThetotalinstalledcostsforthisONSHOREsystemdeclineswithdecreasingoperatingpressure(MAOP),althoughthe

rateofdeclineisalsodecreasing,asmorecompressorstationsareneeded.Fortheonshoresystems,theoperating

cost,particularlyfuelcosts,maybeoneofthekeydecidingparametersfortheoperatingpressure/numberof

compressorstationsdecision.Itiscommonfortotallifecyclecosts(OPEXplusCAPEX)tobeginrisingatsomepointas

thenumberofcompressorstationsandtotalhorsepowerincreaseswithdecreasingoperatingpressure.

Often,withtheoperatingcostsincludedtheoptimumconfigurationfavorshigheroperatingpressuresandfewer

compressorstations.ThecostadjustmentsforprojectlocationonbothCAPEXandOPEXcanmovetooptimum

configurationeitherway.

FinalComments:

Wehavestudiedtransportationofnaturalgasinthedensephaseregion(highpressure)andcomparedtheresultswith

thecasesoftransportingthesamegasusingintermediateandlowpressures.Ourstudyhighlightsthefollowing

features:

1. Theremaybeseveralsystemconfigurations(pipediameter,operatingpressures,andnumberofcompressor

stations)thatshowrelativelysmallvariation.

2. AstheMAOPincreases,therequiredpowerandassociatedcoolingdutycansignificantlydecrease.

3. Thedecreasedcostsforcompressionareoffsetbyincreasingpipelinecosts.Thekeyisbyhowmuch.

4. Projectlocationcanhavesignificantimpactonthecosts,hencethekeydecisionsareonoperatingpressures,

andthenumberandpowerlevelsatthecompressorstations.

5. Withthehighpowerdemandsoflargediameterhighcapacitypipelines,theoperatingcostsforfuelcanbea

keyfactorintheconfigurationselection.Ifthegasatthesourceisnotathighenoughpressure,considerable

compressionpowerandcoolingdutymayberequiredifthedecisionistousethedensephase.

InfutureTipsoftheMonth,wewillconsideroffshoretransportationofnaturalgasaswellastheeffectofprojectlocation

andoperatingcostsonthelifecyclecostsandtheconfigurationselection.

Tolearnmore,wesuggestattendingourG40(Process/FacilityFundamentals),G4(GasConditioningand

Processing),G5(GasConditioningandProcessingSpecial),PF81(CO2 SurfaceFacilities),PF4(OilProductionand

ProcessingFacilities),andPL4(FundamentalsofOnshoreandOffshorePipelineSystems)courses.

JohnM.CampbellConsulting(JMCC)offersconsultingexpertiseonthissubjectandmanyothers.Formoreinformation

abouttheservicesJMCCprovides,visitourwebsiteatwww.jmcampbellconsulting.com,oremailusat

consulting@jmcampbell.com.

By:MahmoodMoshfeghianandDavidHairston

References:

1. Beaubouef,B.,Nordstreamcompletestheworldslongestsubseapipeline,Offshore,P30,December2011.

2. http://www.jmcampbell.com/tipofthemonth/

3. ProMax3.2,BryanResearchandEngineering,Inc.,Bryan,Texas,2012.

Didyouenjoythispost?Doyouhaveaquestion?

LeaveusaCommentbelow!

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

5/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

Tweet

Wanttoreadmorearticleslikethis?

StumbleUpon

SubscribetoourRSSFeedorvisittheTipoftheMonthArchivesfor

pastarticles.

Submit

PostedonMarch1,2013at11:12am

Onecomment

Categories:GasProcessing,Pipeline,ProcessFacilities

Recievenewpostupdates:Entries(RSS)

Recievefollowupcommentsupdates:RSS2.0

WrittenbyDr.MahmoodMoshfeghianandDavidHairston

Dr.MahmoodMoshfeghianisaninstructorandconsultantwithJohnMCampbellandCompany(JMC).Heistheauthor

ofmostofCampbellTipsoftheMonthanddevelopstechnicalsoftwareforJMC.Hehas35yearsteachingexperiencein

universities(OklahomaStateUniversity,UniversityofShiraz,UniversityofSydneyandUniversityofQatar)aswellasfor

oilandgasindustries.Dr.MoshfeghianjoinedJMCin1990asaparttimeconsultantandthenasfulltime

instructor/consultantin2005.PrevioustojoiningJMC,Dr.MoshfeghianwasaSeniorResearchScientistatKuwait

InstituteforScientificResearchandProfessorofChemicalEngineeringatShirazUniversity.Dr.Moshfeghianisasenior

memberofAIChEandhaspublishednumeroustechnicalpapersonthermodynamicproperties,andProcess

Engineering.Dr.Moshfeghianhaspresentedinvitedpapersininternationalconferences.HeholdsaB.S.,anM.S.anda

Ph.D.inChemicalEngineering,allfromOklahomaStateUniversity.

Viewallpostsby:Dr.MahmoodMoshfeghianandDavidHairston

Previouspost

NextPost

OneresponsetoOnshoreNaturalGasPipelineTransportationAlternatives:Capital

CostComparisons

1. MadlynPoxonsays:

April18,2014at6:36am

MybrotherrecommendedImaylikethiswebsite.Hewasoncetotallyright.Thisposttrulymademyday.You

canntimaginejusthowmuchtimeIhadspentforthisinfo!Thankyou!

