Professional Documents

Culture Documents

Ejector Dry Air Equi Calcs

Uploaded by

gagewangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ejector Dry Air Equi Calcs

Uploaded by

gagewangCopyright:

Available Formats

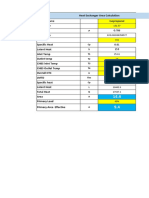

Dry Air Equivalent (DAE) for Ejectors

The DAE is an absolute unit that defines the performance capacity of any ejector stage. The DAE is the equivalent mass flow of 70F dry air & is the industry

standard for ejector capacity rating. Curves for correction factors for molecular weight & temperature to convert any gas stream to its DAE rating are given in

sheet "Mol_WT_Entrainment_Ratio_Curve" & "Temp_Entrainment_Ratio_curve" respectively. The DAE is typically represented in terms of the flow capacity

on the performance curve for an ejector showing suction pressure versus flow capacity.

Dry Air Equivalent (DAE) for gas mixture containing Air & Water Vapor

Example:

What is the DAE for 300 lb/hr of a mixture containing 100 lb/hr of air & 200 lb/hr of water vapor if it is at 350F?

Air =

100 lb/hr

Water Vapor =

200 lb/hr

Total =

300 lb/hr

Air:

From Temp Entrainment Ratio curve, ratio =

DAE =

Water Vapor:

From Temp Entrainment Ratio curve, ratio =

0.93

107.5 lb/hr

DAE =

0.908

0.81

271.9 lb/hr

Total DAE =

379.5 lb/hr

From Mol Wt Entrainment Ratio curve, ratio =

(Air + Water Vapor)

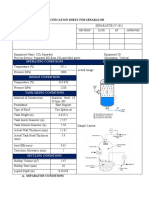

Actual Air Capacity of an Air-Water Vapor Mixture given the DAE

Example:

What is the expected actual capacity at 500F of a mixture rated at 70F?

Air =

225 lb/hr

Water Vapor =

200 lb/hr

Total =

425 lb/hr

Air:

From Temp Entrainment Ratio curve, ratio =

Actual Capacity =

0.897

201.8 lb/hr

Water Vapor:

From Temp Entrainment Ratio curve, ratio =

Actual Capacity =

0.859

171.8 lb/hr

Mixture actual capacity =

373.6 lb/hr

Prepared by :

Ankur Srivastava

Chemical Engineer

(Air + Water Vapor)

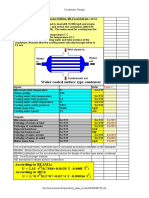

Saturated Mixture of non-Condensable & condensable vapors

Example:

A distillation system is to operate with a horizontal overhead condenser, Sketch above, & pressures are as marked. The estimated air leakage into the system is

7 lb/hr. The molecular weight of the product vapor going into the ejector from the condenser at 80F is 53. The vapor pressure of the condensing vapor is 3 mm

Hg abs at 80F.

Partial pressure of air = 5 - 3 = 2 mm Hg

Vapor required to saturate at 80F & 5 mm abs. total pressure

Wv = Wn*Mv*Pv / Mn*Pn

where

W v = Weight of condensable vapor, lb/hr

W n = Weight of non-condensable gas, lb/hr =

7 lb/hr

Mv = Molecular weight of condensable vapor =

53

Pv = Vapor pressure of condensable vapor, mm Hg absolute =

3 mm Hg abs

Mn = molecular weight of non-condensable gas =

29

Pn = Partial pressure of non-condensable gas, mm Hg absolute =

Wv =

2 mm Hg abs

19.19 lb/hr

moles of air =

moles of product air =

Total moles of mix =

0.241 mols/hr

0.362 mols/hr

0.603 mols/hr

Total weight of air-product vapor mixture =

Avg Molecular weight of mixture =

(729)

(19.1953)

(0.241+0.362)

26.19 lb/hr

43.4

Molecular wt correction from mol wt entrainment ratio curve for mixture =

Air Equivalent of mixture (at 80F) =

22.19 lb/hr

Temperature correction from Temp entrainment ratio curve =

Dry Air Equivalent =

22.22 lb/hr

1.18

0.999

You might also like

- Distillation Column OptimizationDocument14 pagesDistillation Column OptimizationLovely TarunNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDocument11 pagesModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNo ratings yet

