Professional Documents

Culture Documents

Terpen 7 Used PDF

Uploaded by

ibessemalinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terpen 7 Used PDF

Uploaded by

ibessemalinaCopyright:

Available Formats

Brazilian Journal

of Chemical

Engineering

ISSN 0104-6632

Printed in Brazil

www.abeq.org.br/bjche

Vol. 23, No. 03, pp. 273 - 279, July - September, 2006

PRODUCTION OF AROMAS AND FRAGRANCES

THROUGH MICROBIAL OXIDATION OF

MONOTERPENES

H. F. Rozenbaum1, M.L. Patitucci2, O. A. C. Antunes2* and N. Pereira Jr1

1

Escola de Qumica, UFRJ, CT Bloco E, CEP 21945-970, Rio de Janeiro - RJ, Brazil.

2

Instituto de Qumica, UFRJ, CT Bloco A, Lab 641, Phone +(55) (21) 2562-7818,

Fax +(55) (21) 2562-7559, CEP 21945-970, Rio de Janeiro - RJ, Brazil

E-mail: octavio@iq.ufrj.br

(Received: April 10, 2005 ; Accepted: March 21, 2006)

Abstract - Aromas and fragrances can be obtained through the microbial oxidation of monoterpenes. Many

microorganisms can be used to carry out extremely specific conversions using substrates of low commercial

value. However, for many species, these substrates are highly toxic, consequently inhibiting their metabolism.

In this work, the conversion ability of Aspergillus niger IOC-3913 for terpenic compounds was examined.

This species was preselected because of its high resistance to toxic monoterpenic substrates. Though it has

been grown in media containing R-limonene (one of the cheapest monoterpenic hydrocarbons, which is widely

available on the market), the species has not shown the ability to metabolize it, since biotransformation

products were not detected in high resolution gas chromatography analyses. For this reason, other

monoterpenes (alpha-pinene, beta-pinene and camphor) were used as substrates. These compounds were

shown to be metabolized by the selected strain, producing oxidized compounds. Four reaction systems were

used: a) biotransformation in a liquid medium with cells in growth b) with pre-grown cultures c) with cells

immobilized in a synthetic polymer network and d) in a solid medium to which the substrate was added via the

gas phase. The main biotransformation products were found in all the reaction systems, although the adoption

of previously cultivated cells seemed to favor biotransformation. Cell immobilization seemed to be a feasible

strategy for alleviating the toxic effect of the substrate. Through mass spectrometry it was possible to identify

verbenone and alpha-terpineol as the biotransformation products of alpha-pinene and beta-pinene,

respectively. The structures of the other oxidation products are described.

Keywords: Bayer-Villiger; Cytochrome P450; Oxidation; Verbenone; Alpha-terpineol.

INTRODUCTION

Aromas and fragrances are used everywhere in

the modern world, where they are considered

essential for the final quality of, for example, foods

and drinks. The main sources of these substances are

the essential oils and their monoterpene compounds

(Krasnobajew, 1984; van der Werf, Bont & Leak,

1997). Substances with organoleptic characteristics

can be obtained directly from nature. However,

these compounds occur in very low concentrations,

*To whom correspondence should be addressed

and a variety of factors, such as seasonal variations

in concentration, plant diseases, the complexity of

the vegetable extracts and economic and

environmental restrictions, can affect their yield or

the extraction process. Common ways of obtaining

chemical aromas are chemical syntheses using

compounds found in abundance in nature, like

terpenic hydrocarbons.

Presently, however, consumer prefers to avoid

synthetic products, and there has been a

corresponding upsurge in demand for products that

274

H. F. Rozenbaum, M.L. Patitucci, O.A.C. Antunes and N. Pereira Jr

can be labelled natural (Welsh, Murray &

Williams, 1989). Biotechnology has the potential to

generate these products through biotransformation

carried out by microorganisms and their enzymatic

systems (Santos et al., 2003; Santos et al., 2004).