Reply

LeaveaReply

Name(required)

Mail(willnotbepublished)(required)

Website

SubmitComment

Notifymeoffollowupcommentsbyemail.

Notifymeofnewpostsbyemail.

Training

HelpfulLinks

CompanyInformation

PublicCourses

InHouseCourses

OperatorTraining

OnlineCoursePreviews

HGPAEducationalSessions

CourseSchedule

OilandGasTraining

FacilitiesEngineeringTraining

LiquefiedNaturalGasTraining

PetroleumEngineeringCourses

RequestInformation

ConsultingServices

TipoftheMonth

CampbellForums

ConversionTool

JohnM.Campbell&Co.Books

GCAPSoftware

GCAPMobile

ContinuingEducationCredits

FollowusonTwitter

ContactUs

AboutUs

JobPostings

Testimonials

DownloadCatalog(PDF)

RequestCatalog

InstructorBios

FAQ

Links

KindleDisclaimer

JohnM.Campbell&Co.

1215CrossroadsBlvd.

Suite230

Norman,OK.73072

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

6/7

30/11/2015

OnshoreNaturalGasPipelineTransportationAlternatives:CapitalCostComparisons|CampbellTipoftheMonth

http://www.jmcampbell.com/tipofthemonth/2013/03/onshorenaturalgaspipelinetransportationalternativescapitalcostcomparisons/

7/7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Bixby MaxFire and UBB Service ManualDocument71 pagesBixby MaxFire and UBB Service ManualAl Malley92% (13)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Techumseh 4 Stroke Overhead Valve-Service-ManualDocument94 pagesTechumseh 4 Stroke Overhead Valve-Service-Manualmpa61100% (2)

- 1-Chemical Reactions and EquationsDocument10 pages1-Chemical Reactions and Equationsmayank007aggarwalNo ratings yet

- Question and Answers Electrical MaintenaDocument416 pagesQuestion and Answers Electrical MaintenaimranNo ratings yet

- Rectangular Double-Well Potential: HW9.nbDocument10 pagesRectangular Double-Well Potential: HW9.nbMendoza JohnyNo ratings yet

- ADB (2009) Sustainable Energy Efficiency Development Program PDFDocument542 pagesADB (2009) Sustainable Energy Efficiency Development Program PDFaanchanNo ratings yet

- Daylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimDocument365 pagesDaylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimthabisNo ratings yet

- Static MixerDocument2 pagesStatic Mixerjemakl1568No ratings yet

- CH 4 - The Properties of MatterDocument21 pagesCH 4 - The Properties of Matterapi-236666161No ratings yet

- 1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3Document3 pages1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3npNo ratings yet

- 25 HP & 20 HP Solar Pump QuatationDocument5 pages25 HP & 20 HP Solar Pump QuatationAmodNo ratings yet

- Combustion Lecture Midterm ExamDocument3 pagesCombustion Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- Glycolysis TCA ETCDocument61 pagesGlycolysis TCA ETCLê Trà GiangNo ratings yet

- Lab 2 - Electric FieldDocument5 pagesLab 2 - Electric FieldAbdoul BinJimNo ratings yet

- The Starting SystemDocument20 pagesThe Starting SystemRuth MwendaNo ratings yet

- PDFDocument14 pagesPDFMixa SazonovNo ratings yet

- Application TGADocument8 pagesApplication TGAMOHD KHAIRY IZZUAN BIN MOHD YUSOFNo ratings yet

- 2 Pipe - Hot Water Only Direct Drive - Draw Through DesignDocument2 pages2 Pipe - Hot Water Only Direct Drive - Draw Through DesignwipiriNo ratings yet

- Renewable Energy: Ahmed Djebli, Salah Hanini, Ouassila Badaoui, Brahim Haddad, Amina BenhamouDocument13 pagesRenewable Energy: Ahmed Djebli, Salah Hanini, Ouassila Badaoui, Brahim Haddad, Amina Benhamou11751175No ratings yet

- Specification Aeration BlowerDocument52 pagesSpecification Aeration BlowerPendeta MudaNo ratings yet

- Ansi-Hi Pump StandardsDocument2 pagesAnsi-Hi Pump StandardsAndrés Eduardo100% (1)

- Boiler Inspection TechniquesDocument288 pagesBoiler Inspection TechniquesHernan Coba100% (1)

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezNo ratings yet

- Phy130 Tutorial 8Document3 pagesPhy130 Tutorial 8Shuhaila Hanis RosliNo ratings yet

- Why I Must Attack ThriveDocument6 pagesWhy I Must Attack ThriveMatthew EhretNo ratings yet

- D5682 PDFDocument4 pagesD5682 PDFEmilio HipolaNo ratings yet

- Wells Thermostat IDDocument18 pagesWells Thermostat IDJuan A Aguilera ANo ratings yet

- E25b'04 E30h'04 25B'04 30H'04: (69P4) (60B4) (69R4) (69S4)Document61 pagesE25b'04 E30h'04 25B'04 30H'04: (69P4) (60B4) (69R4) (69S4)Mauro SantafeNo ratings yet