- Timah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHDocument1 pageTimah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHAyahKenzie100% (1)

- Graham - Lessons From The Field - Ejector SystemDocument5 pagesGraham - Lessons From The Field - Ejector SystemAnonymous DJrec2No ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersDocument1 pageTransfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersMarco Ordoñez0% (1)

- EjectorDocument9 pagesEjectorManuel Gallegos CalderónNo ratings yet

- Heat Transfer Equipment DesignDocument7 pagesHeat Transfer Equipment DesignBhawani Pratap Singh PanwarNo ratings yet

- Flue gas analysis technology for industryDocument2 pagesFlue gas analysis technology for industrywatson123No ratings yet

- Boiler CalculationsDocument6 pagesBoiler CalculationsJesther Marlou C. OrongNo ratings yet

- Unesco - Eolss Sample Chapters: Vacuum Creating EquipmentDocument7 pagesUnesco - Eolss Sample Chapters: Vacuum Creating Equipmentahmed nawazNo ratings yet

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Document5 pagesCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Input Output: Combustion Calculations For Fuel GasDocument33 pagesInput Output: Combustion Calculations For Fuel GasgsdaundhNo ratings yet

- Unit conversion program for engineering processesDocument9 pagesUnit conversion program for engineering processesAnubhav KhandelwalNo ratings yet

- Thermocompressors Improve Paper Machine Dryer DrainageDocument8 pagesThermocompressors Improve Paper Machine Dryer DrainageclintoncNo ratings yet

- Pressure Safety Valve DatasheetDocument10 pagesPressure Safety Valve DatasheetsithulibraNo ratings yet

- Boiler CalcDocument5 pagesBoiler CalcBhavana KewlaniNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmDocument21 pagesProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperNo ratings yet

- Vessel Weight CheckDocument8 pagesVessel Weight ChecknileshNo ratings yet

- Fluid Properties Correlation for NeonDocument68 pagesFluid Properties Correlation for NeonSiddiqui Muhammad AshfaqueNo ratings yet

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Tubesheet LayoutDocument5 pagesTubesheet LayoutMehta MehulNo ratings yet

- DraughtDocument33 pagesDraughtNipun SabharwalNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- ATFE Installation Costing for Xylene Distillation ProjectDocument27 pagesATFE Installation Costing for Xylene Distillation ProjectPrathmesh GujaratiNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- Product Catalog EjectorDocument142 pagesProduct Catalog EjectortrieuNo ratings yet

- Gas Conditioning System Specification Sheet: Process InformationDocument3 pagesGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNo ratings yet

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Criteria for selecting horizontal or vertical condensersDocument1 pageCriteria for selecting horizontal or vertical condensersParth PurohitNo ratings yet

- Design of Condenser: 1) Heat Balance 2) Temeprature DifferenceDocument1 pageDesign of Condenser: 1) Heat Balance 2) Temeprature DifferenceBhawani Pratap Singh PanwarNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Ist Stage Cooler Process and Mechanical DetailsDocument2 pagesIst Stage Cooler Process and Mechanical DetailsjnmanivannanNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- List of FiguresDocument11 pagesList of FiguresShamsMohdNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- Plate Type Wet ScrubberDocument6 pagesPlate Type Wet ScrubberRoger IsidoreNo ratings yet

- Sop For Fan SizingDocument3 pagesSop For Fan SizingHsein WangNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Thermal vapor-compression system design and performance analysisDocument8 pagesThermal vapor-compression system design and performance analysisBagus HutomoNo ratings yet

- Reactors Dimensions - 1Document10 pagesReactors Dimensions - 1Abhijit MoreNo ratings yet

- Boiler Efficiency Calculation MethodDocument2 pagesBoiler Efficiency Calculation MethodSomplak KudaNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- Flame Arrester Technical FormDocument7 pagesFlame Arrester Technical FormHmd MokhtariNo ratings yet

- Evaporator Vacuum System and Barometric CondenserDocument2 pagesEvaporator Vacuum System and Barometric CondensersalcedopozasNo ratings yet

- Gas Turbines for Aircraft Propulsion AnalysisDocument49 pagesGas Turbines for Aircraft Propulsion AnalysisDk DamoNo ratings yet

- Multiple Effect Evaporator DesignDocument3 pagesMultiple Effect Evaporator DesignAnand AgrawalNo ratings yet