Other advantages of biotransformation include the

fact that a single stage in such a process can

encompass a series of steps in chemical synthesis

and results in the formation of the desired products

(Ribbons, 1990; Krings & Berger, 1998).

As part of our continuous work in microbial

oxidation of natural products (Santos et al., 2003;

Santos et al., 2004; Toniazzo et al., 2005), the

objective of the present work is to investigate the

capacity of Aspergilus niger (previously selected

strain) in oxidizing some monoterpenes.

fungi spores with seven days growth, they were

inverted so that the substrate could be put on the lid,

coming into contact with the microorganism via the

gas phase. This way, it was possible to add the

substrate a number of times, after 0, 24, 48, 96 and

144 hours for the limonene isomers and after 0, 24,

72, 120 and 168 hours for the pinenes and camphor.

All the dishes used in the experiments were

incubated in a microbe culture incubator at 30C.

The growth on the dishes containing R- and Slimonene was interrupted after 168 hours, and that

on for the dishes containing alpha-pinene, betapinene and camphor after 216 hours. Then, solidphase extraction was undertaken by grinding the

material contained in the dish in 20 mL of PA ethyl

acetate 99.5% (VETEC) using a mortar and pestle.

Biotransformation in a Liquid Medium

MATERIALS AND METHODS

Monoterpenes

Four hydrocarbons (R-limonene, S-limonene,

alpha-pinene and beta-pinene) and one ketone

(camphor), from Sigma-Aldrich, were used in this

study. They were analyzed by high resolution gas

chromatography. The purities of monoterpenes

were over 98 %. All the substrates in the

experiments were added at 1% v/v, although in the

case of camphor, a 0.02 mg/mL solution of

camphor in ethyl acetate was used.

Microorganism

The Aspergillus niger IOC-3913 strain used in

this work was kindly supplied by FIOCRUZ

(Coleo de Culturas de Fungos of the Fundao

Oswaldo Cruz, Brazil).

Culture Media

The medium used for microbial growth was

prepared as described in the literature (Asakawa et al.,

1991). Its composition (g/L) consisted of sucrose (15),

glucose (15), hydrolyzed soya peptone (5), K2HPO4

(1), MgSO4.7H2O (1), KCl (0.5) and FeSO4.7H2O

(0.01) in distilled water. pH was not controlled.

Biotransformation in Petri Dishes

The Petri dishes were prepared with 20 mL of

medium [Czapeck (g/L): glucose (20), NaNO3 (2),

MgSO4.7H2O (1.025), KCl (0.5), (NH4)2SO4 (0.01),

agar-agar (20)]. After inoculation with a loop full of

Conical flasks (250 mL) were used for all the

tests in the liquid medium. One hundred mL of

culture medium and the inoculum were added to

each flask. The inoculum consisted of suspensions of

filamentous fungal spores in saline solution (NaCl

0.9%), with 1x108 spores per 100 mL of medium.

The terpenic substrate was added to the medium

together with a surfactant agent (Tween 80) at 1%v/v

each, when microbial growth was being tested.

When the biotransformation was not associated with

growth, the transformation medium consisted only of

the terpenic substrate and the surfactant agent, each

at a 1% v/v concentration.

The experiments were done in a mechanical

rotary shaker at 28C and 150 rpm. The only

exceptions were the flasks intended for immobilizing

the fungus in a synthetic polymer network, which

consisted of 20 cubes with an average volume of 1 cc

each. In this case the biotransformation reaction was

done at 28C and 100 rpm.

The biotransformation not associated with growth

took place in two ways. In the first case, the pellets

formed during the fungal growth in the liquid

medium were filtered after 74 hours, using a vacuum

pump under unsterilized conditions, and immediately

incubated in a transformation medium at 28C with

stirring at 150 rpm. The second strategy consisted of

entrapping mycelia in a synthetic network made up

of small cubes of commercial sponge. After 74 hours

the content of the flasks was inverted and the

immobilized fungi were added to the transformation

medium.

Every 24 hours samples were taken from all the

flasks, including the control flasks, from the very

beginning until the sixth day after addition of the

Brazilian Journal of Chemical Engineering

Production of Aromas and Fragrances through Microbial Oxidation

transformation medium. After the samples were

removed from each flask, they were centrifuged and

submitted to liquid-liquid extraction with ethyl

acetate.

Analytical Methods

The organic extract obtained in the experiments

was submitted to analysis using high resolution gas

chromatography

(HRGC)

to

assess

the

biotransformation and abiotic losses. The equipment

used was a Hewlett-Packard chromatograph model

HP5890 series II with a capillary column model HP5 (crosslinked 5% phenylmethylsiloxane), 30 meters

in length with an internal diameter of 0.32 mm and a

film thickness of 0.25 m. The temperature of the

injector was kept at 250C and that of the detector at

260C. Carrier gas was N2 (120kPa, 4 mL/min). The

detector was supplied with air and hydrogen at 275

kPa and 100 kPa, respectively. The programming

used was an initial temperature of 40C, maintained

for 3 minutes, a heating rate of 5C/min and a final

temperature of 220C. Total analysis time was 39

minutes. The Chemstation program version A.03.34

HP 3365 series II was used to integrate the areas

obtained on the chromatogram.

The products were identified using a gas

chromatograph coupled to a mass spectrometer

(GC/MS) to determine the molecular weights of the

products and ions formed by the fragmentation of

Figure 1: The effect of the presence of R- and Slimonene on the growth of Aspergillus niger

in solid medium.

275

their molecules. The equipment used in this stage

was a Coupled GC/MS Hewlett Packard model

5973 HP, with the temperature of the mass

spectrometer injector at 270C and that of the

interface at 280C. The helium flow rate was 1

mL/min and chemical ionization took place at 70

eV. The other conditions were the same as those

already given for the HRGC.

RESULTS AND DISCUSSION

In the tests Petri dishes, inhibition caused by the

terpenic substrate was found by the ratio of the

diameters of the colonies formed. It was found that

the two limonene isomers interfere more in fungal

growth, with inhibition rates greater than 50%, while

alpha-pinene, beta-pinene and camphor yielded

values lower than 40%. Figures 1 and 2 show the

effect of the monoterpenic substrate on microbial

growth.

Chromatographic analyses of the extracts

obtained did not reveal any biotransformation

product in the media containing R-limonene or Slimonene, showing that the strain of Aspergillus

niger used in this work was not capable of

metabolizing them. However, a number of products

were found in the extracts obtained after microbial

growth in the media containing alpha-pinene, betapinene and camphor.

Figure 2: The effect of the presence of alpha-pinene,

beta-pinene and camphor on the growth of

Aspergillus niger in solid medium.

Brazilian Journal of Chemical Engineering Vol. 23, No. 03, pp. 271 - 279, July - September, 2006

276

H. F. Rozenbaum, M.L. Patitucci, O.A.C. Antunes and N. Pereira Jr

alfa-pinene products concentration (mg/100 mL)

The tests carried out in the liquid medium, where

the substrate was added together with the growth

medium indicated that the consumption of sugars is

affected to a greater degree by the R-limonene.

Moreover, no biotic consumption of R-limonene or

S-limonene was noted.

By monitoring the concentrations of the other

monoterpenic substrates in the inoculated flasks

associated with growth and in the controls it was

possible to calculate the biotic consumption of each

substrate. The maximum values of biotic

consumption for alpha-pinene, beta-pinene were

approximately 80 mg/100 mL of medium, while for

camphor, which was added as a more dilute solution,

biotic consumption was approximately 8 mg/100

mL.

The chromatographic analyses of the extracts

indicated that the biotransformation products

obtained using alpha-pinene, beta-pinene and

camphor are basically the same as those obtained in

solid media. These products were detected in the

samples after 71 h.

The tests done in liquid medium, where the

substrate was added after microbial growth

(noassociated with growth), showed that biotic

consumption in the flasks containing pinenes varied

between 200 and 400 mg/100 mL, while the

consumption of camphor was approximately 20

mg/100 mL. Moreover, the maximum consumption

for each substrate occurred more quickly than in the

cases where microbial growth had not previously

taken place, with the maximum accumulated

consumption taking place in less than 72 hours after

addition of the substrate in all cases.