- Abl12e 09Document2 pagesAbl12e 09jlcheefei9258No ratings yet

- Modern Manufacturing Relies on Compressed AirDocument7 pagesModern Manufacturing Relies on Compressed AirAjith NalakaNo ratings yet

- LPG Manual For Sales Staff: Properties, Characteristics and Hazards of LPG 1. What Is LPG?Document15 pagesLPG Manual For Sales Staff: Properties, Characteristics and Hazards of LPG 1. What Is LPG?Ravindra A GNo ratings yet

- High Back-Pressure Foam Makers: Data/SpecificationsDocument4 pagesHigh Back-Pressure Foam Makers: Data/SpecificationsRIGOBERTO PONCENo ratings yet

- Bpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Document1 pageBpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Amol TupeNo ratings yet

- Eczema and Nummular Dermatitis GuideDocument91 pagesEczema and Nummular Dermatitis GuideJhost Clinton PurbaNo ratings yet

- GOM-292-TQ-001 - Piping SystemsDocument12 pagesGOM-292-TQ-001 - Piping SystemsBhupatiNo ratings yet

- Factors Affecting Chemical Reaction RatesDocument18 pagesFactors Affecting Chemical Reaction RatesExeteurNo ratings yet

- O-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierDocument4 pagesO-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierMorteza ShakerienNo ratings yet

- Engineering Materials MCQs PDFDocument41 pagesEngineering Materials MCQs PDFRamesh KondriNo ratings yet

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarNo ratings yet

- Micro Pile SpecificationsDocument3 pagesMicro Pile SpecificationsAnonymous 5VwQ0KC3No ratings yet

- Density Tower-Sphsummer 2Document3 pagesDensity Tower-Sphsummer 2api-322723623No ratings yet

- Biofar 3Document11 pagesBiofar 3dediNo ratings yet

- 2022 Puc I Chem Imp QuestionsDocument13 pages2022 Puc I Chem Imp QuestionsCHAKRI BABLUNo ratings yet

- AcrylonitrileDocument32 pagesAcrylonitrileKayalvilli ShanmugamNo ratings yet

- Jairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RDocument7 pagesJairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RJhon barreraNo ratings yet

- Non Destructive Testing (NDT) : by Mr. H.P.VaradeDocument42 pagesNon Destructive Testing (NDT) : by Mr. H.P.Varaderaj6062No ratings yet

- CRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)Document3 pagesCRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)azharbNo ratings yet

- MCQ On Molecular BiologyDocument12 pagesMCQ On Molecular Biologyronojoysengupta0% (1)

- MME B.Tech IV-SEM REG MR-21 Model-Question-PapersDocument10 pagesMME B.Tech IV-SEM REG MR-21 Model-Question-Papersankit pandeyNo ratings yet

- PDFsam MergeDocument47 pagesPDFsam MergeAyman JadNo ratings yet

- Lead Glass Treated Blue Sapphire by Hainschwang 2008Document2 pagesLead Glass Treated Blue Sapphire by Hainschwang 2008Vaishali JhaveriNo ratings yet

- Magnesium Chloride PowderDocument2 pagesMagnesium Chloride PowderNatalia NeliNo ratings yet

- Key Physical Variables in The Ocean Temperature, Salinity, and DensityDocument10 pagesKey Physical Variables in The Ocean Temperature, Salinity, and DensityLeon TaufaniNo ratings yet

- Repair and Reinforcing Techniques for Steel ComponentsDocument108 pagesRepair and Reinforcing Techniques for Steel ComponentsValy CoulibalyNo ratings yet

- Spirax Sarco SV74 SeriesDocument2 pagesSpirax Sarco SV74 Series20040384iNo ratings yet

- Downhole Tool Dressing Brochure 2022Document7 pagesDownhole Tool Dressing Brochure 2022Ricky VelascoNo ratings yet

- Calibration of UVDocument8 pagesCalibration of UVMuhammad Abdul BariNo ratings yet

- OBATDocument10 pagesOBATDeiLa SariNo ratings yet

- Lab Report To Determine The Concentration Using GC-MSDocument9 pagesLab Report To Determine The Concentration Using GC-MSSamuel Ogeda OtienoNo ratings yet

- HELIUMDocument2 pagesHELIUMEleojan ContayosoNo ratings yet