Samples obtained by extraction and submitted to

chromatographic analysis allowed not only the

measurement of the substrate concentration, but also

the opportunity to check for the presence of

biotransformation products.

For alpha-pinene, the characteristics of three

products, with retention times in the chromatography

column of 12.9, 14.2 and 14.8 min, were monitored

(Figure 3). Of these, only the substance with the

14.8-min retention time had been observed in

previous experiments and identified as verbenone.

However, the product that disappeared at the start of

the run (Rt=12.9 min) seemed to be directly related

to the formation of this product, which suggests it

could be verbenol, an intermediate alcohol in

verbenone synthesis.

4,0

Free cells;

Rt = 12.9 min

Immobiliz. cells;

Rt = 12.9 min

Free cells;

Rt = 14.2 min

Immobiliz. cells;

Rt = 14.2 min

Free cells;

Rt = 14.8 min

Immobiliz. cells;

Rt = 14.8 min

3,5

3,0

2,5

2,0

1,5

1,0

0,5

0,0

0

20

40

60

80

100

120

140

160

180

Time (h)

Figure 3: Kinetic profile of the formation of biotransformation products obtained

with alpha-pinene, not associated with fungal growth.

Brazilian Journal of Chemical Engineering

beta-pinene products concentration (mg/100 m)

Production of Aromas and Fragrances through Microbial Oxidation

277

18

16

Free cells;

Rt = 14.2 min

Immobiliz. cells;

Rt = 14.2 min

14

12

10

8

6

4

2

0

0

20

40

60

80

100

120

140

160

Time (h)

Figure 4: Kinetic profile of the formation of biotransformation products obtained

with beta-pinene, not associated with fungal growth.

camphor products concentration (mg/100 mL)

In the biotransformation of beta-pinene (Figure

4), a product with a retention time of 14.2 min, terpineol, reached its highest concentrations between

72 and 120 hours.

For camphor, three main products were observed

in all the tests done. The kinetic profile of these

biotransformation products not associated with

growth is shown in Figure 5. The proposed structures

of these products, based on an analysis of the ions

formed by fragmentation in a mass spectrometer, are

of two isomers of a keto acid derivative and one

lactone formed in a Baeyer-Villiger reaction.

Figure 6 shows the substrates utilized and their

biotransformation products.

12

10

Free cells;

Rt = 18.5 min

Immobiliz. cells;

Rt = 18.5 min

Free cells;

Rt = 18.8 min

Immobiliz. cells;

Rt = 18.8 min

Free cells;

Rt = 19.4 min

Immobiliz. cells;

Rt = 19.4 min

0

0

20

40

60

80

100

120

140

160

180

Time (h)

Figure 5: Kinetic profile of the formation of biotransformation products

from camphor, not associated with fungal growth.

Brazilian Journal of Chemical Engineering Vol. 23, No. 03, pp. 271 - 279, July - September, 2006

278

H. F. Rozenbaum, M.L. Patitucci, O.A.C. Antunes and N. Pereira Jr

+

O

-pinene

OH

verbenone

verbenol

OH

-terpineol

-pinene

OH

-terpineol

O

+

O

camphor

O

O

OH

OH

lactone

Figure 6: Monoterpenic substrates and their products of biotransformation

with Aspergillus niger IOC-3913.

In the tests where cell growth and immobilization

did not take place concomitantly, there was a greater

formation of products. Additionally, products

appeared earlier due to the use of previously grown

cells. The immobilization of cells was shown to be

suitable in the media containing the toxic substrates

in higher concentrations, as was the case with the

pinenes, bringing about an increased formation of

products. Tan and Day (1998) have already observed

the possibility of immobilizing the filamentous

fungus Aspergillus niger in biotransformation studies

on limonene, leading to the reutilization of the

biomass. In the tests with camphor using a dilute

solution, the separation of the growth and

biotransformation stages also generally resulted in a

greater formation of products. For camphor, the free

cells had a better performance, probably due to a

larger biomass capable of participating in the

biotransformation, since the toxic effect of the

substrate was reduced through dilution.

Importantly, it has been made possible to obtain

verbenone from alpha-pinene and and alpha-terpineol

from -pinene (Toniazzo et al., 2005). These compounds

are important in the flavor/perfumery industries.

CONCLUSIONS

The results obtained in this work indicate that

the enzymes responsible for the biotransformation

producing the metabolites found in all the reaction

systems studied are probably not of an inductive

nature, since the bioconversions are not related to

the presence of the substrate in the initial stages of

microbial growth and the biomass already formed

anticipates the appearance of the biotransformation

products. In general, the biotransformation of

alpha-pinene, beta-pinene and camphor results in

the formation of oxidized products through the

insertion of oxygen into the substrate molecule.

There are probably a number of mechanisms

involved in the biotransformation of each

monoterpene used in this study, suggesting the

action of a variety of enzymes. Verbenone and

alpha-terpineol were identified as biotransformation

products of alpha-pinene and beta-pinene,

respectively. These products have applications in

the aroma and fragrance industry and as

intermediaries in the synthesis of pharmaceuticals,

adding considerable value to the substrates used.

Brazilian Journal of Chemical Engineering

Production of Aromas and Fragrances through Microbial Oxidation

ACKNOWLEDGEMENTS

The authors are grateful to FAPERJ, CAPES,

CNPq, FUJB, PRONEX and FINEP (PADCT and

FNDCT) for their financial support. The authors

would also like to thank Dr. A. D. Silva (UFRJ/Brazil),

Professor C. M. Resende (UFRJ/Brazil) and Dr. H. R.

Bizzo (EMBRAPA/Brazil) for their helpful aid in the

GC and GC-MS analyses and to Professor Ira Mark

Brinn for the careful reading (and correction) of the

manuscript.

REFERENCES

Asakawa, Y., Takahashi, H., Toyota, M., Noma, Y.,

Biotransformation of Monoterpenoids, (-)- and

(+)-Menthols, Terpinolene and Carvotanacetone

by Aspergillus niger Species. Phytochemistry,

30(12), 3981-3987 (1991).

Krasnobajew, V., Terpenoids. In Biotechnology, A

Comprehensive Treatise, Volume 6A, Editor

Kieslich, K., Verlag Chemie, Weinheim, 97-125

(1984).

Krings, U., Berger, R. G., Biotechnological

Production of Flavours and Fragrances. Applied

Microbiology & Biotechnology, 49, 1-8 (1998).

Ribbons, D. W., Biotransformations Aid Organic

279

Chemists. Science Progress, 74, 205-226 (1990).

Santos, A. S., Pereira Jr., N., Silva, I. M., Sarquis, M.

I. M., Antunes, O. A. C., Peroxidase Catalyzed

Microbiological Oxidation of Isosafrol into

Piperonal. Progress Biochemistry, 39, 2269-2275

(2004).

Santos, A. S., Pereira Jr., N., Silva, I. I., Antunes, O.

A. C., Microbiological Oxidation of Isosafrole

into

Piperonal.

Applied

Biochemistry

Biotechnology, 107, 649-658 (2003).

Tan, Q., Day, D. F. Bioconversion of limonene to Terpineol by Immobilized Penicillium digitatum.

Applied Microbiology Biotechnology, 49, 96101 (1998).

Toniazzo, G., Oliveira, D., Dariva, C., Oestreicher,

E. G., Antunes, O. A. C., Biotransformation of

(1S)-(-)alpha-pinene,

(-)beta-pinene

and

(+)limonene by Aspergillus niger ATCC 9642.

Applied Biochemistry Biotechnology, 123, 837844 (2005).

van der Werf, M. J., Bont, J. A. M., Leak, D. J.,

Opportunities in Microbial Biotransformation of

Monoterpenes.

Advances

in

Biochemical

Engineering, 55, 148-176 (1997).

Welsh, F. W., Murray, W. D., Williams, R. E.,

Microbiological and Enzymatic Production of

Flavor and Fragrance Chemicals. Critical

Reviews in Biotechnology, 9(2), 105-169 (1989).

Brazilian Journal of Chemical Engineering Vol. 23, No. 03, pp. 271 - 279, July - September, 2006

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Suturing TechniquesDocument6 pagesSuturing TechniquesAldo TanNo ratings yet

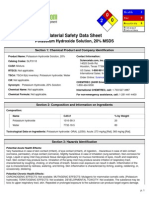

- Potassium Hydroxide Solution, 20% MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesPotassium Hydroxide Solution, 20% MSDS: Section 1: Chemical Product and Company IdentificationibessemalinaNo ratings yet

- Bioenergetics DLLDocument2 pagesBioenergetics DLLAlvin PaboresNo ratings yet

- Appendix A Neraca Massa Basis Batubara Hari Kerja Unit GasifierDocument3 pagesAppendix A Neraca Massa Basis Batubara Hari Kerja Unit GasifieribessemalinaNo ratings yet

- Plant Performance and Economic Summary SheetDocument3 pagesPlant Performance and Economic Summary SheetibessemalinaNo ratings yet

- Plant Performance and Economic Summary SheetDocument3 pagesPlant Performance and Economic Summary SheetibessemalinaNo ratings yet

- Tabel 2Document1 pageTabel 2ibessemalinaNo ratings yet

- Perhitungan DesainDocument6 pagesPerhitungan DesainibessemalinaNo ratings yet

- Plant Performance and Economic Summary SheetDocument3 pagesPlant Performance and Economic Summary SheetibessemalinaNo ratings yet

- Plant Performance and Economic Summary SheetDocument3 pagesPlant Performance and Economic Summary SheetibessemalinaNo ratings yet

- Eacc . Ein Eout +egen . Econs - E H+E K+e P M+Q+WDocument1 pageEacc . Ein Eout +egen . Econs - E H+E K+e P M+Q+WibessemalinaNo ratings yet

- List FilmDocument1 pageList FilmibessemalinaNo ratings yet

- TranscriptDocument4 pagesTranscriptibessemalinaNo ratings yet

- Envirocoal Coal Specs 2015Document2 pagesEnvirocoal Coal Specs 2015ibessemalina100% (1)

- Journal of Cleaner ProductionDocument10 pagesJournal of Cleaner ProductionibessemalinaNo ratings yet

- DocumentDocument6 pagesDocumentHendra AriefNo ratings yet

- Phosphoric Acid, 85% MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesPhosphoric Acid, 85% MSDS: Section 1: Chemical Product and Company IdentificationChemicalB0yNo ratings yet

- Msds Ch3coohDocument6 pagesMsds Ch3coohibessemalinaNo ratings yet

- Cocoa ButterDocument5 pagesCocoa ButteribessemalinaNo ratings yet

- Msds ButanolDocument6 pagesMsds ButanolMaria Regina SudiartaNo ratings yet

- Ea MsdsDocument6 pagesEa Msdsapi-263411629No ratings yet

- Potassium Hydroxide. 0.5N (Alcoholic) MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesPotassium Hydroxide. 0.5N (Alcoholic) MSDS: Section 1: Chemical Product and Company IdentificationibessemalinaNo ratings yet

- De Ionized WaterDocument5 pagesDe Ionized WateribessemalinaNo ratings yet

- Ea MsdsDocument6 pagesEa Msdsapi-263411629No ratings yet

- 2010 Lennette's - Laboratory - Diagnosis PDFDocument512 pages2010 Lennette's - Laboratory - Diagnosis PDFHumberto Azuara Jiménez100% (1)

- Blb-Micro CH 12 Lecture PresentationDocument60 pagesBlb-Micro CH 12 Lecture Presentationprlatino91No ratings yet

- Hariyono 2021 IOP Conf. Ser. Earth Environ. Sci. 752 012022Document7 pagesHariyono 2021 IOP Conf. Ser. Earth Environ. Sci. 752 012022Vanessa Nicole C. CarpenaNo ratings yet

- Animals With 5 Legs - Google SearchDocument1 pageAnimals With 5 Legs - Google SearchBen BerardNo ratings yet

- Bio Music 6in1 enDocument10 pagesBio Music 6in1 enspanda09175No ratings yet

- The Association Between Melasma and Postin Ammatory Hyperpigmenta-Tion in Acne PatientsDocument4 pagesThe Association Between Melasma and Postin Ammatory Hyperpigmenta-Tion in Acne PatientsRicoNo ratings yet

- Richard Ruvalcaba - The Successful Persons Guide To Time ManagementDocument20 pagesRichard Ruvalcaba - The Successful Persons Guide To Time Managementapi-355177293No ratings yet

- NutrigenomicsDocument8 pagesNutrigenomicsGabriel MarcosNo ratings yet

- Template JIBSDocument4 pagesTemplate JIBS1AMutiara AndiniNo ratings yet

- Amount of Casein in MilkDocument4 pagesAmount of Casein in MilkAshutosh PatilNo ratings yet

- Infoprof Eng PDFDocument158 pagesInfoprof Eng PDFacbgdvNo ratings yet

- DMRT Syllabus Final 2022Document16 pagesDMRT Syllabus Final 2022Pupun SahooNo ratings yet

- PRL 8Document2 pagesPRL 8anna ticaNo ratings yet

- BIOLOGYDocument2 pagesBIOLOGYMyraSimoraNo ratings yet

- Etymology: Meros Meaning "Part". The Term Was Coined in 1833 by Jöns Jacob Berzelius, Although HisDocument12 pagesEtymology: Meros Meaning "Part". The Term Was Coined in 1833 by Jöns Jacob Berzelius, Although HisZoya KapoorNo ratings yet

- January 2018Document4 pagesJanuary 2018Athula Dias NagahawatteNo ratings yet

- Local Media5318352258259372198Document23 pagesLocal Media5318352258259372198Marie LlanesNo ratings yet

- Biology Chapter 2 Sexual Reproduction in Flowering PlantsDocument8 pagesBiology Chapter 2 Sexual Reproduction in Flowering PlantsYasir SalahNo ratings yet

- 2010 Nototriton Tomamorum TexiguatDocument17 pages2010 Nototriton Tomamorum TexiguatJosue Ramos GaldamezNo ratings yet

- Biology Answers PDFDocument30 pagesBiology Answers PDFأسيل الشلةNo ratings yet

- Understanding Human Anatomy and Physiology - MaderDocument51 pagesUnderstanding Human Anatomy and Physiology - Maderega monica toumeluk100% (1)

- Cytological Perspectives of Grasshopper: A Comparative Studies of Two MethodsDocument4 pagesCytological Perspectives of Grasshopper: A Comparative Studies of Two MethodsnurulNo ratings yet

- Advanced Ecology Lab Final Exam by Roxanne UyDocument9 pagesAdvanced Ecology Lab Final Exam by Roxanne Uyroxannediane@yahoo.com0% (1)

- Lecture 5: Global-Scale Physical-Biological Interaction ProcessesDocument13 pagesLecture 5: Global-Scale Physical-Biological Interaction ProcessesMaraschino1993No ratings yet

- Gathfan Tsaqif Prasetya - Rsu - BundaDocument1 pageGathfan Tsaqif Prasetya - Rsu - BundaBunk ZoelNo ratings yet

- FoodchaintgDocument3 pagesFoodchaintgapi-2912807630% (3)

- PSYC 21 2022 ANS Additional Notes RevisedDocument1 pagePSYC 21 2022 ANS Additional Notes RevisedsdahjdhasjkdhaskdNo ratings yet

- Nutrition in Plants - Mineral Nutrition: Module - 2Document13 pagesNutrition in Plants - Mineral Nutrition: Module - 2keerthyNo ratings yet